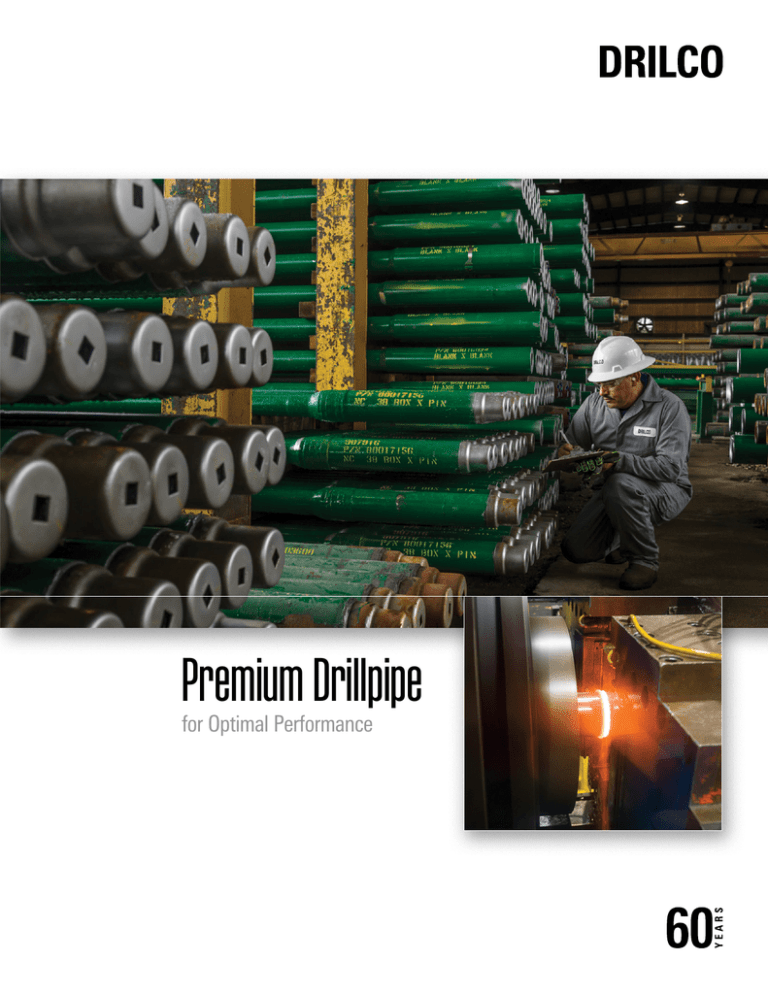

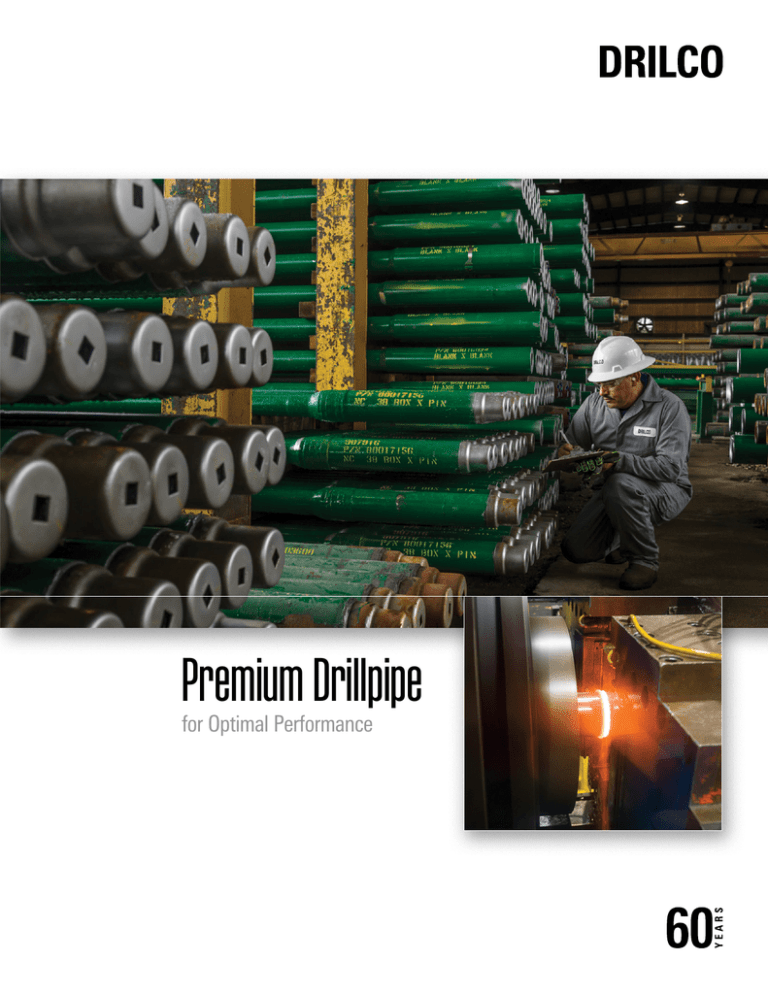

Premium Drillpipe

for Optimal Performance

DRILCO offers a full line of

premium drillpipe available

in a variety of sizes with API and

non-standard wall thickness to

deliver optimal torque, weight,

and durability. Our manufacturing

capability ranges from 27⁄8-in to

75⁄8-in diameter drill pipe in E,

X, G, S or SS GRADES in both

Range 2 and Range 3 lengths.

Special sizes and proprietary

grades are available on an

individual order basis. Our

technical representatives can

help you select the best

features to ensure maximum

BHA performance.

2

Premium drillpipe

Fatigue in the transition area between the tool joint and the drillpipe is

the most common cause of washouts and failures. Therefore, DRILCO uses

specialized forging equipment, proprietary tooling, and manufacturing

techniques to develop drillpipes with extended upset design and gradual

taper, producing a uniform mechanical property throughout the material.

The smooth transition between components results in a clean steel and

enhanced hardenability. In addition, our proprietary tube chemistries are

matched to our quench and temper heat treatment processes to achieve

excellent impact values, high fatigue resistance, and extended product life.

Optional Features

■■

Extended upset double shouldered premium connections

■■

Premium hardbanding

■■

Internal plastic coating

■■

Factory make-up and break-out

Extended upset design maximizes drillpipe durability

by reducing stress resistance

Drillstring durability is maximized by designing pipes that are resistant to

fatigue, which is concentrated in areas with sudden changes in geometry.

This is the upset area adjacent to the tool joint weld, which serves as the

transition from the drillpipe’s cross-sectional part to the tool joint’s thick

cross-sectional part. To increase stress resistance, the upset transition zone

between the drillpipe’s body and the tool joint needs to be as smooth and

gradual as possible.

DRILCO selects steel with stringent cleanliness requirements to ensure

high fractured toughness that translates into higher safety margins. Using

proprietary equipment for the upset areas, we can specify an extended

internal upset with a shallow run-out angle that blends seamlessly into the

drillpipe’s ID. These qualifications improve pipe performance and ensure its

durability in this stress-prone region. To further reduce fatigue, we grind

both the ID and OD of the assembled pipe adjacent to the weld line.

Tool joint forgings are required to meet or exceed API standards. Prior to

assembly, each tool joint is inspected to guarantee dimensional properties and

test to ensure they provide proper mechanical integrity. Our tool joints are

usually supplied 2-in longer than standard API lengths to deliver additional

re-cut capability and longer service life. Tool joints with longer lengths can

also be supplied by special request.

