Application of 48 Volt for Mild Hybrid Vehicles and High

Power Loads

2014-01-1790

Published 04/01/2014

Malte Kuypers

Delphi Automotive

CITATION: Kuypers, M., "Application of 48 Volt for Mild Hybrid Vehicles and High Power Loads," SAE Technical Paper

2014-01-1790, 2014, doi:10.4271/2014-01-1790.

Copyright © 2014 SAE International

Abstract

During the evolution of Hybrid vehicles as well as electrical

vehicles the need for an additional Voltage level was defined

for the utilization of high power loads like electrical

compressors, electrical heaters as well as power steering and

electrical pumps. The main systems benefit is the generation of

approximately 12 kW electrical power by a traditional belt

driven Generator. This allows boost function for acceleration

and recuperation for mild hybrid vehicles with the target to

reduce up to 15% CO2 by keeping the traditional thermal based

engines.

Delphi has developed systems and components that meet the

special 48 Volt related electrical requirements on arcing, hot

plugging and corrosion. Our benefit is the long term expertise

within the total system know how and the derived technical

specification and needs. This includes connection systems for

devices up to 7 kW power, 48 Volt distribution boxes and high

power electronics, energy management as well as total

systems fusing definition, wiring harness specific routing and

design.

Power Steering Pump, Secondary Air Pump as well as

hydraulic functions like suspension control or braking, which

might be replaced by electric high power solutions.

All those loads are not switched on permanently (or they do not

have to be), but even when they are off, they take power from

the engine and it is being discussed, whether they should be

operated engine independently, speaking electrically. Some of

these functions physically require a higher operation voltage.

48V as system voltage is a compromise concerning safety and

functionality. It is considered as the minimum voltage for

efficient energy recuperation in a given LI-ION Battery

technology.

Introduction

Fuel economy and reduction of emissions, especially CO2

reduction, are big issues for new and future vehicles. To meet

future requirements, car manufacturers are looking for methods

to improve vehicle efficiency. A supporting function could be a

“KERS” system, known from formula 1, but here on the voltage

level of 48V. This function is used for acceleration support and

will be powered by energy recuperation during deceleration.

