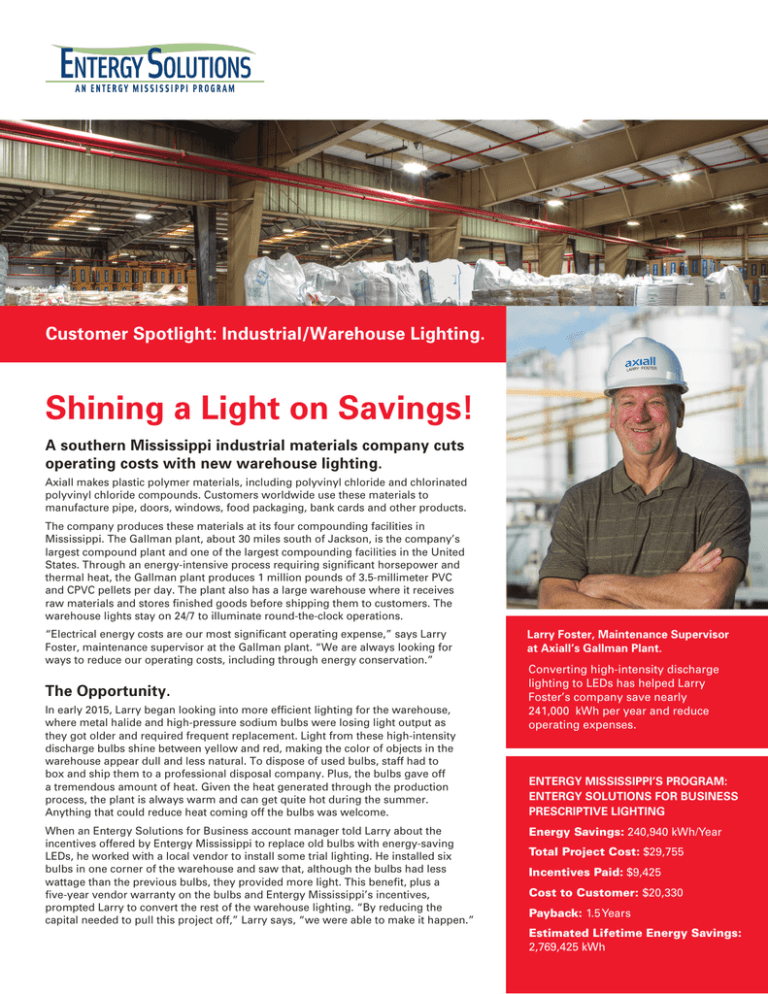

Customer Spotlight: Industrial/Warehouse Lighting.

Shining a Light on Savings!

A southern Mississippi industrial materials company cuts

operating costs with new warehouse lighting.

Axiall makes plastic polymer materials, including polyvinyl chloride and chlorinated

polyvinyl chloride compounds. Customers worldwide use these materials to

manufacture pipe, doors, windows, food packaging, bank cards and other products.

The company produces these materials at its four compounding facilities in

Mississippi. The Gallman plant, about 30 miles south of Jackson, is the company’s

largest compound plant and one of the largest compounding facilities in the United

States. Through an energy-intensive process requiring significant horsepower and

thermal heat, the Gallman plant produces 1 million pounds of 3.5-millimeter PVC

and CPVC pellets per day. The plant also has a large warehouse where it receives

raw materials and stores finished goods before shipping them to customers. The

warehouse lights stay on 24/7 to illuminate round-the-clock operations.

“Electrical energy costs are our most significant operating expense,” says Larry

Foster, maintenance supervisor at the Gallman plant. “We are always looking for

ways to reduce our operating costs, including through energy conservation.”

The Opportunity.

In early 2015, Larry began looking into more efficient lighting for the warehouse,

where metal halide and high-pressure sodium bulbs were losing light output as

they got older and required frequent replacement. Light from these high-intensity

discharge bulbs shine between yellow and red, making the color of objects in the

warehouse appear dull and less natural. To dispose of used bulbs, staff had to

box and ship them to a professional disposal company. Plus, the bulbs gave off

a tremendous amount of heat. Given the heat generated through the production

process, the plant is always warm and can get quite hot during the summer.

Anything that could reduce heat coming off the bulbs was welcome.

When an Entergy Solutions for Business account manager told Larry about the

incentives offered by Entergy Mississippi to replace old bulbs with energy-saving

LEDs, he worked with a local vendor to install some trial lighting. He installed six

bulbs in one corner of the warehouse and saw that, although the bulbs had less

wattage than the previous bulbs, they provided more light. This benefit, plus a

five-year vendor warranty on the bulbs and Entergy Mississippi’s incentives,

prompted Larry to convert the rest of the warehouse lighting. “By reducing the

capital needed to pull this project off,” Larry says, “we were able to make it happen.”

Larry Foster, Maintenance Supervisor

at Axiall’s Gallman Plant.

Converting high-intensity discharge

lighting to LEDs has helped Larry

Foster’s company save nearly

241,000 kWh per year and reduce

operating expenses.

