Magnetic-gravity separation of iron ore

advertisement

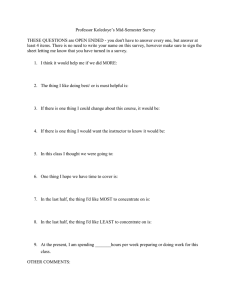

Indian Journal of Engineering & Materials Sciences Vol. 5, June 1998, pp. 130-135 Magnetic-gravity separation of iron ore P A Usachyov & S Yu Korytny Mining Institute, Kola Science Centre, Russian Academy of Sciences, 24 Fersman str., 184200 Apatity, Munnansk region, Russia Received 17 October 1997; accepted 30 April 199'S In order to produce high-grade iron ore concentrates a magnetic-gravity method has been developed for separation of magnetite ore. It provides separation of mineral complexes according to magnetic properties, density and size. Magnetic-gravity separators (MGS) have been designed and their parameters are defined, It has been shown that MGS enables to obtain 1.5-3.0% improvement in Fe content in concentrates and to produce superconcentrate (72% Fe, 0.2-0.3% Si02). MGS also provides for intensification of thickening and desliming of ferromagnetic suspensions. Drum separators with permanent magnets are the most commonly used ones in the beneficiation of iron ores. In these separators the magnetic forces significantly overcome the dynamic forces of pulp flow and gravity forces experienced by the mineral grains. Magnetic systems are used to create magnetic fields with intensity, H=60 to 100 kAlm and high inhomogeneity. In such cases, due to strong magnetic interaction of magnetic mineral grains between themselves and with magnetic field the tloccules of magnetic mineral grains are formed on the surface of the separator's drum which also contains non-magnetic mineral grains and their aggregates with magnetic minerals in it. As a result reduction of the intensity of magnetic field up to 36-40 kAlm in drum separators the improvement of concentrate grade occurs, accompanied by larger losses of Fe with non-magnetic product in which Fe is combined not only with magnetite aggregates but with fine grade magnetite also. This is caused by the fact that on reducing the size by <50 mk, the magnetic susceptibility of magnetite particles sharply decreases and becomes comparable or less than that of aggregates of magnetite and rockforming minerals. That is why beneficiation of iron ore follows complex route of crushing, grinding, classification, magnetic separation, flotation and slime treatment. However the investments for improvement of the flowsheet for low grade, fine phenocrystal ore having complex mineral composition is not cost efficient. The increase in fmer grinding not only sometimes makes the separation more expensive and metal losses' higher but also complicates the production of high-grade concentrate as a result of strong magnetic and adhesion interaction of fine particles. Magnetite concentrates are polydisperse products in which free particles of magnetite have a wide size range and aggregation of magnetite with rockforming minerals occur, mainly, in coarse fraction (Tab"le I). The particles of magnetite concentrate, although having similar magnetic properties, still differ in their density and mass. Taking into account the dispersity, mineral composition and physical properties of magnetite particles, the improvement of magnetite concentrate grade should be based on a ,process providing for selective classification of the most grainy fraction, composed of the aggregates of magnetite with rock-forming minerals. Experimental Procedure Based on the studies of physical and mechanical properties of ferro-suspensions in magnetic fields, a new magnetic-gravity method for separation has been suggested providing for high selectivity of separation of mineral complexes according to their magnetic properties, density and size'". Similar :principle of separation is presented by Shattacharyya and Sali3. The essence of magnetic-gravity separation (MGS) is that, by applying electromagnetic field having the intensity H=4 to 16 kAlm and inhomogeneity gradient up to 4 kAlm2 per meter of suspension, in required hydrodynamic regime, the ferromagnetic particles, as a result of the effect of magnetic and gravity forces, pass into the lower 131 USACHYOV & KORYTNY: MAGNETIC-GRAVITY SEPARATION OF IRON ORE Table l-Composition Size class, mk of magnetite concentrates of the Kostomuksha combinat Output,% Fe +50 -50 Total 38.5 61.5 100.0 37.6 65.9 55.0 +50 -50 Total 8.2 91.8 100.0 41.8 68.9 67.6 Si02 Content,% summary magnet. non-ore II stage separation concentrate 1.8 42.2 13.9 4.7 7.6 66.4 3.6 20.9 58.5 III stage separation concentrate 37.8 3.1 5.6 Fig. I-Maximum speed of ascending water flow (V) excluding the removal. from ferromagnetic suspension of magnetite particles of different grade sizes (d): curve 1without magnetic field; curve 2 - with magnetic field with 4 kAlm intensity. 