INSTR U CTI 0 N MANUAL

advertisement

INSTRUCTI 0 N MANUAL

1ffM.17

Crank & Con-Rod

Apparatus

Crank & Connecting Rod Mechanism

INTRODUCTION

Early examplesof mechanisms

to convert an up and down motion to rotation were the treadle

drivesfor a wood turner'slatheor a tinker's grindingwheel on his barrow. With the inventionof

the steamenginethe needfor a well madeconnectingrod and crank was evidentin order to use

the reciprocatingpistonto drive rotating shaftsfor mills and railway enginesand other machinery.

Now the most commonuseis in the internalcombustionengine.

To designa crank. connectingrod and cross headit is necessaryto detenninethe velocity and

accelerationof the moving parts. Generallyit might be assumedthat the crank rotates at a

uniform speedaided by adding a flywheel to the crankshaft. A more accurateanalysiscan be

madeemployingtrigonometricaltermsto expressthe relationships,and by taking accountof the

fluctuatingspeedof the flywheel.

LIST OF PARTS

The standardset of itemssupplied(HTM.17) consistsof:

1 - Crankand ConnectingRod Apparatus

HTM.17. Page I.

Issue I. September. 1993.

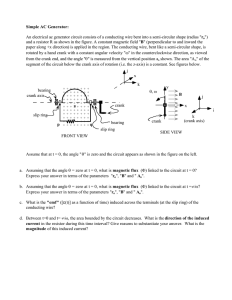

APPARATUS

This experimentalsimulation of a crank uses a circular steel protractor with a central pivot

graduatedin 10° divisionsand numberedfrom 0° at the "outer deadcentre" in an anticlockwise

sense.The crank is a bar attachedto the protractor andwith tappedholesat threeradii, 25, 31.25

and50 rnm. Thereis a bar constrainedto slide along a centreline in the mannerof a pistonwith a

moveablelinear scalealongside. The connectingrod is pinnedto the piston at one end and at the

other end has three holesfor the crank pin, thus providing the different lengthsof 200, 225 and

250 rnm. The whole apparatusis mountedon a steelchannelbaseplate with a supportthat holds

the apparatusupright if requiredfor classdemonstrations.

EXPERIMENT

OBJECT

Therearetwo partsto this experiment

In the first placethe object is to determinethe relationshipbetweenthe rotation of the crank and

the piston stroke, and to see how this is affected by the crank radius and the length of the

connectingrod.

The secondobject is to studythe link betweenthe angularspeedof the crank and the velocity of

the piston.

PROCEDURE

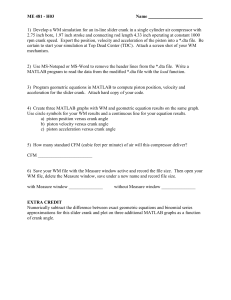

Part 1. Crank & Piston Displacements.

Set up the mechanismwith the minimumcrank radiusand length of connectingrod. Note these

valuesandtheir ratio. With the crankat the outer deadcentreadjustthe pistonguideblock to put

the displacement

readingof zero againstthe piston mark. Turn the crankthrough 10°andnote the

displacement

in table 1. Repeatthis at 10°intervalsup to 180°.

Table I

n. rod I (mrn)

rank r (mm)

tion

Crank Angle

9 (O)

Displacementx

(mm)

(mm)

(mm)

0

to

20

Repeatthe aboveprocedureusing a connectingrod of 250 mrn with a crank radiusof 31.25 and

50 mm,recordingthe readingsin table 1.

HTM./7. Page 2.

Issue /. September./993.

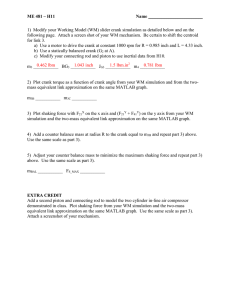

Part 2. Crank and Piston Speeds.

Commencewith the connectingrod at 200 mm length and a crank radius of 50 mm. Zero the

displacementscaleasin part 1 andtake readingsat 20° intervalsof the crank arm from 0° to 360°,

enteringthe displacements

in table 2. Repeatthe procedurehavingchangedthe crank radius to

25 rnm(somepart 1 readingscanbe copiedinto table2).

Table 2

Con. rod

/ (mm)

Crank r (rom)

Ra .

bon:

:

I

Crank Angle

CO)

I

0

I

;

~

I

40

Increment

Dispt.

(mm)

(mm)

Dispt.

(mm)

Increment

(mm)

60

RESULTS

The analytical solution of the displacementsof a crank and connectingrod can be made as

follows:

Let x be the piston displacementfrom the outer dead centre point Q, and let the length of the

connecting rod I be nr.

x = 1coscj)- rcos9 - (/- r)

and r sin e = I sin <I>

This valueof coscI> canbe derivedusingthe binomialexpansion

cos 4>=

-.sm

1

. 29 --.sm 1

2n2

Sn4

.

4

9 -

HTM.17. Page 3.

[...sueI. September. 1993.

As n will alwaysbe severaltimesgreaterthan unity the third term andonwardare usuallyignored.

hence

r=r(1-cose)-nr{l-cos41)

,

:rt

-cos9-

sin2e1

~)

!~ ':iUmlQ""

;;;",...c~:;~j,"

{"'\{"f

';'~"

\

)

The velocity is obtainedby differentiationusing

.Q!= ~.~

dt de dr

Thus

= o>r(sin 6 - sin 26

(2)

~)

Comparethe experimentalresultswith the theory asfollows.

Plot the resultsof Part 1 on a graph of displacementx againstthe crank anglee. Checkthat the

ratio of the displacements

wheren is constant(that is n = 8) is 1.25,the scalebetweenthe two set

ups. At angleswhich are multiplesof 300calculatethe theoreticalvaluesof x to comparewith the

experiment.

In Part 2 it is necessaryto evaluatethe "velocity" of the piston. Assumingthe crankturnsthrough

200per second,then the changein displacementfor each200 interval is approximatelythe mean

velocity at the mid-point of the interval. Hence plot the incrementsagainstcrank angle in

accordancewith the rule

Xn+1 -Xn

against

9"+1+9"

2

noting that half of the incrementswill be -ve. Calculate the theoretical velocity at 900 for

comparisonwith the experimentusingthe conversion

(0=

~

60

rad./s

20 r.p.rn

where N= 60 x 360

OBSERVATIONS

How well did theory and experimentcompare? Would the accuracyof the approximationfor

cos havebeenpossible

to evaluate

by theapparatus?

<I>

/ITA/. 17. Page 4.

Issue I. .september.1993.