information section

advertisement

Issued 06-01-07

E.C.S.

INFORMATION SECTION

FUSING

Section WFS00

Page 1 of 1

INDEX

SECTION WFS01: GENERAL DISTRIBUTION FUSING

GENERAL ....................................................................................... Page 1

TYPES OF OVERCURRENT DEVICES .................................... Page 1

DISTRIBUTION LINE PROTECTION .......................................................... Page 1

SECTION WFS02: GENERAL DISTRIBUTION FUSING

FUSE CUTOUTS .......................................................................... Page 1

FUSE LINKS .................................................................................. Page 4

CURRENT LIMITING FUSES ..................................................... Page 5

BAYONET FUSES ........................................................................ Page 10

SECTION WFS03: OVERHEAD TRANSFORMER FUSING

SECTION WFS04: PADMOUNT TRANSFORMER FUSING

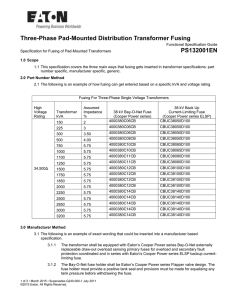

OPERATING VOLTAGE TABLES FOR

PADMOUNT TRANSFORMERS ................................................... Page 1

SECTION WFS05: STEP-TIE TRANSFORMERS

SECTION WFS06: DISTRIBUTION CAPACITORS

SECTION WFS07: RECLOSERS

GENERAL ...................................................................................... Page 1

TYPES OF RECLOSERS ............................................................ Page 1

SEQUENCE AND OPTIONS ......................................................... Page 2

SECTION WFS08: SECTIONALIZERS

GENERAL ...................................................................................... Page 1

TYPES OF SECTIONALIZERS .................................................... Page 1

SECTION WFS09: CIRCUIT BREAKERS AND RELAYS

GENERAL - BREAKERS ............................................................. Page 1

GENERAL - RELAYS .................................................................. Page 1

Issued 06-01-07

E.C.S.

INFORMATION SECTION

FUSING

Section WFS01

Page 1 of 2

GENERAL DISTRIBUTION FUSING

1. GENERAL

The purpose of an overcurrent protective device is to isolate a fault or overloaded piece of

equipment from the electrical delivery system. An overcurrent protective device will not prevent a

fault, only isolate after it has occurred. Equipment that has a capacity rating (e.g. transformers)

should have an appropriately sized overcurrent protective device on the source side of the

equipment to provide overload protection.

2. TYPES OF OVERCURRENT DEVICES

Overcurrent protective devices that are in use on the electrical delivery system are: breakers,

reclosers, sectionalizers, and fuses. Each of the devices has their own operating characteristics and

applications. Some are single-phase devices, while others are three-phase. Some require

replacement parts after operating (fuses), while others just need to be reset (breakers, reclosers).

3. DISTRIBUTION LINE PROTECTION

a. Main Feeder Protection

The main feeder should be protected by a recloser (hydraulic or electronic) or a breaker with

relays in the distribution substation. The main line should be solid to the normal open point or

the end of the main feeder of a radial line if the zone of protection of the substation protective

device reaches to the end of the main feeder. If the substation protective device's zone of

protection does not reach to the end of the main feeder, another protective device should be

installed in the main line at one of the following points:

1) Transition point from urban to rural customer base.

2) Downstream from a large customer.

3) At the end of the substation protective device's zone protection.

The substation protective device can be single or three phase depending on the makeup of the

customers served by the feeder. When sizing the main feeder protective devices, consideration

should be given for backfeeding (if applicable).

b. Protection of Taps off of the Main Feeder

1) Three-Phase Taps

All three-phase taps greater than two spans should have an overcurrent protective device

installed on it to minimize the exposure to the main feeder. This device should be located as

close as possible to the tap point. Installing an overcurrent device on a tap may not be

possible due to load levels (normal and when backfeeding) or miscoordination with

upstream/downstream devices. The type of device used depends on the customer makeup,

amount of line to be protected, load (normal and backfeeding) and upstream/downstream

protective devices.

2) Single-Phase Taps

All single-phase taps greater than two spans should have an overcurrent device installed as

close as possible to the tap point. The type of device used depends on the customer

makeup, amount of line protected, load and upstream/downstream protective devices.

Section WFS01

Page 2 of 2

E.C.S.

INFORMATION SECTION

GENERAL DISTRIBUTION FUSING

Issued 06-01-07

FUSING

c. Protection of Taps Off of Taps

Engineering judgment needs to be used when determining whether or not to install overcurrent

protective devices on taps off of taps. Some items to consider when determining whether or not

to install a device are:

Outage exposure to customers.

Troubleshooting.

Providing locations to sectionalize.

Coordination with upstream/downstream devices.

Cost of the device.

Single-phase taps off three-phase taps that serve three-phase customers should have an

overcurrent device installed on the single-phase tap as close as possible to the tap point. This is

done to reduce the possibility of single phasing the three-phase customers.

d. Riser (Dip) Pole Fusing

1) Main Feeder

Overcurrent protection where the main feeder transitions from overhead to underground is

not required. It is recommended to install switches at the riser pole(s) that are compatible

for use with a loadbuster tool. This allows the underground section to be isolated from the

overhead portion of the main feeder, if so desired.

2) To a Single Transformer

Use the appropriate table to select the riser fuse size.

3) To Multiple Transformers

Use the appropriate table to determine the minimum size fuse that will coordinate with the

largest transformer's bayonet fuse downstream from the riser. When sizing this fuse,

consideration should be given to:

Load current (normal and backfeeding where applicable).

Upstream devices.

Future development.

Size and number of transformers fed from riser.

(END)

Issued 06-01-07

FUSING

E.C.S.

INFORMATION SECTION

Section WFS02

P a g e 1 o f 11

GENERAL DISTRIBUTION FUSING

1. FUSE CUTOUTS

a. General

Most fuse cutouts operate on the expulsion principle. They employ an arc confining tube with a

deionizing fiber liner and a fuse link.

To interrupt fault current, the fiber liner is heated when the fusible element of the fuse link melts,

emitting deionizing gases, which accumulate within the tube.

The arc is stretched, compressed, and cooled within the tube, and escaping gas at the tube

ends carry away a portion of arc-sustaining particles. Reestablishment of the fault current arc

after current passes through the zero point is prevented by the presence of the deionizing gases

and by extreme gas pressure and turbulence which increase the dielectric strength of the air

gap in the tube. High pressure gases then expel arc-supporting ions remaining in the tube.

b. Types

Enclosed, open, and open-link cutouts differ in their external appearance (See Figure 02-1 Fuse

Cutouts) and method of operation. Enclosed cutouts have terminals, fuse clips and fuseholders

mounted completely within an insulating enclosure. Open cutouts have these parts completely

exposed as the name indicates. Open-link cutouts have no integral fuseholder; the arc confining

tube for these cutouts is incorporated in the fuse link.

Source: Alliant Electrical Standards

Figure 02-1 Fuse Cutouts

E.C.S.

INFORMATION SECTION

Section WFS02

Page 2 of 11

Issued 06-01-07

GENERAL DISTRIBUTION FUSING

FUSING

c. Cutout Ratings

VOLTAGE

RATING

MAXIMUM

OPERATING

VOLTAGE

BIL

CONTINUOUS

CURRENT

15 kV

15 kV

95 kV

100A

10,000A

106667

15 kV

15 kV

95 kV

200A

12,000A

151129

15 kV

15 kV

95 kV

300A

12,000A

123342

15 kV

15 kV

95 kV

100A

16,000 A

102012

INTERRUPTING

CAPACITY*

ITEM ID

15 kV

15 kV

95 kV

100A

10,000A

121719**

15 kV

15 kV

95 kV

200A

22,400A

120790***

27 kV

24.9 kV

125 kV

100A

12,000A

120312

27 kV

24.9 kV

125 kV

200A

10,000A

121375

27 kV

24.9 kV

125 kV

300A

12,000A

104947

27 kV

24.9 kV

125 kV

100A

12,000A

120247**

* Asymmetrical Current Rating- Depending on the X/R Ratio the Symmetrical Rating for the 10,000 A. could be

as low as 7,100 A, 12,000 A could be as low as 8,000 A, 16,000 A could be as low as 10,600 A.

