LOW VOLTAGE EARTHING POLICY AND APPLICATION GUIDE

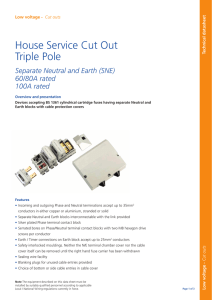

advertisement