DC1245A LTM4616 Dual 2.7VIN(MIN), 8A Step

advertisement

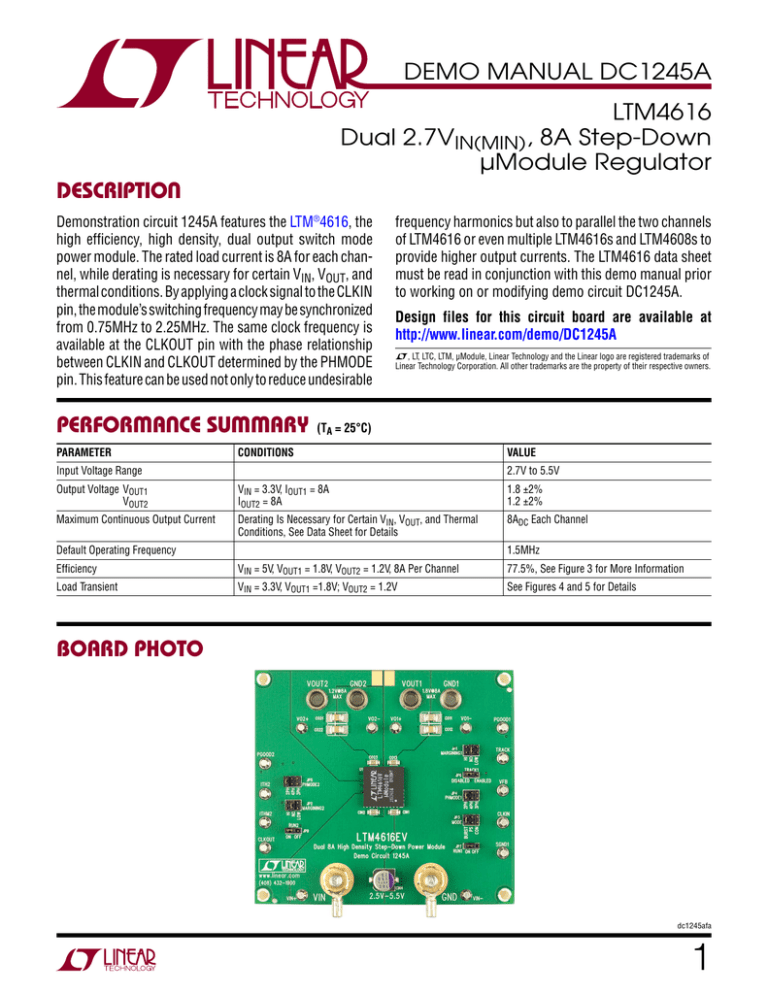

DEMO MANUAL DC1245A LTM4616 Dual 2.7VIN(MIN), 8A Step-Down µModule Regulator Description Demonstration circuit 1245A features the LTM®4616, the high efficiency, high density, dual output switch mode power module. The rated load current is 8A for each channel, while derating is necessary for certain VIN, VOUT, and thermal conditions. By applying a clock signal to the CLKIN pin, the module’s switching frequency may be synchronized from 0.75MHz to 2.25MHz. The same clock frequency is available at the CLKOUT pin with the phase relationship between CLKIN and CLKOUT determined by the PHMODE pin. This feature can be used not only to reduce undesirable PERFORMANCE SUMMARY PARAMETER frequency harmonics but also to parallel the two channels of LTM4616 or even multiple LTM4616s and LTM4608s to provide higher output currents. The LTM4616 data sheet must be read in conjunction with this demo manual prior to working on or modifying demo circuit DC1245A. Design files for this circuit board are available at http://www.linear.com/demo/DC1245A L, LT, LTC, LTM, µModule, Linear Technology and the Linear logo are registered trademarks of Linear Technology Corporation. All other trademarks are the property of their respective owners. (TA = 25°C) CONDITIONS Input Voltage Range VALUE 2.7V to 5.5V Output Voltage VOUT1 VOUT2 VIN = 3.3V, IOUT1 = 8A IOUT2 = 8A 1.8 ±2% 1.2 ±2% Maximum Continuous Output Current Derating Is Necessary for Certain VIN, VOUT, and Thermal Conditions, See Data Sheet for Details 8ADC Each Channel Default Operating Frequency 1.5MHz Efficiency VIN = 5V, VOUT1 = 1.8V, VOUT2 = 1.2V, 8A Per Channel 77.5%, See Figure 3 for More Information Load Transient VIN = 3.3V, VOUT1 =1.8V; VOUT2 = 1.2V See Figures 4 and 5 for Details Board Photo dc1245afa 1 DEMO MANUAL DC1245A quick start procedure Demonstration circuit 1245A is an easy way to evaluate the performance of the LTM4616. Please refer to Figure 1 for proper measurement equipment setup and follow the procedure below: 1.Place jumpers in the following positions for a typical 1.8VOUT and 1.2VOUT application: PHMODE2 MARGINING2 RUN2 MARGINING1 2PH NO ON NO TRACK1 PHMODE1 MODE RUN1 DISABLED 2PH BURST ON 2.With power off, connect the input power supply, load and meters as shown in Figure 1. Preset the load to 0A and VIN supply within the 2.7V to 5.5V operating range. 