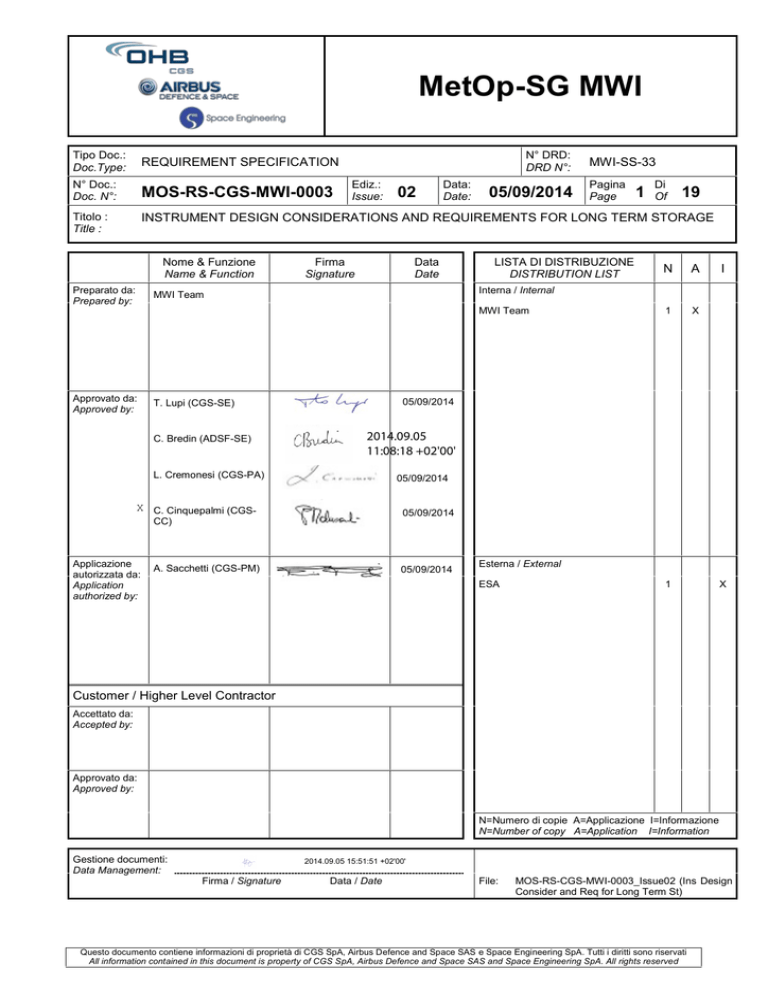

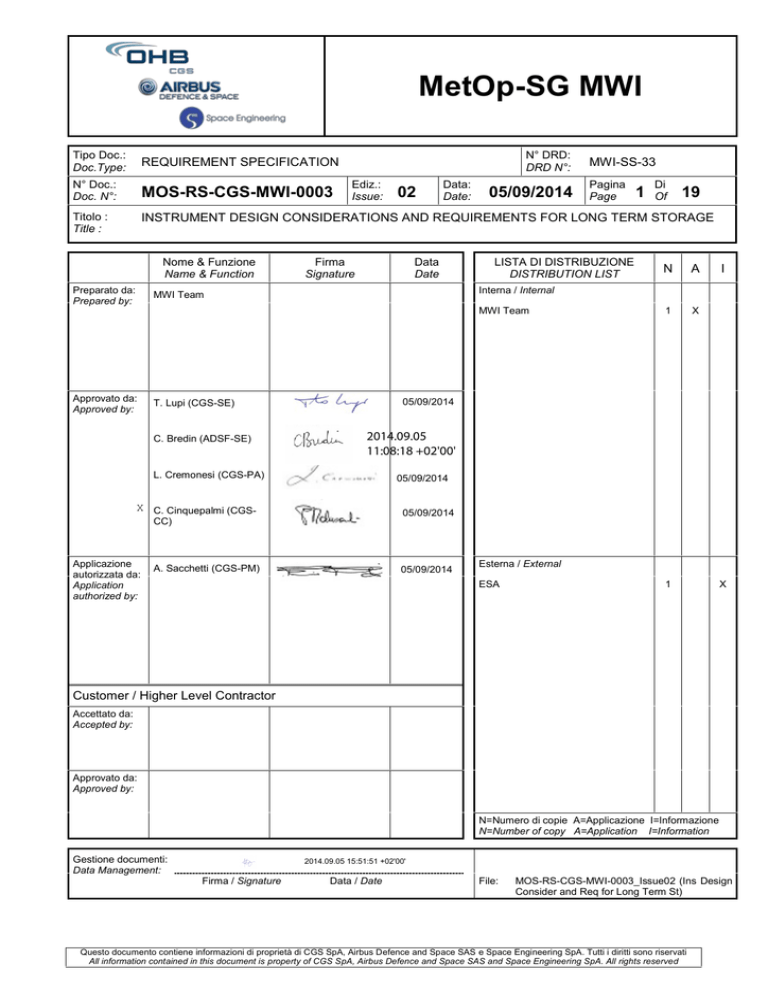

MetOp-SG MWI

Tipo Doc.:

Doc.Type:

REQUIREMENT SPECIFICATION

N° Doc.:

Doc. N°:

MOS-RS-CGS-MWI-0003

Titolo :

Title :

