Radiochemistry of Aluminum and Gallium

advertisement

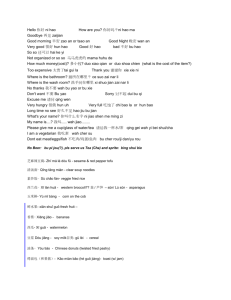

v National Research Council m NUCLEAR SCIENCE SERIES The ~Radiochemistry of Aluminum I .,: 1 ————.. —.., “s, and Gallium COMMITTEE ON NUCLEAR L. F. CUR~, Chairman Nsfional Bureauofstandards SCIENCE ROBLEY D. EVANS, ViceChatrman Maemiclmaerta Lgstinw.e ofTechnology J.A. DeJUREN, .%mretary Weatinghou,ge Electric corporation C. J.BORKOWSKI O=k RidgeNaticmai Laborawry J.W-.IRV~E, JR. MaaeachueettaInstitute ofTecimol~ ROBERT G. COCHIMN Texas A@cultural and Mechanical College E. D. KLEMA Nordmestmm Unfverst~ W. WAYNE MEINKE University ofMichigan SAMUEL EP8TELN California Institute ofTechnology U. FANO National BWSSU J.J.NICKSON Memorial Hospital, New York ofStandards ROBERT L. PLATZMAN Laboratoire de ChimiePhysique HERBERT GOLDSTEIN NuclearDevelopmentCorpx%mionof America D. M. VAN PATTER Bamcd ResearohFoundation LIAISON MEMBERS PAUL C. AEBERSOLD Atomio EnergyCommission CHARLES K. REED U. S.~r Force J.HOWA.RDMOMILLEN National ScieneeFoumM~ion ~~~~ E. WRIGHT OfficeofNavalReseamh SUBCOMMITTEE ON RADIOCHEMISTRY W. WAYNE MEJNKE, Ch.ui~ University of Michigan HAROLD KIRBY Mound Laborato~ GREGORY R. CHOPPIN FloridaStem Universly GEORGE LEDDICOTTE Oak RidgeNationai Laboratory GEORGE A. COWAN Loa Alamoa Scientific Laboratory JULIAN NIELSEN HanfoA Laboratories ARTHUR W. FA.EUIALL I@lverslvofWashington ELLIE P. STEINBERG A’gonneNationalLabormory JEROME HUDIS BrookbavenNational Labommry PETER C. STEVENSON UnI~eraivofCalifornia !Llvermore) EARL HYDE UnlveraiWofC ellfornia (Berkeley) LEO YAFFE McGiilUniversity CONSULTANTS NATliAN BALLOU Navalltadiologlcal DefenseLaboratory ,. JAMES DeVOE University ofMichigan WILLIAM MARLOW NauooalBureau ofStsndards CW2-.7 LL74YC,l CHEMISTRY The Radiochemistry of Aluminum JOHN E. LEWIS Aluminum Alcoa Company Research Physical . and Gallium Chemistry New Kensington, of America Laboratom”es Division ~” Pennsylvania Issuance Date:April 1961 ....—_’------ .— Subcommittee on Radiochemistry National Academy of Sciences —National Research Council Printed inUSA, Price$0.60. AvaileMe fromtheOffice of Technlcel Services, Department ofCommerce,Washington 25,D. C. FOREWORD The Subcommittee on Radlochemlstry is one of a number of subcommittees working under the Cmmlttee on Nuclear Science wlthti the National Academy of Sciences - National Research council . Its members represent government, tidustrlal, and university laboratories in the areas of nuclear chemist~ and analytical chemistry The Subcoinmitteehas concerned Itself with those areas of nuclear science which involve the chemist, such as the collection and d“lstributionof radiochemlcal procedures, the establishment of specifications for radi.ochemicallypure reagents, availability of cyclotron time for service irradlatlons,”the place of radi.ochemistryIn the undergraduate college program, etc. This series of monographs has grown out of the need for up-to-date compilations of radlochemlcal information and procedures. The Subcommittee has.endeavored to present a series which will be of maxlrmx’n use to the working scientist and which contains the latest available information. Each monograph collects In one volume the pertinent Information required for radlochemlcal work with an Indlvi.dualelement or a group of closely related elements. An expert in the radlochemi”stry of the particular element has written the monograph, follow= a standard format developed by the Subcommittee. The Atomic Energy Commission has sponsored the printing of the series. The Subcommittee Is confident these publications wI1l be useful not only to the radlochemlst but also to the research worker In other fields such as physics, biochemistry or medicine who wishes to use radlochemical techniques to solve a specific problem. W. Wayne Melnke, Chalman Subcommittee on Radlochemistry iii INTRODUCTJQIY ; This volume which deals with the radiochemlstry of alumlnum and galllum Is one of a series of monographs.on radlochemistry of.the elements. There Is Included a review of the nuclear and.chemical a discu~sion of features ofpartlculaq interest to the radioche”rn’lst, Droblems of dissolution of.a s~ple and,countlng techniques, and IYnally, a collection of radiochemical procedures for the’element a’s found In the literature. Two considerations dictated the decision to treat aluminum and gallium jointly In this monograph. First, and perhaps the most important, was the over-all slmllarlty In the chemistries of the elements. Secondly, a. cursory survey ,o~tfieradl,ochend.calapplications of isotopes of the elements revealed appreciably more specific applications of isotopes of gallium than aluminum and it was felt that neither element warranted individual attention in ,separatemonographs. The series of monographs will cover all elements for which radiochemlcal procedures are’perttnent. Plans Include revision of the monograph~ perlodlca.lly as new.techniques. and procedures w,ur,ant. The reader ig ,therefore encouragedt”o call ,to the atten~~Qn of the author any published pr unpublished material on,theradio”c,hemlstry of alumlnum and gallium which idght,be Include,din a revised version of the monograph. . CONTENTS >1. II. III. General Reviews of the Inorganic and Analytical Chemistry of AlumLnum and Galllum. ..... ........... 1 General Reviews of the Radiochemistry of Aluminum and Gallium ........... ..................... ..“..... z Tables Of 180tOK8 ......... ................ ....... 2 Iv. Review of Those Features of Aluminum and GalliU Chemistry of Chief Interest to the Radiochemist... 5 A. Metallic State .............. .................. 5 B. Compounds of Aluminum and Gallium ............. 7 c. Gravimetric separations. ............... ....... 10 D. solvent Extraction Separations ................ 12 1!%. Ion Exchange Separations. .............. .......17 F. Electrolytic separations. ......... ............ 19 v. Dissolution of Samples Containing Compounds of Aluminum and Gzillium........... ............ ....... 20 A. Aluminum... ................................... 20 B. Gallium ..................................... .. 21 VI. CoUmting Techniques for’ use with Isotopes “of XIuminum and Gallium ................... .............. 22 A. Aluminum Isotopes... ..... .................. .. . 22 B. Gsllium Isotopes ....................0. ........ 23 VII. Collection Procedure Procedure Procedure Procedure Procedure Procedure Procedure Procedure Procedure Procedure of Detailed Rad&ochemical Procedures.. . 1 .................... ................... 2 ............... ........................ 3 ... .................................... 24 24 25 26 4....................................... 27 5....................................... 29 6....................................... 31 7....................................... 32 8........................................ 35 9....................................... 39 10...................................... 41 v . The kadiochemistry ,, ,“ ~. .$ : . of Aluminum ,: and Gal ium JOHN E. LEWIS Aluminum Company of America Alcoa Research Laboratories Physical Chemistry Division N6w Kensington, Pen~ylvania . I. (1) (2) GENERAL REVIEWS OF THE INORGANIC STRY OF KUJMINUM AND GALLIUM N. V. Sidgwick, “The Chemical p6unds, “ oxford University Press, . London W. R. Schoe\ler and, A. R. POW1l, “The Analysis Minerals Hafner “(3) AND ANALYTICAL Elements Publishing “W. F. Hlll&rand,” Ccqrpany, New York G. E.’ F. “Appiied tion, John Wiley (5) Lundell, ‘H. h.’ Bfigh”t and Inorganic Analy’tiis,‘r 2nd E“dL,,,, and SoIiS, I“nc., New Yotk “(1953).’ “properties Laboratory Report (1937”), Lith6print Ann Akbor, “Michigan Verlag Edition (1944).’ 1 of Gallium, ” Argonne No. ANL-4109 Einecke., “Das Gallium” Leipzig of .:.’ W. D. Wilkinson, ,, Etich (1950 ). (1955). .,, . National Their com- and ores o f the Rarer:,Elements, “ 3rd Edition, J. I.” Hoffman, (4) -d CHEMI- (1948). von Leopold Voss; by J. ‘W’.Edwards, ‘,”, . (6) J. Dolezal, V. Patrovs~. “Analytical Chemistry 1517 II. Z. Sulcek and J. Svaata, of Gallium, ” Chem. Listy — 40, (1955). GENERAL REVIEWS OF ~ RADI~ISTRY OF AIUMIIQUM AND At this writing, the author 18 not aware of any ,.,,. ., .; ,. publication “&ich ‘qualifies to be classified as a review of the radiochemistry ever, a series OF either aluminum of articles, authored associates, ‘1’2’3’4) pertaining Al 26 isotope, . long-lived . ... . category. III. TABLES by R,ightiire and special mention ,... of in this ,, OF ’ISOTOPES ,.. The most field of aluminum significant recent iadiochemist~ et””al., (l)ofWe the meta8t@ble until How- to the identification . deserves ,., .,, Shnanton or gallium. ~ong-l~ved the time of the discovery devoid Iments. half-lives me A126, is~iic AS tfie autho& tiirit””:outi, the is,otope for tracer A128 ‘ ’with in 1954, ,aluminum -s .. . . ‘, of a ,. suitxle of,the to the was the ‘diec”bve~, by’ ,6.6 sec.. isotope.; only element ,,- contribution exper- aqd AI*9 isotopes -e sufficiently long to permit their use in specific applica. .. tions such “as activation smaiysis’, but this use has been confined “to laboratories fortunate enough irradiation, ,facilities. ,, currently a number. of manufacturers are offering ticipated laboratory size nmtcon that short-lived isotopes 2 to-have s,ourcea and it their own in an- such as Al*.a E@l A129 will find increased application in future radiotracer in- vestigations. T&le ISOTOPES Half -Life . 13 I OF ALUMINUM* TYPe of Decay Energy of Radiation Some Typical Modes of Formation Bee. -8.5 1.3a -7.l 7.6 BeC. 6.6 Oec. ~g24 (p,n) s+ 3.2 ie (p,n) ~+ 3.2 Mg25 (d,n) (d,2n) M926 ec axlo5y @ 1’ 100% Mg25 1.16 1.83,1.14 @‘Y 2.86 1.78,1.27 :Pj P 31 6.56 tin. ● Data obtained (d,n) (p,n) (n,2n) ----- Abundance (Stable ) 2.27 min. M926 A127 B‘Y 2.5,1.4 1.2a,2.43 from the following Al Mg (n,7) (d#p) (n,U) (a,2P) (a,p) sources: (A) Friedlander, G. and Kennedy, J. W., “Nuclear and Radiochemistry,n John Wiley and sons, Inc., New York (1955). (B) Strominger, D., Hollander, J. M. and Seshrg, “Table of Isotopas,” Reviewe of MO&!rnPhyslcs No. 2, 585 (1958). G. T., 3Q, Table ISOTOPES of Decay Type Half -Life 2.6 G=” min. 6+ ~a65 15 min. :+ ~a65 8 min. ;+y Ga66 9.4 hrs. Y D+ II OF GALLIuM* Energy of Radiation -5 0.97, 2.2,3.6 2.2 0.052 ----0.092,0.114 4.14 ----- ec ~a67 78 G=68 Ga69 ~a70 Ga71 ~a72 hrs. 68 min. 60. 5% Abundance “(stable) 21.4 min. 39. 5% Abund-ce (Stable) 14.2 hrS. ‘r ec 5.0 8 * hrs. min. Data obtained (A) \ (B) 0.09 to 0.9 1.88 zn64 zn64 (pcn) (d,2n) Id, n) Zn” (d,2n) ~63 (p,n) (a,n) ~n” (d,n) (d., 2n) 1.10 Zn’8 ~u65 *7O 1.65 Ga69 1’ 0.17,1.04 Ga69 G~~2 (n,T) (d,p) (n,p) (d,a) @- 0.6, 0.9, 1. 5,2.5,3.1 0.84,2.508,2.491 plus others 1.4 (to Ge73m=) 1.1,2.0,2.65 0.60, 2.3,0 thers ;+ ec ?’ @- ‘r ~a73 ~a74 0.83 to 4.Q3 ----- Some Typical Modes of Formation P@- from the following ~a71 g~’7~ ~e73 =74 Ge74 (a,n) (d,a] (d,p) (n,y) (n,p) (n,p) (n,p) (n,f) sources: Friedlander, G. and Kennedy, J. W., “Nuclear and Radiochemistry, “ John Wiley and Sons, Inc. , New York (1955). Strominger, D., Hollander, J. M. and Seaor9, G. T., “Table of Isotopes, ” Reviews of Modern Physics —30, No. 2, 585 (1958). REVIEW OF THOSE FEATURES OF ALUMINUM AND GALLIUM ISTRY OF CHIBF INTERBST TO THE RADIW13$MIST IV. A. Metallic State Alumlnum and ranks third trast, gallium although is the must in abundance widely with being occurs sandtha of one per cent) liquors during in trace aluminum brief is unwarranted, mention. in either point or solid of approximately exhibit a blue-greg pxn.ue acquirea coloration to air, which further oxidation Gallium The 3%. properties Selected in Table 111. for their volume deserves of its low -lting with a thin protec- oxide and gallium film upon ex- ability to retiist attack. is remarkable supercooling and will remain of may be encountered Both aluminum impervious and chemical on freezing. gallium alumina. appearance of gallium associated accounts even at ice temperatures. to yield Bo12h solid and liquid gallium 29.8°C. relatively quanti- in the caustic state because tive oxide film on the surface. quickly of gallium. at a few thou- of the physical the appearance Germanite significant of the bauxite In the laboratory, a liquid but concentrated a description 1.5 x 10-3%), source (estimated (B.1%) By con- in nature. known in bauxite, become of all metals (abundance distrtiuted anmunts proceselng while scarce the richest Gallium ties of the element abundant of all the elements. is relatively it occurs is credited CID3M- in its ability indefinitely GalllUm, change in a liquid llke bismuth, on solidification of alumAnum to undergo and gallium state expands is about are listed Table III* Property Atomic Aluminum Number Mass Numbers, Stable Isotopes Density of Solid at 20”c, g/cc Melting Point “c Boiling Point ‘c Ionization Crystal * 13 31 27 69, 71 2.70 ev ti3, ~ Aluminum as &etals commercially .2070 5.9e4 ,, 6.00 ,0.50 0.62 and, in general, creasing lution aluminum dissolve aluminum Foster(5) in.alkaline be- media. increases acids “with in concentrated Increased HC1 but the so,., with the addition of salt. Caustic so- readily. sustains of two-thirds elements, in. and temperature, except in nitric ,. relatively passive. Superpure ie difficultly reports and in dilute mineral HN09 or a trace of mercury but hot aqua regia mixture slowly rate can be markedly Gallium rate. is ioluble remains Johh Willey are amphoteric the rate of dissolution dissolves concentrated lutions aluminum acid concentration acid where aluminum and gallium in acid and as nonmetals pure 29.78 2270 . Therald Moeller, “Inorg~c CheQ)iStW.” Sons, Inc., NeW York (1952). having 5.93 659.8 Potential, Radius Gallium soluble dissolution rapid solution concentrated 6 HzSO* in mineral acide at a respectable of gallium in a and one-third ,: per- chloric acid (72%). trolytic solution num container. solves Foster of gallium in strong Although in hot nitric alkali gallium states is recognized of gallium are of primary chemist. Similarly, .tiivalent aluminum countered in procedures While pounds with pertinent aluminum various those compounds standpoint which l’he hydroxides are of interest hydroxides show l~ted but cipitates to form aluminates tannin, employed practice, (hydrated alkali hydroxides is sometimes ammonium to obtain form numerous reagents, only from a radiochemical precipitate oxides) alu- upon neutral-’ salts of the elements. in excess completely nature anznonium dissolve the pre- of the hydroxide precipi- and precipitant such as and sodium a more granular it is customary com- and gallates. objectionable bisulfite work. and oxides volubility hydroxide tates en- here. of the trivalent The gelatinous to the radio- to radiochemical and alkali hydroxides izing acid solutions in the trivalent is normally and inorganic will be considered and gallium dis- as existing interest and gallium organic Ammonium gallium and Gallium Hydroxides minum acid in a plati- (i.e., +1, +2 and +3), COmPO unds of Aluminum the elec- solutions. compounds B. discuss As in the caae of aluminum, readily three valence and Stumpf(6) thiosulfate product. to uee aluminum 7 may be In analytical and gallium hy- droxides only as intermediate products sequence since are capable a host the hydroxides of contaminating While types described and gallium by the general the radiochemist. cupferrates or organic and quinolates. provide products special care must be exercised to prevent oxide by traces are of interest involving the ig- of the oxides ~ is of 