70 34.4 95.4 90.4 0.2 0.6 0.5 Fig.2-Influenceof magnetic field intensity (H) upon the efficiency (E) of MG-separation of magnetite concentrates of curve 1 - 56% grade class -45 mk; curve 2 - 92% grade class 45 mk.. suspension flow, thus, creating a concentrated mobile layer. The aggregates formed by ferromagnetic particles in the layer are easily destroyed by the hydrodynamic force. Non-magnetic particles and their aggregates with magnetite are taken away with water flow into the upper part of suspension and removed as tailings. A specific feature of the method is that the separation is done within the whole Degree of magnetite liberation,% 84.3 8.9 37.9 28.0 95.7 78.4 65.4 4.0 9.0 59.9 99.0 97.0 volume of suspension concentrated by magnetic field at constantly renewed layer of ferromagnetice particles from the initial suspension. The time of separation can be controlled within a wide range by changing the volume of concentrated ferromagnetic layer. Due to magnetic particles made "heavier" by the application of electromagnetic field it is possible to strongly increase the speed of the ascending water flow up to (1-2).10-2 mis, which enables to remove coarse non-magnetic particles into tailings along with aggregates consisting of ferromagnetic and non-magnetic minerals (Fig. 1). The selectivity of separation of mineral complexes according to their magnetic properties and density is provided by regulating the intensity of magnetic field and speed of outcoming water flow meeting the following ratio of the applied forces, For magnetite particles: Fm<Fg; Fm+F.,i>Ff For magnetite aggregates with non-magnetic particles, Fm<Fg; Fm+Fg<Ff For non-magnetic particles: Ff>Fg, where Fm is magnetic force applied on the particle, Fg is gravity force of the particles, and Ff is the force of ascending water flow. The values and ratio of F m and Ff depend upon size and output of feeding product and the requirements for the grade of the final concentrate. To provide for maximal efficiency of MGseparation while reducing the size of initial feed, the intensity of magnetic field should be increased (Fig. 2). For practical realization of the flowsheet some alternative designs of impeller and non-impeller MGS have been developed'<. A modified design of non-impeller MGS (Fig.J) includes a cylindrical case (1) made of non-magnetic material, magnetic system (2), surrounding the case, charge (3) and discharge (4) devices, sewing chute (5), a device for ~L---~--~5~--~6----7~--~' H,I(A/m magnetite aggregates / \ 132 INDIAN 1. ENG. MATER wash water supply (6) with tangentially installed sleeves (7), ferromagnetic layer level gauge (8), block (9) for control over automated system for concentrate discharge, electromagnetic shutter (10), cone breaking device (11) installed coaxial under the charging device on the same level with the gauge (8). Magnetic-gravity apparatus operates as follows--the initial feed as suspension enters the case (1) through the charge device (3). Under the effect of magnetic field produced by. the magnetic system (2) a ferromagnetic layer is formed with clear upper border. The ascending water flow washes the layer and rotates it by supplying water through tangentially mounted sleeves (7). As a result of magnetic interaction between themselves and the applied magnetic field, the magnetic particles are concentrated in the lower part of the case (I) and are removed from the separator through the device (4). Non-magnetic particles and aggregates not or slightly affected by ferromagnetic layer gravity are carried away from the case by the ascending water flow combined with the feed water into sewing chute (5) and removed as sewage. The automated system for discharge of magnetic product operates as follows--the gauge (8) generates alternative voltage, the value of which is proportional to the relative position of the gauge and the upper border of the layer. Block (9) transforms this signal into direct voltage which is supplied to electromagnetic solenoid valve (10). At feeding the material to the device there is no signal from the gauge until the level of ferromagnetic lay~r reach~s the gauge.' Direct voltage on the solenoid has Its maximal value with the material not being discha:ged. With the level of ferromagnetic layer increasing voltage of the gauge starts to generate decreasing direct voltage supplied to the solenoid of operating mechanism. The capacity of the .sleeve gradually increases until it gets balanced With the amount of entering feed, while the level of ferromagnetic layer is stabilized", MGS-l.5 rn has the following characteristics: Capacity, t/h . 