4.Once the proper output voltage is established, adjust the load within the operating range and observe the output voltage regulation, ripple voltage, efficiency and other parameters. To measure input and output ripple, please refer to Figure 2 for proper setup. 5.To synchronize channel 1 to an external clock, please apply the desired clock signal to CLKIN and SGND1. The external clock signal should have amplitude of at least 2V but less than VIN. 6.VOUT1 can track another supply connected at TP20 as determined by resistors R6 and R17. VOUT2 is set up to track VOUT1 in a manner determined by resistors R15 and R16. By default both resistor pairs have been selected to support coincident tracking. Please refer to Figure 6 for reference. 3.Turn on the power at the input. The output voltage at VO1+ and VO1– should be 1.8V ±2% and the voltage at VO2+ and VO2– should be 1.2V ±2%. INPUT OR OUTPUT CAPACITOR Figure 2. Proper Scope Probe Placement for Measuring Input or Output Ripple Overall Efficiency vs Load Current 95 VIN = 3.3V, VO1 = 1.8V, VO2 = 1.2V 90 85 EFFICIENCY (%) 80 75 VIN = 5V, VO1 = 1.8V, VO2 = 1.2V 70 65 60 55 50 45 40 35 0 2 6 4 8 10 LOAD CURRENT FOR EACH CHANNEL (A) dc1245a F03 Figure 3. Measured Overall Supply Efficiency with Different VIN Figure 1. Test Setup of DC1245A dc1245afa 2 DEMO MANUAL DC1245A quick start procedure 7.Channel 2 is set up to synchronize to the CLKOUT signal of channel 1. The default phase difference is 180°. Please refer to data sheet for how to set up PHMODE1 and PHMODE2 for paralleling more than 2 channels. dc1245a F05 VIN = 3.3V VOUT =1.2V CONTINUOUS CURRENT MODE (CCM) 2A TO 6A LOAD STEP COUT = ×2 100µF CERAMIC (1210, X5R, 6.3V) + 22µF CERAMIC (0805, X5R, 6.3V) CFF2 = 0pF VOUT OVERSHOOT AND UNDERSHOOT = 128mV dc1245a F04 VIN = 3.3V VOUT =1.8V CONTINUOUS CURRENT MODE (CCM) 2A TO 6A LOAD STEP COUT = ×2 100µF CERAMIC (1210, X5R, 6.3V) + 22µF CERAMIC (0805, X5R, 6.3V) CFF1 = 47pF VOUT OVERSHOOT AND UNDERSHOOT = 172mV Figure 5. Measured Load Transient Response for 1.2VOUT (4A Step, 25% to 75%) Figure 4. Measured Load Transient Response for 1.8VOUT (4A Step, 25% to 75%) Figure 6. Measured Tracking Performance of VOUT1 and VOUT2 (with 2A Load Current) dc1245afa 3 DEMO MANUAL DC1245A parts list ITEM QTY REFERENCE PART DESCRIPTION MANUFACTURER/PART NUMBER Required Circuit Components 1 4 CIN1, CIN2, CO13, CO23 Capacitor, X5R, 22µF, 6.3V, 20%, 1206 AVX, 12066D226MAT2A 2 1 CIN4 Capacitor, OS-CON, 150µF, 10V, E7 Size Sanyo, 10SVPA150MAA 3 4 CO11, CO12, CO21, CO22 Capacitor, X5R, 100µF, 6.3V, 20%, 1210 AVX, 12106D107MAT2A 4 1 