INSTRUMENT DESIGN CONSIDERATIONS AND REQUIREMENTS FOR LONG TERM STORAGE

Nome & Funzione

Name & Function

Preparato da:

Prepared by:

N° DRD:

DRD N°:

Ediz.:

Issue:

02

Firma

Signature

Data:

Date:

Data

Date

05/09/2014

LISTA DI DISTRIBUZIONE

DISTRIBUTION LIST

MWI Team

Di

Of

19

N

A

1

X

I

2014.09.05

11:08:18 +02'00'

L. Cremonesi (CGS-PA)

05/09/2014

X C. Cinquepalmi (CGS-

05/09/2014

CC)

Applicazione

autorizzata da:

Application

authorized by:

1

05/09/2014

T. Lupi (CGS-SE)

C. Bredin (ADSF-SE)

Pagina

Page

Interna / Internal

MWI Team

Approvato da:

Approved by:

MWI-SS-33

A. Sacchetti (CGS-PM)

05/09/2014

Esterna / External

ESA

1

X

Customer / Higher Level Contractor

Accettato da:

Accepted by:

Approvato da:

Approved by:

N=Numero di copie A=Applicazione I=Informazione

N=Number of copy A=Application I=Information

Gestione documenti:

Data Management:

2014.09.05 15:51:51 +02'00'

Firma / Signature

Data / Date

File:

MOS-RS-CGS-MWI-0003_Issue02 (Ins Design

Consider and Req for Long Term St)

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Pagina

Page

2

Data:

Date:

di

of

05/09/2014

19

REGISTRAZIONE DELLE MODIFICHE / CHANGE RECORD

EDIZIONE

ISSUE

DATA

DATE

AUTORIZZAZIONE

CHANGE AUTHORITY

OGGETTO DELLA MODIFICA E SEZIONI AFFETTE

REASON FOR CHANGE AND AFFECTED SECTIONS

01

16/10/2012

First Issue

02

05/09/2014

Second Issue:

Updated document logo and intellectual rights note

Updated Applicable document list

General updating to Chapter 4 – 5

Added Chapter 7

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Pagina

Page

3

Data:

Date:

di

of

05/09/2014

19

LISTA DELLE PAGINE VALIDE / LIST OF VALID PAGES

PAGINA

PAGE

EDIZIONE

ISSUE

1 - 19

02

PAGINA

PAGE

EDIZIONE

ISSUE

PAGINA

PAGE

EDIZIONE

ISSUE

PAGINA

PAGE

EDIZIONE

ISSUE

PAGINA

PAGE

EDIZIONE

ISSUE

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Pagina

Page

4

Data:

Date:

di

of

05/09/2014

19

TABLE OF CONTENTS

1.

INTRODUCTION AND SCOPE ................................................................................................................. 5

1.1

MWI PROGRAMME PLANNING ........................................................................................................ 5

2.

APPLICABILITY ........................................................................................................................................ 6

3.

DOCUMENT ORGANISATION.................................................................................................................. 6

3.1

RELEVANT DOCUMENTS ................................................................................................................. 7

3.1.1

APPLICABLE DOCUMENTS ............................................................................................................... 7

3.2

REFERENCE DOCUMENTS .............................................................................................................. 8

3.3

ACRONYMS........................................................................................................................................ 8

4.

GENERAL PRINCIPLES ........................................................................................................................... 9

4.1

5.

SPECIFIC LIFETIME REQUIREMENTS APPLICABLE TO FLIGHT INSTRUMENT/EQUIPMENTS ... 13

5.1

5.2

5.3

5.4

6.

DESIGN REQUIREMENTS DERIVED FROM THE MWI TRS [AD09] ............................................. 13

DESIGN REQUIREMENTS DERIVED FROM INSTRUMENT GDIR [AD13A] ................................ 13

REQUIREMENTS DERIVED FROM PA REQUIREMENT FOR SUPPLIER [AD14B] ..................... 17

REQUIREMENTS COMING FROM ECSS-E-ST-33-01C ................................................................ 17

GSE SPECIFIC DESIGN REQUIREMENTS ........................................................................................... 18

6.1

7.

CONSIDERATIONS ON INSTRUMENT STORAGE ........................................................................ 10

MWI STORAGE CONTAINER SPECIFIC DESIGN REQUIREMENTS ........................................... 18

INSTRUMENT LONG STORAGE CONSTRAINTS ................................................................................ 19

LIST OF TABLES

Table 3-1: Applicable Documents ...................................................................................................................... 7

Table 3-2: Reference Documents...................................................................................................................... 8

Table 4-1 – General Guidelines for long term storage .................................................................................... 10

Table 4-1 – Instrument storage consideration ................................................................................................. 12

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Pagina

Page

5

Data:

Date:

di

of

05/09/2014

19

1. INTRODUCTION AND SCOPE

This document presents the design requirements and constraints that shall be applied from the very

beginning of the instrument design at all levels of the instrument development to ensure compatibility with the

long term storage requirements applicable to the MetOp-SG MWI Instrument.

The purpose of this document is to provide requirements in order to minimize the need for satellite and/or

instrument intervention and revalidation during and after the storage period by design and ensure all features

necessary to support the storage/destorage activities are designed in from the start of the programme.