** Arc chute cutout for fixed capacitor banks.

*** This unit is for SMU-20 fuses.

Source: Alliant Electrical Standards

Chart 02-1 Cutout Ratings

d. Replacement Parts

ITEM

VOLTAGE

RATING

CURRENT

RATING

INTERRUPTING

RATING

ITEM ID

Fuseholder

15 kV

100A

10,000A

106793

Fuseholder

15 kV

200A

12,000A

Fuseholder

15 kV

100A

104799

--

Switchblade

15 kV

300A

16,000A

--

Fuseholder

27 kV

100A

12,000A

107487

Fuseholder

27 kV

27 kV

200A

10,000A

--

104799

Switchblade

300A

122582

102209

Source: Alliant Electrical Standards

Chart 02-2 Replacement Parts

Issued 06-01-07

E.C.S.

INFORMATION SECTION

FUSING

Section WFS02

P a g e 3 o f 11

GENERAL DISTRIBUTION FUSING

e. Current Rating Applications

The American National Standard Institute's (ANSI) C37.42-3.2.1 states:

1) "For all cutouts except as noted in 2), fuse link sizes shall be from one Ampere to the

rated continuous current of the cutout.

2) For cutouts rated above 100 Amperes, fuse link sizes shall be from above 100 Amperes

to the rated current of the cutout."

Even though a fuse link may fit, cutout fuseholders are designed for a specific fuse range.

Thus, the fuse range for a 100 Ampere cutout runs up to and includes the 100 Amp fuselink.

The fuse range for a 200 Ampere cutout is from 125 Amp up to and including the 200 Amp

fuselink. Misapplication may result in a cutout that will not operate properly.

DO NOT FUSE A 200 AMPERE CUTOUT WITH LESS THAN A 125 AMP FUSE LINK

NOR A 100 AMPERE CUTOUT WITH MORE THAN A 100 AMP FUSE LINK.

f.

Cutout Installation Guidelines

1) Don't mount a cutout in a vault or other enclosed area. The cutout operates by expelling

gases during interrution. Limiting the gas flow can result in insulator flashover.

2) Don't mount cutouts directly above transformers, capacitors, etc. Expelled gases and debris

can cause flashovers. This will also minimize any safety hazard to the operator in case of

equipment failure while opening or closing the cutout.

3) Always cut off any excess tail of the fuse link. Never stick excess fuse link cable (tail) into

the fuse tube or allow it to hang free where it could get in the way of the fuseholder swinging

open or cause a flashover.

4) Don't pull too hard on the pigtail of the fuse link. According to ANSI specifications, fuse links

are designed to withstand up to ten pounds of tension. Pulling in excess of ten pounds can

damage the fuse element, especially on small fuse links.

5) Do not remove or damage the small tube on the fuse link. This tube is not packaging. Low

fault currents which do not clear in the fuseholder tube of the cutout, are cleared in this

auxiliary fuse tube.

g. Fuse Link Installation

There have been some problems with fuse links pulling apart. This may be caused by not

pulling the tension setting mechanism (flipper) all the way back when installing a fuse in the

holder. If the tensioning device is not pulled all the way back, it will exert extra tension on the

fuse link when the holder is slammed in the cutout.

h. Cutouts in Open Position

Cutout doors (fuse holders)should not be left in the open position. Moisture can build up in the

fuse holder causing freezing and thawing action which can result in premature failure upon reenergization. Water in the fuse holder can also make the liner swell and trap the fuse link. In this

condition, the fuse holder may not drop open when subjected to fault current. When a cutout

must be disconnected from the line, hang the door on the pole by the hotstick ring with a nail so

the fuse tube or switch blade is in the upright position.

Section WFS02

Page 4 of 11

E.C.S.

INFORMATION SECTION

GENERAL DISTRIBUTION FUSING

i.

Issued 06-01-07

FUSING

Cutout Fuse Tubes With Exposed Fiberglass

Fuse tube paint coatings are expected to last approximately 20-25 years under normal

conditions (there may be a reduction in the useful life in areas of high chemical contamination).

However, the paint coating on cutout fuse tubes can become weathered to the point of exposing

the fiberglass. The exposed fiberglass presents a potential safety hazard to line personnel

during refusing of these cutouts. These same fuse tubes are also susceptible to the entrance of

moisture which can affect the electrical operation of the cutout. For these reasons, all cutout

fuse tubes with exposed fiberglass should be replaced.

j.

Cracking of Cutout Porcelain

Cutout porcelain bodies can break allowing the cutout door to fall free. Cutout porcelain bodies

were changed from brown to gray in about 1965. For these reasons, brown cutouts, whether in

inventory or in service, should be replaced and/or junked. Also, extreme care should be

maintained when handling and working around gray porcelain cutouts. To minimize the

possibility of damage, keep cutouts in the shipment box until they are to be installed at the job

site. Avoid accidental banging of the porcelain body during handling and installation. Inspect

new and existing cutouts for cracks. If cracks are seen in gray porcelain cutouts, they also

should be replaced.

2. FUSE LINKS

a. General

A distribution fuse link consists of three basic

parts - button, fusible element, and leader as

shown in Figure 02-2 Fuse Link. Various types

of links are available, designed under NEMA

specifications, to fit the several types of cutouts

mentioned previously.

A link with an element of given material, length,

and cross section is rated to carry a specific load

current and melt in a definite time when

subjected to a specific fault current.

When placed in a cutout and connected into a

distribution line, a fuse link is ready to function

as a protective device. When a fault occurs, the

fusible element is melted by the fault current.

Simultaneously, because of its high resistance,

the strain wire is heated and separates. At this

instant, an arc establishes itself across the

severed link. The arc is a conducting path of

ionized particles, among which are metallic ions

of the melted element and wire and ionized gas.

Because the arc provides a path for fault current

to flow, it must be extinguished rapidly in order

to prevent damage to the system and equipment.

Issued 06-01-07

E.C.S.

INFORMATION SECTION

FUSING

Section WFS02

P a g e 5 o f 11

GENERAL DISTRIBUTION FUSING

As shown in Figure 02-3 Expulsion Fuse Fault Interruption, the expulsion fuse is capable of

interrupting higher currents, but does not limit the current before the circuit is interrupted.

SOURCE: Alliant Electrical Standards

Figure 02-3 Expulsion Fuse Fault Interruption

b. Fuse Link Loading

Fuse links should not be loaded continuously above 100% of their current rating. Fuse links may

be overloaded for short, infrequent periods of time up to 140% of their rated current. Loading

fuse links beyond 100% of their current rating for long, frequent lengths of time can change their

time - current characteristics resulting in coordination problems, or may partially melt the fuse

link resulting in the malfunctioning of the fuse link and cutout during a fault.

c. Fuse Link Failures

A fuse link installed in a cutout with a loose buttonhead can cause overheating and result in

premature failure. Fuse link buttonheads are supposed to be properly installed at the factory,

however, they may become loose during handling and transportation. Therefore, be sure all

buttonheads are correctly secured (screwed all the way down - tight) before installing fuse links

in cutouts.

3. CURRENT LIMITING FUSES

a. General

Current limiting fuses have many features which make them ideally suitable as protective

devices. They primarily limit the fault current to a fraction of its damage potential within the first

one-half cycle of fault current (see Figure 02-4 Current Limiting Fuse Fault Interruption). They

do not expel any gases and are completely silent during operation. These characteristics are

particularly useful for protective devices in constricted areas such as indoor and underground

applications. By limiting the fault current, they greatly reduce the mechanical and thermal stress

imposed on system components.

Section WFS02

Page 6 of 11

E.C.S.

INFORMATION SECTION

Issued 06-01-07

GENERAL DISTRIBUTION FUSING

FUSING

Source: Alliant Electrical Standards

Figure 02-4 Current Limiting Fuse Fault Interruption

Issued 06-01-07

E.C.S.

INFORMATION SECTION

FUSING

Section WFS02

P a g e 7 o f 11

GENERAL DISTRIBUTION FUSING

The fusible element consists of one or more silver elements spirally wound and surrounded by a

high-purity silica sand and enclosed in a high-temperature resistant material tube.

Source: WP&L Electrical Standards

Figure 02-5 Current Limiting Fuse Element

When exposed to a high-current fault, the element melts almost instantaneously over its full

length. The resulting arc loses its heat energy rapidly into the surrounding sand. This energy

melts the sand to a glass-like substance. The rapid loss of heat energy and arc confinement by

the molten glass literally chokes off the current to a relatively small value known as the letthrough current.

b. Partial Range Current Limiting Fuses

1) General

The partial range current limiting (PRCL) fuse is similar to the full range current limiting

(FRCL) fuse in that it will limit high energy fault current to a fraction of its potential within the

first one-half cycle of fault current (see section on current limiting fuses).