3

PIPE BODY

TOOL JOINT

ASSEMBLY

Nomimal Size, in

Premium Makeup, ft.lbf

Premium OD, in

Displacement (open end), galUS/ft

Capacity, galUS/ft

Adjusted Weight, lbm/ft

Torsional Ratio

Tensile Strengh, lbf

Torsional Strength, lbf

Makeup Torque, ft.lbf

Box Tong Space, in

Pin Tong Space, in

ID, in

OD, in

Connection Type

Collapse Pressure, psi

Burst Pressure, psi

Tensile Strength, lbf

Torsional Strength, ft.lbf

ID, in

Wall Thickness, in

Upset

Grade

Nominal Weight, lbm/ft

Nominal Size, in

27⁄8 10.4 G-105 EU 0.362 2.151 16,176 300,082 23,137 23,112 NC-31

41⁄8 2

9 11

7,895 13,389

495,726 0.83 11.39 0.19 0.17 315⁄16

6,110 27⁄8

27⁄8 10.4 G-105 EU 0.362 2.151 16,176 300,082 23,137 23,112 27⁄8 OH

37⁄8 25⁄32

9 11

5,194

345,566 0.54 11.4

0.19 0.17 319⁄32

4,411 27⁄8

27⁄8 10.4 S-135 EU 0.362 2.151 20,798 385,820 29,747 29,716 NC-31

43⁄8 15⁄8

9 11

623,844 0.83 12.12 0.18 0.19 41⁄16

7,694 27⁄8

27⁄8 10.4 S-135 EU 0.362 2.151 20,798 385,820 29,747 29,716 27⁄8 OH

37⁄8 25⁄32

9 11

345,566 0.42 11.4

0.19 0.17 321⁄32

4,950 27⁄8

31⁄2 13.3 G-105 EU 0.368 2.764 25,970 380,200 19,320 19,758 NC-38

5

27⁄16 10 121⁄2 13,221 22,213

708,063 0.86 14.68 0.31 0.23 421⁄32

9,879 31⁄2

31⁄2 13.3 S-135 EU 0.368 2.764 33,392 488,825 24,840 25,404 NC-38

5

21⁄8

842,440 0.79 15.68 0.3

31⁄2 13.3 S-135 EU 0.368 2.764 33,392 488,825 24,840 25,404 NC-38

47⁄8 29⁄16 10 121⁄2 12,057 20,326

8,814

10,086 17,170

5,194

8,814

10 121⁄2 15,902 26,515

0.31 0.23 43⁄4

11,500 31⁄2

31⁄2 13.3 S-135 EU 0.368 2.764 33,392 488,825 24,840 25,404 NC-38 DS 47⁄8 29⁄16 10 121⁄2 15,375 25,626

649,158 0.77 15.41 0.31 0.23 45⁄8

12,576 31⁄2

31⁄2 13.3 S-135 EU 0.368 2.764 33,392 488,825 24,840 25,404 NC-38 DS 5

27⁄16 10 121⁄2 17,505 29,176

708,063 0.87 15.74 0.3

31⁄2 13.3 S-135 EU 0.368 2.764 33,392 488,825 24,840 25,404 NC-38 DS 5

29⁄16 10 121⁄2 15,477 25,794

649,158 0.77 15.63 0.31 0.24 45⁄8

12,576 31⁄2

17,858 29,930

897,161 0.9

16.44 0.3

12,569 31⁄2

10 121⁄2 15,902 26,515

842,440 0.9

18.32 0.27 0.27 423⁄32 10,957 31⁄2

9 12

649,158 0.61 15.4

0.24 413⁄16 12,614 31⁄2

0.24 419⁄32 12,930 31⁄2

31⁄2 13.3 S-135 EU 0.368 2.764 33,392 488,825 24,840 25,404 NC-40

53⁄8 27⁄16

31⁄2 15.5 G-105 EU 0.449 2.602 29,500 451,890 23,573 23,484 NC-38

5

21⁄8

31⁄2 15.5 G-105 EU 0.449 2.602 29,500 451,890 23,573 23,484 NC-38

5

27⁄16 10 121⁄2 13,221 22,213

708,063 0.75 18.06 0.27 0.27 423⁄32 10,957 31⁄2

31⁄2 15.5 G-105 EU 0.449 2.602 29,500 451,890 23,573 23,484 NC-38

5

29⁄16 10 121⁄2 12,057 20,326

649,158 0.69 17.95 0.28 0.27 423⁄32 10,957 31⁄2

31⁄2 15.5 G-105 EU 0.449 2.602 29,500 451,890 23,573 23,484 NC-40

51⁄4 29⁄16

31⁄2 15.5 S-135 EU 0.449 2.602 37,960 581,000 30,308 30,194 NC-38

16,616 27,760

838,257 0.94 18.19 0.28 0.27 415⁄16 11,363 31⁄2

5

27⁄16 10 121⁄2 13,221 22,213

708,063 0.59 17.86 0.27 0.27 413⁄16 12,625 31⁄2