The Storage Plan document, addressing the necessary actions to be undertaken in preparation of storage,

during the storage period and the frequency of the operations will be provided in the Instrument Long Term

Storage Plan in accordance to DRD MWI-SS-32.

The present document as well as the Storage Plan will be provided at the MWI instrument reviews as well as

at the satellite CDR in order to confirm the feasibility of the satellite storage plan and associated design

requirements, constraints and provisions necessary to support long term storage and destorage activities.

This document also address the specific requirements to be applied to the MWI Instruments should the

Agency /Prime opts for a stand alone storage.

1.1

MWI PROGRAMME PLANNING

ESA and EUMETSAT are currently working on securing the development of the MetOp Second Generation

system.

Such MetOp-SG system will provide continuity and enhancement of meteorological observation from polar

orbit in the time frame 2020 to 2040.

The Metop-SG consists of two series of satellites, designated as “Satellite A” and “Satellite B”.

The Microwave Imager (MWI) will be part of the complement for “Satellite B” as shown in the next table:

Payload name

SCAtterometer

MicroWave Instrument

Radio Occultation sounder

Ice Cloud Imager

Argos-4 data collection system

Satellite B

SCA

MWI

RO

ICI

Argos-4

The target operational system foresees 21 years of operations for both series of satellites. The nominal

planning foresees the recurrent satellites being launched at interval of 7 years for each Satellite A and B,

which implies three units in each series (so-called “3+3” configuration). However, the final configuration in

terms of number of recurrent satellites will be decided by EUMETSAT during the approval of its EPS-SG

Programme. Therefore, the baseline until the end of Phase B2 will consist of two flight models of each

satellite (including associated instruments), with an option for a third recurrent unit. These options will be

exercised (or not) prior to starting Phase C/D.

At the date of this issue three solutions are envisaged for the storage of the MWI instrument:

Instrument integrated on the satellite (baseline)

Instrument stored at CGS premises before integration onto satellite (SOW option 3)

Instrument stored in its own container and associated GSE at the Instrument Supplier premises and

requiring a recalibration process before integration on the satellite (SOW option 4)

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Pagina

Page

6

Data:

Date:

di

of

05/09/2014

19

2. APPLICABILITY

This specification is intended to provide the requirements to be applied at:

MWI Instrument, subsystems, equipments, spares level

the relevant deliverable GSE

the SDVE (SW Development and Validation Environment ) and SVF (SW Validation Facility)

the non deliverable GSE, if they are necessary in case of MWI Instrument unit maintenance. In such

case the maintenance in operational conditions shall be kept up to the SIOVR (Satellite In Orbit

Validation Review) of the last MetOp-SG Satellite B on which the unit is embarked.

In case the instrument is stored in its own container at the Instrument Supplier (option 3 and 4), dedicated

requirements are applicable to the container and to the storage area.

3. DOCUMENT ORGANISATION

This document is structured in the following way:

Chapter 3 gives the list of applicable and reference documents as well as the acronyms;

Chapter 4 identifies the high level long term storage principles;

Chapter 5 consolidates the specific requirements imposed by the MWI Instrument to the S/C;

Chapter 6 lists the long term storage requirements applicable to the MWI Instruments. In particular

consolidates the requirements coming from the MWI IRS, GDIR and ECSS Standards;

Chapter 7 provides the specific requirements applicable to the MWI GSE, including the requirements

for the storage/transportation containers.

This document is derived from GDIR R-ENV-1010.

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

3.1

RELEVANT DOCUMENTS

3.1.1

APPLICABLE DOCUMENTS

AD

Issue/

Rev.

Doc. No.

Reserved

AD02

Reserved

AD03

Reserved

MOS-SOW-ADS-SATB-0579

1.1

Reserved

AD06

Reserved

AD07

Reserved

AD08

Reserved

MOS-SP-ADS-SATB-0580

1.4

Ediz.:

Issue:

02

Pagina

Page

7

Data:

Date:

di

of

05/09/2014

19

Statement Of Work for the MicroWave Imager [SOW-MWI]

AD05

AD09

MOS-RS-CGS-MWI-0003

Title

AD01

AD04

N° Doc:

Doc N°:

Technical Requirements Specification for the MicroWave

Imager Instrument [TRS-MWI]

AD10

Reserved

AD11

Reserved

AD12

Reserved

AD13a

MOS-SP-ASF-SYS-00816

1.1

MetOp-SG Instrument General Design and Interface

Requirements [INS-GDIR]

AD13b

MOS-SP-ASF-SYS-00349

2.2

MetOp-SG Units General Design and Interface

Requirements [Units GDIR]

AD13c

ENS-06-00123-ASTR

8.0

General Design and Interfaces Requirements [Generic

GDIR]

AD14

MOS-RS-ESA-INS-0434

1.0

MetOp-SG Instruments Product Assurance and Safety

Requirements [PARD]

AD14b

MOS-SP-ASF-SYS-00401

1.0

MetOp-SG Product Assurance Requirements for Suppliers

AD14c

MOS-SP-ASF-SYS-00402

1.0

MetOp-SG Software Product Assurance Requirements for

Suppliers

AD15

MOS-RS-ESA-INS-0435

1.0

MetOp-SG Instruments Project Management Requirements

[MARD]

AD16

MOS-LI-ESA-SYS-0067

1.1

MetOp-SG Deliverable Items and Services List [DISL]

AD17

MOS-LI-ESA-INS-0436

1.0

MetOp-SG Instruments Document Requirements List [DRL]

AD18

MOS-LI-ESA-INS-0437

1.0

MetOp-SG Instruments Document Requirements Definition

[DRD]

AD19

MOS-RS-ESA-INS-0438

1.0

MetOp-SG Instruments Tailoring Of ECSS-E Standards

Table 3-1: Applicable Documents

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

3.2

RD

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Pagina

Page

8

Data:

Date:

di

of

05/09/2014

19

REFERENCE DOCUMENTS

Doc. No.