However, the PRCL will not clear the low level faults and transformer overloads that the

FRCL fuse will. For this reason, it is used in series with a bayonet expulsion fuse in

padmount transformers and with an expulsion fuse on overhead transformers and capacitor

banks.

The PRCL fuse performs its function in a manner similar to the FRCL fuse does. In

padmount transformers, the PRCL fuse is permanently installed under oil. It operates only

on high energy faults due to transformer failure. Therefore, a padmount transformer with a

blown PRCL fuse must be changed out.

Where the current limiting fuse is mounted on the load side of the cutout, the manufacturers

recommend that the current limiting fuse be mounted well out of the expulsion-fuse venting

area of the cutout. Also, one foot of clearance must be maintained between the fuse and:

a) other phase conductors

b) grounded leads

c) primary conductor of the same phase

Section WFS02

Page 8 of 11

E.C.S.

INFORMATION SECTION

GENERAL DISTRIBUTION FUSING

Issued 06-01-07

FUSING

These recommendations will help prevent short-circuits from expulsion fuse gases during

cutout operations.

2) Application

Current limiting fuses are used to protect transformers from catastrophic failure during a high

fault current event. The available fault current levels which determine when current limiting

fuses are installed are as follows:

a. For 4kV systems, the threshold fault current is 7,100 amps, phase to ground.

b. For 12.5kV – 13.8kV, the threshold is 6,400 amps, phase to ground.

c. For 24kV and 24.9kV systems, the threshold is 4,500 amps, phase to ground.

There are two different styles of partial range current limiting fuses used at Alliant Energy.

K-Mate fuses are mounted to the bottom terminal of a cutout as shown in figure 2-6. The Kmate current limiting cartridge is provided in a 40 Amp rating and is used to protect the

following overhead transformers:

a. 4kV systems – 37.5 kVA and 50 kVA transformers.

b. 12.5kV, 13.2kV and 13.8kV systems – 100 kVA transformers.

c. 24 kV & 24.9 kV systems – 250 kVA transformers.

Figure 02-6 K-Mate Partial Range Current Limiting Fuse

ELF Tandem mount - The Cooper Power Systems Tandem ELF current-limiting fuse

combines the features of a series fuse link and a backup current-limiting fuse cartridge. The

Tandem ELF unit replaces an S&C, Chance, etc. standard cutout door/assembly as shown

in figure 2-6. The ELF has a 25 Amp current limiting fuse that coordinates with up to a 15T,

25K and 25 standard speed expulsion fuse links. This limits the size of transformer that can

be effectively protected without miss-coordination of overcurrent devices. Tandem ELF

devices are used as follows:

a. 4kV systems – all overhead transformers 25kVA and smaller.

b. 12.5kV, 13.2kV and 13.8kV systems – all overhead transformers 50kVA and smaller.

c. 24kV and 24.9kV systems – all overhead transformers 167kVA and smaller.

Issued 06-01-07

E.C.S.

INFORMATION SECTION

FUSING

Section WFS02

P a g e 9 o f 11

GENERAL DISTRIBUTION FUSING

The Cooper Tandem ELF Current-Limiting Dropout Fuse is a cost effective alternative to the

K-Mate current limiting fuse/fuse cutout combination. This unit combines a current limiting

fuse with a shortened expulsion fuse assembly and is designed to be interchangeable with

standard S&C type XS and Chance type C fuse cutouts doors/fuse tubes. This feature

makes the installation, removal and testing of the ELF units easier and safer than the KMate devices.

Figure 02-7 Tandem Mount Series Expulsion and Current Limiting Fuse Cutout

3)

Alliant Application Philosophy

The pressure generated by an arc in the transformer tank during a fault is a function of the

energy delivered to the fault by the electric delivery system. This energy is dependent

upon the available fault current, the arc resistance (or arc voltage), arc length and the

duration of current flow.

The utility industry has relied upon testing and operating experience to develop thresholds

for the application of current limiting fuses to minimize the risk of a pole-type transformer

tank failure. ANSI standard c57.12.20-1988, Requirements for Overhead-type Distribution

Transformers, 500 kVA and Smaller; High Voltage, 34,500 and Below; Low Voltage

7970/13,8090 Volts and Below specifies design tests to demonstrate the capability of a

transformer enclosure to withstand pressure changes due to specified faults. ANSI

standard C57 requires that transformer enclosures have the capability of withstanding

pressure changes due to an 8,000 amp fault at 7,200 volts for ½ cycle. The total clearing

time for a fuse cutout is 0.8 cycle. For this amount of time, a fault of approximately 6,400

amps will generate approximately the same amount of energy as the ANSI test at 8,000

amps. This fault current level is applicable for 12.5kV through 13.9kV delivery systems.

Based on this energy let-through capability, and assuming the transformer sees fault

current for 0.8 cycles, the fault current thresholds stated above were determined. The 0.8

cycle is more conservative than the ½ cycle standard and is based on the amount of time

a fuse link will take to clear higher current faults.

Limited information is available regarding 2.4kV transformer tank damage and failures due

to internal faults. At lower voltages, it is difficult to sustain a 1-inch arc. Shorter arc

lengths generate less energy. From Alliant Energy experience, very few, if any,

catastrophic transformer failures have occurred on our 2.4/4.16 kV systems. The fault

current interrupting rating of a 10,000-amp cutout is 7,100 amps. Therefore, on

2.4/4.16kV delivery systems at locations where the available fault current may exceed the

interrupting rating of the cutout, a current limiting fuse will be installed.

Section WFS02

P a g e 10 o f 1 1

E.C.S.

INFORMATION SECTION

GENERAL DISTRIBUTION FUSING

Issued 06-01-07

FUSING

At this time, WP&L has very few, if any, 2.4 kV single phase delivery systems. More

2.4/4.16 kV systems exist in IES & IPC service territories. Very few of these systems

have available fault current levels in excess of 7,100 amps.

4)

Failures

Back-up current limiting fuses (used on the overhead distribution system) that have

operated under low fault conditions will not normally withstand voltage for an extended

period of time and can breakdown resulting in the generation of an extreme amount of

heat. These failures are due to pre-conditioning of the PRCL fuse. A "window of exposure"

exists where the protection characteristics of the expulsion fuse and the PRCL fuse

overlap such that at low levels of fault current the expulsion fuse will not totally clear

before the PRCL fuse element begins to melt. This results in partial melting of the PRCL

fuse element.

In some cases, following a low current fault, the element of the PRCL fuse may be

damaged. Therefore, after replacing the expulsion fuse, voltage may not be restored. This

is the result of the PRCL fuse element burning open. The partially melted element of the

PRCL fuse then begins arcing over internally until the fuse burns itself up. Depending on

the extent of the partial melt and amount of load current, this internal arcing and burning

up may take a few days. Customer complaints of blinking lights are an indication of this

process.

Therefore, it is very important to check the continuity of the current limiting fuse before

refusing the fuse link in the cutout. Replace the current limiting fuse if it is found to be

open.

4. BAYONET FUSES

A bayonet fuse is an oil-immersed expulsion-type fuse used in both single-phase and three-phase

deadfront padmount transformers. This bayonet expulsion fuse is a part of the two fuse protection

scheme. This fuse is in series with a nonreplaceable, partial range current limiting (PRCL) fuse

which is placed under oil inside the transformer by the manufacturer. The two fuses are connected

in series between the high-voltage bushing and the transformer coil as shown in Figure 02-8

Bayonet Expulsion Fuse With PRCL Fuse on Page WFS02.11.

Issued 06-01-07

E.C.S.

INFORMATION SECTION

FUSING

Section WFS02

P a g e 11 o f 11

GENERAL DISTRIBUTION FUSING

Source: Alliant Electrical Standards

Figure 02-8 Bayonet Expulsion Fuse With PRCL Fuse

The bayonet expulsion fuse sits in a bayonet fuseholder. The main advantages of the bayonet

fuseholder are that it provides a loadbreak function and is externally removable. This allows positive

visual indication that load has been interrupted and enables the operator to inspect and replace the

fuse element. This fusing scheme also provides cost advantages in that it reduces both transformer

costs and replacement fuse costs.

The fuse characteristics of the bayonet expulsion fuse and PRCL fuse combine to form a

characteristic very similar to the full range drywell fuse. In this protection scheme, the expulsion

fuse is coordinated to clear low level faults and excessive load currents. The PRCL fuse is then

coordinated to clear the high energy faults due to transformer failure.

The bayonet expulsion fuse is a dual element link which is sensitive to both current and oil

temperature. The link is used to sense secondary faults and excessive load currents, but is also

affected by excessive transformer oil temperatures. This feature limits long time transformer heating

due to overloads or elevated temperature environments.

