Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

Intake Manifold Study & Design

We are not the first racers to coax and push a 16v 928 engine to its limits – there are those before us

that have applied all the tried-and-true methods of head porting, camshaft work, euro throttle bodies,

headers, exhaust upgrades and the like – and the 16v 928 engine responds to these improvements as

you would expect it to – up to a point.

It has some limiting factor that sets the HP ceiling for this engine. That ceiling is about 420 HP NA

and 450-460 HP under boost. You can throw all kinds of things at it one you reach this ceiling but it

doesn’t matter – it does not improve anymore, or if it does, the HP improvements are no longer in relationship to the modification as they should be… they are smaller.

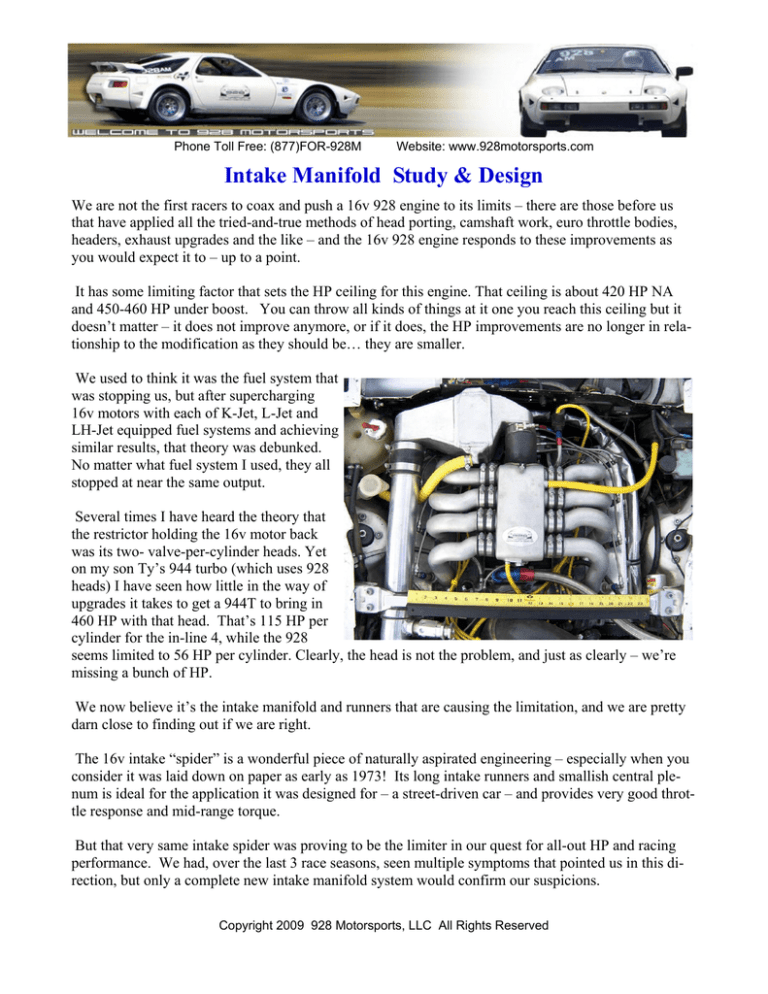

We used to think it was the fuel system that

was stopping us, but after supercharging

16v motors with each of K-Jet, L-Jet and

LH-Jet equipped fuel systems and achieving

similar results, that theory was debunked.

No matter what fuel system I used, they all

stopped at near the same output.

Several times I have heard the theory that

the restrictor holding the 16v motor back

was its two- valve-per-cylinder heads. Yet

on my son Ty’s 944 turbo (which uses 928

heads) I have seen how little in the way of

upgrades it takes to get a 944T to bring in

460 HP with that head. That’s 115 HP per

cylinder for the in-line 4, while the 928

seems limited to 56 HP per cylinder. Clearly, the head is not the problem, and just as clearly – we’re

missing a bunch of HP.