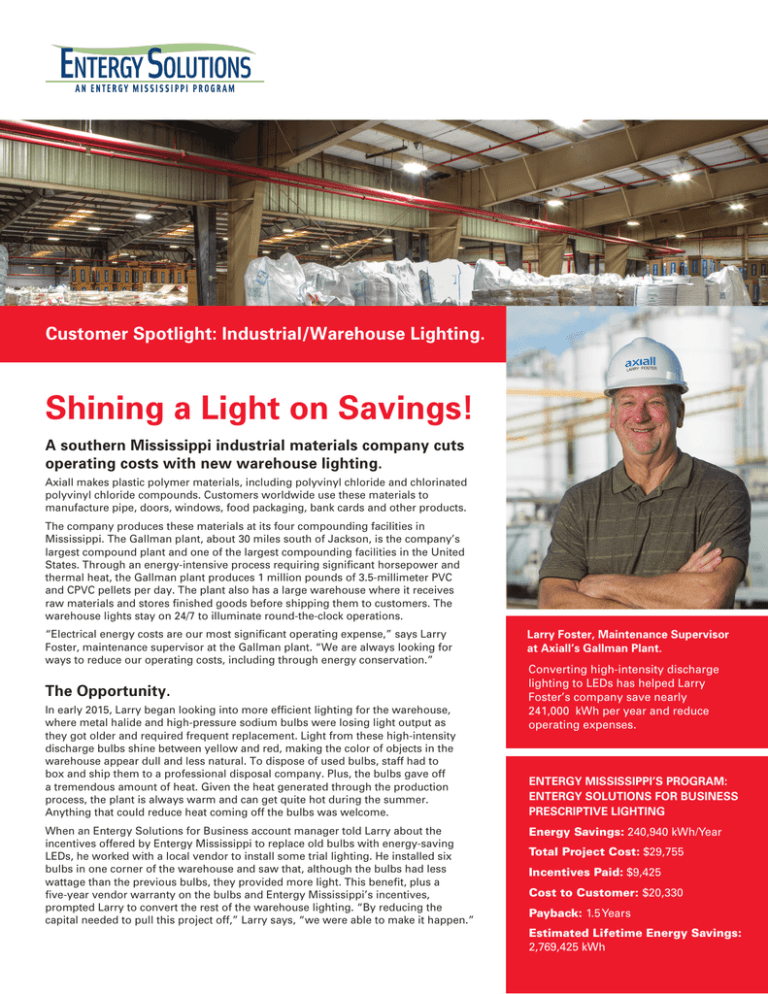

ENTERGY MISSISSIPPI’S PROGRAM:

ENTERGY SOLUTIONS FOR BUSINESS

PRESCRIPTIVE LIGHTING

Energy Savings: 240,940 kWh/Year

Total Project Cost: $29,755

Incentives Paid: $9,425

Cost to Customer: $20,330

Payback: 1.5 Years

Estimated Lifetime Energy Savings:

2,769,425 kWh

The Project.

The conversions took place in September 2015, with contractors performing

the work in sections of the warehouse. Entergy Mississippi provided $9,425 in

incentives to replace 145 250w HID fixtures with LED technology. The new

100-watt LEDs plugged directly into a ceiling receptacle, making maintenance

much easier than it had been with the previous, pendulum-mounted light fixtures.

“Now, if a light fails, we’ll simply unplug it and hook a new one up in its place,”

Larry says. “For our maintenance group, that’s a big plus.”

The Benefits.

Larry estimates the plant will save nearly 241,000 kWh of energy per year, which,

along with the incentives from Entergy Mississippi, means the investment will pay

for itself in 1.5 years. Operators in the warehouse have noticed it is much brighter

and easier to see box labels, tools and other supplies, especially at night.

In addition to approximately 60 percent energy reduction, the company also

eliminated the need to dispose of the HID bulbs. The LEDs provide added safety,

too. If the lights are ever off in the warehouse, when they are turned back on, LEDs

are immediately fully lit, helping employees to work safely. HID bulbs generally

have a delay—sometimes up to 15 minutes—before they are fully lit.

In the past, heat generated by the production process and gas bulbs caused ballast

problems. The plant had to replace lighting in production areas because the

ballasts holding up the metal halide lights in the ceiling could not withstand the

heat. Cool operation of LEDs can better withstand the heat, making them ideal for

the facility’s production areas.

The Future.

Axiall is already looking into converting other lighting at the Gallman plant,

including changing office lighting to LEDs. Another Axiall facility has installed

some pendulum-mounted LEDs as well. “We’re gaining the benefits we

anticipated,” Larry says. “I wouldn’t hesitate to work with Entergy Mississippi on

another energy efficiency project.”

White light from LEDs makes it easier

for operators to see in the warehouse,

day and night. Package labels that had

looked dim under the old lighting are

now easier to read.

“Axiall is dedicated to the continual improvement of

our processes, products and services. Incentives from

Entergy made it easier to do something we already

knew was a good idea.”

Larry Foster, Maintenance Supervisor at Axiall’s Gallman Plant

For more information

Visit: EntergySolutionsMS.com/Business.

Email: EntergySolutionsforBusiness@icfi.com.

Call: 844-523-9979.

A message from Entergy Mississippi, Inc. ©2016 Entergy Services, Inc. All Rights Reserved.

The Entergy Solutions program is an energy efficiency program and not affiliated with Entergy Solutions, LLC. Authorized by the Mississippi Public Service Commission.