Furthermore, today we have belt-driven loads on the engine

like Water Pump, Air-Condition Compressor, ABS-Pump,

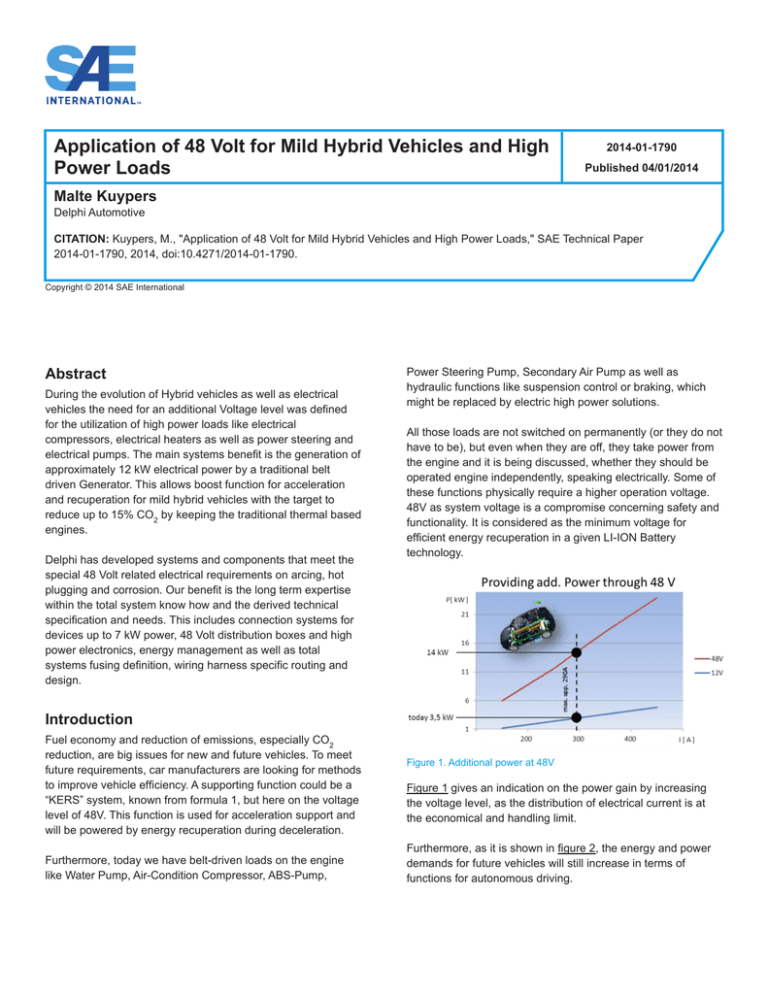

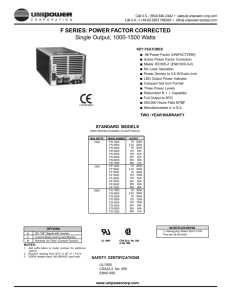

Figure 1. Additional power at 48V

Figure 1 gives an indication on the power gain by increasing

the voltage level, as the distribution of electrical current is at

the economical and handling limit.

Furthermore, as it is shown in figure 2, the energy and power

demands for future vehicles will still increase in terms of

functions for autonomous driving.

Electrical propulsion in Hybrid Vehicles operates on a High

Voltage (HV) Level between 150V and 650V. At this voltage

level a high effort for protection against electrical shock is

legally required. For this reason it is planned to supply high

power functions on the 48V level in Hybrid Vehicles as well,

because the installation effort is considered to be lower.

The corresponding E/E Architecture is like the 48V Base

Architecture where the Motor - Generator is shifted to the HV

level and the lower voltage levels are supplied by a DCDC

converter. This converter is currently considered to operate

from HV to 14V.

Figure 2. Evolution of E/E Systems

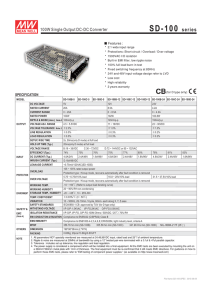

Currently discussed general E/E Architectures for application of

an additional voltage level of 48V are indicated in figure 3.

Characteristics and Requirements of the

48V E/E System

Currently the only official specifying document for 48V is the

so-called LV 148, issued by German OEMs.

Figure 4. Voltage levels of 48V System according to LV 148 (Source LV

148 / VW 82148-1 Issue 201109)[1]

Figure 3. Multi-voltage Architectures

The base architecture - depending on the focus of the OEM,

CO2 reduction or performance enhancement - comprises the

unchanged 14V E/E System being powered via a DC/DC

converter in the power class of 3 kW, and the portion of the

48V System as requested, for example a Motor - Generator in

the power range of 12 kW for energy generation, acceleration

support and recuperation plus a storage device on 48V, here a

Li-Ion Battery. In some cases the battery can be substituted or

supported by a super-capacitor, depending on the application.

Once 48V are installed in the vehicle, high power functions as

mentioned earlier are about to follow. These additional

functions have power levels of around 500 Watts to 5 kW.

Currently it is not planned to convert the whole E/E System to

48V.

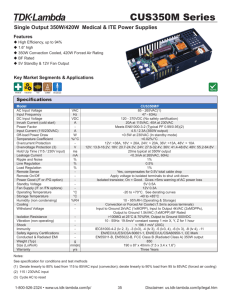

The LV 148 [1] specifies first of all the voltage levels of the 48V

system as seen in figure 4. The usual operation area is

between 36V and 52V. following are areas with functional

restrictions for under voltage and upper voltage. Important

borders are 54V (U48max, high, limited) and 60V (U48 sh protect). 60V

must not be reached, respectively exceeded. The same applies

for 54V. The area between the levels is a safety margin.

Furthermore the LV 148 specifies test procedures for 48V

components in expected use cases.

In addition the LV 148 provides some premises, where

requirements can be derived from, as:

• Electrical shock protection is not required for DC-Voltage <

60V.

(No High Voltage Interlock System (HVIL) is required to

protect humans against electrical shock)

• A single malfunction must not lead to a Short Circuit

between 48V and 12V E/E System.