31⁄2 15.5 S-135 EU 0.449 2.602 37,960 581,000 30,308 30,194 NC-38

5

29⁄16 10 121⁄2 12,057 20,326

649,158 0.54 17.76 0.27 0.27 413⁄16 12,070 31⁄2

31⁄2 15.5 S-135 EU 0.449 2.602 37,960 581,000 30,308 30,194 NC-40

51⁄2 21⁄4

9 12

19,616 32,943

979,996 0.87 18.31 0.27 0.28 53⁄32

14,419 31⁄2

4

14

G-105 IU 0.33

3.34

32,603 399,502 15,159 15,896 NC-40

51⁄2 27⁄16

9 12

17,858 30,114

897,161 0.92 16.87 0.44 0.26 5

12,569 4

4

14

G-105 IU 0.33

3.34

32,603 399,502 15,159 15,896 NC-40

51⁄4 29⁄16

9 12

16,616 27,760

838,257 0.85 16.49 0.43 0.25 5

12,569 4

4

14

G-105 IU 0.33

3.34

32,603 399,502 15,159 15,896 NC-40 DS 51⁄4 211⁄16

9 12

19,524 32,541

776,406 1

4

14

G-105 EU 0.33

3.34

32,603 399,502 15,159 15,896 NC-46

6

31⁄4

9 12

19,937 33,625

901,164 1.03 16.79 0.45 0.26 57⁄16

12,813 4

4

14

S-135 IU 0.33

3.34

41,918 513,646 19,491 20,141 NC-40

51⁄2 27⁄16

9 12

17,858 30,114

897,161 0.72 16.87 0.44 0.26 55⁄32

15,677 4

4

14

S-135 IU 0.33

3.34

41,918 513,646 19,491 20,141 NC-40

51⁄4 27⁄16

9 12

17,848 29,747

897,161 0.71 16.6

0.43 0.25 55⁄32

15,677 4

4

14

S-135 IU 0.33

3.34

41,918 513,646 19,491 20,141 NC-40

51⁄4 29⁄16

9 12

16,616 27,760

838,257 0.66 16.3

0.44 0.25 55⁄32

15,677 4

4

14

S-135 IU 0.33

3.34

41,918 513,646 19,491 20,141 NC-40 DS 51⁄4 29⁄16

9 12

21,769 36,282

838,257 0.87 16.49 0.43 0.25 429⁄32 15,812 4

4

14

S-135 EU 0.33

3.34

41,918 513,646 19,491 20,141 NC-46

6

9 12

23,399 39,229 1,048,426 0.94 17.24 0.45 0.26 59⁄16

15,787 4

4

15.7 G-105 IU 0.38

3.24

36,134 453,765 17,456 18,055 NC-40

51⁄2 27⁄16

9 12

17,858 30,114

897,161 0.83 18.44 0.41 0.28 51⁄16

13,797 4

4

15.7 G-105 IU 0.38

3.24

36,134 453,765 17,456 18,055 NC-40 DS 51⁄4 29⁄16

9 12

21,769 36,282

838,257 1

4

15.7 G-105 EU 0.38

3.24

36,134 453,765 17,456 18,055 NC-46

9 12

23,399 39,229 1,048,426 1.09 18.81 0.42 0.29 515⁄32 13,547 4

4

15.7 S-135 IU 0.38

3.24

46,458 583,413 22,444 23,213 NC-40 DS 51⁄4 29⁄16

9 12

21,769 36,282

4

15.7 S-135 EU 0.38

3.24

46,458 583,413 22,444 23,213 NC-46

9 12

23,399 39,229 1,048,426 0.84 19.27 0.42 0.29 521⁄32 18,083 4

4

6

6

3

3

3

9 12

0.25 5

16.38 0.44 0.25 413⁄16 13,067 4

18.25 0.41 0.27 413⁄16 14,043 4

838,257 0.78 18.25 0.41 0.27 5

17,629 4

PIPE BODY

TOOL JOINT

ASSEMBLY

Nomimal Size, in

Premium Makeup, ft.lbf

Premium OD, in

Displacement (open end), galUS/ft

Capacity, galUS/ft

Adjusted Weight, lbm/ft

Torsional Ratio

Tensile Strengh, lbf

Torsional Strength, lbf

Makeup Torque, ft.lbf

Box Tong Space, in

Pin Tong Space, in

ID, in

OD, in

Connection Type

Collapse Pressure, psi

Burst Pressure, psi

Tensile Strength, lbf

Torsional Strength, ft.lbf

ID, in

Wall Thickness, in

Upset

Grade

Nominal Weight, lbm/ft

Nominal Size, in

41⁄2 16.6 X-95 IEU 0.337 3.826

39,022 418,707 12,450 12,765 NC-46

61⁄4 3