RSET1 Resistor, Chip, 4.99k, 1/16W, 1%, 0402 Vishay, CRCW04024K99FKED 5 1 RSET2 Resistor, Chip, 10k, 1/16W, 1%, 0402 Vishay, CRCW040210K0FKED 6 1 U1 IC LTM4616EV 144-Pin LGA Linear Technology, LTM4616EV Additional Demo Board Circuit Components 1 0 CO14, CO15, CO24, CO25 (OPT) Capacitor, 1210-3743 2 2 R7, R5 Resistor, Chip, 100k, 1/16W, 5%, 0402 3 0 R9, R11, R19 (OPT) Resistor, Chip, 0402 Vishay, CRCW0402100KJNED 4 0 CTHP1, CTHP2, C1, CFF2, CSP (OPT) Capacitor, 0402 5 1 CFF1 Capacitor, C0G, 47pF, 50V, 10%, 0402 AVX, 04025A470KAT2A 6 1 R17 Resistor, Chip, 4.99k, 1/16W, 1%, 0402 Vishay, CRCW04024K99FKED 7 3 R15, R16, R6 Resistor, Chip, 10k, 1/16W, 1%, 0402 Vishay, CRCW040210K0FKED 8 1 R18 Resistor, Chip, 0, 1/16W, 0402 Vishay, CRCW04020000Z0ED Hardware/Components (For Demo Board Only) 1 0 CIN3(OPT) Capacitor, 1210-3743 2 5 JP1, JP2, JP3-JP5 2 × 3, 0.079 Double Row Header Samtec, TMM103-02-L-D 3 3 JP6, JP7, JP9 Header 3-Pin 0.079 Single Row Samtec, TMM103-02-L-S 4 8 JP1-JP7, JP9 Shunt, 0.079" Center Samtec, 2SN-BK-G 5 15 TP1, TP2, TP7-TP10, TP12, TP14-TP18, TP20-TP22 Testpoint, Turret, 0.094" Pbf Mill-Max, 2501-2-00-80-00-00-07-0 6 2 TP6, TP3 Stud, Test Pin PEM KFH-032-10 7 4 TP6, TP3 Nut, Brass Nuts #10-32 Any #10-32 8 2 TP6, TP3 Ring, Lug Ring #10 Keystone #10 9 2 TP6, TP3 Washer, Tin Plated Brass Any #10 10 4 TP4, TP5, TP11, TP13 Jack Banana Keystone, 575-4 11 4 (STAND-OFF) Stand-Off, Nylon 0.50" Keystone, 8833(SNAP ON) dc1245afa 4 TP3 TP8 TP6 BURST SVIN1 Information furnished by Linear Technology Corporation is believed to be accurate and reliable. However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights. SGND1 CLKIN TP22 TP21 TP20 3PH (PHASE) 4PH (PHASE) 2PH (PHASE) 2 6 4 6 3 5 10K R6 R17 4.99K CIN3 100uF opt ITHM2 ITH2 CIN1 22uF 6.3V ON OFF 2 SVIN1 C1 opt RUN1 JP7 CFF1 47pF ITHM2 RSET1 4.99K R11 opt opt A11 VFB F5 A7 F6 E8 A9 D8 F7 E7 A8 A10 A6 G11 MODE1 MGN1 BSEL1 PGOOD2 PGOOD1 SGND1 CLKIN1 RUN1 TRACK1 PHMODE1 FB1 CLKOUT1 ITHM1 CTHP1 F8 ITH1 opt. CLK R7 100K R9 MODE R5 100K ITH2 VOUT1 TP16 TP15 CIN2 22uF 6.3V SVIN1 SVIN2 IN LAYOUT, MANUALLY TIED ALL GND TOGETHER ON LAYER 2. *DC1245A STILL USES THE OLD METHOD TO DISABLE MARGINING. AN IMPROVED METHOD OF TYING THE MGN PIN TO A VOLTAGE DIVIDER WITH 50k RESISTORS FROM VIN TO GROUND IS RECOMMENDED NOW. ENABLED 2 SVIN1 JP6 TRACK1 2 1 JP4 PHMODE1 4 5 2 6 4 3 1 JP3 MODE DISABLED SVIN1 (CONTINUOUS) CON TRACK HI 1 150uF 10V + CIN4 JP1* MARGINING1 TP12 TP10 NO 3 LOW 5 SVIN1 (PULSE SKIPPING) PS VOUT1 PBS1 PGOOD2 PGOOD1 VIN- GND 