Fusing Equipment

Catalog Data

CA132026EN

Effective June 2015

Supersedes 327-30 May 2013 and

235-26 August 2012

COOPER POWER

SERIES

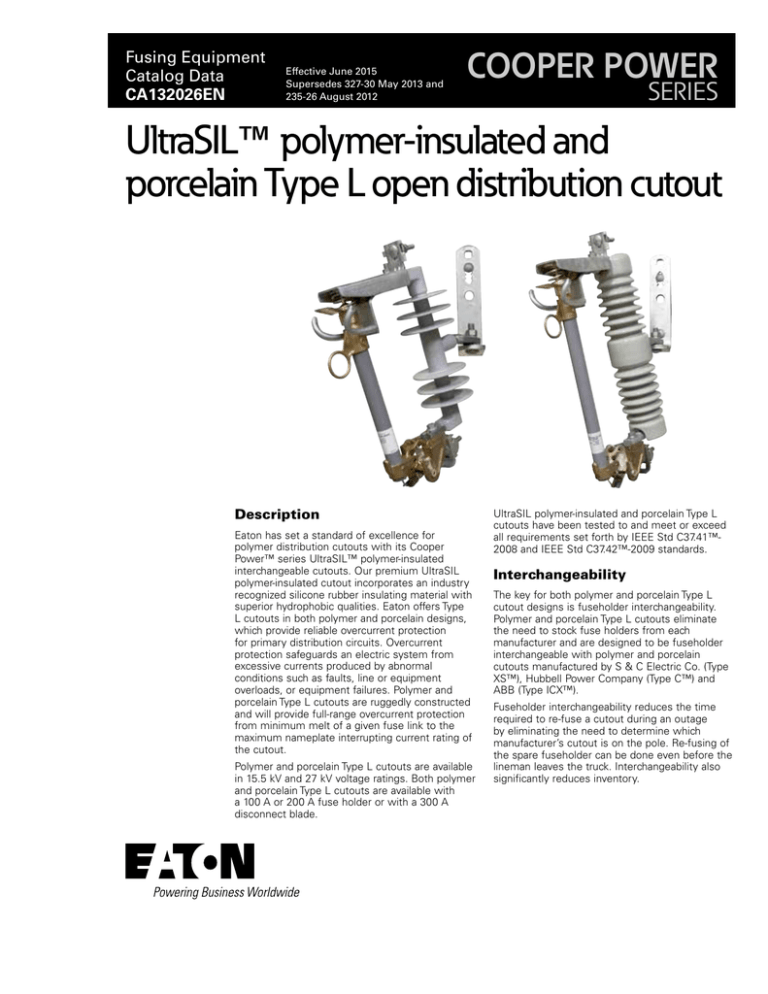

UltraSIL™ polymer-insulated and

porcelain Type L open distribution cutout

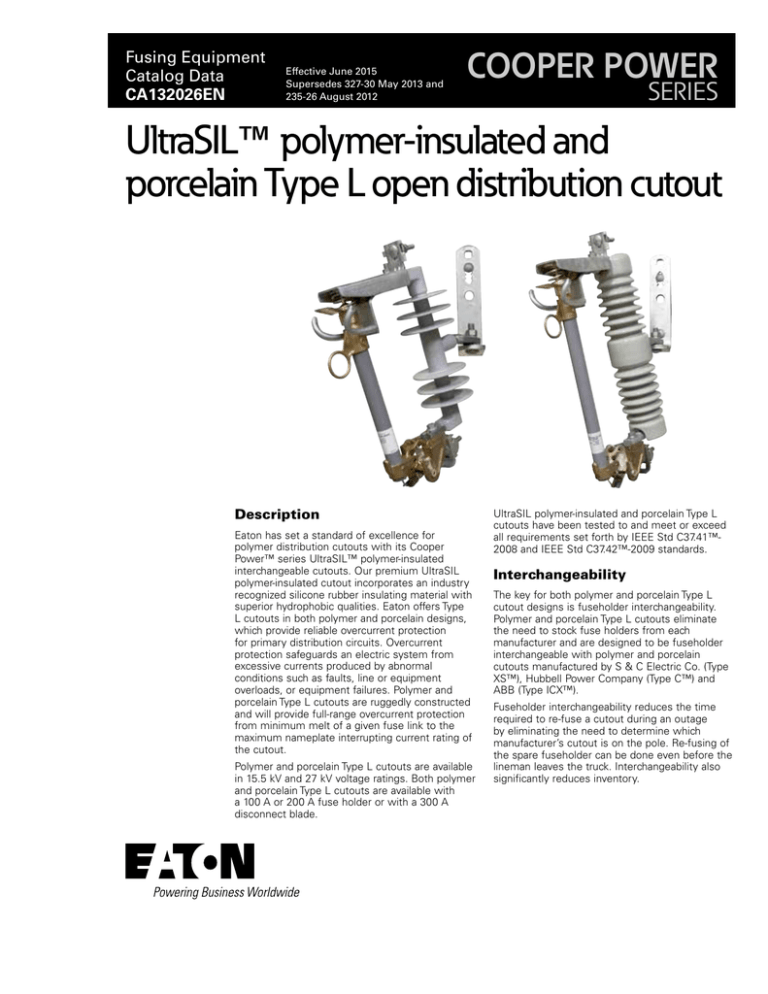

Description

Eaton has set a standard of excellence for

polymer distribution cutouts with its Cooper

Power™ series UltraSIL™ polymer-insulated

interchangeable cutouts. Our premium UltraSIL

polymer-insulated cutout incorporates an industry

recognized silicone rubber insulating material with

superior hydrophobic qualities. Eaton offers Type

L cutouts in both polymer and porcelain designs,

which provide reliable overcurrent protection

for primary distribution circuits. Overcurrent

protection safeguards an electric system from

excessive currents produced by abnormal

conditions such as faults, line or equipment

overloads, or equipment failures. Polymer and

porcelain Type L cutouts are ruggedly constructed

and will provide full-range overcurrent protection

from minimum melt of a given fuse link to the

maximum nameplate interrupting current rating of

the cutout.