(Such a short circuit between the voltage levels without

connection to ground might destroy the complete 12V

System due to permanent overvoltage)

• There is a common ground (chassis) potential for 12V and

48V, which is connected by spatially divided wires and

ground terminals.

(Loss of common ground might lead to reverse voltage on

the 12V side and thus destruction of 12V electronics)

• No component may lead to a transition into the overvoltage

level (54V (U48max, high, limited)) i.e. due to Load Dump or

resonance step-up.

(This is a very important statement, as this requires special

measures at inductive loads and limits the effects of arcing)

The statement mentioned first, that no electrical shock

protection is required has led to the opinion, that 48V or any

voltage below 60V could be treated as 12V.

This is correct concerning the system components as such like

wires, because they are validated for voltages up to 60V (LV

112 or ISO 6722).

But there are some effects at higher voltages like 48V which

might require additional system protection measures for

technical reasons.

One critical effect is arcing. If arcing occurs, the surrounding

materials might be set to fire due to the high temperature of the

plasma of around 6000°C.[2],[3]

Failure Modes in the 14V/48V E/E System

valid for both voltage levels, although special care has to be

given to the involved conductor materials and fuse size. At 48V

the short circuit will be accompanied by an electric (parallel)

arc and therefore the current will be reduced [4] in comparison

to the short circuit without arc. In general a melting fuse can be

considered as feasible solution for classical short circuit

protection.

Loss of Common Ground

As mentioned earlier and especially as one of the premises of

LV 148, loss of common ground has to be avoided. The

recommendation here is separation. Separate GND

connections on dual voltage electronics as for instance DCDC

converters and separate wires to separate GND bolts on the

chassis. If this is not feasible, alternatively an electronic GND

supervision should be installed which could switch off the

power to the device when a failure is detected.

Voltage Short Circuit

A short circuit between the voltage levels has to be avoided. As

stated in the LV 148 it must not occur by a single failure. Here

again the recommendation is separation:

• Separate routing of 14V and 48V power lines and low ohmic

sensor lines

• Separate connectors for different voltage levels

• Additional wall in cable channels if separate routing is not

feasible

Alternatively the voltage short circuit can be handled by

• Application of low-tolerance melting fuses on 48V

• Shielded wires for 48V in order to force a short circuit to

GND

• Shielded wires for 48V in order to detect an insulation fault

• Application of (smart) MOSFETs for switching and output

supervision

Broken Wire

Figure 5. Failure modes in the 14V/48V E/E System

In figure 5 the different failure modes in the dual- or multivoltage E/E System are indicated. The high voltage area is

neglected here, as there is no interaction between HV and the

lower levels due to the fact that the HV System is considered

safe by legal requirements.

Short to Ground

This failure mode is what we usually expect when a short

circuit occurs. Due to the high current a melting fuse will open

the circuit and the current flow is interrupted. This is basically

Broken wire is an arc - creating failure and stands as synonym

for any kind of intermittent contact like bad crimp, loose

terminal, loose connector, damaged insulation by abrasion. On

the contrary to the 14V E/E System, electric arcs are not

self-extinguishing at 48V, as the length of the arc for a 2.4 kW

resistive load (50A @ 48V) can be up to 5 mm.

In figure 6 some examples for arc length are given. The arc

length depends on conductor material, power and type of load.

If an inductive load is disconnected, a voltage overshot can be

observed. Fortunately the LV 148 postulates, that no

component is allowed to generate a voltage entering the

overvoltage area of 54V (U48max, high, limited), meaning that

appropriate measures have to be taken inside the inductive

load. If the disconnection or interruption is caused by a broken

wire, the arc will extinguish when its maximum length is

reached by material destruction.

This may be the really critical scenario because it occurs

unintended on the contrary to opening a connector.

• A: E < 5J small damage

• B: E < 20J material starts melting

• C: E < 200J melting drops at edges

For a given load, the energy can be influenced by the speed of

disconnection. With manual opening of a connector the speed

is difficult to predict. At Delphi some measurements with

different loads and speed were conducted. We used the

DUCON 9.5 terminal system, as it fits nicely to the load

requirements of up to 5 kW in the 48V system. The results are

shown in figures 9 and 10.