Issue/

Title

Rev.

[RD01]

MOS-LI-CGS-MWI-0001

01

List of acronyms and abbreviations

[RD02]

MOS-DD-CGS-MWI-0001

02

Instrument Design and Technical Description

[RD03]

MOS-PL-CGS-MWI-0006

02

Instrument Design, Development and

Verification Plan

[RD04]

MOS-PL-CGS-MWI-0015

01

Instrument AIT plan

Table 3-2: Reference Documents

3.3

ACRONYMS

Definitions and acronyms used in the present document are compliant with the ones given in [RD01].

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Pagina

Page

9

Data:

Date:

di

of

05/09/2014

19

4. GENERAL PRINCIPLES

Instrument, equipments and GSE designs shall be such that:

a cost effective storage can be guaranteed;

the human intervention is minimized.

Material, EEE, process and storage containers selection shall be as far as possible consistent with the long

term storage, in particular the PA shall control and assure that in the design solutions, process selection and

definition (defined in the DDVP), the storage time is considered and when a not qualified solution is the only

available, the storage time shall be evaluated in terms of risk identifying all the risk mitigation actions.

The following general guidelines are applicable for long term storage fulfilment:

ID

Guideline descrtiption

The materials shall have high properties stability vs time

1

2

3

4

5

6

7

8

9

10

11

Impact @

Equipment/Instrument/Satellit

e levels

Equipment/Instrument levels

The creep in preloaded structural parts shall be considered in the

design

The joints shall be designed to avoid preload relaxation (bolted

junction used for connecting materials not creep sensitive, low CTE

differences, the junction number shall be minimized);

The maintenance shall be minimized

The instrument shall be stored in Nitrogen to minimize aging effect

on coatings and lubricant property change, then the Nitrogen

storage shall minimize the galvanic action and the also cleanliness

shall be guaranteed

Periodic check of cleanliness witness sample shall be performed if

needed

Tests activities shall be performed during and at the end of the long

term storage to assure that no degradation occurred to process and

hardware both on instrument and on representative samples

(adhesive, creep of flexible preloaded parts, coatings, etc.)

EEE components (active or passive) aging effect shall be

considered in the procurement specification, board design,

manufacturing process (conformal coating) and in the storage

condition definition (the ageing mechanisms are ruled by

temperature, voltage and humidity .for the largest part of the

components, while other predictable aging effects are the variation

in the magnetic permittivity for ceramic capacitor and the quartz

resonance frequency variations).

EEE passive components that are affected by failure due to long

term storage shall be avoided (i.e.: tantalum capacitor). If it is not

possible to replace these tantalum capacitors, they shall be

activated each 2 years by protecting them from in-rush current

failure to avoid the internal oxide layer deterioration.

Life limited items shall be avoided as far as possible

Equipment/Instrument levels

The capability to check or refresh the EEPROM memory and to

upload software correction shall be guaranteed after de-storage

Periodic functional test on mechanism shall be performed in case of

usage of lubricated bearings

Equipment/Instrument/Satellite

levels

Equipment/Instrument/Satellite

levels

Equipment/Instrument levels

Instrument/Satellite levels

Instrument/Satellite levels

Instrument/Satellite levels

Equipment level

Equipment/Instrument/Satellite

levels

Equipment level

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

ID

12

13

14

15

16

Guideline descrtiption

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Data:

Date:

Pagina

Page

10

di

of

05/09/2014

19

Impact @

Equipment/Instrument/Satellit

e levels

Equipment/Instrument/Satellite

levels

Electrical / functional tests and relifing activities shall be performed

during and at the end of the long term storage to assure that no

degradation occurred to process and hardware on instrument and on

representative samples

Obsolescence of parts shall be considered in the procurement in the Equipment level

spare philosophy (for the GSE as well)

GSE periodic check shall be performed during storage

Equipment/Instrument/Satellite

level

Containers shall be designed to fulfil the long term storage

Instrument level

requirements

Before launch, a de-storage procedure shall be applied to verify the Instrument/Satellite level

instrument performances and calibration and then to put the

instrument in flight configuration

Table 4-1 – General Guidelines for long term storage

4.1

CONSIDERATIONS ON INSTRUMENT STORAGE

The following table reports a critical discussion on the instrument needs during storage

ID

1

2

Title

Discussion

Remarks

At present there are no special needs for cleanliness Impacts @

identified for the MWI instrument. The same means for Instrument/Satellite levels

contamination minimization and monitoring as used for

the satellite should be applicable (GDIR_R-ENV-0045)

Points 4 – 5 of Table 4-1

Anyway particular attention shall be dedicated to avoid

lubricant degradation as well as to guarantee a

Cleanliness,

controlled environment (humidity and temperature) for

purging port,

the RF components (non-hermetically sealed Millimeter

cleanliness

wave components) during all life phases including

test samples

storage, test, launch, transportations.