1000”c to nonhygroscopic. in igniting the lose of gallium organic as b from the reduction of unconsumed to the such as in excess are completely (GaaO) resulting Mao and me09, precipitates at temperatures which down of the are frequently Ignition performed suboxide w, procedures ueually of gallium formulas The sesquioxides of hydroxides form oxides (A1203 end GasO=) final product, ip gravimetric nition of carrying elements. aluminum only the sesquioxides in an “analysis compounds volatile of the sesqui- carbon. Halides T’& halides of gallium are hydroscopic and undergo The dichlorides and dlbromides temperatures metal. to yield ie the exception) in aqueous disproportionate GaCla trihalides ia of prm solution. at elevated plus free interest in radiochemistry. Anhydrous dry hydrogen relatively hydrolysis the respective of the trihalides, analytical (fluoride chloride GaCls, fonued by reacting or chlorine low temperature gasea, (b.p. 201”c) 8 the metal volatilizes and sublimes. with at a This property can be used to advantage compound or separating the loss of gallium evaporations during it from lees volatile as the chlorides of acid solutions the ignition exists various organic solvents anion exohange resins form a similar chloride general similarity their reparation ion exchange drogen such as XX-1. tie halides Like is produced chloride sublimes of tM chloride, into adsorbability Aluminum from the of the elements solvent by does not and ~s”depature of aluminum, its gallium by reaction or chlorine. at approximately Hydrated permits extraction and ,anhydrous of the metal with gaeeous hy- Alclg readily and volatilize chloride;A lClg”6Hao, in concentrated hydrochloric tation can be used to “separate aluminum C) ie of pri- 17B°C. alumlnum (See Section ALCla counterpart, attack ryllium. loss may occur technique. interest. A1C19 and chows strong in the chemietry While nil during is extractable from each otherv ia Among mary ion which complex species. the compounds. (5) bearing acid solution ae the GaCl~ of purifying presumably of the salt, of gallium In.a hydrochloric gallium aa a means resists acid and A1C19 precipifrom iron and be- . Sulfides ., The literature gal~ium, namely of altinum, GaeS, AIzSS.. li~ts three stable sulfides of Gas and “Gazsg, and only one sulftde The”ae sulfides 9 form by reacting & ~ ‘ metals with hydrogen temperatures sulfide and are of little Aluminum their solutions small amounts weakly HQS . and gallium Arsenic Gravimetric amounts with echeme. tanium, method chemical and gallium ration seine only AlC13.6HSO vides of the matrix aluminum such that separation by this of impurity involving snalysis element step in radio- of interest. may carry from a cold hydrochloric In in alumirequires the sepa- The renmval of alumi- the voluminous, down elements suggested the precipitation which frequently because A procedure product elements to facilitate is unsuitable precipitate a crystalline iron, ti- etc. accompany as an intermediate by activation or entrainment. Havens(’) sepa- schemes. num as the hydroxide tation “get- as “RaOg” group including rare earth metals of the element(s) gelatinous by are precipitated of elements A number The determination the removal precipitable is an excellent auznonia in the familiar analysis num and gallium from of gallium. in the precipitate usually adsorptively Separations zirconium, and gallium when HOWeVef, sulfide. elements in particular, Both aluminum ration do not form s~lfides containtig sulfide, at elevated to the analyst. of ga”llium can be separated acid solutions hydroxides interest are gassed with hydrogen ter” for small c. or stiifur vapors by coprecipiby Gomh of aluminum acid-ether and as solution, is comparatively pro- free of copracipitated contaminants. in separating alumlnum Aluminum a dilute acetic (NH4)aHP04 will be procedure can be employed from gallium. may be precipitated acid-sodium but elements acetate as the phosphate solution from with exceae such as iron, titanium and others found in the precipitate. Phenyhydrazine parating *ich ~is aluminum accompany is a useful from divalent precipitant iron and other it in the ammonia for se- elcsnents group precipitation pro- cedure. 8-hydxo~quinoline tatively precipitates in the pH range of”4.2 A1(CBH61!?O)S, can be weighed quioxide, acidic AleOg. or alkaline contaminating cipitated media el~ts has become 6 and 9 in section H~S04 ing an excess following um camphorate is also pre- 3, 5, gallium (approxtiately The 9alliUm quantitatively 10%by volume) is collected us- as GaeO= of the cupferrate. cobalt reports tbe separation and others additions Gallium of possible (See Procedures will precipitate solution Hopkins(g) zinc, cadmium, Gallium in either and its use in radiochemical widespread. of reagent. ignition knowledge to the ses- VII) Cupferron from dilute or ignited is” desirable. quanti- The precipitate, is not specific and prior by this reagent aeparationa to 9.8.(8) directly The method aluminum to acetic with camphoric from acid or sodi- acid solutions. can be separated Kl of gallium from aluminum and chrom- ium by precipitation as the ferrocyanide. precipitate witi” gallium separation. Following gallium D. removed reprecipitated solvent from acid solution, ignition tate, the iron can.be Zinc, by familiar technitiea ., and g.alliqm form extractable Steinbach chloroform at PH’S of 4 and 2, res~t,ively. ,: Void of the gallium and gallium et al.(ll) crystals to distinguish were g~llium Bolomay and Wish(12) at pH 5.5 by 0.02M that aluminum oroacetone solution .by microscopic the extraction TTA in benzene. .. Eshelman(13) extracted pH 5.5 to 6.0 with solution and gallium. (TTA) (TTA) in 4-methyl-2-pentanone. an acetate-buffered cupferron of of alu,ob- from an acetate- O-I-M 2-thenoyltrifluAlternative ly, of PH 2.5 to 4.5, c0ntainin9 ,,,. with 4-methyl-2-pentanone, .12 90% frop aluminum. report is selectively . to extract of aluminum identified in ,, used acetylacetone b. Thenovltrifluoroacetone ,.,. ..’ buffered by.acetylacetone from 61% HC1 solution Ga-acetylacetonate chelates’ Frqiser (10) de~Crfie. tbe -d of aluminum sened and the Separation extraction min~ precipi- Acetvlacetone acetylacetone. exanQnation prior as the hydroxide. Extraction ..- Alym$num with requires of the ferrocyanide 1. ,.chelate Complexes a. which wmld was used. Morin (3,5,7,2,4-pentahydroxyf lavone) c. Morin acidic media amyl, butyl d. reacts to form complexes and cyclohql lective with aluminum and gallium that are extractable in by (14) alcohols. 8-Qu inolinol Although complexes with both (Oxine) aluminum form extractable the extractions 8-quinolinol, and are subject and gallium to contamination zwe not se- by interfering iom. Luke and Campbell germanium 6N HC1, and germanium determined dioxide metrically cyanide solution. in tbe yellow Kambara for extraction Gallium oxinate can be extracted from from photo- extract. discuss the theory by chloroform. report completely (PH 3.0 to 6.2) salt solutions solutions was determined and Hoshitani(16) ‘Moeller “&.ndcohon(17) oxinate) extraction oxine-hloroform of aluminum and by ether extraction followed by an oxine<hloroform alkaline gallium that gallium (as from acetate-buffered by shaking with chloroform of 8-hydroxyquinoline. Lecroix(18) could be separated as the oxlnate demonstrated from 104 parts at pH-Z into that one part of aluminum ,, chloroform. of gallium by extraction e. Cupferron @mmonium droxy lamine) The extraction chloroform has been Salt of N-nitrosopheny of alundnum investigated as the cup ferrat by Meunier (19) and Ba and Furst. (20) f. Sodium Diethyldithlocarbamate Cherniko and Kobkina(21) of the galliUIU complex ing excess acetate The extraction at pH-3 to preclude of aluminum with the above reagents quantitative lar reagent 2. for a specific via an ion pairing of gallium, partner of gallium halides selective a to refer to t the suitability of metallic elements complex of a F is made in the aqueous Ae an example, in the c is that gal”lium forms an ext via incorporation Milner for application. mechanism. of the ion pair of the co via complex ia cautioned of a metal the consensus able complex extract Complexes The extraction ble by the formation decomposition Is not necessarily . to determine Ion Aseceiatfon the into a ethyl acetate en and gallium agd the reader ginal publications report (#, of the metal in the ani GaC14-). et al. ’22) investigated from acid solutions and obser,ved that the chloride the extracta with organic was extracted ly than either the broriide or iodide. 