We now believe it’s the intake manifold and runners that are causing the limitation, and we are pretty

darn close to finding out if we are right.

The 16v intake “spider” is a wonderful piece of naturally aspirated engineering – especially when you

consider it was laid down on paper as early as 1973! Its long intake runners and smallish central plenum is ideal for the application it was designed for – a street-driven car – and provides very good throttle response and mid-range torque.

But that very same intake spider was proving to be the limiter in our quest for all-out HP and racing

performance. We had, over the last 3 race seasons, seen multiple symptoms that pointed us in this direction, but only a complete new intake manifold system would confirm our suspicions.

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

Making a completely new manifold from scratch (and doing it well) was going to be a task. I really

wanted something more than my theories and suspicions alone to go on before I diverted this much

time and materials to the project.

The task of computer modeling the fluid characteristics of the 16v manifold went to my son Taylor “Ty”

Fausett. He had designed the 1st-place winning manifold for the 2006 Formula SAE engine, and had

graduated with a BSME with an emphasis on fluid

dynamics. This was right up his ally.

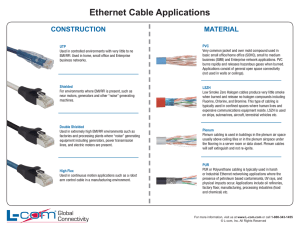

Here are some of the fluid modeling iterations that

his computer modeling bore out for us. You may note

that the intake runner is the same for each of the 8

legs of the intake in this study. The large radius bends

in the other runner made them no different than this

one to our purposes, so we used the same leg for all 8

runners in the computer to save time and effort. It wouldn’t change the study of the distribution from

the central plenum to have simulated the legs individually.

Note the colored legend on the left – where blue indicates the areas of lowest velocity and red indicates the areas of highest velocity. Remember too that low velocity areas equate to higher air density in

those areas, and higher velocities indicate areas of lower air density.

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

The outcome surprised me – from a casual look you would expect the distribution of air into the engine

from this manifold system to be pretty even and consistent. But it was not. And the results from Ty’s

computer modeling also showed us why the rear cylinders were first to encounter detonation under

high boost.

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

Some equations helped us find out what the optimum runner length, plenum size, and throttle

body diameter would be – and then we built to those specifications. As I am not writing an

engineering essay here, I’ll leave those equations out of this article. But they are available in

a number of fine books and publications if you need them.

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

Our Design Objectives

Central plenum: increase from 2.86 liters for the

OEM 928 16v plenum to about 6.5 liters. Cautions include: too small a plenum limits WOT HP

and Torque output, too large can cause poor throttle response and supercharger surge at corners

when the lifting.

Intake runners, length: the original runners were 18.5” long and tuned to come in at 5200 rpm. And

they do – the 16v 928 produces peak torque right about there. I would design our new runners in two

different lengths to hit two harmonics. We could have four 12” runners that would peak at 6000 rpm on

the 4th harmonic; and four runners at 14” tuned for 6500 on the 3rd harmonic. The resulting power band

should be wider, and higher in the rpm band than stock.

Intake runners, diameter: runner diameter also needed to be increased slightly. Our heads have an

inlet diameter of 38.86mm, or 1.53”. The “Euro” runners were 1.58 ID and holding us back a little at

the top end, we felt. We would build ours with 1.75” mandrel bent aluminum tube, which yields an

inner diameter of 1.62”, and step it to the heads smoothly.

Throttle body: …and we needed a throttle body between 75 to 80mm for this 5.0 liter motor. Cautions include: too small restricts WOT output, too large can cause a loss of throttle responsiveness and

feel. Fortunately, the throttle body diameter is one place where there is quite a range that will work

well, which makes sourcing one off another motor easy and affordable.

Space envelope: allow for the peripherals in the engine bay (oil separator, filler neck, access to the

throttle body, and especially easy access to the spark plugs (they get inspected often on a race engine).

In addition, I wanted to be able to use one of the 4 air-to-water intercoolers I had designed for my supercharger kits so that I would not have to add the expense of a custom intercooler to this project.