Polymer and porcelain Type L cutouts are available

in 15.5 kV and 27 kV voltage ratings. Both polymer

and porcelain Type L cutouts are available with

a 100 A or 200 A fuse holder or with a 300 A

disconnect blade.

UltraSIL polymer-insulated and porcelain Type L

cutouts have been tested to and meet or exceed

all requirements set forth by IEEE Std C37.41™2008 and IEEE Std C37.42™-2009 standards.

Interchangeability

The key for both polymer and porcelain Type L

cutout designs is fuseholder interchangeability.

Polymer and porcelain Type L cutouts eliminate

the need to stock fuse holders from each

manufacturer and are designed to be fuseholder

interchangeable with polymer and porcelain

cutouts manufactured by S & C Electric Co. (Type

XS™), Hubbell Power Company (Type C™) and

ABB (Type ICX™).

Fuseholder interchangeability reduces the time

required to re-fuse a cutout during an outage

by eliminating the need to determine which

manufacturer’s cutout is on the pole. Re-fusing of

the spare fuseholder can be done even before the

lineman leaves the truck. Interchangeability also

significantly reduces inventory.

Catalog Data CA132026EN

UltraSIL polymer and porcelain open distribution cutout

Effective June 2015

Design features

Application

The backbone of the UltraSIL polymer-insulated Type L cutout is

comprised of an E-glass fiberglass rod with crimped-on galvanized

steel hanger and end fittings. The crimping process results in a

robust design capable of withstanding numerous opening and

closing operations and the severe forces present during fault

current interruptions. The frame is over molded with the industry

leading, track resistant, UltraSIL silicone rubber polymer-housing.

Independent laboratory tests have verified the superiority of silicone

rubber in terms of resistance to UV degradation, surface tracking/

performance in contaminated environments and other important

insulating properties. The complete cutout assembly works together

as a system and will stand up to years of exposure to environmental

extremes.

Proper cutout application requires several major system considerations: system operating voltage, insulation level, type of system

grounding, maximum available fault current the cutout may be

subjected to and anticipated maximum continuous load current.

The porcelain Type L cutout is designed with a solid core, birdproof,

one piece porcelain frame with uniform shed configuration. Sulfur

cemented studs provide high strength connections.

The fuseholder is constructed of an epoxy impregnated glass filament wound tube over an arc-quenching inner liner material. A large

bronze cast pull ring is utilized for ease of installation and re-fusing.

The bronze trunnion, with lifting ring having both front and side

accessibility, is silver plated for minimum contact resistance. The

grooved flipper assembly controls link tension, assures low fault

current interruption and prevents link breakage on “close-in.”

The cast bronze lower hinge assembly has deep pockets for the

trunnion to pivot to minimize accidental fuse removal. The rugged

design with wide opening means easy fuseholder installation and

removal. The lower contact assembly utilizes stainless steel backup

springs and silver-to-silver contacts to minimize contact resistance

and assure excellent continuous contact throughout the life of the

cutout. The contacts are designed to carry 300 A continuous. Silverto-silver top contacts are again used to minimize contact resistance.

Type L cutout design develops high contact pressure to assure

excellent contact for operating currents and until fault interruption is

completed.

Loadbreak hooks, for use with a loadbreak tool, are standard and

serve as a “close-in” guide to assure positive make.

Lubricant is applied to all separable connector interchanges. All

hardware is designed to interlock during assembly to assure correct

alignment. The rugged design assures smooth operation and long

life.

2

www.eaton.com/cooperpowerseries

The polymer and porcelain Type L cutout voltage rating is the

maximum design voltage of the cutout. It can be applied, without

restrictions, on any three-phase system that has system line-to-line

voltage less than or equal to the cutout rating. Type L cutouts can

also be applied on single-phase or three-phase solidly grounded wye

connected circuits. The circuit can have line-to-neutral voltages up to

the voltage rating of the cutout as long as the maximum recovery

voltage does not exceed the cutout's rating.

The Basic Impulse Insulation Level (BIL) of a cutout should be

coordinated with the insulation of other connected apparatus. The

interrupting rating of a cutout should be greater than or equal to the

maximum available system fault current unless used in conjunction

with current-limiting fuses such as the Companion™ II backup fuse

or the ELF™ full-range fuse. The cutout selected should have a

continuous current rating sufficient to handle the expected load. The

100 A rated fuseholder accepts fuse links from a fraction of 1 A to

100 A. The 200 A fuseholder will accept fuse links with ratings above

100 A to 200 A.

When selecting a cutout or fuse, it is important to consider future

load growth and other planned system expansion.

Eaton offers full-range current-limiting fuses for applications where

system fault current exceeds the maximum interrupting rating of an

expulsion fuse. ELF full-range current-limiting fuses and Tandem ELF

fuses are designed to be mounted directly in a polymer or porcelain

Type L cutout replacing the cutout expulsion fuse holder. The ELF

fuse's versatile designs allow for safe capacitor protection and

reduces the installation costs associated with bolted connections.

See Catalog sections CA132027EN and CA132028EN or consult

your local Eaton representative for further information.

Catalog Data CA132026EN

UltraSIL polymer and porcelain open distribution cutout

Effective June 2015

Fuseholders and blades

300 A disconnect blade­

100 A fuseholder­

UltraSIL polymer-insulated and porcelain Type L 300 A disconnect

blades (refer to Figure 3) are constructed of a high conductivity

copper tube. 300 A fuse caps are threaded directly onto the copper

tube, reducing the number of current interchanges on the blade to

only two.