2.5V - 5.5V VIN 1 3 VIN 1 3 F1 F2 F3 F4 E1 E2 E3 E4 D1 D2 C1 C2 VIN1 VIN1 VIN1 VIN1 VIN1 VIN1 VIN1 VIN1 VIN1 VIN1 VIN1 VIN1 B6 SW1 E5 SVIN1 H6 SW2 J1 J2 K1 K2 L1 L2 L3 L4 M1 M2 M3 M4 A1 A2 A3 A4 A5 A12 B1 B2 B3 B4 B5 B7 B8 B9 B10 B11 B12 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12 D3 D4 D5 D6 D7 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 GND1 VIN2 VIN2 VIN2 VIN2 VIN2 VIN2 VIN2 VIN2 VIN2 VIN2 VIN2 VIN2 L5 SVIN2 FB2 CLKOUT2 ITHM2 ITH2 MODE2 MGN2 BSEL2 VOUT2 VOUT2 VOUT2 VOUT2 VOUT2 VOUT2 VOUT2 VOUT2 VOUT2 VOUT2 VOUT2 VOUT2 VOUT1 VOUT1 VOUT1 VOUT1 VOUT1 VOUT1 VOUT1 VOUT1 VOUT1 VOUT1 VOUT1 VOUT1 SGND2 CLKIN2 PLLFLTR1 PLLFLTR2 RUN2 TRACK2 PHMODE2 LTM4616EV U1 M5 G7 E6 L6 M6 L8 G9 K8 M7 L7 M8 G8 G10 G6 K9 K10 K11 K12 L9 L10 L11 L12 M9 M10 M11 M12 D9 D10 D11 D12 E9 E10 E11 E12 F9 F10 F11 F12 CLK ITHM2 MODE ITH2 CSP opt CTHP2 opt. APPROVED Friday, February 15, 2008 3/7/07 M. Xie 6 4 2 VOUT1 VO1+ GND1 VO2+ VO1- TP13 HI VFB 1630 McCarthy Blvd. Milpitas, CA 95035 Phone: (408)432-1900 Fax: (408)434-0507 TP18 TP17 CLKOUT SVIN2 VOUT2 PBS2 VO2- GND2 VOUT2 TP11 1.2V @ 8A MAX TP9 TP7 TP5 1.8V @ 8A MAX TP4 TP14 NO 3 5 LOW 1 TECHNOLOGY 3PH (PHASE) 4PH (PHASE) FILENAME: CAGE CODE SCALE: SIZE CO25 opt 6.3V CO15 opt 6.3V JP2* MARGINING2 2PH (PHASE) CO24 opt 6.3V CO14 opt 6.3V TP2 DWG NO SHEET DC1245A 1 OF LTM4616EV Dual 8A High Density Step-Down Power Module 5 TITLE 3 6 DATE 1 4 3/7/07 CHECKED opt VOUT2 SVIN2 R19 2 J. Wu ENGINEER CO23 22uF 6.3V SVIN2 JP5 PHMODE2 APPROVALS DRAWN JP9 RUN2 ON opt VFB PFB2 PFB1 CFF2 OFF SVIN2 2 CO22 100uF 6.3V CO21 100uF 6.3V VOUT2 CO13 22uF 6.3V VOUT1 10.0K 1% CO12 100uF 6.3V CO11 100uF 6.3V RSET2 CONTRACT NO. R16 10.0K 1% R15 10.0K 1% VOUT1 R18 0 LINEAR TECHNOLOGY HAS MADE A BEST EFFORT TO DESIGN A CIRCUIT THAT MEETS CUSTOMER-SUPPLIED SPECIFICATIONS; HOWEVER, IT REMAINS THE CUSTOMER'S RESPONSIBILITY TO VERIFY PROPER AND RELIABLE OPERATION IN THE ACTUAL APPLICATION. COMPONENT SUBSTITUTION AND PRINTED CIRCUIT BOARD LAYOUT MAY SIGNIFICANTLY AFFECT CIRCUIT PERFORMANCE OR RELIABILITY. CONTACT LINEAR TECHNOLOGY APPLICATIONS ENGINEERING FOR ASSISTANCE. THIS CIRCUIT IS PROPRIETARY TO LINEAR TECHNOLOGY AND SUPPLIED FOR USE WITH LINEAR TECHNOLOGY PARTS. CUSTOMER NOTICE GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 GND2 G1 G2 G3 G4 G5 G12 H1 H2 H3 H4 H5 H7 H8 H9 H10 H11 H12 J3 J4 J5 J6 J7 J8 J9 J10 J11 J12 K3 K4 K5 K6 K7 TP1 1 3 VIN+ A 1 REV DEMO MANUAL DC1245A Schematic Diagram dc1245afa 5 DEMO MANUAL DC1245A DEMONSTRATION BOARD IMPORTANT NOTICE