Figure 6. Quasi Static Arc Curve

The Ayrton-Equation (Herta Marks Ayrton) is used to determine

arc length in relation to voltage and electrode material. The

coefficients are evaluated experimentally:

Figure 9. hot disconnect @20A and 10 mm/s disconnection speed

Figure 7. Coefficients of Ayrton-Equation

The severity of electric arcs is high, the occurrence is not very

much investigated.

At 20A, 10 mm/s disconnection speed we have an energy of

around 110 Joule. The resulting damage is low, a little

blackening of the terminals, functionality is still given to 100%.

If an intermittent contact occurs in the 14V System for one of

the reasons mentioned above, a function is lost or interrupted.

The wire will be exchanged, the connector plugged correctly

and so on, but the occurrence is not documented well.

If something like that happens at 48V, the vehicle might burn!

The remaining questions are: Is the likelihood of occurrence

high enough to take measures, are cost effective measures

available, are high cost detection systems necessary or can we

just ignore the effect?

The scenario discussed more often is the “Hot Plugging” issue.

When opening a connector with the load being active an arc

will be created. The degree of damage is linked to the arc

energy:

Figure 10. hot disconnect @50A and 10 mm/s disconnection speed

At 50A, 10 mm/s disconnection speed we have an energy of

around 310 Joule. The resulting damage is more spectacular.

The terminals might have to be exchanged.

How to handle that situation, as the power level of around 2400

Watts is supposed to be the most popular in the 48V system.

Functions like PTC Heaters, E-Steering, Active Roll Control,

etc. The LV 148 does not give an answer.

Figure 8. arc energy

Tests have given an indication on the degree of damage

related to the energy and of course to the thermal capacity of

the terminals, respectively the size:

In the past, different concepts for avoiding arcs or minimizing

the effects have led to a variety of connection system

proposals. Currently most of the OEMs are tending to consider

this issue as “misuse”. However, there are different concepts

with different effort available and will be mentioned below.

The more critical effect, since it will occur unintended and

unexpected, is the arcing in a broken wire or unseated terminal

situation.

We simulated this scenario with a relatively small load of 960

Watts and a disconnection speed of 0.5 mm/s. In reality there

would be no disconnection speed at all, besides the gap being

created by melting conductor material, in our case we used

copper with a gauge of 6 mm2.

The result can be seen in figure 11: large flame, melting

conductor.

Figure 13. Corrosion test @ 48V

At 48V (figure 13) the reaction is much more intensive. The

aqueous solution is boiling, material transport is seen by

change of color. This test was stopped after 15 seconds. The

terminals were destroyed due to corrosion.

Recommendations for 48V E/E System

design

General requirements for system layout, system protection,

connection system design are quite rare. Different OEMs are

following different strategies for different applications. Based

on our experience and findings during tests we established a

set of own requirements and derived some recommendations

for the design of a 48V E/E System.

Battery Box

Figure 11. broken wire simulation @ 20A, 0.5 mm/s, conductor material

copper

An additional issue at higher voltages is the effect of intensified

terminal corrosion. In the 14V system we distinguish between

wet and dry areas. Sealed boxes and connection systems are

mandatory for wet areas as for instance engine compartment

and outer area of doors. In dry areas unsealed systems can be

applied.

How about the 48V system? Is it the same situation? We

conducted a test where we applied salt water (5% NaCl) in the

male part of a 2-way 9.5 DUCON connection system and

connected the two terminals to 12V and GND, respectively 48V

and GND. The result can be seen in figures 12 and 13.

In the 12V System the battery is usually a stand- alone

component with accessible permanently powered contacts.

This should be avoided for the 48V Battery.

Due to the higher risk of arcing, the output to the environment

should be switched and protected. The protection should

comprise:

• Electronic battery disconnection switch for output control in

different vehicle modes (production, transport, park, service,

driving)

• Pyrotechnical device for crash protection

• Master Fuse for overcurrent protection related to FET

parameters

Power Distribution Boxes

Components for Power Distribution Boxes (PDBs) as we know

them from the 12V E/E System like fuses and relays are

available for the 48V System from different suppliers.

Figure 12. Corrosion test @ 12V

At 12V (figure 12) some gassing can be observed, but after the

test duration of 60 seconds the terminals show slight change in

color only. The functionality is still given.