The High Ampere (HA) bayonet fuse has an integral fuse link and should not be disassembled. If

the HA fuse blows, the entire fuse cartridge should be replaced.

(END)

E.C.S.

INFORMATION SECTION

Issued 06-01-07

FUSING

Section WFS03

Page 1 of 6

OVERHEAD TRANSFORMER FUSING

2.4/4.16 KV OPERATING VOLTAGE

Table 03-1 - Overhead Transformer Fusing for 2400 Volt Single-Phase or 4160 Volt Three-Phase

KVA

1

3

5

7.5

10

15

25

37.5

50

75

100

167

250

333

TANK MOUNTED

ARRESTER

(NON-STANDARD)

STANDARD

(SPEED)

LINK

T

(SPEED)

Link

CURRENT

LIMITING

FUSE

SIZE

“CU”

SIZE

“CU”

SIZE

“CU”

SIZE

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

15STD

FUNIVSTSPD15A

25STD

FUNIVSTSPD25A

30STD

FUNIVSTSPD30A

50STD

FUNIVSTSPD50A

65STD

FUNIVSTSPD65A

100STD

FUNIVSTSPD100A

150STD

FUNIVSTSPD150A

2STD

FLB20STD

2STD

FLB20STD

3STD

FLB3STD

5STD

FLB5STD

7STD

2STD

FLB20STD

2STD

FLB20STD

3STD

FLB3STD

10STD

FUNIVSTSPD10A

15STD

FUNIVSTSPD15A

25STD

FUNIVSTSPD25A

30STD

FUNIVSTSPD30A

50STD

FUNIVSTSPD50A

65STD

FUNIVSTSPD65A

100STD

FUNIVSTSPD100A

150STD

FUNIVSTSPD150A

--

--

-6T

FLB6T(W)

10T

FLB10T(W)

15T

FLB15T(W)

25T

FLB25T(W)

30T

FLB30T(W)

50T

FLB50T(W)

65T

FLB65T(W)

100T

FLB100T(W)

140T

FLB140T(W)

200T

FLB200T

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

40 KMATE

40 KMATE

40 KMATE

-----

Current Limiting Fuses should be installed where available fault current exceeds 7100 Amps

E.C.S.

INFORMATION SECTION

Section WFS03

Page 2 of 6

Issued 06-01-07

OVERHEAD TRANSFORMER FUSING

FUSING

7.2 KV, 7.6 KV, 7.9 KV SINGLE-PHASE AND

12.47 KV, 13.2 KV AND 13.8 KV

THREE-PHASE OPERATING VOLTAGE

Table 03-2

Overhead Transformer Fusing for 7200, 7600, and 7900 Volt Single-Phase

and 12470, 13200, and 13800 Volt Three-Phase.

TANK MOUNTED

ARRESTER

(NONSTANDARD)

STANDARD

(SPEED)

LINK

SIZE

“CU”

SIZE

“CU”

SIZE

“CU”

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

15STD

FUNIVSTSPD15A

20STD

FUNIVSTSPD20A

30STD

FUNIVSTSPD30A

50STD

FUNIVSTSPD50A

2STD

FLB20STD

2STD

FLB20STD

2STD

FLB20STD

3STD

FLB3STD

3STD

FLB3STD

5STD

FLB5STD

5STD

FLB5STD

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

15STD

FUNIVSTSPD15A

20STD

FUNIVSTSPD20A

30STD

FUNIVSTSPD30A

50STD

FUNIVSTSPD50A

2STD

FLB20STD

2STD

FLB20STD

2STD

FLB20STD

333

--

--

500

--

--

KVA

1

3

5

7.5

10

15

25

37.5

50

75

100

167

250

T

(SPEED)

Link

-3STD

FLB3STD

5STD

FLB5STD

6T

FLB6T(W)

8T

FLB8T(W)

10T

FLB10T(W)

15T

FLB15T(W)

20T

FLB20T(W)

30T

FLB30T(W)

50T

FLB50T(W)

65T

FLB65T(W)

100T

FLB100T(W)

CURRENT

LIMITING

FUSE

SIZE

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

40 KMATE

40 KMATE

---

Current Limiting Fuses should be installed where available fault current exceeds 6400 Amps.

E.C.S.

INFORMATION SECTION

Issued 06-01-07

FUSING

Section WFS03

Page 3 of 6

OVERHEAD TRANSFORMER FUSING

7 . 2 K V D E L T A T H R E E - PH A S E O P E R A T I N G V O L T A G E

Table 03-3 - Overhead Transformer Fusing for 7200 Volt Delta Three-Phase

KVA/PHASE

1

3

5

7.5

10

15

25

37.5

50

75

100

167

250

NOTE:

TANK MOUNTED

ARRESTER

(NON-STANDARD)

STANDARD

(SPEED)

LINK

SIZE

“CU”

SIZE

“CU”

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

15STD

FUNIVSTSPD15A

20STD

FUNIVSTSPD20A

30STD

FUNIVSTSPD30A

40STD

FUNIVSTSPD40A

65STD

FUNIVSTSPD65A

100STD

FUNIVSTSPD100A

2STD

FLB20STD

2STD

FLB20STD

2STD

FLB20STD

5STD

FLB5STD

5STD

FLB5STD

7STD

10STD

FUNIVSTSPD10A

15STD

FUNIVSTSPD15A

20STD

FUNIVSTSPD20A

30STD

FUNIVSTSPD30A

40STD

FUNIVSTSPD40A

65STD

FUNIVSTSPD65A

100STD

FUNIVSTSPD100A

For open delta banks, fuse each outside leg per single-phase transformer fusing recommendations. The middle leg should be fused for the largest connected transformer.

For closed banks of unequal size, fuse for the largest transformer connected to that leg.

E.C.S.

INFORMATION SECTION

Section WFS03

Page 4 of 6

OVERHEAD TRANSFORMER FUSING

Issued 06-01-07

FUSING

14.4 KV SINGLE-PHASE AND 24.9 KV

THREE-PHASE OPERATING VOLTAGE

Table 03-4 - Overhead Transformer Fusing for 14400 Volts Single-Phase and 24900 Volt ThreePhase

KVA

1

3

5

10

15

25

37.5

50

75

100

167

250

333

500

T

(SPEED)

Link

CURRENT

LIMITING

FUSE

SIZE

“CU”

SIZE

2STD

FLB20STD

2STD

FLB20STD

2STD

FLB20STD

2STD

FLB20STD

2STD

FLB20STD

3STD

FLB3STD

6T

FLB6T(W)

6T

FLB6T(W)

8T

FLB8T(W)

10T

FLB10T(W)

15T

FLB15T(W)

25T

FLB25T(W)

30T

FLB30T(W)

50T

FLB50T(W)

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

TANDEM MOUNT

40 KMATE

--

Current Limiting Fuses should be installed where available fault current exceeds 4500 Amps.

Issued 06-01-07

E.C.S.

INFORMATION SECTION

FUSING

Section WFS03

Page 5 of 6

OVERHEAD TRANSFORMER FUSING

12.5 KV AND 13.8 KV DELTA

SINGLE-PHASE OPERATING VOLTAGE

Table 03-5 - Overhead Transformer Fusing for 12500 Volt and 13800 Volt Delta Single-Phase

TANK MOUNTED

ARRESTER

(NON-STANDARD)

STANDARD

(SPEED)

LINK

T

(SPEED)

Link

SIZE

“CU”

SIZE

“CU”

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

10STD

FUNIVSTSPD10A

15STD

FUNIVSTSPD15A

20STD

FUNIVSTSPD20A

30STD

FUNIVSTSPD30A

2STD

FLB20STD

2STD

FLB20STD

2STD

FLB20STD

SIZE

“CU”

2STD

FLB20STD

2STD

FLB20STD

2STD

FLB20STD

--

--

2STD

FLB20STD

2STD

FLB20STD

3STD

FLB3STD

5STD

FLB5STD

7STD

10STD

FUNIVSTSPD10A

15STD

FUNIVSTSPD15A

20STD

FUNIVSTSPD20A

30STD

FUNIVSTSPD30A

333

--

--

500

--

--

2STD

FLB20STD

2STD

FLB20STD

3STD

FLB3STD

6T

FLB6T(W)

6T

FLB6T(W)

10T

FLB10T(W)

12T

FLB12T(W)

20T

FLB20T(W)

30T

FLB30T(W)

40T

FLB40T(W)

50T

FLB50T(W)

KVA

1

3

5

7.5

10

15

25

37.5

50

75

100

167

250

NOTE:

For open delta banks, fuse each outside leg per single phase transformer fusing

recommendations.