Linear Technology Corporation (LTC) provides the enclosed product(s) under the following AS IS conditions: This demonstration board (DEMO BOARD) kit being sold or provided by Linear Technology is intended for use for ENGINEERING DEVELOPMENT OR EVALUATION PURPOSES ONLY and is not provided by LTC for commercial use. As such, the DEMO BOARD herein may not be complete in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including but not limited to product safety measures typically found in finished commercial goods. As a prototype, this product does not fall within the scope of the European Union directive on electromagnetic compatibility and therefore may or may not meet the technical requirements of the directive, or other regulations. If this evaluation kit does not meet the specifications recited in the DEMO BOARD manual the kit may be returned within 30 days from the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY THE SELLER TO BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. EXCEPT TO THE EXTENT OF THIS INDEMNITY, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES. The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user releases LTC from all claims arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all appropriate precautions with regard to electrostatic discharge. Also be aware that the products herein may not be regulatory compliant or agency certified (FCC, UL, CE, etc.). No License is granted under any patent right or other intellectual property whatsoever. LTC assumes no liability for applications assistance, customer product design, software performance, or infringement of patents or any other intellectual property rights of any kind. LTC currently services a variety of customers for products around the world, and therefore this transaction is not exclusive. Please read the DEMO BOARD manual prior to handling the product. Persons handling this product must have electronics training and observe good laboratory practice standards. Common sense is encouraged. This notice contains important safety information about temperatures and voltages. For further safety concerns, please contact a LTC application engineer. Mailing Address: Linear Technology 1630 McCarthy Blvd. Milpitas, CA 95035 Copyright © 2004, Linear Technology Corporation dc1245afa 6 Linear Technology Corporation LT 0913 REV A • PRINTED IN USA 1630 McCarthy Blvd., Milpitas, CA 95035-7417 (408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com LINEAR TECHNOLOGY CORPORATION 2011