15-20 Consumption: electric energy, kW/h 3 water, m' concentrate 3-5 up to IJ.2 Size of material separated, mm 2.0 - 2.5 Dimensions, m Weight, kg 1500 sci, JUNE 1998 FEED tI ICONCENTRATE Fig. 3-Design of electromagnetic separator Results and Discussion During the technological research and commercial testing of magnetite concentrates from AJS Karelsky Okatysh, Olkon Lebedinsky GOK (Russia), and AJS Sydvaranger (Norway) it was revealed that MG-separation provides for high selectivity of separation by removing into tailings the main part of coarse grain fraction containing magnetite aggregates and non-magnetic particles with 40-60% magnetite content. This effect can be observed for concentrates of different size grade (Tables 2-4). Tailings obtained at MG-separation after thickening are reasonable to be reground and subjected to further separation in a separate cycle. Significant improvements in grade of magnetite concentrate by MG-separation at other iron ore complexes are reported earlier='. MG-separation enables to reduce silica, phosphorus and sometimes sulfur content in iron concentrates---e.g., MGseparation enables to reduce P2~ content in Kovdor magnetite concentrate from 0.15 to 0.09%. MGseparation during desliming provides for acceleration of ascending water flow 2-3 times as compared with desliming agents, which enables !o have more efficient removal of coarse gram aggregate fraction into sewage. Taking into account mineral composition and physical characteristics of magnetite concentrates USACHYOV & KORYTNY: MAGNETIC-GRAVITY SEPARATION Lebedinsky GOK Table 2---Parameters ofMG-separation of magnetite concentrates in AlS Output,% Product Content,% Fe sio, Recovery,% Fe sto, 133 OF IRON ORE -50 mk grade class Content"/o Recovery'Y. Class Fe Class Fe +50 mk grade class Content"10 Recovery% Class Fe Class Fe Density of sewage, kg/m" III Stage separation concentrate 8.2 91.8 100.0 Non-magnetic product Concentrate Feed 23.5 69.7 66.0 56.7 2.9 62.4 3.1 97.1 37.6 7.5 100.0 100.0 45.2 14.5 17.0 11.0 21.8 63.5 78.2 52.1 100.0 0.6 12.8 13.4 54.8 85.5 83.0 33.8 5.4 70.8 94.6 68.8 100.0 2.3 84.3 86.5 3200 0.3 2.1 2.4 66.7 97.3 95.6 47.2 3.9 70.7 96.1 69.8 100.0 2.5 95.1 97.6 3500 V Stage separation concentrate 5.4 94.6 100.0 Non-magnetic product Concentrate Feed 35.0 70.3 68.4 43.6 2.8 53.8 2.1 97.2 46.2 4.3 100.0 100.0 Table 3-MG-separation Product,% Output, % 33.3 2.7 4.4 13.2 40.8 56.7 59.2 38.9 100.0 from NS Karelsky Okatysh of concentrates Content, % --45mk Fe grade class Si02 Recovery, % grade class, mk Fe --45 +45 MG-separation H, , Wm Y, cmls Concentrate of III separation stage Non-magnetic product Concentrate Feed 3.6 40.7 20.1 62.9 1.6 27.3 1.1 33.3 96.4 100.0 94.1 92.2 68.5 66.8 4.7 6.8 98.4 100.0 72.7 100.0 98.9 100.0 66.4 6.5 1.9 4.5 2.4 Concentrate of II separation stage 21.8 17.6 22.3 61.9 6.9 40.8 8.3 78.5 78.2 100.0 66.7 56.0 68.2 58.3 4.8 17.2 93.1 100.0 59.2 100.0 91.7 100.0 21.5 100.0 Non-magnetic productConcentrate Feed Table 4--MG-separation Product of magnetite concentrates from NS Olkon Output, % Content, % -71 grade mk class Recovery,% grade class, mk -71 +71 Fe Fe Concentrate of 8-12 Sections Non-magnetic Concentrate Feed product 5.2 94.8 100.0 65.5 80.6 79.8 22.6 67.7 65.4 4.3 1.8 60.5 4.7 7.6 95.7 100.0 8.9 91.1 100.0 98.2 100.0 41.5 58.5 100.0 58.7 2.4 6.5 4.6 95.4 100.0 9.6 90.4 100.0 3.1 96.9 100.0 65.5 34.5 100.0 Combined Concentrate Non-magnetic Concentrate Feed product 7.2 92.8 100.0 30.5 59.7 47.8 (Table 1), the capability of MG-separation to separate mineral complexes under their magnetic properties and density (Tables 2-4) a new principle for design of flowsheets for processing of magnetite .ore has been developed providing for production of open ore phase as ready iron concentrate and processing of aggregate fraction in a separate cycle. The kernel of the technology is as follows-feed rough magnetite concentrate with over 55-60% Fe content goes to classification by means of screening, e.g., on