For closed banks of unequal size, fuse for the largest transformer connected to that leg.

E.C.S.

INFORMATION SECTION

Section WFS03

Page 6 of 6

Issued 06-01-07

OVERHEAD TRANSFORMER FUSING

Table 03-6 - Tandem Mount Series Expulsion and Current Limiting Fuse Cutouts

CUTOUT, TANDEM MOUNT, SERIES EXPULSION AND CURRENT LIMITING FUSE

OPERATING

VOLTAGE

CUTOUT

RATING

APPLICATION

CU CODE

4KV

15KV

1 TO 25KVA TRANSFORMER

CO15TECL

104728

15KV

15KV

1 TO 75KVA TRANSFORMER

CO15TECL

104728

15KV

25KV

1 TO 75KVA TRANSFORMER

CO1525TECL

101939

25KV

25KV

1 TO 167KVA TRANSFORMER

CO25TECL

102397

ITEM ID

Includes CL fuse and link holder. Order fuse link separately.

Table 03-7 - Tandem Mount Fuse Holders

HOLDER, TANDEM MOUNT, SERIES EXPULSION AND CURRENT LIMITING FUSE

OPERATING

VOLTAGE

CUTOUT RATING

CU CODE

ITEM ID

4-15KV

15KV

HF15TECL

125001

15KV

25KV

HF1525TECL

125002

25KV

25KV

HF25TECLL

125003

Holders can be installed in existing cutout bodies when CL protection must be added to existing

transformer installations. Fuse link must be ordered separately.

Figure 03-1 Tandem Mount Holder

(END)

FUSING

E.C.S.

INFORMATION SECTION

Issued 06-01-07

FUSING

Section WFS04

Page 1 of 12

PADMOUNT TRANSFORMER FUSING

1. OPERATING VOLTAGE TABLES FOR PADMOUNT TRANSFORMERS

7.2/12.47 kV OPERATING VOLTAGE

Table 04-1 -Padmount Transformer Full-Range Current Limiting Fusing for WP&L Territory

('Drywell' Fuses in Transformers Manufactured Prior to 1986)

TRANSFORMER kVA

FUSE VOLTAGE

FUSE AMPS

ITEM ID

15

8.3 kV

3

123102

25

8.3 kV

6

100022

50

8.3 kV

12

103384

100

8.3 kV

20

120257

167

8.3 kV

30

106844

Single-Phase 240/120 V

Three-Phase 480Y/277 V or 208Y/120 V

75

8.3 kV

6

100022

150

8.3 kV

12

103384

300

8.3 kV

20

120257

500

8.3 kV

30

120956

75

15 kV

6

101471

150

15 kV

12

106254

300

15 kV

20

103193

500

15 kV

30

105132

Three-Phase 240/120 V Delta

E.C.S.

INFORMATION SECTION

Section WFS04

Page 2 of 12

Issued 06-01-07

PADMOUNT TRANSFORMER FUSING

FUSING

2.4/4.16 kV OPERATING VOLTAGE

Table 04-2 -2.4/4.16 kV Padmount Transformer Bayonet-Type Expulsion Fusing

BAY-O-NET FUSING

FUSE SIZE

COOPER NUMBER

15

15DE

4038108C07B

121033

25

25DE

4038108C09B

108431

50

50DE

4038108C12B

101731

100

65HA

4038361C03CB

103191

167

100HA

4038361C04CB

101650

75

25DE

4038108C09B

108431

150

50DE

4038108C12B

101731

300

65HA

4038361C03CB

103191

500

100HA

4038361C04CB

101650

750

125HA

4038361C05CB

102292

kVA

ITEM ID

Single-Phase

Three-Phase

NOTE 1: Fuse Size with "DE" Suffix is a Dual Element Bay-O-Net

NOTE 2: Fuse Size with "HA" Suffix is a High Ampere Overload Bay-O-Net

NOTE 3: "HA" Type Fuses have an Integral Cartridge, and Should Not be Disassembled

Issued 06-01-07

E.C.S.

INFORMATION SECTION

FUSING

Section WFS04

Page 3 of 12

PADMOUNT TRANSFORMER FUSING

7.2/1 2.47 kV, 7.6/1 3.2 kV, 7.9/1 3.8 kV, and

7.2 kV DELTA OPERATING VOLTAGE

Table 04-3 -7.2/12.47 kV; 7.62/13.2 kV 7.96/13.8 kV, 7.2 kV Delta Padmount Transformer Bay-O-Net

Type Expulsion Fusing

BAY-O-NET FUSING

Single-Phase

COOPER

ITEM ID

NUMBER

5DE

4038108C03B

103225

15

6DE

4038108C04B

105712

25

15DE

4038108C07B

121033

50

25DE

4038108C09B

108431

100

50DE

4038108C12B

101731

167

Three-Phase 7.2 kV Delta, 7.2/12.47 kV Delta-Wye Switch on Primary Side

COOPER

ITEM ID

FUSE SIZE

KVA

NUMBER

12DE

4038108C06B

109930

75

25DE

4038108C09B

108431

150

50DE

4038108C12B

101731

300

65HA

4038361C03CB

103191

500

100HA

4308361C04CB

101650

750

125HA

4038361C05CB

102292

1000

125HA

4038361C05CB

102292

1500

Three-Phase 7.2/12.47 kV, 7.6/13.2 kV, 7.9/13.8 kV, 14.4 kV Delta With 4 Taps All Down

6DE

4038108C04B

105712

75

15DE

4038108C07B

121033

150

25DE

4038108C09B

108431

300

50DE

4038108C12B

101731

500

65DE

4038108C14B

109267

750

65HA

4038361C03CB

103191

1000

100HA

403836AC04CB

101650

1500

125HA

403836AC05CB

102292

2000

125HA

403836AC05CB

102292

2500

NOTE 1: Fuse Size with"DE" Suffix is a Dual Element Bay-O-Net

NOTE 2: Fuse Size with "HA" Suffix is a High Ampere Overload Bay-O-Net

NOTE 3: "HA" Type Fuses have an Integral Cartridge, and Should Not be Disassembled

KVA

FUSE SIZE

Section WFS04

Page 4 of 12

E.C.S.

INFORMATION SECTION

Issued 06-01-07

PADMOUNT TRANSFORMER FUSING

FUSING

14.4/24.9 kV OPERATING VOLTAGE

Table 04-4 -14.4/24.9 kV Padmount Transformer Bay-O-Net Type Expulsion Fusing

KVA

BAY-O-NET FUSING

COOPER

FUSE SIZE

NUMBER

ITEM ID

Single-Phase

5DE

4038108C03B

103225

15

5DE

4038108C03B

103225

25

8DE

4038108C05B

107270

50

15DE

4038108C07B

121033

100

25DE

4038108C09B

108431

167

Three-Phase

5DE

4038108C03B

103225

75

8DE

4038108C05B

107270

150

15DE

4038108C07B

121033

300

25DE

4038108C09B

108431

500

40DE

4308108C11B

102453

750

50DE

4038108C12B

101731

1000

65HA

4038361C03B

103191

1500

100HA

4038361C04B

101650

2000

100HA

4038361C04CB

101650

2500

NOTE 1: Fuse Size with"DE" Suffix is a Dual Element Bay-O-Net

NOTE 2: Fuse Size with "HA" Suffix is a High Ampere Overload Bay-O-Net

NOTE 3: "HA" Type Fuses have an Integral Cartridge, and Should Not be Disassembled

Issued 06-01-07

FUSING

E.C.S.

INFORMATION SECTION

Section WFS04

Page 5 of 12

PADMOUNT TRANSFORMER FUSING

GUIDELINES FOR USING FUSE TABLES 04-5, 04-6 AND 04-7

DETERMINE SECTIONALIZING FUSE FOR SINGLE PADMOUNT TRANSFORMER

BACKGROUND

The sectionalizing fuse identified in Table 04-5 - Used to Determine Sectionalizing Fuse Size for

Serving a Single Padmount Transformer on Page WFS04.6 Table 04-6 - Used to Determine

Sectionalizing Fuse Size for Serving a Single Padmount Transformer on Page WFS04.7, and

Table 04-7 - Used to Determine Sectionalizing Fuse Size for Serving a Single Padmount

Transformer on Page WFS04.8and is the recommended minimum size fuse capable of carrying

transformer full-load current, moderate overloads, inrush and cold-load pickup. The fuse sizes were

chosen by following utility industry transformer fusing guidelines.