14 sc more effl It was also fou that extraction of the chloride as the customary diethyl red in their wrk gallium involving was recovered after buffering ate buffer by precipitation (III) and Ga extraction While this procedure, indicated The Al Au acid form- of chloride organic solvents aluminum in the following (111) showed negli- complexes of gallium considerable to separation is excellent, by as tabulation: HC1 Ethyl Ether 7M HC1 Isopropyl 3M HC1 Tribu@rlphosphate (III), to mention from HC1 solu- has received Per Cent Extraction elemsnta from 20M respectively). is not amenable the extraction the extrac- complexes (III) and Ga 6M Additional with camphoric (III) as fluoride Aqueous Ga III l%e investigated (i.e. 0.2% and <0.05%, into various attention. mixtures. formic acid-ammonium have and Herman The extraction tions with ketones but ether was prefer- gallium-uranium the solution HI’ into ethyl ether. gible solvent, using of PH-3.3. Bach tion of Al ether was as efficient Ether such as Sb (V), As a few, are likely Reference 97 (24) >99.9 (25) 99.9 (26) (III), Ff3 (III) and to extract with the gallium. The extractabili~ into ethyl ether has been of a number investigated 15 of metal bromides by Bock et al.(27) While Al tent, 95 to 97% extraction of gallium (III) was observed to extract solution was found. the gallium nants would be accompanied The extraction or gallium by a variety (V) and Fe extraction, of contami- (111). and galliti of aluminum has not looked promising. ex- from 5 to 6~ HBr As is the caae of chloride such as In (III), Sb of aluminum to a neglig~le Kitachara(2a) as Iodides found no extraction from 6.9M HI solutions into ethyl ether. B~k(*9) h as made of the extraction a function of metal of NH4SCN mum extraction that best tration thiocyanates concentration. (approximately (III) exhtiited999% gested results In the aqueous are extractable amyl alcohol. Sundaram butyric extraction ethyl ether (III) showed from 7MBN&cN. when as a maxi- while Ga It is sug- the HC1 concen- Is 0.5M. has obsemed lium benzoates into Al are obtained phase Investigation 19%) from 6& BN4SCN extraction Johnson complete a comprehensive that aluminum by ethyl ecetate and Banerjee(31) report of aluminum by chloroform and gal- or butyl essentially from aqueous acid at pH of 9.3 to 9.5. White(32) reported complete extraction of Ga (0.11.i (III) from 7M’Hc1 with tri-n-actylphosphine oxide. in cyclohexane. ) (III) was af- fected complete from 7~ HC1 using n-hexylphosph ine oxide. company or aluminum in both extraction of Al a O.I.M solution A variety extraction 16 of tris-2-ethyl- of other elements procedures. ac!- The majority section on solvent of the material extraction presented was taken in this from the book by Morrieon and Freiser. (33) E. IOn Exchange separatlon~ The ion exchange is ideal for trace element radiochemical work. approach partitions Aluminum ‘separation from each other from a host of other The investigator exchange influence technique elements by ion exchange between (Dowex-50 resin an anion or cation will likely Ti and Fe reports (III) in Dowex was employed by Kejima and aluminum. Kcl mixture to Al of Al and the aluminum In recent years, with lR-120 column eluted with removed anion in uee for effecting 1.31Q (III) from 2N HC1. Ti- in the H + form to separate iron a O.lN KI-O.15N with 2N HC1. exchange elemental 17 with (III) with the same acid and Kakihana(36) The iron hs a Iridium was was removed 50x8 by SlutIon An Amberlite ex- by elution HC1 solutions. the separation and iron elute prior concentration. a cation in H+ form) to effect iridium and germanium concentrated Strelow(3’) increaaed to techniques. conditions eluted with 0.4N Hc1 and the gallium tanium in are amenable and Sandmann ’34) utilized of gallium, increasing Hcl. required his decision. separation with separations and each in turn can be separated and experimental Klement change often and gallium has to choo~e procedure to c@.mical procedures have . separations pre- viously assigned metallic tively to cation elementB charged complexes exist complex are strongly and Nelson(37) sorbability discuss of Ga exchange procedures. (or may be converted ions in aqueous adsorbed in to) as nega- solution by various detail Many and these Kraus resins. the mechanics (III) as the anion complex, of the adGaCIA-, from that Al (III) Hcl solution. Iccaus, Nelson and smith(3a) undergoes negligible exchanger of the polystyrene-divinylbenzene (III) exhibits adsorption showed strong an HC1 concentration adsorption, of 7M. (III), In (III) and T1 the aid of Ga67, on Dowex-1 (strongly basic type) while the maximum TW separation (III) on Dowex-1 occurring of Al Al [Al (III) appearing first 20 ml. of eluant (III) following 50 ❑l.] while.Ga was used (III) was eluted witl~HCl to remove T1 basis resins from halogen for specific exchange media behavior in the next and 4M HC104 separations end Nelson fromadsorbable as the elements (40) (41), have of the majority (HC1 concentrations on anion ex- acid media has served such as zirconium ‘39)and others. Kraus in the (111). The fact that Al iIS not adsorbed change with (III) and In (III) were eluted wiiih 7gHcl and In at (III), Ga was observed In114 and T1204 tracers. Ga ranging extined of elements the SIlioll in chloride from 0.1 to 12M). Faris, (42) in his investigation of the adsorption charac. teristics of some fifty elements on Dowex 1-X1O resin 18 - showed 67 that Ga .[111),‘as Gis ,,tracer, ehibits adsorption from “1, 2 “&d 4~ “~. coefficient Al of approximately 5.5 for Ga (III) shows a distribution 1.5 for lM HF &ich He retirti a dietributlon (III) in 0.4M ~. coefficient decreasee .negligtile to zero.at of approximately approximately 12M m?. Marinaky Kruger(+) and Eichler(43) give specific. ion exchange tion VII] for separating produced and GrUVermSn gallium VII include carrier isotopes. procedures free amounts Procedures the use of ion exchange and (see Sec- of CyClOtrOn 7 and 10 in Section” in the separation of ~126, .. ,, F. Electrolytic Separation The cathodic aqueous solutions electrddeposition of its salts provides an efficient elements such as alumifiumand from aqueous media.” nmans while (GaClg, Gae(S04)g, of separating sodium which other &laments, iridium, zinc and lead to mention gallium, the nuntmr by controlled electrolytic! methods. for example, elements can’be and other A qm.ntitative recovery difficult not a serious lbdtation Electrolysis, in conjunction to achieve in most radiochemical with used procedure from do not deposit elactrolysia by electrolgaiia may prove is a frequently gallium fractional for purifying 19 from NaGaoa) a.few, may codeposit of interfering potential of gallium ~~ wiEtI limited seleotive of gallium but this iS application. crystallization, gallium. ~45) v. DISSOLUTION AND GALLIUM A. Aluminum OF wLES CONTAINING COMFOUNDS OF ALUMIHIJM ores and Refractory Aluminous Materiala 1. Bauxite acid mixture. bauxite