This will require housing the MWI instrument in GN2

ambient, or storage of the whole satellite in inert gas

atmosphere with controlled temperature.

In addition to periodically control the contamination of the

instrument it will be required to store with the instrument

cleanliness witness samples.

Witness

Witness samples have to be stored the same

samples

environmental condition of MWI (the same container

where MWI is stored) for:

Structural bonding

Adhesives

Thermo-optical and optical properties

Lubricants

On-board calibration target absorber

Reflectors coating

Impacts @

Equipment/Instrument/Satellite

levels

Point 6 of Table 4-1

These witness samples shall be inspected / tested

before the MWI periodic test in order to confirm that no

degradation in the process/hardware storage sensitive

items occurred.

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

ID

3

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Data:

Date:

Pagina

Page

11

di

of

05/09/2014

19

Title

Discussion

Remarks

Specific

The instrument shall be stored with the gravity vector Instrument/Satellite levels

Orientation

aligned to the rotation axis in order to spread loads

and storage (gravity) on all rolling elements.

configuration

For what concerns the storage configuration, at this

project stage, it is foreseen to store the MWI both at

payload and at S/C levels by clamping the rotating deck

by using the locking mechanism applying a reduced

preload needed only to:

4

N° Doc:

Doc N°:

Allow the MWI to be kept in nearly any tilt angle

when clamped;

Avoid stress and possible deformation of the

Scan Mechanism (creep).

In order to keep the payload in this intermediate preload

configuration the hold device could use additional

“remove before flight” item (ground locking device),

avoiding additional complexity on the flight hardware.

Dedicated provisions shall be included in the MWI

instrument design to allow for the installation/removal of

these items. Removal/Installation of the locking device

will require the use of LLD loading/offloading device.

As minimum a rotation of the SCM is needed every year Impacts @

Periodic Test

in order to re-generate the oil film, minimizing the Equipment/Instrument/Satellite

and

possibility of false brinelling in the bearings.

levels

accessibility

to

the

During this activation a full functional test is needed to Points 8-10-11-12 of Table 4-1

instrument

check the instrument status and functionality.

This test will require physical and functional During this periodic testing

accessibilities to the instrument.

the functionality of the

Physical accessibility is need to:

Downconverter shall be

1. Install the loading/offloading device in the LLD verified (maximum interval

areas;

less than 5 years). These units

2. Install the Zero-g MGSE on top of the are not hermetically sealed

instrument;

and a GaAs diode not

3. Route and connect the test harness for the encapsulated is installed on

instrument.

them. At the present time the

Functional accessibility is needed to operate the acceptability of storage over 5

instrument without activating

the satellite and the years is not fully

following has to be considered:

demonstrated. The storage in

GN2 environment with

Location of dedicated test ports for accessibility controlled temperature is

at satellite level;

considered a mitigation action.

Compatibility of Platform-MWI interfaces with

this operational configuration (MWI active,

satellite inactive) shall be assessed .

In addition to the full functional test, simple health check

modes shall be identified to verify the status of the

equipment(s).

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

ID

5

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Data:

Date:

Pagina

Page

12

di

of

Title

Discussion

Before launch a de-storage procedure shall be followed

De-storage

to prepare the instrument.

Test

and

A full functional test and a performance test shall be

accessibility

performed in ambient:

to

the

These tests will require physical and functional

instrument

accessibilities to the instrument.

Physical accessibility is need to:

1. Install the loading/offloading device in the LLD

areas;

2. Install the Zero-g MGSE on top of the

instrument;

3. Route and connect the test harness for the

instrument;

4. Position the calibration target in the instrument

field of view for performance test

Functional accessibility is needed to operate the

instrument without activating

the satellite and the

following has to be considered:

05/09/2014

19

Remarks

Impacts @

Instrument/Satellite levels

Points 8-10-11-12-16 of Table

4-1

Location of dedicated test ports for accessibility

at satellite level;

Compatibility of Platform-MWI interfaces with

this operational configuration (MWI active,

satellite inactive) shall be assessed .

Once the instrument functionalities and performances

have been verified the instrument shall be prepared for

launch. In particular the Zero-g MGSE will be removed

and final preload will be applied to the LLD. Finally all the

“remove before flight” protection will be removed.

When the launch configuration is completed only the

simple health check modes could be verified to evaluate

the status of the equipment(s).

Table 4-2 – Instrument storage consideration

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

5. SPECIFIC LIFETIME REQUIREMENTS

INSTRUMENT/EQUIPMENTS

5.1

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Data:

Date:

Pagina

Page

13

di

of

APPLICABLE

TO

05/09/2014

19

FLIGHT

DESIGN REQUIREMENTS DERIVED FROM THE MWI TRS [AD09]

IRS_R-MWI-1220-R

All MWI feed horns shall include a dust cap in order to protect receiver HW from dust and particles.

These dust caps shall be identified as “Remove Before Flight”.

5.2

DESIGN REQUIREMENTS DERIVED FROM INSTRUMENT GDIR [AD13a]

GDIR_R-IFM-1105

The Instruments shall withstand the on-ground operations environment specified in Table 4.4-02 of

[AD13a]. (Pressure, Humidity, Temperature, Cleanliness).