9 12 23,399 39,659 1,048,426 1.02 20.08 0.57 0.31 517⁄32 15,035 41⁄2

41⁄2 16.6 X-95 EU 0.337 3.826

39,022 418,707 12,450 12,765 NC-50

63⁄8 33⁄4

9 12 22,605 37,676

41⁄2 16.6 G-105 IEU 0.337 3.826

43,130 462,781 13,761 13,825 NC-46

61⁄4 3

9 12 23,399 39,659 1,048,426 0.92 19.85 0.57 0.3

41⁄2 16.6 G-105 EU 0.337 3.826

43,130 462,781 13,761 13,825 NC-50

63⁄8 33⁄4

9 12 22,605 37,676

41⁄2 16.6 S-135 IEU 0.337 3.826

55,453 595,004 17,693 16,773 NC-46

61⁄4 23⁄4

9 12 26,615 44,871 1,183,908 0.81 20.07 0.57 0.31 525⁄32 21,230 41⁄2

41⁄2 16.6 S-135 EU 0.337 3.826

55,453 595,004 17,693 16,773 NC-50

65⁄8 31⁄2

9 12 26,674 44,673 1,109,920 0.81 20.03 0.59 0.31 61⁄16 21,017 41⁄2

5

19.5 G-105 IEU 0.362 4.276

57,633 553,833 13,304 12,999 NC-50

65⁄8 31⁄4

9 12 30,730 51,447 1,268,963 0.89 23.35 0.71 0.36 63⁄32 21,914 5

5

19.5 G-105 IEU 0.362 4.276

57,633 553,833 13,304 12,999 NC-50 DS 65⁄8 31⁄2

5

19.5 G-105 IEU 0.362 4.276

57,633 553,833 13,304 12,999 51⁄2 FH

7

5

19.5 S-135 IEU 0.362 4.276

74,100 712,070 17,105 15,672 NC-50

65⁄8 23⁄4

5

19.5 S-135 IEU 0.362 4.276

74,100 712,070 17,105 15,672 NC-50 DS 65⁄8 31⁄4

5

19.5 S-135 IEU 0.362 4.276

74,100 712,070 17,105 15,672 51⁄2 FH

71⁄4 31⁄2 10 12 43,328 72,627 1,619,231 0.98 24.67 0.72 0.38 63⁄4

5

25.6 G-105 IEU 0.5

4

73,160 742,201 18,375 18,900 NC-50

65⁄8 23⁄4

5

25.6 G-105 IEU 0.5

4

73,160 742,201 18,375 18,900 NC-50 DS 65⁄8 31⁄4

5

25.6 G-105 IEU 0.5

4

73,160 742,201 18,375 18,900 51⁄2 FH

5

25.6 S-135 IEU 0.5

4

94,062 954,259 23,625 24,300 NC-50 DS 65⁄8 31⁄4

5

25.6 S-135 IEU 0.5

4

94,062 954,259 23,625 24,300 51⁄2 FH

71⁄4 31⁄4 10 12 47,230 76,156 1,778,274 0.81 30.58 0.63 0.47 615⁄16 35,446 5

51⁄2 21.9 G-105 IEU 0.361 4.778

70,994 611,963 12,061 10,753 51⁄2 FH

71⁄4 31⁄2 10 12 43,328 72,482 1,619,231 1.02 26.96 0.88 0.41 623⁄32 27,645 51⁄2

51⁄2 21.9 S-135 IEU 0.361 4.778

91,278 786,809 15,507 12,679 51⁄2 FH

71⁄2 3

51⁄2 21.9 S-135 IEU 0.361 4.778

91,278 786,809 15,507 12,679 51⁄2 FH

71⁄4 31⁄2 10 12 43,328 72,482 1,619,231 0.79 26.93 0.88 0.41 615⁄16 35,446 51⁄2

51⁄2 21.9 S-135 IEU 0.361 4.778

91,278 786,809 15,507 51⁄2 FH 51⁄2 FH DS 71⁄4 31⁄2 10 12 60,893 101,488 1,619,231 1.11 26.93 0.88 0.41 69⁄16 39,323 51⁄2

51⁄2 24.7 G-105 IEU 0.415 4.67

79,204 696,111 13,856 14,013 51⁄2 FH

51⁄2 24.7 S-135 IEU 0.415 4.67

101,834 894,999 17,826 17,023 51⁄2 FH

71⁄2 3

51⁄2 24.7 S-135 IEU 0.415 4.67

101,834 894,999 17,826 17,023 51⁄2 FH

71⁄4 31⁄4 10 12 47,230 76,156 1,778,274 0.75 29.95 0.84 0.46 71⁄32 38,901 51⁄2

51⁄2 24.7 S-135 IEU 0.415 4.67

101,834 894,999 17,826 17,023 51⁄2 FH DS 71⁄4 31⁄2 10 12 60,893 101,488 1,619,231 1

939,095 0.97 18.93 0.59 0.29 523⁄32 14,926 41⁄2

519⁄32 16,546 41⁄2

939,095 0.87 18.93 0.59 0.29 529⁄32 16,638 41⁄2

9 12 35,926 59,877 1,109,920 1.04 23.3

0.72 0.35 513⁄16 22,691 5

33⁄4 10 12 37,742 60,338 1,448,407 1.05 24.1