In general, the size of the sectionalizing fuse in the aforementioned tables was minimized to aid in

coordination with upstream devices. As a result, the sectionalizing fuse does not coordinate with the

transformer internal bayonet or full range current limiting fuse. This miscoordination is not an important

factor since only one transformer is being served by the sectionalizing fuse. If desired, the

sectionalizing fuse size can be increased when serving transformers containing internal bayonet or fullrange current limiting fuse protection. Consult your Distribution Engineer on these applications.

EXAMPLE

Determine the recommended size sectionalizing fuse to serve the padmount transformer shown below:

Figure 04-1 - Sectionalizing Fuse, Single Padmount

a.

Step #1 - Refer to proper fusing chart. Since this example involves a single padmount

transformer on the 7.2/12.47 kV distribution system, use Table 04-6 - Used to Determine

Sectionalizing Fuse Size for Serving a Single Padmount Transformer on Page

WFS04.7. If the distribution system operating voltage had been 14.4/24.9 kV, you would

need to refer to Table 04-7 - Used to Determine Sectionalizing Fuse Size for Serving a

Single Padmount Transformer on Page WFS04.8.

b.

Step #2 - Locate the transformer size and type in the left column of the table.

c.

Step #3 - Follow the row across to the right to determine the recommended size

sectionalizing fuse. For this example in WPL territory, Table 04-6 - Used to Determine

Sectionalizing Fuse Size for Serving a Single Padmount Transformer on Page

WFS04.7 recommends that a 25T riser fuse or 30E SM-4 switchgear fuse be installed.

E.C.S.

INFORMATION SECTION

Section WFS04

Page 6 of 12

Issued 06-01-07

PADMOUNT TRANSFORMER FUSING

FUSING

2.4/4.16 KV OPERATING VOLTAGE SINGLE PADMOUNT

TRANSFORMER FUSING

Table 04-5 - Used to Determine Sectionalizing

Fuse Size for Serving a Single Padmount

Transformer

RISER FUSES

KVA

STANDARD

TCC 123-6

SWITCHGEAR FUSES

ITEM ID #

T SPEED

TCC 170-6

ITEM ID #

SMU-20

TCC 119-2

ITEM ID #

SMU-20

TCC 165-2

ITEM ID #

SINGLE-PHASE

15

10A

121831

8T

105380

10E

106919

10K

101003

25

15A

106996

12T

106362

15E

121728

15K

106528

50

25A

105571

25T

105891

25E

100809

25K

106214

100

50A

107456

50T

108986

50E

108672

50K

109355

167

80A

121942

80T

100063

80E

105834

80K

108663

THREE-PHASE

(2)

75

15A

106996

12T

106362

15E

121728

15K

106528

150

25A

105571

25T

105891

25E

100809

25K

106214

300

50A

107456

50T

108986

50E

108672

50K

109355

500

80A

121942

80T

100063

80E

105834

80K

108663

750

125A

100398

140T(2)

102029

125E

123256

140K

120889

These fuses coordinate with the Bay-O-Net above 400A

E.C.S.

INFORMATION SECTION

Issued 06-01-07

FUSING

Section WFS04

Page 7 of 12

PADMOUNT TRANSFORMER FUSING

7.2/12.47 KV, 7.6/13.2 KV, 7.9/13.8 KV, AND 14.4 DELTA OPERATING VOLTAGE

SINGLE PADMOUNT TRANSFORMER FUSING

Table 04-6 - Used to Determine Sectionalizing

Fuse Size for Serving a Single Padmount

Transformer

RISER FUSES

IES

STANDARD

KVA TCC 123-6

Single-Phase

SWITCHGEAR FUSES

IPW/WPL

IES/IPW/WPL

IES/IPW

ITEM ID #

T SPEED

TCC 170-6

ITEM ID #

SMU-20

TCC 119-2

ITEM ID #

SMU-20

TCC 165-2

ITEM ID #

WPL

SM-4

TCC 119-4

ITEM ID #

15

10A

121831

3A/2.5X(2)

104307

5E

102799

5E(1)

5E(1)

25

10A

121831

6T

107031

5E

102799

5E(1)

5E(1)

50

10a

121831

8T

121334

10E

106919

10K

101003

10E(1)

107947

100

15A

106996

15T

106953

15E

121728

15K

106528

20E

107527

167

25A

105571

25T

106050

25E

106919

25K

106214

30E

109160

Three-Phase 7.2 kV Delta and 7.2/12.47 kV Tranfsormers Equipped with a Delta/Wye Switch on Primary Side

75

10A

121831

8T

121334

10E

106919

10K

101003

10E(1)

107947

150

15A

106996

15T

106953

15E

121728

15K

106528

15E

122034

300

30A

101496

30T

102152

30E

106222

30K

107432

30E

109160

500

50A

107456

50T

123035

50E

108672

50K

109355

50E

122921

750

65A

102042

65T

120424

65E

100747

65K

101433

65E

106148

1000

100A

120363

100T

109005

100E

121395

100K

104648

100E

123298

1500

125A

100398

140T

121946

125E

123256

140K

120889

125E

108218

5E(1)

106645

Three-Phase 7.2/12.47 kV, 7.6/13.2 kV, 7.9/13.8 kV and 14.4 kV Delta W/4 Taps Down

75

10A

121831

6T

107031

5E

102799

5E(1)

(1)

150

10A

121831

8T

121334

10E

106919

10K

101003

300

15A

106996

15T

106953

15E

121728

15K

106528

20E

107527

500

25A

105571

25T

106050

25E

106919

25K

106214

30E

109160

750

40A

120109

40T

120518

40E

121728

40K

122214

50E

122921

1000

50A

107456

50T

123035

50E

108672

50K

109355

65E

106148

1500

80A

121942

80T

103087

80E

105834

80K

108663

80E

102049

2000

100A

120363

100T

109005

100E

121395

100K

104648

100E

128298

2500

125A

100398

140T

121946

125E

123256

140K

120889

125E

108218

(1)

This fuse is a standard speed TCC 153-2 for SMU-20 or 153-4 for SM-4.

(2)

Standard Speed TCC 123-6 (IPW) Kearney X-Link (WPL).

10E

107947

E.C.S.

INFORMATION SECTION

Section WFS04

Page 8 of 12

Issued 06-01-07

PADMOUNT TRANSFORMER FUSING

FUSING

14.4/24.9 KV OPERATING VOLTAGE SINGLE PADMOUNT TRANSFORMER

FUSING

Table 04-7 - Used to Determine Sectionalizing

Fuse Size for Serving a Single Padmount Transformer

RISER FUSES

SWITCHGEAR FUSES

IES

STANDARD

KVA TCC 123-6

Single-Phase

10A

15

25

10A

IPW/WPL

IE S/IP W/WPL

ITEM ID #

T SPEED

TCC 170-6

ITEM ID #

SMU-20

TCC 119-2

ITEM ID #

121831

2A/2X(2)

107236

5E(1)

106672

104307

(1)

106672

(1)

121831

3A/2.5X ( 2 )

5E

100

10A

10A

121831

121831

6T

10T

107031

121716

5E

10E(1)

106672

108026

167

15A

106996

12T

122617

15E

108943

Three-Phase

10A

75

121831

3A/2.5X(2)

104307

5E(1)

106672

50

150

10A

121831

6T

107031

(1)

108026

(1)

10E

500

10A

15A

121831

106996

10T

12T

121716

122617

10E

15E

108026

108943

750

20A

109718

20T

105936

25E

109982

1000

1500

25A

40A

105571

120109

25T

40T

106050

120518

30E

50E

103633

107111

2500

65A

102042

65T

120424

80E

107016

300

(1)

This fuse is a standard speed TCC 153-2.

(2)

Standard Speed TCC 123-6 (IPW) / Kearney X-Link (WPL)

Issued 06-01-07

FUSING

E.C.S.

INFORMATION SECTION

Section WFS04

Page 9 of 12

PADMOUNT TRANSFORMER FUSING

GUIDELINES FOR USING FUSE TABLES 04-8, 04-9 AND 04-10

DETERMINE SECTIONALIZING FUSE FOR MULTIPLE PADMOUNT TRANSFORMERS

BACKGROUND

The sectionalizing fuse identified in Table 04-8 Use to Coordinate Sectionalizing Fuse with Largest

Padmount Transformer Bayonet Fuse in a Multiple Transformer System on Page WFS04.10,

Table 04-9 - Use to Coordinate Sectionalizing Fuse with Largest Padmount Transformer Bayonet

Fuse in a Multiple Transformer System on Page WFS04.11 and Table 04-10 - Use to Coordinate

Sectionalizing Fuse with Largest Padmount Transfomer Bayonet Fuse in a Multiple Transformer

System on Page WFS04.12 is the minimum size fuse that will properly coordinate with the transformer

internal bayonet fuse under secondary fault conditions. The fuse sizes were chosen such that when a

transformer secondary fault occurs, the transformer internal bayonet fuse will open without affecting the

sectionalizing fuse. As a result, the other transformers served by the sectionalizing fuse will remain

energized.