High enough out of the V to allow for a heat shield to be placed under it, and low enough to fit under

the hood when closed.

These design parameters would occupy us for quite a while we explored various layouts

in the engine bay.

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

The most cost-effective way to get the flange to the head and set the correct injector angle was to cut the

feet off a set of US intake runners. One of our goals was to increase our intake runner size to 1.75” OD,

1.62 ID (Up from 1.4” ID in the US runners and 1.58” in the euro runners) and reduce the number of bends

in the runners.

We found a way to use the same mandrel bent tube in each of the 8 runners so we knew there would be no

inconsistency from runner-to-runner. We also decided to run the new runner all the way to the head so we

did not have any seams or stepping turbulence as caused by sudden changes in diameter or flanges. Note in

the photos below how the intake runner remains perfectly smooth right to the gasket.

Here crew chief Ryan Silva is milling out the old intake flange to accept the new runner. The old L-Jet injector bung was also milled out to accept the larger injectors we would be using, and Ryan made 8 new injector bungs from billet to match.

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

The modified flanges were mounted to a dummy engine

we were using for mock-up purposes. Ryan milled them

to nearly a press-fit, tight enough that we had to heat

them with a torch to get the tubing pressed in. That allowed me to rotate them as I pleased to help me establish the shape of the center plenum, but they held that

location fast once they cooled.

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

Where the location of the updraft intake into the center

plenum was biased to the front on the OEM manifold,

this caused the relative starvation of some of the rear

cylinders that we experienced under WOT high-load

situations. This could be avoided by a) centering the

inlet more carefully to all the runners, b) widening it,

and c) radiusing the edges for a smooth flow.

The throttle body and “shoe” we used was scavenged off a 1985 928 32v manifold. This is a 75mm throttle

body at the narrows, just right for us and a near freebie from the salvage yard. We modified the shoe by

removing a number of unneeded taps and lines, and add a v-band clamp at the top that would provide a secure yet serviceable attachment from the inlet to the plenum bottom.

Heights were played with by changing wooden blocks below the shoe, until we had the correct distance

from the runner to the plenum floor.

The inlet shoe was located optimally, the height set, and we tested the throttle body for interference with

any of its mechanisms. The radiusing of the inlet would come a little later.

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

With all the runners pointed optimally at the inlet, the shape of the plenum was becoming easier to see. I

had decided on a box design for the manifold (walls, a lid, and a floor) because it added both manufacturability and gave use greater control of the shapes where the inlets pierced the plenum sides. Curved sidewalls

were considered, but offered no HP advantage, and complicated the shaping and welding a great deal. So

they were dismissed.

The intake runner bell-mouths are an important element and perform two main functions. First, a proper

bell-mouth allows the pressure wave bouncing back from the backside of the intake valve when it closes to

reverse direction and run back towards the valve again – making the “Helmholtz effect” possible and adding

as much as another 10% of charged air to the cylinder if our runner length was calculated so that the pressure wave would reach the intake valve just as it

was opening again. Secondly, and often missed, a

significant amount of the air drawn into the intake

runner comes from the sides and even up to 120

degrees behind the runner. Without a properly

formed and radiused bell-mouth, only the air right

in front of the inlet can get in.

We selected our bell mouths from those at velocity of sound

(www.velocity-of-sound.com) and incorporated them into our

design. Wonderful designs, reaching all the way around to

about 170 degrees of curl.

The bell-mouths were taped to our inlet runners so we could

visualize the final and complete runner and how they interacted with each other and the throttle body inlet.

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

Starting with the plenum floor (which would define the shape of everything else, cardboard was laid atop

the inlet, and then I could draw lines 90 away from each runner on both sides and see where they’d intersect. The goal with that was to try to have the runners pierce the plenum sides at right angles or as close to it

as I could get. The space envelope required clearances for the oil breather and thermostat housing at the

front, and the throttle body at the rear. Access to spark plugs was checked and repeated on every design – so

essential to a racecar. Because we were replacing the distributor with distributerless ignition provided by the

Tec3 GT system, the trouble getting the plenum around it and to cylinder number 5 was made moot.