The UltraSIL polymer-insulated and porcelain Type L cutouts accommodate standard IEEE® and NEMA® universal type fuse links. This

fuseholder can handle universal links up to 100 A.

An arc shortening rod can be used to obtain the higher interrupting

current ratings. The arc shortening rod is made of silver-plated, high

conductivity copper and is mechanically attached to the fuse cap.

Removable buttonhead fuse links must be used with arc shortening

rods.

The 100 A fuseholder features a spring assist which helps clear the

fuseholder under low current operations. It also comes standard

with a 9/16" bolt for easy leader installation.

Figure 3. 300 A disconnect blade.

Connectors/brackets

Figure 1. 100 A fuseholder.

200 A Fuseholder­

This fuseholder can handle universal links above 100 A up to 200 A

and is fully rated for 15.5 kV or 27 kV voltage ratings.

The 200 A door comes standard with an arc shortening rod. The arc

shortening rod is made of silver-plated, high conductivity copper and

is mechanically attached to the fuse cap. Removable buttonhead

fuse links must be used with arc shortening rods. The 200 A

fuseholder features a spring assist which helps clear the fuseholder

under lower current operations. It also comes standard with a 9/16"

bolt and captive washer for easy leader installation and capturing.

UltraSIL polymer-insulated and porcelain Type L cutouts include a

tin-plated bronze parallel-groove connector as standard. The parallelgroove connector fits a conductor range of #8 solid (.128" diameter)

to 250 MCM (.575" diameter). Tin plated bronze eyebolt and large

eyebolt connector options are also available. The eyebolt connector

fits a conductor range of #8 solid (.128" diameter) to 2/0 stranded

(.419" diameter) and the large eyebolt connector fits a conductor

range of #6 solid (.162" diameter) to 250 mcm (.575" diameter).

UltraSIL polymer-insulated and porcelain Type L cutout crossarm

mounting includes a heavy-duty NEMA® Type B crossarm mounting

bracket to withstand the mechanical forces generated during fault

current interruptions when using an expulsion fuse link. An extended

crossarm mounting bracket option is also available. Type L cutouts

are also available without crossarm mounting brackets. See Table 3

for all connector and bracket options.

Figure 2. 200 A fuseholder.

www.eaton.com/cooperpowerseries

3

Catalog Data CA132026EN

UltraSIL polymer and porcelain open distribution cutout

Effective June 2015

Electrical ratings

Electrical insulation ratings for the polymer and porcelain Type L

cutouts are shown in Table 1.

All cutouts have been tested in accordance with IEEE Std C37.40™2003, IEEE Std C37.41™-2008 and IEEE Std C37.42™-2009 standards.

Figure 4. Parallel-groove connector.

Figure 6. Additional arrester mounting hardware (bagged)

included for Options 5 and 6.

Figure 5. Eyebolt connector.

Table 1. 15 and 27 kV Polymer and Porcelain Type L Interchangeable Cutout Specifications

Interrupting Rating (A rms)

Creep Distance

inches (mm)

Approximate Weight

lbs. (kg)

Polymer

Porcelain

Maximum

Voltage

Rating

(kV)

BIL (kV)

Continuous

Current (A)

Symmetrical

Asymmetrical

Polymer

Porcelain

Polymer

Porcelain

S4B1

L4B1

15.5

110

100

7,100

10,000

14.2 (362)

8.5 (216)

8.2 (3.7)

14.5 (6.5)

S4BA**

L4BA**

15.5

110

100

10,600

16,000

14.2 (362)

8.5 (216)

8.3 (3.8)

14.6 (6.6)

S4B2**

L4B2**

15.5

110

200

8,000

12,000

14.2 (362)

8.5 (216)

8.7 (3.9)

15.0 (6.8)

Disconnect†

14.2 (362)

8.5 (216)

7.7 (3.5)

14.0 (6.4)

Base Catalog Number*

S4B3

L4B3

15.5

110

300

Disconnect†

L9C1

27

125

100

5,300

8,000

11.0 (279)

16.7 (7.5)

L9CA**

27

125

100

8,000

12,000

11.0 (279)

16.8 (7.6)

L9C2**

27

125

200

7,100

10,000

11.0 (279)

17.2 (7.8)

L9C3

27

125

300

Disconnect†

Disconnect†

11.0 (279)

16.2 (7.3)

S9D1

L9D1

27

150

100

5,300

8,000

22.3 (566)

17.0 (432)

10.2 (4.6)

22.5 (10.2)

S9DA**

L9DA**

27

150

100

8,000

12,000

22.3 (566)

17.0 (432)

10.3 (4.7)

22.6 (10.3)

S9D2**

L9D2**

27

150

200

7,100

10,000

22.3 (566)

17.0 (432)

10.7 (4.9)

23.0 (10.4)

S9D3

L9D3

27

150

300

Disconnect†

Disconnect†

22.3 (566)

17.0 (432)

9.7 (4.4)

22.0 (10.0)

* Base catalog number for standard polymer-insulated and porcelain Type L unit. See Table 3 for optional connectors and brackets.

** These units include an arc shortening rod and must be used with removable buttonhead fuse links.

† 300 A disconnect short-time current ratings: 12 kA (Asym) momentary, 8.6 kA (sym) 15-cycle and 1.6 kA 3 sec.

4

www.eaton.com/cooperpowerseries

Catalog Data CA132026EN

UltraSIL polymer and porcelain open distribution cutout

Effective June 2015

Option 1 in digit 6 Table 3

4.00" max (102 mm).

Option 2 digit 6 in Table 3

5.00" max (152 mm)

Option 7 digit 6 in Table 3,

5.50" max.