The sectionalizing fuse size can be increased if more capacity is needed to serve the full load of the

tap. Consult your Distribution Engineer for these applications.

EXAMPLE

Determine the minimum size sectionalizing fuse for serving the multiple padmount transformers shown

below:

Figure 04-2 - Sectionalizing Fuse, Multiple Padmounts

a. Step #1 - Refer to proper fusing chart. Since this example involves multiple padmount

transformers on the 7.2/12.47 kV distribution system, use Table 04-9 - Use to Coordinate

Sectionalizing Fuse with Largest Padmount Transformer Bayonet Fuse in a Multiple

Transformer System on Page WFS04.11.

b. Step #2 - Identify the largest size transformer to be served. For this example, the largest

transformer is 500 kVA, 480/277 volt. Locate this transformer size and type in the left

column of the table.

c. Step #3 - Follow the row across to the right to determine the minimum size sectionalizing

fuse that will coordinate with the transformer internal bayonet or full-range current limiting

fuse. For this example in WPL territory, Table 04-9 - Use to Coordinate Sectionalizing

Fuse with Largest Padmount Transformer Bayonet Fuse in a Multiple Transformer

System on Page WFS04.11 identifies that the minimum size sectionalizing fuse should be

a 65T riser fuse or 80E SM-4 switchgear fuse.

E.C.S.

INFORMATION SECTION

Section WFS04

Page 10 of 12

Issued 06-01-07

PADMOUNT TRANSFORMER FUSING

FUSING

d. Step #4 - Estimate the diversified load on the tap and compare to the size of the

sectionalizing fuse. If appropriate, consult your Distribution

Engineer to increase the size of the sectionalizing fuse.

2.4/4.16 KV OPERATING VOLTAGE MULTIPLE

PADMOUNT TRANSFORMER FUSING

Table 04-8 Use to Coordinate Sectionalizing Fuse with

Largest Padmount Transformer Bayonet Fuse in a Multiple

Transformer System

RISER FUSES

IES

STANDARD

KVA TCC 123-6

SINGLE-PHASE

SWITCHGEAR FUSES

IPW/WPL

IES/IPW

ITEM ID #

T SPEED

TCC 170-6

ITEM ID #

SMU-20

TCC 119-2

ITEM ID #

SMU-20

TCC 165-2

ITEM ID #

15

15A

106996

12T

122617

15E

121728

20K

104456

25

20A

109718

15T

106953

20E

106896

25K

106214

50

65A

102042

40T

120518

50E

108672

65K

101438

100

100A

120363

65T

120424

80E

105834

100K

104648

167

125A

100398

140T

121946

125E

123256

140K

120889

40T

120518

50E

108672

65K

101438

THREE-PHASE

75

65A

102042

150

100A

120363

65T

120424

80E

105834

100K

104648

300

125A

100398

140T

121946

125E

123256

140K

120889

500

150A

103308

140T

121946

150E

105026

200K

101789

750

200A

104883

140T(1)

121946

175E

101419

200K

101789

(2)

These fuses coordinate with the Bay-O-Net above 400A

E.C.S.

INFORMATION SECTION

Issued 06-01-07

FUSING

Section WFS04

Page 11 of 12

PADMOUNT TRANSFORMER FUSING

7.2/1 2.47 KV, 7.6/13.2 KV, 7.9/1 3.8 KV AND 14.4 DELTA OPERATING VOLTAGE

MULTIPLE PADMOUNT TRANSFORMER FUSING

Table 04-9 - Use to Coordinate Sectionalizing Fuse

with Largest Padmount Transformer Bayonet Fuse in a Multiple

Transformer System

RISER FUSES

SWITCHGEAR FUSES

IES

STANDARD

KVA TCC 123-6

10A

15

IPW/WPL

IES/IPW/WPL

IES/IPW

WPL

ITEM ID #

121831

T SPEED

TCC 170-6

8T

ITEM ID #

121334

SMU-20

TCC 119-2

15E

ITEM ID #

106528

SMU-20

TCC 165-2

10K

ITEM ID #

101003

SM-4

TCC 119-4

10E(1)

ITEM ID #

107947

25

15A

106996

10T

121716

15E

106528

15K

106528

15E

122034

50

40A

120109

25T

106050

30E

107432

40K

122214

30E

109160

100

65A

102042

40T

120518

65E

101438

65K

101438

65E

106148

167

100A

120363

65T

120424

80E

108663

100K

104648

80E

102049

106214

20E

107527

Three-Phase 7.2 kV Delta and 7.2/12.47 kV Tranfsormers Equipped with a Delta/Wye Switch on Primary Side

75

20A

109718

15T

106953

20E

106896

25K

150

65A

102042

40T

120518

50E

108672

65K

101438

50E

122921

300

100A

120363

65T

120424

80E

105834

100K

104648

80E

102049

500

125A

100398

140T

121946

125E

123256

140K

120889

150E

102703

750

150A

103308

140T

121946

150E

105026

200K

101789

175E

109002

(2)

1000

200A

104883

140T

121946

175E

101419

200K

101789

200E

102499

1500

200A

104883

140T(2)

121946

175E

101419

200K

101789

200E

102499

Three-Phase 7.2/12.47 kV, 7.6/13.2 kV, 7.9/13.8 kV and 14.4 kV Delta W/4 Taps Down

75

15A

106996

10T

121716

15E

106528

15K

106528

15E

122034

150

40A

120109

25T

106050

30E

107432

40K

122214

30E

109160

300

65A

102042

40T

120518

50E

108672

65K

101438

50E

122921

500

100A

120363

65T

120424

80E

105834

100K

104648

80E

102049

750

125A

100398

80T

103087

100E

121395

140K

120889

100E

123298

1000

125A

100398

140T

121946

125E

123256

140K

120889

150E

102703

1500

150A

103308

140T

121946

150E

105026

200K

101789

175E

109002

(2)

2000

200A

104883

140T

121946

17TE

101419

200K

101789

200E

102499

2500

200A

104883

140T(2)

121946

175E

101419

200K

101789

200E

102499

(1)

This fuse is a standard speed TCC 153-4.

(2)

These fuses coordinate with the Bay-O-Net above 400A.

E.C.S.

INFORMATION SECTION

Section WFS04

Page 12 of 12

Issued 06-01-07

PADMOUNT TRANSFORMER FUSING

FUSING

14.4/24.9 KV OPERATING VOLTAGE

MULTIPLE PADMOUNT TRANSFORMER FUSING

Table 04-10 - Use to Coordinate Sectionalizing Fuse

with Largest Padmount Transfomer Bayonet Fuse in a

Multiple Transformer System

RISER FUSES

IES

SWITCHGEAR FUSES

IPW/WPL

IES/IPW/WPL

STANDARD

TCC 123-6

ITEM ID #

T SPEED

TCC 170-6

ITEM ID #

SMU-20

TCC 119-2

ITEM ID #

15

10A

121831

8T

105380

15E

108943

25

10A

121831

8T

105380

15E

108943

50

15A

106996

12T

106362

15E

108943

100

40A

120109

25T

105891

30E

103633

167

65A

102042

40T

102029

50E

107111

75

10A

121831

8T

105380

15E

108943

150

15A

106996

12T

106362

15E

108943

300

40A

120109

25T

105891

30E

103633

500

65A

102042

40T

102029

50E

107111

750

80A

121942

50T

108986

6TE

103586

1000

100A

120363

65T

121327

80E

107016

1500

2500

125A

150A

100398

103308

100T

140T

107536

102889

125E

150E

105031

102072

KVA

Single-Phase

Three-Phase

(END)

Issued 06-01-07

E.C.S.

INFORMATION SECTION

FUSING

Section WFS05

Page 1 of 4

STEP-TIE TRANSFORMERS

GUIDELINES FOR USING FUSE TABLE 05-1

STEP-TIE TRANSFORMER PROTECTION

SOURCE AND LOAD SIDE FUSING

BACKGROUND

The source and load side fuse combination identified in Figure 05-1 - Step-Tie Transformer Fuse is the

recommended method for fusing step-tie transformer applications. The load side fuse protects the steptie transformer from overloads and downstream faults. The source side fuse provides protection in the

event of a step-tie transformer failure. This fuse combination will coordinate throughout the entire range

of fault levels on the Alliant distribution system.