In caaea where fusion procedures borax fuaion~ conducted (46) ia ob- is to be determined la usually mind. For inetance, mining silicon, media via in familiar attack in acid of a solution objective ia Interested of the aanple may result formation AlloYa by the ultimate in in deter- ia desirable, in an incomplete to ailic,a and silicon of procedures can be diaaolved and the choice if the analyat since acid decomposition Solution or carbonate- are familiar and Aluminum dictated an alkali tion of the silicon Biaulfate and ita alloys hydroxide hydride ia oxide. solution of Aluminum procetie aalta dissolution in platinum aluminum Aluminum silicon aillca silica (aodiuiu carbonate”, alkali pyroaulfate ia to be recommended. or alkaline when of foreign refractories, etc.) for diaaolving by an HF-HES04-HN03 method and the presence or calcined 2. readily This La a preferred to be eliminated jectionable. ia attacked losaea oxida- due to may be encountered. aluminum mstal proceeds well in Hcl, $ HF and otier binary by HzS04, halogen HH09 and other acida. common The attack inorganic 20 of the metal acids used aepa- is S1OW, but rately by the addition agent of a pinch in the industry ndxture acida solution reagenta ra~er in dry hydrogen formation of anhydrouB relatively The reaction attacked aluminum by’organic chlorine chloride (slightly metal regia or sodium hydroxide IS a of organic by heating or oxygen-free resi6ta whiah above the metal with the mblks at a 180”c). attack by HC1 but salt may be used to accelerate high purity the metal re- utilized. low temperature High purity A etandard B1OW and solution la readily chloride can be hastened salt. for dissolving is not cu~tomarily Aluminum B. of mercury of HC1, HNOS and HaSo4. 1s, in general, mercury in these media the action. are also effective a Aqua reagents for aluminum. Gallium 1. “&es and RefractoW GalllUm eximte CQmPou.nd?l in trace quantities of ores such as germanite, zinc blende. bauxite, AS in the case of aluminum, tacked by acid or acid-mixtures, flux fusion procedures jected provided temperature during the oxide ham been calclned 1000”c, and the ores are at- or the conventional of gallium, in alkali hydroxide to high iron ores salt may be utilized. The sesquioxide soluble various in a number fugion procedures Gago9, it has not been drying at temperatures are necessary ble. 21 is easily operations. in excess to render mbIf of it solu- 2. Gallium and Gallium The volubility sent in aluminum in commercial separates as globules chloride which subll.mes. LMWAS ,, such a procedure for separating 23O-255”C (b.p. GaCl~ Gaclg and the metal soluble “in HC1.” most readily by aluminum, gall~um to form the anhydrous s.nd BrldgTMUUI(48~ adopted gallium from in&ium ‘“ and in a stream of dry chlorine at - 215-220”c). ,. ,. VI. pre- in that solution in ma~sium Like with dry HC1 or” chlorine zinc by ualaklllzing in solid is attacked hydroxides. whether is different are “not readily gallium aqua regia or alkaline exists acid, “tine which In generai, of gallium, alloys, aluminum, gallium in hy&ochloric rea& behavior or magnesium dissolves will A11OYS COUDlTD9G TECHNIQUES AND GALLIUM FOR USE WITH ISOTOPES OF ALUMINUM ,“ A. Alumlnum Isotopes : ~ “- ., ..,’. to the table of alumlnum isotopes (Sec.,. ,. ., tion III) it is obse~ed that the half-lives fall Into two Refering ,’. of half-life less than one hour, ,,, “.’ ,’ snd one isotope with an extremely long half-life of approxi,. mately 8 x 105 years. For purposes of this discussion, only categories: six isotopes the isotopes of mass Al&num2B ~- emission 26, 28 and .29 will be considered. .. . 2.3 @l/2 approximately ,, min.) decays “ by (~- 2.86 mev.’j followed by the emission of a pri,. mary game ray of 1.78 mav. While this isotope “can be assayed ,,. ,.!. by a conventional Geiger-Mueller counting procedure, a ganmIa- 22 ray acintiilktion ing counting Gu&nn :e,pectrometer provides procedure in view or t- and Wagner ’49) describe scheme for determining ploying discriminat- short half-life an instrumental aluminum a scintillation a rapid, in a variety involved. neutron analysis of materials em- apectrcmeter. ,. Al&num29 ganma.raya devices. (tl/2 = 6.56 min.) “=ta and is amenable Spectrometers to advantage interfering ,., measuring &d detection and propaitiorial &ounters”may be used its ratilat”i.on in activities. !rhe;giound’ etate A126 ,,, ,., beta to assay by conventional for discriminately the presenceof boh isotope, a half-life with timated .at apprQxiinately 8 x 105 years, (2) ~ts ,. es- 1.16 llMSV- ,. positrons, EC radiations and gamma rays with energies of 1.83, ,,, .’ follotirig 2.97 and 1.14 mev. Kohman et al. (4)’de~cr~e’tk assay procedures: .. (1) Routine - “positrons by Geiger and proportional counting procedures. (2) specific - gamma scintillation a~ctrometer for. counting: tbe 1.8?msv. gamma ray. (3) Absolute - measurn poeitrwm in 4 pi counter. .. . . . .. (S~le efialosed in aluminized exclude electron-capture Mylar foil ’(1.O mg./cm.2) . ,. \ radiation.) . B. Gallium . Isotoms It iS seeh galllum to isotopes frOm Table II that the m@ority decay with P “and y ray emissiohs ‘sufficiently energetic proportional and “scintillation counting which to be assayed by’ conventional procedur&B. ., 23 of are Geiger,’ VII. COLLECTION OF DETAILED IU4DIOCHEMICAL PROCEDURES Procedure 1 Gallium Source: mental Ernst Bleuler and George Nucleonics, “ Rinehart J. Goldsmith, and Company, “Experi- Inc., New York (1952) . Reagents: HC1 - 5.45M, ,HNos Cone. NH4 OH - dilute Ether H=S Irradiation: clea cu target 10 mg. or lees. 1 - DiaOolve Step 2 - target 3 ml. cone. (Caution: Step 3 - Saturate shaking mtiutes. Final - approximately Activity Step COIIC. (thin foil) bombarded 5 microampere for about Add 0.3M, in 1 m+. cone. sample weight 200 counts/aec. HNOs. HC1 and evaporate lowheat with a parti- to -as. to avoid bumping.) 25 ml. ether with in separator 25 ml. 5.45~ Hc1 by funnel. save both ether and acid portions. Step 4 - Cool evaporated to saturate Step 5 - Extract remove in clean ether er because with three Cu and Ga. 1 ml. portions Combine ether r3eparatory funnel. solution cu which and add the acid used ether. to remove fractions 6 - Extraat the said solution of ether Step residue with may have 10 ml. 5.45M Hc1 to dissolved of tie water which the ether. 24 in ether is dissolved layin Procedure 1 (Continued) step 7 - Evaporate ether solution to dryneaa for gallium aaeay. Skep 8 - Evaporate aqueous solution to dryness; dissolve C!u salt in 15 ml. 0.3~ ECl and saturate solution wifi HsS. Step 9 - Coagulate copper sulfide precipitate and filter on fine filter paper. hol, followed with by heating, D= wltb alCo- ether. Procedure 2 Gallium Source: Same as for Procedure Reagents: See Procedure Irradiation: several Deuteron microampere 1. 1. btiardment minutes. of zinc foil target ActivLty for - approximate ly 200 coumts/sec . The chemical gallium except activity precipitated with ~am) ether duplicates that the tsrget is again rmmved processing of the target steps is dissolved by solvent from neutral directly extraction solution and the ZnS is assayed fraction containing 1 through gallium for assay. 25 to remove 7 of procedure in ml. into ether. with HaS Gallium zinc ia (Eiclneutralized for zinc activity. is evaporated 1 The to dryness Pro&sdure 3 Qalliuni. J. A. Marin,slw Source: c!hem.& and, E. Eichler, 223:,(1960). 2 ml. uranyl Target: nitrate u/ml. ). solution (approximately 2 minutes time: ratory Reactor. x-10 1 - After 850 mg. .. ,. Irradiaticm Step J. Inorg. Nucl. in o+ Ridge National Labo- ,. 