Fuses had been developed for the 42V System and the

components can be applied in the 48V System as well, as the

border - requirements are the same. This is valid for relays as

well.

The arising question is:

Will the functionality, as we know it from today's PDBs be

sufficient for the 48V System ?

Based on the requirements we know today, the answer is YES!

BUT this is likely to change, because features like

• Power Shut - Off in certain vehicle modes

• Arc detection

• Current supervision for optimized wiring

might require the application of different technologies.

Pre-Fuse Boxes

Right now there seems to be a trend that the Pre-Fuse-Box will

be an integral part of the 48V - Battery - DCDC Converter System.

This “Box” will provide a switchable and protected 48V Supply

to the vehicle (see DCDC converter section).

Figure 13. Delphi “Energy Storage System” Bi-Directional DCDC

Converter with battery pack included featuring Pre-Fuse functionality

Even if the pre-fuses are not part of that system, at least the

switch will be inside the “Box”, supported by a crash protection

device.

Wires for 48V Application

In this case the pre-fuses could be conventional MEGA(BF2) or MIDI(BF1) - like fuses for 48V.

Some effects like arcing at 48V require special care on wire

type selection.

Bussed Electrical Centers

Aluminum wires are not recommended. If applied, special care

has to be taken for short circuit protection (electronic

supervision) and for vibration resistance.

So far we haven't seen a requirement for arc detection. For

wire protection functionality, conventional melting fuses could

be applied, although every short circuit will be accompanied by

an electric arc. For that reason some OEMs are tending to go

for electronic protection instead of using melting fuses. Some

characteristics of conventional BECs in relation to 48V:

• Available technology for fuses

• Available technology for relays

• 12V and 48V close together at relays (Coil 12V, Contact

48V) common connector should be avoided due to

separation requirements for inter-voltage-short circuit

protection

Automotive wires are specified for a voltage range up to 60V

and therefore can be used in the 48V environment.

Shielded wires like in HV Systems are not considered, if not

required for EMC reasons.

Routing

Routing will be defined according to RQA (routing quality

assessment) plus application of a separation strategy. Special

consideration of routing passes and material selection for

moving parts (doors, axles …), engine-compartment and

underbody routing (environment).

• Hard wired boxes not preferred

Materials

• Durability of relays unclear

Choice of wire types according to same procedures as for 12V

systems. Special focus on flexibility for moving parts and areas

of high vibration impact to reduce the risk of broken wires,

especially with application of Aluminum wires.

• No arc detection

Electric / Electronic Centers (Smart E/E centers)

The future for power distribution boxes will be smart E/E

centers. Here we can implement features like current

supervision, input/output comparison (arc detection).It is

possible to allow over-currents (inrush) for a defined time in

order to design the wiring according to average current.

Electronic Modules (DCDC converters)

Currently there are Converters with a power-range of 3 kW in

discussion. For certain applications unidirectional converters

are sufficient, especially from HV to 12V or from 12V to 48V, if

only a single function has to be supplied, but in most cases a

bi-directional converter will be required.

Color Coding

There is no standard color defined for 48V wiring and

components like in High Voltage Systems where all

components are marked orange. There was an approach by

General Motors to apply light blue color for wires on a 36V

(42V) level to distinguish those wires from the 12V level wiring

related to the higher risk of arcing.

Connection Systems for 48V Application

In general all the connection systems applied in the 12V E/E

System can be used for the 48V System in terms of terminal

distance or creeping distance.

Related to the affinity to arcing and increased sensitivity to

corrosion, precaution should be considered to avoid terminal

destruction. Taking the results of the salt water test (figure 13)

into account, our recommendation here is to apply sealed

connection systems for every 48V application with different

potentials in one connector; for single cavity connectors it may

not be necessary.

single cavity sealing and terminal position assurance to avoid

unseated terminals. The connector can be closed only, if every

part is seated correctly. Thus the chance for arcing is low.

In wet areas we recommend to use single cavity sealing to

assure a long lasting functionality.

Currently discussed functions on the 48V level are on a power

level of 500 Watts to 5 kWatts with a majority of functions

around 2 kWatts. The corresponding current is around 11A to

110A.