0.73 0.37 619⁄32 23,357 5

9 12 38,036 63,406 1,551,706 0.86 24.23 0.7

0.37 65⁄16 28,381 5

9 12 43,010 71,683 1,268,963 0.97 23.82 0.71 0.36 61⁄32 28,796 5

28,737 5

9 12 38,036 63,406 1,551,706 0.87 30.19 0.62 0.46 69⁄32 27,437 5

9 12 43,010 71,683 1,268,963 0.98 29.68 0.63 0.45 57⁄8

27,455 5

71⁄4 31⁄2 10 12 43,328 72,627 1,619,231 0.99 30.06 0.64 0.46 623⁄32 27,645 5

9 12 43,010 71,683 1,268,963 0.76 29.68 0.63 0.45 65⁄32 35,519 5

10 12 52,059 87,341 1,925,536 0.96 28.16 0.87 0.43 615⁄16 35,446 51⁄2

71⁄4 31⁄2 10 12 43,328 72,482 1,619,231 0.92 29.38 0.85 0.45 625⁄32 29,836 51⁄2

10 12 52,059 87,341 1,925,536 0.86 30.88 0.83 0.47 71⁄32 38,901 51⁄2

29.66 0.85 0.45 65⁄8

41,475 51⁄2

65⁄8 25.2 S-135 IEU 0.33 5.965 127,045 881,035 11,768

6,036 65⁄8 FH

81⁄2 41⁄4 10 13 65,012 109,227 2,102,260 0.86 32.14 1.37 0.5

715⁄16 49,689 65⁄8

65⁄8 27.7 S-135 IEU 0.362 5.901 137,331 961,556 12,909

7,813 65⁄8 FH

81⁄2 41⁄4 10 13 65,012 109,227 2,102,260 0.8 34.17 1.34 0.53 81⁄32 54,225 65⁄8

65⁄8 27.7 S-135 IEU 0.362 5.901 137,331 961,556 12,909

7,813 65⁄8 FH DS 8

41⁄2 10 13 75,503 125,838 1,896,062 0.92 32.26 1.35 0.49 75⁄8

65⁄8 27.7 S-135 IEU 0.362 5.901 137,331 961,556 12,909

7,813 65⁄8 FH DS 8

5

57,695 65⁄8

10 13 55,927 93,212 1,448,416 0.68 31.38 1.38 0.47 713⁄16 55,422 65⁄8

5

Double-shouldered connections improve torque

and hydraulic performance

DRILCO offers drillpipe with standard API threaded connections for all

available sizes. In addition, we offer DRILCO DS compatible double-shouldered

connections, which use a standard API thread form with a secondary

internal shoulder. The connection allows you to increase ID or reduce OD,

which significantly improves hydraulic and torque performance over

conventional API connections. The DRILCO DS connections are compatible

with standard API connection thread forms as well as other standard

double shouldered connections.

Typical double-shouldered connections provide 30% to 40% greater torque capacity than

standard API connections.

6

Hardbanding minimizes deterioration during drilling

and casing rotation

Hardbanding material can be welded to the tool joint’s circumference to

protect it from deterioration during drilling. Some hardbanding types also

offer protection for the casing when rotating inside the casing. Whether

the application is for standard tungsten carbide or casing friendly using our

proprietary DRILCO DEFENDER series hardbanding products, we have the

materials available to meet your most stringent requirements. Please be

sure to specify your requirements when ordering or discuss your options

with our DRILCO representatives.

Internal plastic coating prevents corrosion

and maximizes durability

The internal plastic coating is applied to the inside of the drillpipe to

prevent corrosion and extend pipe service life by reducing friction