B

4.1" (105 mm)

to

5.1" (131 mm)

C

2.6" (67 mm)

(standard

bracket)

5.9" (149 mm)

(extended

bracket)

E

A

D

Figure 7. Polymer-insulated Type L cutout assembly shown. Dimensions apply to both polymer-insulated and porcelain Type L

cutouts.

Table 2. Polymer-Insulated and Porcelain Type L Cutouts Dimensional Data (refer to Figure 4)

Creepage Distance

inches (mm)

Dimensions inches (mm)

Voltage

Rating

kV

BIL

kV

A

B

C

D

E

Polymer

Porcelain

15.5

110

11.3 (288)

13.5 (343)

8.1 (207)

11.5 (292)

16.3 (414)

14.2 (362)

8.5 (216)

10.1 (257)

14.9 (379)

19.6 (498)

–

11.0 (279)

22.3 (566)

17.0 (432)

27

125*

150

14.7 (374)

14.0 (358)

14.2 (363)

* Electrical and dimensional information applies to porcelain cutouts only.

8.9

(227 mm)

10.3

13.3

(339 mm) (260 mm)

EXTENDED BRACKET

12.0

(305 mm)

2.6

(67 mm)

5.9

(149 mm)

Figure 8. NEMA® "D" pole mounting bracket (Option 8) and extended bracket (Option 4) in Table 3, digit 6.

www.eaton.com/cooperpowerseries

5

Catalog Data CA132026EN

UltraSIL polymer and porcelain open distribution cutout

Effective June 2015

Ordering information

To order a complete Type L cutout with a fuseholder or disconnect

blade choose the appropriate part number from Table below.

To order an individual fuseholder, disconnect blade or the cutout

mounting frame, refer to Tables 8 or 9.

Table 3. Polymer-Insulated and Porcelain Type L Cutout Combination Numbering System

Digit 6 Bracket and Hardware

0 = No Bracket

Digit 4 interrupting

Rating

1 = NEMA® "B" (5” bolts)

1 = 100 A, 10 kA

2 = NEMA® "B" (6" bolts)

A = 100 A, 12 kA

3 = Extended Bracket (5” bolts)

2 = 200 A, 12 kA

4 = NEMA® "D" Pole Mounting Bracket Extended

3 = 300 A Blade 12 kA

5 = Same as 1 with Arrester Mounting Hardware

E = Elf Fuse

6 = Same as 3 with Arrester Mounting Hardware

T = Tandem ELF™ Fuse

7 = NEMA® "B" (6.5" bolts)

Digit 1

8 = NEMA® "D" Pole Mounting Bracket

S = Polymer Type L Cutout

L = Porcelain Type L Cutout

1

2

3

4

5

6

7

8

9

S 4 B 1 E 1 A

Digits 2 and 3 Voltage

and BIL Rating

Digits 8 and 9 Combo Options

4B = 15.5 kV, 110 kV BIL

Standard Configuration - Leave blank*

9C = 27 kV, 125 kV BIL *

W/ELF - Refer to Table 4 (15 kV ) or Table 5 (27 kV) for ELF code**

9D = 27 kV, 150 kV BIL

W/Tandem ELF - Refer to Table 6 (15 kV) or Table 7 (27 kV) for Tandem ELF code***

* Porcelain only

* If E or T is selected for Digit 4, digits for 8 & 9 must be selected

** Refer to ELF fuse Catalog section CA132027EN for further detail

*** Refer to Tandem ELF fuse Catalog section CA132028EN for further detail

Digit 7 Packaging

A=Individual Packaging (Standard)

Digit 5 Terminal Options

E = Small Eyebolt

L = Large Eyebolt

P = Parallel Groove

R = Parallel Groove - bottom vertical entry

T = Large Eyebolt - bottom vertical entry

6

www.eaton.com/cooperpowerseries

Catalog Data CA132026EN

UltraSIL polymer and porcelain open distribution cutout

Effective June 2015

Table 4. ELF Fuse Ratings for 15 kV UltraSIL Polymer-Insulated and Porcelain Type L Fuse Cutouts

ELF Fuse Rating Code*

ELF Fuse Ratings

Continuous Current Ratings Aa

Digit 8

Digit 9

Voltage kV

Current A

25 °C

40 °C

55 °C

Maximum Interrupting Current

A rms symmetrical

3

3

3

3

3

3

3

3

3

3

3

4

4

4

4

4

A

B

C

D

E

F

G

H

J

K

L

A

B

C

D

E

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

15.0

15.0

15.0

15.0

15.0

6

8

12

18

20

25

30

40

50**

65**

80**

6

8

12

18

20

8

12

18

25

27

34

43

50

68

78

95

8

12

18

25

27

7

11

17

24

26

33

41

48

65

75

91

7

11

17

24

26

6

11

16

23

25

31

39

46

62

71

87

6

11

16

23

25

31000

31000

31000

31000

31000

31000

31000

31000

31000

31000

31000

20000

20000

20000

20000

20000

a For temperatures other than listed, a deration factor of 0.26% per °C can be applied.

* Replace digits 8 and 9 of the catalog number with the correct ELF fuse rating codes.

**Double-barrel design

NNote: For more information regarding the ELF fuse, refer to Catalog section CA132027EN.