2 minute decay period very short-lived isotopes, to permit solution decay of is trans- ferred to a separator funnel containing (approximately Ga carrier, 20 w.) 20 reg.) Ba aarrier proximately 2 ml. 2 ml. (ap- and 6 ml. 12~ HC1. Step 2 - Solution with 30 sec. ether - “15to rated from aqueous provide Step is contacted (12.8 WY phase fission-yield 3 - Ga is back extracted 12 ml. of diisopropyl ali@ot Ba140 is sepa- sampiea “to ,, standard.) into 10 ml. HaO after wash- ing ether” layer witl”three 5 mi. pofiions’of 6K HC1. Step 4 - Solution “is made lE in HF” and then passed Dowex-1 anion exahange compressed lected Step column air ‘toadsorb Me). tirough (with the”aid Effluent of is col- in 5 ml. co”nc. HBr. 5 - Acid mixture evaporated 26 just to mess. Residue Procedure 3 (Continued) is innnediateiy dissolved and the Ga extracted In 10 ml. chilled wI* 6~ HC1 10 ml. cold diisopropyl etier. 6 - step Ether =tract of 63 HC1. Step 7 - Aqueous ia washed Ga is back sample twice with extracted 5 ml. portions into 10 ml. HzO. 18 made 0.3~ in HC1 after addition of 10 mg. Bi and approximately 3 mg. MO scavenger carriers. Step 8 - Bi aad MO are precipitated tate are removed. with H2S ati precipi- Additional MO ia”precipitated with a-benzoinoxime. step 9 - Filtrate is made slimtly Ga in precipitated Step with 10 - Ga-8-hydroxyquinolate for activity baaic with 6E ~oH 8-hydroxyquiholine ia filtered’on p“a~r and reagent. disk measurement. &cedure 4 Gallium Source: Irwin J. Gruverman Radiation and Isotopes Isotope: Ga67 Target Material: Product: and Paul KXuger, ~, No. 1, 21 J. Applied (1959). zinc 98+% G.67 pure HNOS or HC1 solution. combined gallium activities in Procedure 4 (Continued) Product Reactions: ,, Chemical separation from HN40H 2- (d,2n) ==67 Principles: Ga is carried cu is retained on Fe(OH)s in supernate. KOH solution. Fe IS K and residual Cu 80+% 6 HOLUS zn target, minhum Step Zn67 by ion exchange. Time Required: 1- ~a67 from strong are separated Step (d,n) solution. precipitated Recovery: Zn66 approximately of HC1. 5 g., is dissolved Solution 20 mg. each of Fe la diluted (III) and cu in a to 100 ml. (II) carriers are added. Step 3- PH la adjuated ed to digest Step 4- Precipitate solved Step 5- to 5.5 with lmhoH: solution allow- 15 minutes. ia removed by centrifugation in .HC1. A second precipitation ed to inmre separation Precipitate la diaaolved Hcl: volume is adjuated and &hsla perfom- from’ Cu. in a minimam amoumt to 20 ml. with H~Oj of an ex- teas of KOH is added. Step 6- Heat to boil; fugation. gallate Step 7- precipitate Supernate, ia separated which contains by centri- activity aa ion, is reserved. Precipitate cipitation la dissolved is made. 28 in HC1 and a second pre- Procedure 4 (Contkued) Step B - supernateo excess Step HC1 is added 9 - Solution has been volumes move are combined, is passed neutralized to make through conditioned wI* solution Cu. 3y in HC1. a Dowex-1 3~ HC1. of 3N HC1 are passed K and residual with HC1 and column Three through which column column.to Ga is eluted re- with 0.2~ Hcl. Step 10 - Solution is evaporated matter is r&oved peated evaporations to ne~ dryness: by evaporation organic with HNOS. with HC1 convert Re- the gallium to the chloride. Procedure 5 “Gallium source: H. J. M. Bowen, and Isotopes Target &, 227 Time: J. of Applied Radiation (1959). 0.3 g. tomato Material: Irradiation Internat. 12 hours seeds; 5 g. blood. at approximately 1 x 1012 n/cm2/sec. Time Required: (MO + Ga) approximately 4 hours for 8 sam- pies. Step 1 - Seeds are dissolved is dissolved in hot drops perchloric in hot fuming HMOS. fuming HNO= plus acid. 29 Blood a few Procedure 5 (Continued) Step 2 - Carriers: 10 mg. MO as ammonium Ga as gallium nitrate. Holdback molybdate; 5 mg. carriers: Cu, CO, Mn, P snd Y. Step 3 - Solution ia evaporated to approximately 1 ml. Made up to 10 ml. and 6E In HC1.. Step 4 - Solution is transferred shaken with equal is discarded; step 5 - Ether to separator volume ether is waahed layer Is extrected Aqaeous layers of ether; aqueous twice with twice with are combined funnel end layer 63 HC1. 5 ml. HsO. and boiled to rexmva ether. Step 6 - Aqueona fraction precipitated Step 7 - Supernate and made 1.smade with to four times with Step 8 - Gallium chemical Yieldz Ga) is boiled with potash and scavenged as 8-hydxoxyquinolate acetate buffer 50-70%. to remove HRS three Fe(OH)~. is precipitated an ammonium is anunonium sulfide. (containing alkaline 2~ in HC1 and MoS solution in of pH-6. Chief contaminant in galli%m frti- tion identified as P32. 30 Procedure 6 Gallium Sowce : man, -al. Ridge, W. A. Brooksbank, G. W. Leddicotte Cbam. Div. , oak Ridge National Tennessee, J. Phys. Chern. ~, Gallium 1 - Aluminum target of concentrated concentrated evaporated Step LSbOratOrY, 815 (November Oak 1953). in Aluminum 0.1 to 0.2 g. aluminum in quartz tubes . TUgOt: Step and H. A. Mahl- 2 - is diseolvgd HC1. in small Standardized HBr are added Smotit Ga carrier and the solution and IB to dryness. Reeidue is dissolved tracted three in 6~ HC1 and solution times with equal volume is ex- of diethyl ether. step 3 - Bxtracts are combined the gallium of H30. is back and waahed extracted with 6q HC1 and into an equal volume Cu, Fe and Ba holdback carriers are added to the solution. Step 4 - Cu is removed by Has precipitation; raved Step 5 - After by precipitation filtration, the gallium diethyl Step 6 - Gallim with NaOH solution 1s made Fe and Ba are and NasCOs. 6~ In HC1 end is extracted with an equal volum of ether. is back layer is heated extraoted to expel 31 into Hao and the aqueous equilibrated ether. - procedure Step 7 ‘- A few ml. of B-hydro~quinoline in 2M acetic quinolate acid) 8 - Afti& dried with solution (50 g./l are added and gallium IS precipitated of 6U ammonium Step 6 (Continued) with dropwise 8-hydroWaddition acetate. filtration, precipitate for 15 minutes scintillation is washed with HaO, at 11O”C, weighed; counted detector. Procedure 7 Aluminum Sourae: R. A. Rightmire, T. P. Kohman Internat. J. Applied Element: Al” - Carrier-free Separated from: D8COnt8d.natiOII Chemical& Radiation @gnesium Faator: end IOotopea ~, 274 (1957). A126. (U bombarded). >108 and Equipment:” aa follows; and A. J. Allen, Polyethylene ion exchange aolunwe 2 - 35 cm. x 1 cm. 1 -60cm. DO~X-1’ xlm. (1OO-2OO megh) ing with Dowex-50 12~ HC1, with iron, then with - coated by waeh- followed by H50. - prepared (50-100 msh) ing thoroughly Glaemiare - prepared by waeh- 6N HCl until “free of HaO. with a thin silicone ., film. 32 Procedure 7 (Continued) Freshly distilled H20 and freshly prepared NH40H were used througkmut. Step 1 - Dissolve activity from megneaiun””t&get with 6N . HC1. A. Step Separ ation,of 2 - Al from Mq and Na Add Hao until twice methyl volum Of Be+2, Ca+2 red. indicator. end point is approx-tely 6N HC1 added in Step 1. of the amount 10 “&g..‘e~h ~d Add NH40H to precipitate 3 - centrifuge; Add SC+3 carriers to methyl Be(OH)~ at 50-60”C “Yor 10 minutes Digest Step solution wash precipitate””with plus red and Sc(OH)g. tid cool. 0.00IE NH.40H. :,.. B. step Purification o! A126 4 - The precipitate xl + O.~ anion 5 - ~ o.~ Be2+ column wlkh + O.~HSCZO~l. is eluted in 100 ml. of 0..l5~ and introduced wi& onto” a s=11 had-been’ filled to a of 20 cm. tid washed (0.12~HCl Step hs dis~olved HrX%04 exchange height ,. with 500”ml. ““See Note 50 “ml. of HSC=04), or ur&il no precipi”tite of 1. (0.”15g HC1 + Of Be(OH)a forms In the elute upon addition of NH’40H. Step 6 - The Alw is eluted the eluate with is’dihtdd 50 ml. of”12~HCl,” with ,,., Few is added. 33 and’ 100 ml. Hao and 30 mg. Procedure 7 (Continued) Step 7- The solution is made the precipitate slightly basic is digested with NH40H, at 50-60”c for and washed, and one half ta one hour . Step Step 8- 9- The precipitate is centrifuged the solution aupernatant The precipitate is dissolved HC.1 and the solution cation exchange a height and washings with Introduced column discarded. 