GDIR_R-IFM-1110

The Instruments shall withstand the on-ground operations and handling loads specified in Table 4.403 of [AD13a].

GDIR_R-SYS-0070

Each of the MetOp-SG satellites and their respective instruments shall be designed for a nominal

lifetime in space of at least 7,5 years , including commissioning , validation and calibration.(this

requirements is reported here for sake of completeness , i.e.: definition of the nominal mission

lifetime).

GDIR_R-SYS-0080

Each of the MetOp-SG satellites and their respective instruments shall be provisioned with

consumables for an extended mission lifetime of 9.5 years (7.5 + 2 year).

GDIR_R-SYS-0085

(Mandatory Requirement). Each of the MetOp-SG satellites and their respective instruments shall be

designed, manufactured and qualified to sustain at least 15 years – i.e. corresponding to 2 times the

duration of the nominal operational lifetime – of storage with minimum intervention (typically a once

per year functional test) before having to meet the above stated lifetime requirements (SSRD_RSYS-0280-TAR, SSRD_R-SYS-0300-TAR).

As goal the GDIR indicates: GDIR_G-SYS-0086

Each of the MetOp-SG satellites and their respective instruments shall be designed, manufactured

and qualified to sustain at least 19 years – i.e. corresponding to 2 times the duration of the extended

operational lifetime – of storage with minimum intervention (typically a once per year functional test)

before having to meet the above stated lifetime requirements (SSRD_R-SYS-0280-TAR, SSRD_RSYS-0300-TAR).

GDIR_R-SYS-0088

The Instruments shall meet the requirements of their specification after a minimum on-ground

lifetime, as specified in [AD13b], GDI-50000. (minimum on-ground lifetime of 20 years including up to

15 years in storage).

GDIR_R-STR-0020

The structure shall be designed to cope with the whole satellite operational life including ground

testing, transport, on-ground storage and in-orbit operations. See the details in [AD13b], GDI-299.

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Data:

Date:

Pagina

Page

14

di

of

05/09/2014

19

GDIR_R-STR-0130

Mounting interfaces shall allow for easy maintenance, mounting and demounting.

GDIR_R-STR-0140

The layout of the structure shall provide sufficient accessibility to allow for easy integration, removal

and maintenance activities.

GDIR_R-TCS-0120

The Thermal Control design shall take into account the degradation of surface properties (alpha,

epsilon) during the mission lifetime.

GDIR_R-MEC-0100

Mechanism lifetime shall be demonstrated by test using the sum of predicted nominal ground test

cycles (other than lifetime test), cycles during on-ground storage and the in orbit operation cycles.

The number of predicted cycles shall be multiplied by the factors specified in [ECSS-E-ST-33-01C].

GDIR_R-MEC-0101

Mechanisms lifetime qualification tests shall be performed as specified by GDIR_R-MEC-0100 and

by ECSS-S-ST-33-01C, taking into account the Nominal Lifetime in-orbit as specified in GDIR_RSYS-0070.

SSRD_R-MEC-0250

All preloaded elements in mechanisms shall be able to sustain the ground transportation and storage

conditions and durations without affecting performance. This includes also to launch preloads. For

long storage periods alternative solutions shall be provided if needed.

GDIR_R-MEC-1020

For all surfaces pre-loaded together for launch , and/or for storage configurations, special care shall

be taken in materials selection to avoid materials adhesion, fretting or cold welding.

SSRD_R-MEC-0280

Where wet lubrication systems are proposed, specific methods shall be included to avoid lubricant

migration, during on-ground storage and in-orbit operations.

SSRD_R-MEC-0290

The effectiveness and longevity of the systems to avoid lubricant migration shall be demonstrated

with representative tests.

SSRD_R-MEC-0380

The mechanism shall be designed to be maintenance free during ground life including storage. If

specific maintenance and/or refurbishments are unavoidable, these shall be defined, justified and

agreed by the Agency and Airbus DS.

SSRD_R-MEC-0390

Any maintenance operation required at spacecraft level shall be compliant with the nominal

spacecraft configuration and environment during storage.

SSRD_R-MEC-0400

All mechanisms shall be designed to remain installed at spacecraft level during long- term storage.

SSRD_R-MEC-0410

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Data:

Date:

Pagina

Page

15

di

of

05/09/2014

19

All mechanisms shall be able to perform nominally after the specified storage period on-ground at

satellite level, after completion of all activities at equipments, subsystem and satellite levels prior to

the formal Pre-Storage Review.

SSRD_R-MEC-0420

If mechanism and/or associated lubrication systems require special cleanliness or environmental

constraints (e.g. very low humidity to avoid corrosion) desiccated gas purge ports shall be provided.

These shall be fully accessible throughout all levels of satellite integration, testing and storage.

SSRD_R-MEC-0430

Dedicated purging shall not be required following encapsulation on the Launch Vehicle, or during

short term transportations during AIT activities.

GDIR_R-MEC-1050

If needed, easy replacement of life time expired devices shall be ensured by design.

GDIR_R-ENV-0030

Assembly, ground testing and calibration, transportation and storage environmental conditions shall

be as specified in [SDS02, SDS03, ECSS-Q-20-07A, PSS-01-202 issue 1].

