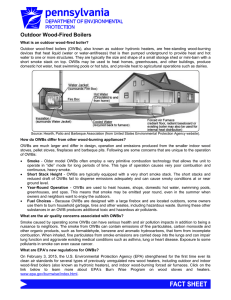

Assessment of Outdoor Wood

advertisement