50 ml. 0.50~ onto a small which had been to 20 cm. and washed filled to thoroughly with Hao. Step 10 - The flow rate is adjusted the column is washed Step 11 - Fe3+ and Alw column with are eluted volumes to LO drops/minute 50 ml. 0.80x Hc1. with in a volum is added, and the solution step 13 - Vanadium by heating carrier ing 10 mg. vf405 the above at 70-80”c. see Note aoluti.on is prepared j+3 5 ml. 12E HC1, to one 2. by dissolv- and is added to solution. of dilute NH40H, and washed with a slight and 151s precipitate excess centrifuged with H20. Step 15 - The precipitate solution equal to the above concentrated Step 14 - The soluti’on is made basic and me of four a minimm 5M HC1. Step 12 - Concentrated’ HNOS half volume and solution is dissolved satuxated is introduced 34 in 10 ml. 12N Hc1, with HC1 gas. The onto a large anion-xchanger Procedure 7 (Continued) Step column Which had been prepared height of 50 cm. and washing 16 - The flow rate i~ adj u~ted the carrier-free volumes M2’ la of 12~ HC.1. by with filling to a 12~ HCI. to 10 drops/minute, waehed See Note out with and 1.5 column 3. NOJ?ES (1) The flow rate was adjusted (2) Venadium (3) To convert is converted HNOS were to it8 highe~t to a chloride added, sure of A1C$9 solution, and the solution in a silicone-coated done cautiously to 8-10 drops/minute. beaker. because oxidetion 200 ml. of eonc. evaporated The evaporation of the significant at elevated state. to 10 nil.. must be vapor pres-= temperatures. Prooedure 8 Galll- Source: Radiation G. M. Iddinga, LabOratOry, Purification: old solution University Livermore, of California, California. 109 atoms of Ga 72 isolated of 2.6 x 1014 foreign radionuclides when fr~ fissions she-d followd through liveai. 35 Lawrence a 36-hour no detectable eleven balf- Procedure 8 (Continued) Yield: step About 70% 1 - Toa6g HC1 solutionof 125 ml. Erlenmeyer 2 - activities in a flask, add 10 nq. Ga carrier and 1 mg. Te+4 carrier. Boil minutes. should be approximately Final 20 ml. Step mixed solution solution for 10 (Note 1) Cool and transfer cal, open-top, tached solution separator bmediately to a 60 ml. cyli&rifunnel below (with stem de- the stopcook). Add 4 ml. cone. E@l to the 20 ml. of 6~ HC1 to make solution 73 in HC1. isopropyl ether and extract by rapid stirring stirrer this step (paddle) separation 3 - Drain minutes. Step RePeat Step aqueous time of layer. Wash organic 15 ml. of 7X HC1 for two the Ga from the ether with approxi- layers approximately for two minutes. with 10 ml. of water in a 40 ml. centrifuge 5 - Add 5 rng. Fe+3 carrier. water bath Record rod 7~ HC1 wash. extraction bine water minutes. glass of Zn 72 from Ga72. 15 ml. of water the back 25”ml. the Ga into the ether a rotor-driven approximately 4 - Back eX&act mately with for tm and discard layer with Add approximately 13”(0.U 3 minutes Add and comcone. 10~ Na@. mtil in OH-). to coagulate 36 Repeat pH IS Heat on boiling Fe(OH)g ppt. Procedure 8 (Continued) Cool to room temperature. the Fe(OH)3 Step 6 - Tr~sfer separator funnel previously). 7. (identical (The solution adding the formic and extract phase by rapid Immediately peat 1~ NaoH wash. proximately Wash organic layer during 9 - Combine water aqueous organic lay- layer and re- layer with ap- for ten seconds. approximately extracting these washes. the Ga with 15 ml. of Repeat be- from the orSee Note 2.) approximately for 20 minutes. 15 ml of Hcl back cone. for 20 minutes. cone. until Wash organic (Step 7 should be done quickly ganic extraction Step wash Ga is slowly back cone. HC1 30 ml. of 0.40~ TTA layer. drain layer w%th extract at pH 3.3-3.6 by 15 ml. of lx NaoEi for ten cause 8 - Back formic for 15minutes. 15 ml. of,water 1~ HC1 twice. Step Add aqueous approximately seconds. of cone. the Ga into the TTA-benzene stirring and discard with the pH is approxhnately is buffered acid.) the one used amc$unt (4 or 5 drops) this,amount acid. er with Add a measured Then add twice 7 - Drain to a new 60 ml. cylindrical formic acid until in benzene Step and discard precipitate. the supernate of cone. centrifuge HC1 solutions the solution (add approximately and dilute is approximately 21 ml. of water “37’ it with 7g HC1 to 30 ml. of Procedure 8 (Continued) cone. HC1). Transfer ml. cylindrical, open-top, (with stem detached funne1 separator immediately the stop- below Add approximately 30 ml. of isopropyl cock) . ether to a 125 7g HC1 solution and extract the Ga into the ether by rapid stirring for two minutes. step 10 - Drain and discard aqueous layer. Wash organic layer with approximately 15 ml. of 7~ HC1 for two ndnutes. Repeat 7~ HC1 wash. Step 11 - Back extract the G“a from the ether with approxi- mately 10 ml. of water for two minutes. Repeat the back extraction with approximately 10 ml. of water. Step 12 - Combine water fuge cone. rated Add approximately solution the solution - Filter filter paper Step 14 - Powder m@m Heat Ga(OH)g until in boil- for ten minutes. No. 42 filter 2 per cent NHAN09. a poreclain crucfile for at 9OO-1OOO”C. the Gazo3 “hat”. ing plate.and and/or in with dropwise pH-6 . with Whatman Wash precipitate one hour 0.5 ml. of a satu- Add NH40H to precipitate out Ga(oH)3 paper. Ignite of NH-. is approxtitely ing water bath Step13 of Ga in a 40 ml. centri- solutions and transfer Weigh. count it to a taxed alu- Mount hat on “aluminum countthe 14.3-hour ganuna counter. 38 Ga72 in a beta Procedure 8 (Continued) (1) Boiling any Te +6 to Te’4 and ensures in 6~ HC1 reduces complete exchange between ‘re carrier and radioactive Te. (2) The ~ NaOH washes layer, with leaving the “free” TTA away the Ga-TTA chelate. 1~ HC1, the equilibrium tends to leave the organic from tie benzene In subsequent Is shifted layer. washes so that the Ga However, ‘in low ‘+3, Al acid (~ HC1) the rate is ‘slow (similex to “Fe such as Zr, NP+4 , rare earths, and Bej. Elements Th, etc., are rapidly when there’is back essentially extracted Pa, into the N_ HC1 no “frea” TT.A in the benzene. Procedure 9 ,, ,. Gallium Harrison Source: 347 Brown andEdward Gcildberg, science ~, (1949). Target: Unknown - 0.3 to 0.5 g. iron meteorite. - 10 mg. gallium ,. Standard Irradiation - approximately 8-hydro~quinolate. 30 minutes at 1012 n/cm2/sec. A. Step chemical Processing of Meteorite Unknown 1 - Sample is dissolved 50 ml. beaker. in h’otconceritrated 4-5 mg. Ga+3 carrier 39 IiCl in added. - Procedure 9 (Continued) 2 - Adjust Step solution acid. Extract saturated with to 5.5 to 6.5~ in hydrochloric gallium ether. with equal volume Strip galll~ of HC1 from ether phase HzO. step 3 - Repeat Step 2. Step 4 - Precipitate droxide ether from aqueous phase. ion by addition of NaoH (hy- ferric concentration of l-2~). centrifuge, and discard aeroeol, Acidify Evaporate supernate to pH-1 Add one drop of precipitate. and heat to 60-70°C. 5 - Add 5 ml. of a 1 per cent acetic acid solution Step S-hydroxyquinoline. wise) Add to completely 3M ammonium precipitate acetate gallium of (drop- 8-hydroxy- quinolate. Step wash precipitate 6 - Filter; by ether. termine B. Processing step Dry sample with hot water 15 minutes followed . at llO°C and de- yield. of Gallium 1 - Dissolve Standard 10 mg. quantity nolate, which was ditions as the meteorite of gallium 8-hydroxyqui- irradiated under sample, identical con- in hot concentra- ted HC1. step 2 - Dilute to 50 ml. quantity Take 0.S ml. aliquot; of gallium precipitate carrier as above. 