coefficient and improving flow rate and hydraulics. To provide you

with high-quality coatings and fast turnaround on orders, we partner

with coating service companies that have a proven reputation for

timely deliveries based on scheduled workloads.

Service after the sale

DRILCO is one of the few manufacturing companies that service and

support what we sell. Our global infrastructure with strategically located

inventory locations and machine shop facilities enable us to support your

drilling operations 24/7. In addition, our fully-equipped service and support

facilities offer fast and dependable tubular service that meets your drilling

needs such as:

■■

inventory control and tubular tracking

■■

advanced service and maintenance equipment

■■

stringent quality control

■■

■■

24-h service centers

■■

support inclement weather support operations

■■

■■

Make and break method minimizes galling

and damage to drillpipe connections

premium connection repairs—Grant Prideco, VAM,

and Tenaris licenses available in selection locations

single-source responsibility for inspection, maintenance,

repairs, inventory, and storage

global network of DRILCO service centers.

Factory make-up and break-out of tool joints is a proven method used to

minimize galling and damage to new drillpipe connections. The process is

performed in the manufacturing plant under controlled conditions to ensure

consistency for optimal performance. If galling does occur during the

process, the joint is repaired or replaced immediately, saving you rig time

and logistical complications.

7

Premium Drillpipe

For more information about DRILCO premium drillpipe, visit DRILCO.com.

For more than 60 years, DRILCO has

provided premium tubular products

and services to the drilling industry.

■■

DRILCO also offers specialized services

such as field inspection, machine shop,

field hardbanding, and other tubular

management services to provide expert

maintenance for essential BHA tools

and equipment.

■■

Premium Tubular Products

DRILCO Machine Shop Services

DRILCO offers a full line of premium

tubulars and tubular products available

in a variety of standard sizes to suit your

drilling requirements.

For a common tubular connection or

a proprietary connection requiring licensing,

DRILCO recuts and repairs tubulars, 24/7.

DRILCO Inspection Services

Qualified DRILCO personnel provide a full range

of inspection services, which include third-party

and customer-defined standards.

DRILCO Tubular Management Services

DRILCO tubular management services provide

tubular inventory visibility, storage location

management, and centralized maintenance

to reduce repair time.

DRILCO.com

*Mark of Schlumberger

Other company, product, and service names are the properties of their respective owners.

Copyright © 2014 Schlumberger. All rights reserved. 14-DT-0037