The Delphi portfolio offers a wide range of available connection

systems for this area of application.

Selection of a suitable system follows an evaluation procedure

as shown in figure 14, examples of available terminals are

shown in figure 15.

Figure 16. Sealed connection system with DUCON 9.5 female terminal

for wire gauge up to 16 mm2 and continuous current up to 80A.

When it comes to high current connections, for instance

connections to the Motor - Generator and the 48V storage

system, there is always the discussion whether to use bolt-type

connection or pluggable components. The related current level

is about 220A for some seconds and about 60A continuous

current. At this level pluggable devices are available at Delphi,

both solutions are feasible.

An internal evaluation of plug vs. bolt resulted in an advantage

for plugs. Major advantages of the plug solution are linked to

the assembly process:

• Assembly time

• Space requirement for assembly

• No tools needed for assembly

It depends on OEM philosophy which solution will be preferred.

Examples are shown in figure 17.

Figure 14. Evaluation procedure for selection of connection system

Figure 17. Example for high current connection methods

Avoidance of “Hot Plugging”

Although currently there is no defined requirement how to

handle the “Hot Plugging” issue, there are concepts available:

Figure 15. Examples of available terminals for 48V application

A typical connection system for 48V application with a power

demand of up to 4 kW is the DUCON 9.5 system shown in

figure 16. It fulfills the requirements for wet area application as

Component Level

• Place connector at places difficult to access

• Tagging of connector

• Establish repair guideline

• Active barrier for plug and unplug

• Contact geometry

• Defined disconnection speed

System Level

• Automatic disconnection with sensor contact inside the

connector

◦◦ Separate routing of wiring branches or application of

shielded wires

◦◦ Separate connectors for different voltage levels

◦◦ Electronic fusing

• Separate grounding bolts and wires

• Use of sealed connection systems

• Accurate installation and material selection in order to avoid

arc faults

• Manual disconnection with bridge contact

• Arc detection

References

1. NDE_VW82148-1_LV148.pdf LV 148 here: internal VW

standard

2. Kuhn, Paul K., Furse, Cynthia, Smith, Paul “Locating

Hidden Hazards in Electrical Wiring” University of Utah

LiveWire Test Labs Inc. Aged Electrical Systems Research

Application Symposium, October 18-19, 2006 Chicago,

Illinois

3. Hastings, J., Zuercher, J., and Hetzmannseder, E.,

“Electrical Arcing and Material Ignition Levels,” SAE

Technical Paper 2004-01-1565, 2004, doi:10.4271/200401-1565.

Figure 18. Examples for “Hot Plugging” prevention on system level

The last example in figure 18, arc detection, can be used for

detection of a serial arc caused by a broken wire as well.

Comparison of output voltage at the power distribution device

and input voltage at the function control module will deliver an

indication about a fault-free system. A necessary requirement

are detailed data of the function behavior.

Summary/Conclusions

4. Naidu, M., Schoepf, T., and Gopalakrishnan, S., “Arc

Fault Detection Schemes for an Automotive 42 V Wire

Harness,” SAE Technical Paper 2005-01-1742, 2005,

doi:10.4271/2005-01-1742.

Contact Information

Malte.Kuypers@delphi.com

Acknowledgments

Preparation of this paper was supported by Delphi 48V Team:

Dominik Hermes, Stephan Terbeek, Frank Trommer, Andreas

Urbaniak, Christoph Wevelsiep.

Respecting some boundary conditions, the introduction of an

additional voltage level of 48V in the vehicle E/E System is

technically feasible.

The boundary conditions are:

• 48V must not be permanently active

• Application of a Main Disconnection Switch inside the

battery pack featuring vehicle modes crash, park, transport

and service

• Avoidance of inter-voltage short circuit leading to 12V

system loss by

The Engineering Meetings Board has approved this paper for publication. It has successfully completed SAE’s peer review process under the supervision of the session

organizer. The process requires a minimum of three (3) reviews by industry experts.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written permission of SAE International.

Positions and opinions advanced in this paper are those of the author(s) and not necessarily those of SAE International. The author is solely responsible for the content of the

paper.

ISSN 0148-7191

http://papers.sae.org/2014-01-1790