40 add same aE for the unknown and Procedure 10 Aluminum Source: W. D. Ehmann mochimica Materials: Acts 14, and T. P. XOhman, 340 Geochtica et Co13- (1958). A. chemicals - reagent B. Filtering - analytical c. IOn Exchange Resins 1. X-10, Dowex-1, grade gradeta (Wl&tman) 100-200 mesh anion exchange. X-8, 50-100 mesh cation Dowsx-50, 2. exchange. A. Procedure for Iron Meteorites Iron meteorite distilled step E_ple--100 1 - Sample ia dlaeolved beakers until in consecutive each portion complete 2 - 25 ml. concentrated tions to oxidize evaporated 3 - solution HNOa excess filtered 200 ml. portions in separate im achieved. is added to ccmbined . all Fe2+ to Fe-. is adjusted (solution etirred dissolution to near dryness of HC1 to rem&e Step with HzO and acetone. of aqua regia, step Washed to 150 g. with solution soluis 500 ml. portions HUOg. to one liter with [whatman-50 paper] 9~ HC1 and residues discarded). Step 4 - Accurately known quantities 41 of tlie following car- Procedure 10 (Continued) riera A1+3-,20 rng.; Be 2+-13.9 are added: ca2+-20 mg. Iron is removed by extraction ,. 9~ HC1 saturated Step isopropyl ether. the aqueous phase proceeds 5 - The aqueous phase is adjusted volume Do-x-l reg.; into Proceaeing of as follows: ., to 10H in HC1 (total approximately 750 ml. ) and passed through .. Alw, which is not adsorbed in column. the column is retained Ca+2r Be2+ and others. in the elute Column ml.” of 10~ HC1 end the washings a along with Ni2+, is washed with combined 500 with the main elute. Step 6 - The. elute from Step.5 ml. and A1(OH)9 NH40H and Be(oH)a (PH approximately ered on Millipore of 5% NH@l hydroxides cipltated Step 7“- A1(OH)9 is reduced. in volfi n adjusted are precipitated Hydroxide 7). paper end washed and filtered with are filtwith to approxi.inately pH 7. are dissolved to 300 25 ml. The in diltite Hc1 and repre- twice. and Be(oH)a precipitates” are tran’eferred to a 250 ml. beaker, 10-20 rng. Fe3+ carrier is “added plus filter 25 ml. of 8~ NaoH. insoluble precipitated step hydroxides on fritted a - Reprecipitate after diluting Al(OH)g to boiling scavenged by Fe(OH)= 6~ HC1 to 250 ml. wi~”HzO. in dilute 42 and glaarn. and Be(OH)awith filtrate solve precipitate Heat Dis- HC1 “and reprecipitate Procedure 10 (Cont@ued) twicq wi’~ NH40H Step 9 - Dissolve 6~ HC1. l.l&HCl to remove Na+. A1(OH)S and Be(QH)= DllUte to” 50 ml. wi& With H40 and make to step .10 - Pass, solution. through, 25 ml. resin column (10 in. flow rate of approximately with 6-7 resin volumes in column of ‘ HC1. 6~ ion exchange volume in minti volume Dowex-5Q x 1/2 in. dismeter):qt 1 ml./min. of l.~_ HC1. EIUte Be2+” Alw held iS 12 to 15 resin but will elute with vol- umes of l.U_ HC1. 100 ml. of 3M HC1. step 11 - Elute A13+’with step 12 - Reduce volume of A13+ on hot plate. cool on ice bath 5 ml. of 12~ HC1. tion Bubble for 5 minutes; tinue gassing cating until saturation on standing contalntng solution to l~°C and add dry ,x1 gas through add 10 ml. ethyl solution by HC1. for extended to 5 ml. ether and con- layers combine AICl~-6Ha0 period solu- indi- precipitates In ice bath. Filter precipitate by suction on fritted and wash with cold 1:1 12~ Hcl-ether glass solution disc satu- rated with HC1. Step 13 - Dissolve twice A1C19.6H20 and finally 8tep 14 - Precipitate end-point. filter h in 5 ml. HeO; reprecipitate dissolve in distilled Hao. Al(~)s with NH40H at methyl-red Collect precipitate on Millipore Btichner funnel. 43 HA “Procedure10 (Continued) Step 15 - Ignite B. to A1z03 at 1000°C in”platiti~” dish. Procedure for Silicate Materials . Procedure is similar to that for meteorite sample except” for dissolution of sampie, and sizes of ion exchange amounts of reagents used columns . ,.. ,:., .. ,;. ,, ,)”, >- ,.. 44 REFERENCES ., ( 1) Simanton, J. R., Rightmire, R. A., Long, A. L. and Kohman, T. P. ,.Phys., Rev. & 1711, (1954), ( 2) Rightmire, R. A. , n DcxAoral Dissertation,!’ Carnegie Institute of l&chnology, U. S.A. E.C. ~CUmSnt NYO6633 (1957). ,, ( 3) Rlghtire, R.” A., Kohman, topes ~, 274 (1957). ( 4) Kohman, ‘i: P., Rightmire, R. A., Hhmann, W. D. and S1.UEUItOn,J. R., “Radi0iSOt0pet3 in Sci6ntlfic”Research, “,volume 1, Prce. :lgt u?.aEScoIn6t. conf.., Paris, 1957, Pergamon Press (1959). . ( 5) Foster, ( 6) Foster. L. M. and Stumpf, ~, 1590 (1951). T. P., J., Appl. L. :S., J. Am. Chem. Sot. Q, 3122 Red. ,Iso- (1939). H. C., J. Am. Chem. S,pc. ( 7) Gooch, ,F. A. ,and,Havens, F. S., Am. J.. Sci., 2_, 416 (1696),.: , . ~ ( 8) Goto, H.,, J. Chem. ( 9) Hopkins, B. S., “Chapters in the Chemistry of the -SB FamAliar Elements,” ,stripes publishing .company~, Cham@&rn, Illinois (1939). (lo) Stehbach,, J. F., and.Freiser, 375 (1954). (11) Woldo ~, A:, 546 (12,) Bolomay, 4483 (13) Baird, [1954). SQC. Japan ~, 72S (1933). H., An?l. Chem. ~, J. H.~ and Hough, ,.C. R., Anal. ‘“ B. .A. qnd Wish, (1958). ““ L., T. Am. Chem. Eshelman, H. C., Anal. Chem. ~, Chem. Sot,,, ,., 72, 183 (1959). (14) of Traces SaI’d@ll, E. B., “COIOrime&ic Determination of Metals, ” 2nd Edition, Intersciemce Publ&shera, Inc. , New York (1950). (15) Luke, C.. L. and.Campbell, 1340 (16) M. E., Anal. Chem. ~, (1956). Kambara, (1959) . (17) Moeller, T. and Hoshitani, H., Anal. Chem. 31, 567 T. and Cohen, A. J., Anal. Chem. 22, 606 (1950) . (18) LecrOiX, S., Anal. Chim. Acts ~, 260 (1947). (In French ) (19) Meunier, ‘P., Compt. rend. 199, 1250 (1934). (20) B“audisch, O. and FUrSt, R., Ber. deut. chd. ~, 324 (21) Chernikov, ~, Gas. (1917), 1143 Y. A. and Kobkina, (1949)”. B. M., Zavodskaya Lab. \ (22) Milner, Analyst (23) Bock, R. and Heriman, 284, 2S8 (1956). (24) SWiY%, (25) Nachtrieb, N. H. and FVell, Sot. Q, 4035 (1949). (26) Be~et, (27) Bock, R., Kusche, 167 (1953). (28) Kitahsra, s., Bull. ~, 454 (1948). (29) Bock, (30) Johnson, S. E. J., “Colorlmetric Dete~ination of Traces of metals,” 2nd Edition, Intekticience publishers Inc., New York (1950). (31) Sund=am, ‘A. K. and Banerjaee, ~, 526 (1953). G. W. C., Wood, A. J. and Woodhood, ~, 272 (1954). E. H., J. h. M., Z. anorg. Chem. Sot. @ J. L., u. allgem. 2378 Cheude (1954). R. E., J. Am. Chem. W. and Irvine, J. W., Mass. Inst. Technol. Lab. of Nuclear Sci. Prog. Rept.,’(February, 1953). R., Z. Anal. H.”and Beck, E., Z. Anai. Chem. ~, Inst. Phyti. Charn. Res6srch Chem. ~, 46 110 (Tokyo) (1951). S., Ana~. chim. Acts (32) (33) White, J,..,C., Oak Ridge National I@bo.ra$ory, Preaented at Pittsburgh Conference on Anal. ~em. and Applied Spectroscopy, March 1957. ““ .. MOrr100n, G. H. and Freiser, H., “SolVent Extraction in Analytical chemistry,”” John Wiley and Son@, Inc., New York (1957). (34) Klement, R. and Sandmann, H., Z. Anal. 325 (1955). (35) Strelow, (36) Kejma, s. -d Kakihana, H., Japan Analyst ~, 421 (1953) and ~, 42 (1954). (37) Kraus, K. A. and Nelson, F., “symposium on Ion Exchange and chromatography in Analytical Chemistry,” A.S.T.M. Special Technical Publication No. 195 (January 1958). (38) Kraus, K. A., Nelson, Chem. 58, 11 (1954). F. and Smithi (39) Freund, H. and Miner, (1953). F. J., Anal. F. W. E., Anal. Chem. ~, 1974 (1959). Chem. 31, G. W., J. Phys. Chem. ~, (40) Horton, 1326 A. D. and !rhomason, P. F., Anal. (1956). 564 Chem. ~ (41) Kraus, K. A. and Nelson, F., Proceedings, Intern. Conf. on Peaceful Uses of Atomic Energy ~, pp. 113, 131, United Nations (1956). (42) Farie, (43) Marinsky, Chem. ~, (44) Gruverman, I. J. and Kruger, P., J. Applied tion and Isotopes ~, 21 (1959). (45) Hoffman, Research (46) @ndell, W. F. et al., ‘Applied Inorganic Analysie,” 2nd Edition, John Wiley and Sbns, Ins., New York (1953) . (47) “chemical Analysis of Aluminum,” 3rd Edition, Alcoa Research Laboratories, tJew Kensington, Pennsylvania (1950). J. P., Anal. them. ~, J. A. and EichleK, 223 (1960). J. I., “Preparation Paper R.P. 734. 47 520 (1960). E., J. InOrg. and NUC1. Radia- of Pure GalliURI,” N.B.S. (46) (49) Dannis, L. M. and Bridgman, ‘Q, 1534 (1918) . Guinn, v. P. and Wagner, (1960). J. A. , J. Am. Chem. !. C. D. , -1. Chem. u, Sot. 317 ,, USMC OffI.o d Technicallnk,m@Ion EXMNI.., Ode RI+, 48 T,nn-