Ultra-Precision SMT Current Sense Resistor (Wrap

advertisement

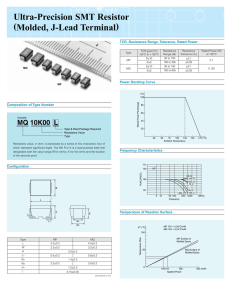

Ultra-Precision SMT Current Sense Resistor (Wrap-Around Terminals) TCR, Resistance Range, Tolerance, Rated Power Type PWG Resistance Range ()** 0.002 to 0.003 0.003 to 0.01 0.01 to 0.02 0.02 to 0.1 TCR (ppm/°C) +25°C to +125°C 0±100 (K)* 0±50 (H)* 0±25 (J)* 0±25 (J) Resistance Tolerance (%) ±5 (J) ±2 (G) ±2 (G) ±0.5 (D) ±1 (F) Rated Power (W) at 70°C 2 Symbols parenthesized are for type number composition. *Temperature Range is +25°C to +125°C **Please contact us for resistance values. PWG Power Derating Curve (%) Composition of Type Number egatnecreP rewoP detaR 100 80 Example: 60 PWG J R0100 F L 40 20 Tape & Reel Package Required Tolerance Resistance Value TCR Type Resistance value, in ohm, is expressed by a series of five characters, four of which represent significant digits. The fifth R or K is a dual-purpose letter that designates both the value range (R for ohmic; K for kilo-ohm) and the location of the decimal point. 70 20 40 60 80 155 100 120 140 160 (¡C) Ambient Temperature Temperature of Resistor Surface R = 34.4¡C/W (Glazed Epoxy Board) R = 12.1¡C/W (Aluminum Board) Configuration T (¡C) L L1 PWG L 7.0±0.2 W 4.0±0.2 L1 0.3±0.2 L2 6.4±0.2 c 3.0±0.1 T 0.9±0.2 Dimensions in mm c 50 40 30 Mounted on Aluminum Board (100mm x 40mm x 2.0mmt) 20 10 1.0 1.5 2.0 Applied Power 2.5 (W) Please use board made of metal for continuous use with 2W at 70°C. Please keep the temperature of board less than 90°C when using the glazed epoxy board. 5 12 60 0.5 c Construction 6 Mounted on Glazed Epoxy Board (100mm x 40mm x 1.6mmt) 70 Type esiR erutarepmeT W L2 L1 80 T 3 7 1 2 4 1 Copper Terminals 2 Insulation Resin 3 Metal Foil 4 Laser Beamed 5 External Terminal (Sn-Cu) 6 Solder Resist 7 Insulation Resin (Epoxy) Performance Parameters Test Condition Alpha Specification Alpha Typical Test Data 70°C -65°C to +155°C 50 A Maximum Rated Operating Temperature Working Temperature Range Maximum Working Current Thermal Shock Overload -65°C/30 min., +155°C/30 min., 5 cycles Rated Voltage x 2.5, 5 sec. ±0.1% ±0.1% ±0.05% ±0.05% Low Temperature Storage and Operation Substrate Bending Test -65°C, No Load, 24 hrs. Rated Power, 45 min. Substrate Bent 3mm, 60 sec. ±0.1% ±0.1% ±0.05% ±0.05% Dielectric Withstanding Voltage Insulation Resistance Resistance to Soldering Heat Moisture Resistance Atmospheric: AC 200V, 1 min. DC 100 C, 1 min. 260°C, 10 sec. -65°C to -10°C, 90% RH to 98% RH, Rated Voltage, 10 cycles (240 hrs.) ±0.05% over 10,000M⍀ ±0.1% ±0.1% ±0.01% over 10,000M⍀ ±0.05% ±0.05% Shock High Frequency Shock 100G, 6 ms., Sawtooth Wave, X, Y, Z, 10 shocks each 20G, 10Hz to 2,000Hz to 10Hz, 20 min., X, Y, Z, 2.5 hrs. each ±0.05% ±0.05% ±0.01% ±0.01% Life 70°C, Rated Power, 1.5 hr. – ON, 0.5 hr. – OFF, 2,000 hrs. ±0.2% ±0.1% Storage Life 15°C to 35°C, 15% RH to 75% RH, No Load, 10,000 hrs. ±0.05% ±0.01% High Temperature Exposure 155°C, No Load, 2,000 hrs. ±0.5% ±0.1% Internal Thermal Resistance Between Resistive Elements and Terminals 15°C/W 1V /°C Thermal Electromotive Force Tape and Reel Package (based on EIA-481-1) Tape Dimensions W2 Tape Dimensions Sprocket Hole D0 0.40±0.05 Cavity E D A0 F B N W 0B r P1 P2 P0 1.30±0.1 A0 4.3 ±0.1 B0 7.3 ±0.1 W 16.0 ±0.3 C F 7.5 ±0.1 E 1.75 ±0.1 P1 8.0 ±0.1 P2 2.0 ±0.1 P0 4.0 ±0.1 A D0 1.5 +0.1-0 Dimensions in mm Precaution in Using SMT Current Sense Resistors N 60 min. B 13 ±0.5 C 21 ±0.8 D 2.0 ±0.5 W1 17.0 ±0.3 Reel Capacity: 1,000 pieces/reel W2 19.4 ±0.1 r 1.0 ±0.5 Dimensions in mm Recommended Land Layout 3.6 0.6 3.6 Current Terminals 6.4 1. Storage Storage conditions or environment may adversely affect solderability of exterior terminals. Do not store in high temperature and humidity. The recommended storage environment is lower than 40°C, has less than 70% RH humidity and is free from harmful gases such as sulphur and chlorine. 2. Caution in Soldering 1 Solder Reflow in Furnace Recommended • Peak Temperature: 245°C • Holding time: 220°C (40sec.max.) • To cool gradually at room temperature 2 Dipping in Solder (Wave or Still) Recommended • Solder Temperature: 240°C to 250°C • Length of Dipping: 3 to 4 seconds 3 Other Corrosion-free flux such as rosin is recommended. 3. Cleaning Use volatile cleaner such as methylalcohol or propylalcohol. A 178 ±0.2 W1 Voltage Sensing Terminals 13