Table 5. ELF Fuse Ratings for 27 kV UltraSIL Polymer-Insulated and Porcelain Type L Fuse Cutouts

ELF Fuse Rating Code*

ELF Fuse Ratings

Continuous Current Ratings Aa

Digit 8

Digit 9

Voltage kV

Current A

25 °C

40 °C

55 °C

Maximum Interrupting Current

A rms symmetrical

3

3

3

3

3

3

3

3

3

3

3

4

4

4

4

4

4

4

4

4

5

5

5

5

5

5

5

A

B

C

D

E

F

G

H

J

K

L

A

B

C

D

E

F

G

H

J

A

B

C

D

E

F

G

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

15.0***

15.0***

15.0***

15.0***

15.0***

15.0***

15.0***

15.0***

15.0***

23.0

23.0

23.0

23.0

23.0

23.0

23.0

6

8

12

18

20

25

30

40

50**

65**

80**

6

8

12

18

20

25

30**

40**

50**

6

8

12

18

20

25**

30**

8

12

18

25

27

34

43

50

68

78

95

8

12

18

25

27

34

43

50

68

8

12

18

25

27

34

43

7

11

17

24

26

33

41

48

65

75

91

7

11

17

24

26

33

41

48

65

7

11

17

24

26

33

41

6

11

16

23

25

31

39

46

62

71

87

6

11

16

23

25

31

39

46

62

6

11

16

23

25

31

39

31,000

31,000

31,000

31,000

31,000

31,000

31,000

31,000

31,000

31,000

31,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

31,000

31,000

31,000

31,000

31,000

31,000

31,000

a For temperatures other than listed, a deration factor of 0.26% per °C can be applied.

* Replace digits 8 and 9 of the catalog number with the correct ELF fuse rating codes.

**Double-barrel design

***These ELF fuses have been tested and approved for a 17.2 kV application.

NNote: For more information regarding the ELF fuse, refer to Catalog section CA132027EN.

www.eaton.com/cooperpowerseries

7

Catalog Data CA132026EN

UltraSIL polymer and porcelain open distribution cutout

Effective June 2015

Table 6. Tandem ELF Fuse Ratings for 15 kV UltraSIL Polymer-Insulated or Porcelain Type L Cutouts

Tandem ELF Fuse Rating Code*

Companion II Fuse Ratings**

Digit 8

Digit 9

Voltage (kV)

Current (A)

Fuse Link Current

Ratings***

(A)

Maximum Interrupting

Current A rms

Symmetrical

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

0

A

B

C

D

E

F

G

H

J

K

L

M

N

P

0

A

B

C

D

E

F

G

H

J

K

L

M

N

P

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

None

0.33

0.50

0.75

1

1.25

1.50

2

3

4

5

7

10

15

20

None

0.33

0.50

0.75

1

1.25

1.50

2

3

4

5

7

10

15

20

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

* Replace digits 8 & 9 of the catalog number with the correct Tandem ELF fuse rating codes.

** Digit 8 defines the Tandem ELF fuse voltage rating with the Companion II fuse current rating.

*** Digit 9 defines the Tandem ELF fuse link current rating. X-Link=1/3-2A, D-Link=3-20A.

† 15kV Companion II fuses have been tested and are approved for 17.2 kV applications.

NNote: For more information regarding Tandem ELF fuse refer to Catalog section CA132028EN.

8

www.eaton.com/cooperpowerseries

Catalog Data CA132026EN

UltraSIL polymer and porcelain open distribution cutout

Effective June 2015

Table 7. Tandem ELF Fuse Ratings for 27 kV UltraSIL Polymer-Insulated or Porcelain Type L Cutouts

Tandem ELF Fuse Rating Code*

Companion Fuse Ratings**

Digit 8

Digit 9

Voltage (kV)

Current (A)

Fuse Link

Current Ratings***

(A)

Maximum Interrupting

Current A rms

Symmetrical

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

0

A

B

C

D

E

F

G

H

J

K

L

M

N

P

0

A

B

C

D

E

F

G

H

J

K

L

M

N

P

0

A

B

C

D

E

F

G

H

J

K

L

M

N

P

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

8.3

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

15.0 †

23.0

23.0

23.0

23.0

23.0

23.0

23.0

23.0

23.0

23.0

23.0

23.0

23.0

23.0

23.0

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

None

0.33

0.50

0.75

1

1.25

1.50

2

3

4

5

7

10

15

20

None

0.33

0.50

0.75

1

1.25

1.50

2

3

4

5

7

10

15

20

None

0.33

0.50

0.75

1

1.25

1.50

2

3

4

5

7

10

15

20

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

43,000

31,000

31,000

31,000

31,000

31,000

31,000

31,000

31,000

31,000

31,000

31,000

31,000

31,000

31,000

31,000

* Replace digits 8 & 9 of the catalog number with the correct Tandem ELF fuse rating codes.

** Digit 8 defines the Tandem ELF fuse voltage rating with the Companion II fuse current rating.

*** Digit 9 defines the Tandem ELF fuse link current rating. X-Link=1/3-2A, D-Link=3-20A.

† 15 kV Companion II fuses have been tested and are approved for 17.2 kV applications.

NNote: For more information regarding Tandem ELF fuse refer to Catalog section CA132028EN.

www.eaton.com/cooperpowerseries

9

Catalog Data CA132026EN

UltraSIL polymer and porcelain open distribution cutout

Effective June 2015

Table 8. Polymer-Insulated and Porcelain Type L Fuseholders, Disconnect Blades, and Replacement Caps

Maximum Design

Voltage kV

Replacement

Caps

10,000

1.9 (.86)

LDB100CAP

16,000

2.0 (.91)

LDBA00CAP

2.4 (1.1)

LDB20BCAP

1.4 (.64)

LC12X1

8,000

2.1 (.95)

LDB100CAP

12,000

2.2 (1.0)

LDCA00CAP

2.6 (1.2)

LDC20BCAP

1.6 (.73)

LC12X1

8,000

2.1 (.95)

LDB100CAP

12,000

2.2 (1.0)

LDCA00CAP

2.6 (1.2)

LDC20BCAP

1.6 (.73)

LC12X1

Interrupting Rating

A-rms Asym

LDB100A

100

LDBA00A†

100

200

12,000

300

Disconnect**

LDC100A

100

LDCA00A†

100

200

10,000

300

Disconnect**

LDC100A

100

LDCA00A†

100

200

10,000

300

Disconnect**

Catalog Number

Approximate

Fuseholder

Length

Inches (mm)

Approximate

Weight

lbs. (kg)

Continuous

Current A-rms

For 15.5 kV, 110 kV BIL Cutouts

15.5

LDB200B†

LDB300A

11.32 (288)

For 27 kV, 125 kV BIL Cutouts

27

LDC200B†

LDC300A

14.74 (374)

For 27 kV, 150 kV BIL Cutouts

27

LDC200B†

LDC300A

14.74 (374)

† These fuseholders include an arc shortening rod and must be used with removable buttonhead fuse links.