GDIR_R-ENV-0010

The satellites, instruments and their Ground Support Equipments (GSE) shall be protected from or

designed to survive, without performance degradation, the applicable ambient natural environment

during commercial air, sea and road transportation and handling in Europe and at the launch site

(conditions according to GDIR_R-ENV-0030)

.

GDIR_R-ENV-0020

The satellite/Instrument shall be compatible with the contamination and cleanliness conditions

specified for the assembly, ground testing and calibration, transportation and storage.

GDIR_R-ENV-0021

The satellites, instruments and their Ground Support Equipments (GSE) shall be designed to allow

the performance of all on- ground AIV activities, including storage, both in Europe and at the launch

site, in a controlled environment with a minimum cleanliness level of ISO 8 Class as defined in

ECCS-Q-ST-70-01C, Table G-1. .

GDIR_R-ENV-0022

Instruments Suppliers shall provide:

o

o

o

An Instrument Cleanliness and Contamination Control Plan, defining the measures and

methods used at Instrument level to prevent contamination,

An Instrument level Contamination Budget, quantifying the Instrument contamination levels

resulting from the MAIV operations at instrument level, before delivery to the Satellite Prime

Contractor,

A Satellite level Contamination Budget, specifying the Instrument contamination levels

required during the Satellite AIV operations, storage, launch campaign execution, launch

preparation (encapsulation under fairing), launch, in-orbit lifetime operations, together with

the assumed conditions (cleanliness class, duration of each operations). An example of such

a satellite level contamination budget is provided in Table 4 of R-ENV-0022 and shall be

completed by the Instrument supplier.

GDIR_R-ENV-0040

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Data:

Date:

Pagina

Page

16

di

of

05/09/2014

19

Mechanical and thermal loads induced by the environment during assembly, transportation and

storage shall not establish the dimensioning case for any element of the satellite. This shall be

ensured by the use of adequate means of transportation and protective ground support equipment.

GDIR_R-ENV-0045

During long-term storage, satellites (and instruments if dismounted) shall be kept in an

environmentally controlled and monitored container with dry GN2.

GDIR_R-ENV-0050

The storage and de-storage needs and associated requirements shall be established by the entity

responsible for maintaining the integrity of the performances and reliability.

GDIR_R-ENV-1010

For long term storage (See GDIR_R-SYS-0085; GDIR_G-SYS-0086) of their respective Instruments,

the Instrument Suppliers shall define and specify :

• Storage conditions (Container; Cleanliness; Purging; …)

• Regular maintenance and verification activities (typically once a year),

• Accessibility requirements and constraints.

GDIR_R-GSE-0010

The Ground Support Equipment (GSE) shall be designed and manufactured to support the MetOpSG programme throughout its lifetime including long-term storage, with minimal needs for

refurbishment.

GDIR_R-GSE-0020

The GSE shall include all hardware and software necessary to support the AIV activities at all levels

of integration including the launch campaign and long-term storage.

SSRD_R-AIV-0590

It shall be possible to store the satellite, with the instruments integrated, in a controlled environment

for at least 15 years with no risk of performance or reliability degradation. Storage lifetime is

specified in SSRD_R-SYS-0310-TAR and SSRD_G-SYS-0320-TAR.

SSRD_R-AIV-0600

During storage, a satellite functional test (including the activation of all the mechanisms) shall be

envisaged once per year.

Such functional test shall be a repeat of a baseline functional test performed throughout the AIV

programme, exercising all redundant chains and checking instrument performances.

For mechanism activation, the following sequence have to be considered each time the instrument is

activated :

1) Initial measurement

2) Activation sequence (typically 1 or 2 days of continuous rotation of the mechanism)

3) Final measurement.

SSRD_R-AIV-0610

Provisions shall be made to have witness plates and process manufacturing samples to check the

contamination and the ageing of the satellites and instruments.

SSRD_R-AIV-0620

The witness plates and process manufacturing samples shall be stored together with the satellite /

instrument in identical conditions.

SSRD_R-AIV-0620

The witness plates and process manufacturing samples shall be stored together with the satellite /

instrument in identical conditions.

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

5.3

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Data:

Date:

Pagina

Page

17

di

of

05/09/2014

19

REQUIREMENTS DERIVED FROM PA REQUIREMENT FOR SUPPLIER [AD14b]

ECSS-Q-ST-10_MOS-016 – Note 1

Due to the long storage requirements and mission duration for the MetOp-SG system, it is necessary

to retain full visibility of ALL historical NCR’s in case of future anomalies and for future reference.

ECSS-Q-ST-70_MOS-009

a. The supplier shall evaluate the obsolescence risk of materials and processes (e.g. by REACH,

RoHS) throughout its supply chain, establish any such risks and present in the Risk Register, and

inform the project on technical or programmatic implications. Obsolescence related issues shall be

communicated via the MPCB process and reported (e. g. in the DMPL Tool).

ECSS-Q-ST-70_REQ-039

b. The supplier shall identify and evaluate the materials, mechanical parts and processes considered

as long term storage sensitive in the frame of the MPCB process.

ECSS-Q-ST-70_MOS-010

c. The Long Term Storage Plan shall address material performance during the storage period and

identify mechanisms to predict and/or verify material or process or mechanical part performance

throughout the storage period until de-storage and launch campaign activities.