Once I had a working shape, I’d calculate the volume it would produce and compare it to our plenum volume goals, and then stretch and reshape as needed. In the final iteration, I was able to shorten the runners

another 1” each and increase the plenum to 6.5Liters in volume (not counting the shoe area after the throttle

body).

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

Now the shape of the plenum floor was known (and with it we made a twin for the plenum top). These two

“flats” went to Steve Nietzel, the tinsmith on our team, who folded and rolled it into shape.

Then Tom Jeffords, our new cracker-jack aluminum welder, TIG-welded it together. We also had Tom

weld the runner mounting flanges; the mandrel bent tubes, and the injector bungs together. Three different

alloys, a sand-casting, a tube, and billet piece – now one.

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

While Tom welded, I addressed the plenum floor. An abrupt

corner coming into the plenum from the inlet would cause turbulence and negatively affect equal distribution to all the

cylinders.

Several ideas were put forth, but the winner came from Ryan.

We increased the cross-section of the plenum floor with a plate

(we had to strengthen it anyway) and this allowed us to mill a

nice radius right into the floor of the plenum.

The tool for this job was big-boy 3 HP router that I had previously used to hog out troughs in 2 X 6’s when

making molds for rocker panels. Here is the result:

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

Now the plenum floor is done, the plenum walls are done, and the bell-mouths are attached to the walls.

Note the distance from the back of the bell-mouths to the plenum walls. If they are too close to the plenum

walls, you restrict the amount of air that is available to the runner from the sides and behind the bell-mouth.

There is an equation for this, so you can calculate the point at which you attain an ‘infinite distance” from

the plenum walls – that is, you can make it farther away if you like, but there is no further benefit.

For our runner diameter, planned air density and velocities, the infinite (and therefore optimum) distance

from the bell-mouth fronts to the plenum walls behind them was .0.8 inches.

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

Tom did a beautiful job of welding the top and bottom

plates to the sides. The finished plenum had a plate in

the bottom already, but I worried about the 1/8” aluminum on the top under boost.

A little quick math showed that under 15 psi of boost

on the span of 9”, the plenum roof would have to resist 141 pounds of force, then vacuum, then force –

again and again hundreds of times each race.

With aluminum’s tendency to work-harden and then

crack if it flexes too many times – this plenum lid

would need reinforcement.

A reinforcing girdle was shaped for the roof, and we

had our logo milled into it just for grins.

When this was welded in place, Myles Lowery of our

staff started polishing the finished piece. The polish

helps reflect heat from the intake and also makes it easier to wipe off grease and oil.

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

He did a pretty darn good job of polishing,

don’t you think?

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

More importantly, Myles was also responsible for

the necessary adapters to mount the Throttle Position

Sensor (TPS) to the Porsche throttle body, and because this is a 1985 block, he had to make an adapter

for both the knock sensor and the Hall sensor too.

Here is the TPS mounted and ready-to-go.

We are manufacturing these parts now so installation

of the Electromotive Tec3 GT system will be a plug-in

for the next 928 owners who want to upgrade their

LMB, EZK and wiring harness.

It was finally time to move it from

the dummy/mock-up engine to the

real engine in the car and make all

the hook-ups.

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

Because we were upgrading to the Tec GT distributer-lees ignition, the distributor hole in

the head was blocked off.

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

The direct-fire coil units were installed and custom

ignition wires made.

We also made our own high-flow fuel rails from

aluminum billet.

Copyright 2009 928 Motorsports, LLC All Rights Reserved

Phone Toll Free: (877)FOR-928M

Website: www.928motorsports.com

With the fuel rails in place the intake manifold project is “done”.

The Dyno will show us how we did.

Copyright 2009 928 Motorsports, LLC All Rights Reserved