**300 A disconnect short time current ratings: 12 kA (Asym) momentary, 8.6 kA (Sym) 15-Cycle and 1.6 kA 3 sec.

Table 9. Polymer-Insulated and Porcelain Type L Open Cutout Mounting Frames Only (Without Fuseholder or Disconnect

Blade)

Base Catalog Number*

Type L Cutout

Polymer

Porcelain

Maximum Design

Voltage (kV)

15.5

S4B0

L4B0

-

L9C0

S9D0

L9D0

27

BIL (kV)

Creepage Distance

Inches (mm)

Approximate Weight

lbs. (kg)

Polymer

Polymer

Porcelain

110

14.2 (362)

8.5 (216)

6.6 (3.0)

12.6 (5.7)

125**

-

11.0 (279)

-

14.6 (6.6)

150

22.3 (566)

17.0 (432)

10.3 (4.7)

20.4 (9.3)

* See Table 3 for optional connectors and brackets.

** Electrical and dimensional information applies to 27 kV 125 kV BIL porcelain Type L cutouts only.

10

Porcelain

www.eaton.com/cooperpowerseries

UltraSIL polymer and porcelain open distribution cutout

Catalog Data CA132026EN

Effective June 2015

Construction

The Type L fuse cutout/arrester combination comes complete with

a crossarm mounting bracket for application on the utility pole

crossarm. Standard arrester line and ground terminal hardware

includes a silicon bronze nut, a stainless steel wire clamp and a line

lead. The arrester line and ground terminal fits a conductor range of

#6 (.184” diameter) to 2/0 standard (.418” diameter).

Figure 9. Fuse cutout/arrester combination.

Type L fuse cutout/arrester combination

Eaton’s Cooper Power series Type L interchangeable fuse cutout/

arrester combinations are available in a wide variety of both

arrester and fuse cutout designs. Surge arresters are available in

silicone rubber (UltraSIL™ polymer-housing) or porcelain-housing

in heavy-duty, normal-duty or heavy-duty riser pole classifications,

and UltraSIL Polymer-Housed Evolution™ surge arrester designs in

ratings 3-36 kV. Type L fuse cutouts are available with silicone rubber

(UltraSIL polymer-insulated) or porcelain insulators for both 15 kV

and 27 kV voltage ratings.

Cutouts are available with a 100 A or 200 A fuseholder or with a

300 A disconnect blade. Type L cutouts will also accommodate

Eaton’s Cooper Power series ELF™ full range current-limiting fuse

and Tandem ELF backup fuse with series fuse link.

Combining the functions of a distribution-class surge arrester with

a fuse cutout provides the convenience of a compact, efficient unit

with less pole-top hardware. Combining these units also provides

easier installation, handling and procurement.

All surge arresters used in Type L fuse cutout/arrester combinations

have been tested to, and meet or exceed, all requirements of IEEE

Std C62.11™-2005 standard, “IEEE Standard for Metal-Oxide Surge

Arresters for Alternating Current Power Circuits”.

UltraSIL polymer-insulated and porcelain Type L cutouts have been

tested to and meet, or exceed, all requirements set forth by the

latest revisions of IEEE Std C37.41™-2008 and IEEE Std C37.42™2009 standards.

www.eaton.com/cooperpowerseries

11

Catalog Data CA132026EN

UltraSIL polymer and porcelain open distribution cutout

Effective June 2015

Dimensions

A

Figure 1 shows an outline drawing of an UltraSIL polymer-housed

surge arrester/porcelain Type L fuse cutout/arrester combination.

Figure 2 shows an outline drawing of an UltraSIL polymer-housed

surge arrester/UltraSIL polymer-insulated Type L fuse cutout/arrester

combination. Figure 3 shows an outline drawing of porcelain-housed

surge arrester/porcelain Type L fuse cutout/arrester combination.

Porcelain arresters are not available in combination with UltraSIL

polymer-insulated Type L cutouts.

G

10.78”

(274 mm)

D

1.43” (36.3 mm)

4.13” (105 mm)

5.16” (131 mm)

A

F

10.78”

(274 mm)

G

4.13”(105 mm)

TO

5.16”(131 mm)

C

D

1.43”

(36.3

mm)

Figure 11. UltraSIL polymer-housed surge arrester/UltraSIL

polymer-insulated Type L fuse cutout combination.

F

B

2.34”

(60 mm)

12.87”

(327 mm)

3.87” (98 mm)

D

4.13”(105 mm)

TO

5.16”(131 mm)

Figure 10. UltraSIL polymer-housed surge arrester/porcelain

Type L fuse cutout combination.

E

F

C

Figure 12. Porcelain-housed surge arrester/porcelain Type L fuse

cutout combination.