Note: For example this can include adhesive samples stored with the flight adhesives they represent

(i.e. under the same storage conditions), tested at intervals throughout the storage period and

evaluated against initial results and control samples; laminated materials (e.g. magnetics) samples

stored under the same storage conditions, checked for corrosion/delamination during the storage

period and compared to control samples; material samples in a flight representative configuration

that may be prone to Creep during the storage period (e.g. resin/plastic washers) and checked

throughout the storage period for the presence of Creep.

5.4

REQUIREMENTS COMING FROM ECSS-E-ST-33-01C

Maintainability (Chapter 4.2.4.4)

a. The mechanism should be designed to be maintenance free during storage and ground life.

b. If the design is not maintenance free, the maintenance requirements shall be documented in the

SMS, justified, agreed by the customer.

c. If ground maintenance during storage or ground operation is not avoided, the maintenance

procedures shall be provided.

Flushing and purging (Chapter 4.2.6)

a. If operating the mechanism in air is detrimental to the performance of the mechanism over its

complete mission, means for flushing the critical parts with an inert clean dry gas shall be

provided.

NOTE Example of detrimental cause to operate the mechanism in air is the presence of

moisture or other deleterious contamination.

b. Only lubricants qualified in respect to the residual humidity of the dry gas shall be used.

Tribology (Chapter 4.7.3)

It shall be verified that the degradation of the lubricant in the on‐ground and in‐orbit environments

does not lead to a mechanism performance degradation below the limits specified in the Specific

Mechanism Specification.

The effect of exposure to on‐ground storage and related gravity effects, and other ground or in‐orbit

accelerations on lubricant distribution shall be validated.

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Data:

Date:

Pagina

Page

18

di

of

05/09/2014

19

6. GSE SPECIFIC DESIGN REQUIREMENTS

The MWI GSE shall be designed in order to meet the overall MWI programme duration including the long

term storage (for example no corrosion sensitive material will be used for mechanical parts)

The GSE manufacturer shall identify if the GSE storage shall be carried out in the relevant container.

The GSE, when housed in their container, shall be designed for the following non operating storage

conditions:

o Temperature: TBD

o Relative Humidity: TBD

o Shock: TBD

o Pressure : from sea level up to 16000 m

The limited life items shall be identified (e.g. batteries).

Components / Commercial SW shall be procured taking into consideration the obsolescence risks, and

as far as possible, portability on newer generation hardware.

When a GSE with commercial SW is provided, it shall be provided with the last available revision.

To support the long term availability of the GSE it should be based on the use of ESA SCOS.

Upgrade/maintenance requirement of the GSE shall be documented. Detailed maintenance procedures

shall be provided.

Spare parts for the critical items shall be delivered.

6.1

MWI STORAGE CONTAINER SPECIFIC DESIGN REQUIREMENTS

These requirements are applicable in case the instrument is stored in its container at the instrument supplier

facilities (option).

The container design shall be compatible with the long term storage lifetime without degradation of its

structural properties.

The container shall be designed to sustain a number TBD of transportations.

The container shall allow for the monitoring of the internal temperature and humidity without the need of

opening it.

The container internal surface shall be compatible with the storage lifetime, without releasing

particulates, dust or contaminants in excess of TBD.

The container shall allow for dry Nitrogen filling, with a delta pressure of TBD, and a leak rate of less

than TBD.

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved

MetOp-SG MWI

INSTRUMENT DESIGN CONSIDERATIONS AND

REQUIREMENTS FOR LONG TERM STORAGE

N° Doc:

Doc N°:

MOS-RS-CGS-MWI-0003

Ediz.:

Issue:

02

Data:

Date:

Pagina

Page

19

di

of

05/09/2014

19

7. INSTRUMENT LONG STORAGE CONSTRAINTS

According to the discussion of chapter 4, the following constraints are induced by MWI when integrated on

the satellite:

Need of storage in an environmentally controlled and monitored container with dry GN2 – (See Table

4-2 – Row1 );.

Need of cleanliness test samples – (See Table 4-2 – Row1 );

Need to store some process/hardware witness samples sensitive to long storage in the same

environmental condition of the payload – (See Table 4-2 – Row2 );

Need to be stored with the rotation axis aligned to the gravity vector and with ground locking device

installed (LLD with minimal preloaded applied) – (See Table 4-2 – Row3 );

Need of periodic testing (possibly less or equal test once per year). Periodic testing shall be carried

out based on a procedure and results shall be recorded. The testing orientation shall be with the

instrument rotation axis aligned to the gravity vector and with the main reflector looking to the ground

– (See Table 4-2 – Row4 ). The expected time for periodic testing is 1 week;

Need of de-storage operation implementation before launch. For de-storage operation the instrument

rotation axis aligned to the gravity vector and with the main reflector looking to the ground – (See

Table 4-2 – Row5 ) . The expected time for de-storage is 2 weeks;.

Need to guarantee the instrument accessibility both hardware accessibility and EGSE ports

connection for testing purpose during storage, periodic testing and the de-storage – (See Table 4-2 –

Row3-4-5 ).

Questo documento contiene informazioni di proprietà di CGS SpA, Airbus Defence and Space SAS e Space Engineering SpA. Tutti i diritti sono riservati

All information contained in this document is property of CGS SpA, Airbus Defence and Space SAS and Space Engineering SpA. All rights reserved