Since the load side fuse is the device protecting the step-tie transformer from overloads and down

stream faults, it must be located as close to the transformer as possible. In overhead step-tie

transformer applications, the load side fuse should be installed on the transformer pole. It is

recommended that the source side fuse be located one span away from the step-tie transformer to

provide a safe physical separation for line personnel in the event that a damaged transformer is refused.

There are other devices (i.e., reclosers) and protection schemes which can be used to protect step-tie

transformers, providing the transformer damage curve is not exceeded. Consult your Distribution

Engineer on these applications.

EXAMPLE

Determine the source and load side fuse sizes for protecting the step-tie transformer shown below.

Figure 05-1 - Step-Tie Transformer Fuse

a. Step #1 - Refer to proper fusing chart. Since this example involves fusing for both the source

and load side of the step-tie transformer, use Figure 05-1 - Step-Tie Transformer Fuse.

b. Step #2 - This example involves a 14.4/24.9 kV distribution source. Locate the 250 kVA step-tie

transformer in the 14.4/24.9 kV portion of the table.

c. Step #3 - Follow the row across to the right to determine the recommended size source and

load side fuse. For this example, Table 05-1 recommends that a 40T source side fuse and

a 40T load size fuse be installed.

E.C.S.

INFORMATION SECTION

Section WFS05

Page 2 of 4

Issued 06-01-07

STEP-TIE TRANSFORMERS

FUSING

STEP-TIE TRANSFORMER PROTECTION

(SOURCE AND LOAD SIDE FUSING)

Table 05-1

Use to determine maximum source side and load side fuse combination for protection of

overhead or padmount step-tie transformers. This fuse combination will protect the step-tie

transformer and coordinate throughout the entire range of fault levels on the WP&L distribution system.

This is the recommended method for fusing step-tie transformer applications. In situations where there

is no load side fuse, use Figure 05-2 - Step-Tie Transformer Fuse.

14.4/24.9 kV Distribution Source(Step-Down Applications)

kVA

PHASE

100

167

250

333

500

500

750

1000

1500

2500

5000

1-Phase

1-Phase

1-Phase

1-Phase

1-Phase

3-Phase

3-Phase

3-Phase

3-Phase

3-Phase

3-Phase

14.4/24.9kV

SOURCE SIDE T-LINK

10T

15T

25T

30T

40T

15T

25T

30T

40T

80T

140T

7.2/14.47 kV

LOAD SIDE T-LINK

12T

20T

30T

40T

50T

20T

30T

40T

50T

100T

140T

7.2/12.47 kV Distribution Source (Step-Up Applications)

kVA

PHASE

100

167

250

333

500

500

750

1000

1500

2500

5000

1-Phase

1-Phase

1-Phase

1-Phase

1-Phase

3-Phase

3-Phase

3-Phase

3-Phase

3-Phase

3-Phase

7.2/12.47 kV

SOURCE SIDE T-LINK

20T

30T

50T

65T

80T

30T

50T

65T

80T

140T

200T

14.4/24.9 kV

LOAD SIDE T-LINK

8T

10T

15T

20T

25T

10T

15T

20T

25T

50T

100T

Do not exceed the fuse size identified or transformer protection will be compromised.

Issued 06-01-07

E.C.S.

INFORMATION SECTION

FUSING

Section WFS05

Page 3 of 4

STEP-TIE TRANSFORMERS

GUIDELINES FOR USING FUSE TABLE 05-2

STEP-TIE TRANSFORMER PROTECTION

SOURCE SIDE FUSING ONLY

BACKGROUND

The source side only fuse protection scheme identified in Figure 05-2 - Step-Tie Transformer Fuse is

an alternative method for fusing step-tie transformer applications. This method should be used when a

load side fuse is not located at the transformer. The source side fuse protects the step-tie transformer

from overloads and down stream faults. It also provides protection in the event of a step-tie transformer

failure.

In overhead applications, it is recommended that the source side fuse be located one span away from

the step-tie transformer to provide a safe physical separation for line personnel in the event that a

damaged transformer is re-fused. It is also recommended that a disconnect device (cutout) be located

on the load side of the step-tie transformer to aid line personnel when troubleshooting outages.

There are other devices (i.e., reclosers) which can be used to protect step-tie transformers providing

the transformer damage curve is not exceeded. Consult your Distribution Engineer on these

applications.

EXAMPLE

Determine the source side fuse size for protecting the step-tie transformer shown below.

Figure 05-2 - Step-Tie Transformer Fuse

a. Step #1 - Refer to proper fusing chart. Since this example involves fusing only the source side

of the step-tie transformer, use Figure 05-2 - Step-Tie Transformer Fuse.

b. Step #2 - This example involves a 14.4/24.9 kV distribution source. Locate the 250 kVA step-tie

transformer in the 14.4/24.9 kV portion of the table.

c. Step #3 - Follow the row across to the right to determine the recommended size source side

fuse. For this example, Table 05-2 recommends that a 20T or 25E source side fuse be installed.

E.C.S.

INFORMATION SECTION

Section WFS05

Page 4 of 4

Issued 06-01-07

STEP-TIE TRANSFORMERS

FUSING

STEP-TIE TRANSFORMER PROTECTION

(SOURCE SIDE FUSING ONLY)

Table 05-2

Use to determine maximum source side fuse for protection of overhead or padmount step-tie

transformers. This method of fusing step-tie transformers should be followed when there is no load

side fuse.

14.4/24.9 kV Distribution Source(Step-Down Applications)

kVA

PHASE

100

167

250

333

500

500

750

1000

1500

2500

5000

1-Phase

1-Phase

1-Phase

1-Phase

1-Phase

3-Phase

3-Phase

3-Phase

3-Phase

3-Phase

3-Phase

MAXIMUM SOURCE SIDE FUSE

T-LINK

SMU-20

8T

10E

15T

20E

20T

25E

25T

30E

40T

50E

15T

20E

20T

25E

25T

30E

40T

50E

65T

80E

140T

150E

7.2/12.47 kV Distribution Source (Step-Up Applications)

kVA

PHASE

100

167

250

333

500

500

750

1000

1500

2500

5000

1-Phase

1-Phase

1-Phase

1-Phase

1-Phase

3-Phase

3-Phase

3-Phase

3-Phase

3-Phase

3-Phase

MAXIMUM SOURCE SIDE FUSE

T-LINK

15T

25T

40T

50T

80T

25T

40T

50T

80T

100T

200T

SM-4

20E

30E

50E

65E

100E

30E

50E

65E

100E

125E

200E

Do not exceed the maximum source side fuse identified or transformer protection will be compromised.

(END)

E.C.S.

INFORMATION SECTION

Issued 06-01-07

FUSING

Section WFS06

Page 1 of 1

DISTRIBUTION CAPACITORS

Table 06-1 - Distribution Capacitor Bank Fusing Chart

MAXIMUM COORDINATING FAULT CURRENT

COOPER TYPE EX

VOLTAGE

(KVLL)

4.16

BANK

SIZE

(KVAR)

150

STD LINK

FUSE

SIZE

25STD

K LINK

FUSE

SIZE

20K

T LINK

FUSE

SIZE

25T

50

KVAR

CELLS

100

KVAR

CELLS

200

KVAR

CELLS

GE

400

KVAR

CELLS

100

KVAR

CELLS

200

KVAR

CELLS

*

*

ABB

400

KVAR

CELLS

50

KVAR

CELLS

100

KVAR

CELLS

1000

*

520

300

50STD

40K

50T

4.16

450

65STD

65K

65T

4.16

600

100STD

80K

100T

12.47

150

7STD

6K

8T

*

12.47

300

15STD

15K

15T

*

*

4200

4200

5200

12.47

450

25STD

20K

25T

*

*

4200

3800

5200

12.47

600

30STD

30K

30T

*

*

4000

4800

5000

12.47

900

50STD

50K

50T

*

*

1000

3800

3500

12.47

1200

65STD

65K

65T

13.2

300

15STD

15K

15T

13.2

600

30STD

30K

25T

*

*

4200

4800

5200

13.2

900

50STD

50K

40T

*

*

3300

4400

4500

13.2

1200

65STD

65K

65T

13.8

150

7STD

6K

8T

*

13.8

300

15STD

15K

15T

*

*

4200

4200

5200

13.8

450

20STD

20K

20T

*

*

4200

4200

5200

13.8

600

25STD

30K

25T

*

*

4200

4800

5200

13.8

900

50STD

50K

40T

*

*

3300

4400

4500

13.8