vibration screens, thus obtaining coarse- 28.6 70.0 66.9 grain and fine-grain products. Redistribution of free ore minerals and aggregates occurs proportional to their content in grade classes of feed concentrate. Selection of grade class at classification i~according to the level of ore mineral liberation in the feed concentrate and requirements for the grade of final concentrate. Fine grain product of classification is MG-separated with obtaining final concentrate and product (sewage), presented mainly by magnetite aggregates. Coarse grain product of classification is MG-separated in a separate cycle with removing -134 INDIAN 1. ENG. MATER. grain fraction (sewage) into tails. Magnetic product obtained with thickened sewage of MG-separation fine-grain product is reground, dressed in drum magnetic separators and MG-separated with final concentrate and dump tails produced. Derrick screen with polyurethane grid can be used for classification of rough magnetite concentrate providing for over 80% efficiency of beneficiation for 100 mk class. These screens are used at some iron processing plants in the U.S. and Norway. In Figs 4 and 5 the principal flowsheets for regrinding of rough magnetite concentrates at Lebedinsky GOK and Karelsky Okatysh are shown. Pre-classification of 70(100) mk class by fine screening with the following MG-separation of classification products of magnetite concentrate of the first stage in Lebedinsky GOK enable to produce final concentrate (over 40% of I stage concentrate) and 14.8% tails of over 70(100) mk. Regrinding is about only 40% of the feed concentrate (Fig. 3). By eliminating the third stage of dressing and obtaining coarse grain tails (45-50% of -50 mk class) under the suggested flowsheet 20-30% reduction of energy consumption is possible as compared with the operating one [II]. From the V separation stage concentrate, MG-separation enables to get high grade iron concentrate (about 70% of Fe and not more than 3% of silica for electrometallurgical production of steel (Table 2). Similar technological and engineering solutions for regrinding of concentrate of the second concentration stage in A/S Karelsky Okatysh, provide for production of concentrate with 70% Fe of 92% -50 mk grade and coarse grain tails (62% 50 mk grade). Less than 40% is sent to regrinding from the second stage of concentration. Thus, without extra costs for regrinding it is possible to increase Fe content in Karelsky Okatysh from 67.5/70% (Fig. 5). MG-separators enable to establish commercial production of superconcentrates (72% Fe, 0.2-0.3% silica) in A/S Olkon (Russia) and A/S Sydvaranger (Norway). At Olkon, MG-separators are used also for combined thickening up to 65% of solid hematite-magnetite concentrate at simultaneous 0.30.5% improvement of concentrate Fe grade. sci, JUNE 1998 '·1-- lOO.OJi,i 100.0 ~A1lON "·~·<l· AItA1lON 1lON ••.r-l'.Z•7 -r"~ 59.6 00.< 6.7-& ".8~ '7.Z ,.~9.0 55.' <., ".8~ "'.2 Z5.Z~ 5.8 c- T•••• Fig. 4--Flowsheet of processing I concentration stage magnetite concentrate with MG-separation being used at A/S Lebedinsky GOK. 9.I1~:: 'S.9~:~. Con<en_ T•••• 25. ~.£a262 5.1 ?4.37C•3-':,::'Cj2 _(%)" l~E-~" "'.9 , .••••• F. ,-auIpIl;~, ~""""y; P... ~.••.••• Fe, 1i1ica_·50 ••••• tI_ ••.• ·Fe~ Fig. 5--Flowsheet of processing II concentration stage magnetite concentrate with MG-separation being used at A/S Karelsky Okatysh. content, intensify the process of beneficiation of Magnetic-gravity method and separators with low fines and slimes of magnetite-containing ores and intensity of magnetic field enable to produce high desliming and thickening of ferromagnetic grade iron concentrates with minimal impurities suspensions. MG-separators used at production of Conclusion USACHYOV & KORYTNY: MAGNETIC-GRAVITY materials for blast furnace and electrometallurgical production of metal do not require regrinding of 2 rough concentrates, provide for 1.5-2.0 times reduction of magnetic separation operations and for 3 20-30% less energy consumption. References 1 Usachyov P A, Magnetic rheology of mineral separation in SEPARATION OF IRON ORE l35 suspensions (Nauka, Leningrad), 1983. Usachyov P A & Opalev A S, Magnetic-gravity mineral processing (Kola Science Centre RAS, Apatity), 1993. D N & Sali V T, Indian J Technol, Vol 23 Shattacharyya (1985) 21. 4 Usachyov P A, Opalev A S & Pershukov 1540088 (Mining Institute KSC RAS),1987. 5 Usachyov P A, Gorn Zh, N 12, (1993), 22. / \ A A, Rus Pal