12

www.eaton.com/cooperpowerseries

Catalog Data CA132026EN

UltraSIL polymer and porcelain open distribution cutout

Effective June 2015

Table 10. UltraSIL Polymer-Housed or Porcelain-Housed Surge Arrester/ 15 kV UltraSIL Polymer-Insulated or Porcelain Type L

Fuse Cutout/Arrester Combination Dimensional Data

A

UltraSIL Polymer-Housed

Arrester

Arrester

Rating

kV

VariSTAR

in. (mm)*

Evolution

in. (mm)*

B

Porcelain

Arrester**

in. (mm)*

3

6.9 (175)

7.9 (201)

9.19 (233)

C

UltraSIL PolymerInsulated and

Porcelain Type L

Cutout

in. (mm)*

D

UltraSIL PolymerInsulated and

Porcelain Type L

Cutout

in. (mm)*

E

Porcelain

Arrester**

in. (mm)*

F

UltraSIL PolymerInsulated and

Porcelain Type L

Cutout

in. (mm)*

G

UltraSIL PolymerInsulated and

Porcelain Type L

Cutout

in. (mm)*

19.68 (500)

13.5 (343)

4.72 (120)

8.18 (208)

4.12 (105)

6

7.9 (201)

9.0 (229)

11.67 (296)

19.68 (500)

13.5 (343)

4.72 (120)

8.18 (208)

4.12 (105)

9

9.0 (229)

9.0 (229)

14.77 (375)

19.68 (500)

13.5 (343)

5.34 (136)

8.18 (208)

4.12 (105)

10

9.0 (229)

9.0 (229)

14.77 (375)

19.68 (500)

13.5 (343)

5.34 (136)

8.18 (208)

4.12 (105)

12

10.0 (254)

11.1 (282)

17.25 (438)

19.68 (500)

13.5 (343)

5.96 (151)

8.18 (208)

5.17 (131)

15

11.1 (282)

11.1 (282)

17.25 (438)

19.68 (500)

13.5 (343)

5.96 (151)

8.18 (208)

5.17 (131)

18

12.2 (310)

12.2 (310)

20.97 (533)

19.68 (500)

13.5 (343)

6.58 (167)

8.18 (208)

5.17 (131)

21

13.2 (336)

13.2 (336)

20.97 (533)

19.68 (500)

13.5 (343)

6.58 (167)

8.18 (208)

5.17 (131)

24

14.3 (363)

14.3 (363)

24.07 (611)

19.68 (500)

13.5 (343)

7.20 (183)

8.18 (208)

5.17 (131)

27

15.3 (389)

15.3 (389)

24.07 (611)

19.68 (500)

13.5 (343)

7.20(183)

8.18 (208)

5.17 (131)

30

16.4 (417)

16.4 (417)

27.79 (706)

19.68 (500)

13.5 (343)

7.82 (199)

8.18 (208)

5.17 (131)

36

18.5 (470)

18.5 (470)

27.79 (706)

19.68 (500)

13.5 (343)

7.82 (199)

8.18 (208)

5.17 (131)

* Refer to Figures 11 and 12.

**Dimensions pertain to normal-duty, heavy-duty and heavy-duty riser pole VariSTAR porcelain arresters.

Table 11. UltraSIL Polymer-Housed or Porcelain-Housed Surge Arrester/ 27 kV UltraSIL Polymer-Insulated or Porcelain Type L

Fuse Cutout/Arrester Combination Dimensional Data

A

UltraSIL Polymer-Housed

Arrester

Arrester

Rating

kV

VariSTAR

in. (mm)*

Evolution

in. (mm)*

B

Porcelain

Arrester**

in. (mm)*

C

UltraSIL PolymerInsulated and

Porcelain Type L†

Cutout

in. (mm)*

D

UltraSIL PolymerInsulated and

Porcelain Type L†

Cutout

in. (mm)*

E

Porcelain

Arrester**

in. (mm)*

F

UltraSIL PolymerInsulated and

Porcelain

Type L† Cutout

in. (mm)*

G

UltraSIL PolymerInsulated and

Porcelain

Type L† Cutout

in. (mm)*

3

6.9 (175)

7.9 (201)

9.19 (233)

25.04 (636)

14.09 (358)

4.72 (120)

10.12 (257)

4.12 (105)

6

7.9 (201)

9.0 (229)

11.67 (296)

25.04 (636)

14.09 (358)

4.72 (120)

10.12 (257)

4.12 (105)

9

9.0 (229)

9.0 (229)

14.77 (375)

25.04 (636)

14.09 (358)

5.34 (136)

10.12 (257)

4.12 (105)

10

9.0 (229)

9.0 (229)

14.77 (375)

25.04 (636)

14.09 (358)

5.34 (136)

10.12 (257)

4.12 (105)

12

10.0 (254)

11.1 (282)

17.25 (438)

25.04 (636)

14.09 (358)

5.96 (151)

10.12 (257)

5.17 (131)

15

11.1 (282)

11.1 (282)

17.25 (438)

25.04 (636)

14.09 (358)

5.96 (151)

10.12 (257)

5.17 (131)

18

12.2 (310)

12.2 (310)

20.97 (533)

25.04 (636)

14.09 (358)

6.58 (167)

10.12 (257)

5.17 (131)

21

13.2 (336)

13.2 (336)

20.97 (533)

25.04 (636)

14.09 (358)

6.58 (167)

10.12 (257)

5.17 (131)

24

14.3 (363)

14.3 (363)

24.07 (611)

25.04 (636)

14.09 (358)

7.20 (183)

10.12 (257)

5.17 (131)

27

15.3 (389)

15.3 (389)

24.07 (611)

25.04 (636)

14.09 (358)

7.20 (183)

10.12 (257)

5.17 (131)

30

16.4 (417)

16.4 (417)

27.79 (706)

25.04 (636)

14.09 (358)

7.82 (199)

10.12 (257)

5.17 (131)

36

18.5 (470)

18.5 (470)

27.79 (706)

25.04 (636)

14.09 (358)

7.82 (199)

10.12 (257)

5.17 (131)

* Refer to Figures 11 and 12.

**Dimensions pertain to normal-duty, heavy-duty and heavy-duty riser pole VariSTAR porcelain arresters.

† Dimensions pertain to 27 kV, 150 kV BIL UltraSIL polymer-insulated cutouts and 27 kV, 125 kV, and 150 kV porcelain cutouts.

www.eaton.com/cooperpowerseries

13

Catalog Data CA132026EN

UltraSIL polymer and porcelain open distribution cutout

Effective June 2015

Ordering information

To order cutout/arrester combinations complete the appropriate

catalog number shown in Table 12.

Table 12. UltraSIL Polymer-Insulated and Porcelain Type L Cutout/Arrester Combination Numbering System

Digits 8 and 9 Combo Options

00 = Standard Configuation

If E in digit 4 of the cutout number (w/ELF), Refer to Table 4 (15 kV) or Table 5 (27 kV) for ELF Code**

If T in digit 4 of the cutout number (w/Tandem ELF) , Refer to Table 6 (15 kV) or Table 7 (27 kV) for Tandem ELF Code***

* Refer to ELF fuse Catalog CA132027EN for further detail.

** Refer to Tandem ELF fuse Catalog section CA132028EN for further detail.

Digit 12 Arrester Line Terminal Hardware

0=Terminal Clamp (SS), Hex Nut (SiBrz), Leadwire *†

Digits 1 - 7 Cutout Part Number

* Standard arrester line terminal hardware.

Determine cutout part number from Table 3 on page 6

† 15 kV Type L cutouts w/arrester use 11.0” leadwire.

† 27 kV Type L cutouts w/arrester use 9.0” leadwire.

1

2

3

4

5

6

7

8

9

S 4 B 1 P 1 A 0 0

10

11

12

13

1

C

0

A

Digit 10 Arrester Type

Digit 13 Arrester Ground Terminal

1 = ND Polymer VariSTAR Arrester*

3 = HD Polymer VariSTAR Arrester*

5 = RP PolymerVariSTAR Arrester*

8 = HD/RP Polymer Evolution Arrester**

A = ND Porcelain VariSTAR†

C = HD Porcelain VariSTAR††

A = Flat Washer (SS), Terminal Clamp (SS), Hex Nut (SiBrz)*

* Standard arrester ground terminal hardware.

* See UltraSIL Polymer-Housed VariSTAR arrester catalog

section CA235005EN for further information.

** See UltraSIL Polymer-Housed Evolution arrester Catalog

section CA235018EN for further information.

† See ND VariSTAR Type AZS arrester Catalog section

CA235017EN for further information.

††See HD VariSTAR Type AZL catalog section CA235006EN for

further information.

Digit 11 Arrester kV Rating

NNote: Porcelain arresters are not available in combination

with UltraSIL polymer-insulated Type L cutouts.

14

www.eaton.com/cooperpowerseries

A = 3 kV

B = 6 kV

C = 9 kV

D = 10 kV

E = 12 kV

F = 15 kV

G = 18 kV

H = 21 kV

J = 24 kV

K = 27 kV

L = 30 kV

M = 36 kV

UltraSIL polymer and porcelain open distribution cutout

Catalog Data CA132026EN

Effective June 2015

Additional information

Refer to the following reference literature for more information:

S327-30-1 Type L Open Distribution Cutout Installation Instructions

S235-26-1 Surge Arrester/Type L Fuse Cutout Combination Installation Instructions

CP-9618 Type L Open Distribution Cutout Certified Test Report

CA132008EN Edison™ Links Catalog

327-40 Kearney Fuse Links Catalog

CA132027EN ELF Current-Limiting Drop Out fuse Catalog

CA132028EN Tandem ELF Fuse Catalog

B327-11011 Type L Cutout Product Improvements

CA235005EN UltraSIL Polymer-Housed VariSTAR IEEE Surge Arresters; Normal-Duty (5 kA), Heavy-Duty, and Riser Pole (10 kA) for MV Systems to 36 kV

CA235006EN VariSTAR Type AZL Heavy-Duty Distribution-Class MOV Arrester

CA132018EN UltraSIL Polymer-Housed Evolution (10 kV) IEEE Surge Arresters for MV Systems to 36 kV

CA235017EN VariSTAR AZS Normal-Duty Distribution-Class MOV Arrester

Contact your Eaton representative for further information.

www.eaton.com/cooperpowerseries

15

Catalog Data CA132026EN

UltraSIL polymer and porcelain open distribution cutout

Effective June 2015

Eaton

1000 Eaton Boulevard

Cleveland, OH 44122

United States

Eaton.com

Eaton’s Cooper Power Systems Division

2300 Badger Drive

Waukesha, WI 53188

United States

Eaton.com/cooperpowerseries

© 2015 Eaton

All Rights Reserved

Printed in USA

Publication No. CA132026EN

Eaton, Cooper Power, UltraSIL, Evolution,

VariSTAR, Kearney, Edison, and ELF are

valuable trademarks of Eaton in the U.S. and

other countries. You are not permitted to use

these trademarks without the prior written

consent of Eaton.

IEEE Std C37.41™-2008 and IEEE Std

C37.42™-2009, IEEE Std C37.40™-2003, IEEE

C62.11-2005 standards are trademarks of the

Institute of Electrical and Electronics

Engineers, Inc., (IEEE). This publication/product

is not endorsed or approved by the IEEE.

NEMA® is a registered trademark of the

National Electrical Manufacturers Association.

For Eaton's Cooper Power series fusing

product information call 1-877-277-4636 or

visit: www.eaton.com/cooperpowerseries.