48V Mild Hybrid Systems

advertisement

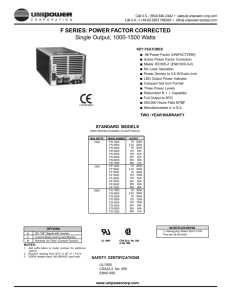

48V Mild Hybrid Systems Market Needs and Technical Solutions Ulf Stenzel AVL Engineering and Technology Content 48V Market Situation & Needs 48V Powertrain Technologies and Challenges AVL’s Project Examples AVL UK Expo 2014 / Ulf Stenzel 2 Content 48V Market Situation & Needs 48V Powertrain Technologies and Challenges AVL’s Project Examples AVL UK Expo 2014 / Ulf Stenzel 3 Mild Hybrids – Global Market Overview Global xEV Production Vehicle Production [units] 7,000,000 In 2020 (10-15)% of global xEV production are Mild Hybrids 6,000,000 5,000,000 4,000,000 3,000,000 2,000,000 1,000,000 0 2013 2014 2015 2016 2017 2018 2019 2020 Year of Production Hybrid-Mild (incl. 48V) Vehicle Production [units] Mild Hybrids, per Region Hybrid-Full (incl. PHEV) EVs (incl. REEV) 800,000 700,000 Mild HEVs produced in NA in 2020 will most likely be dominated by High Voltage Systems 600,000 500,000 400,000 300,000 In 2020 almost all Mild HEV’s produced from European OEMs are 48V Systems 200,000 100,000 0 2013 2014 2015 2016 2017 2018 2019 2020 Year of Production South Asia North America Japan/Korea AVL UK Expo 2014 / Ulf Stenzel Greater China Europe Source: IHS Q3 2013 4 EU Mild Hybrids – Market Overview Europe Mild Hybrids produced in Europe (of which 98% is 48V in 2020) Vehicle Production [units] 300,000 E-Segment D-Segment 250,000 200,000 150,000 C-Segment B-Segment 100,000 50,000 Vehicle Production [units] 400,000 400,000 350,000 per Vehicle Brand 350,000 300,000 250,000 200,000 Luxury Premium Mid Entry 150,000 100,000 50,000 2013 2014 2015 2016 2017 2018 2019 2020 No 48V applications in the A segment (e.g. Ford Ka, Chevrolet Spark) forecasted until 2020 Significant 48V shares in larger vehicle classes and in the B segment (e.g. VW Polo) Early implementation in E segment vehicles (e.g. BMW 7 series, MB E-Class) (see 2018) AVL UK Expo 2014 / Ulf Stenzel 400,000 350,000 300,000 250,000 200,000 150,000 100,000 50,000 Rolls-Royce Nissan Smart Porsche BMW Ford Peugeot Citroen Audi Mercedes-Benz Dacia Renault 0 0 0 Vehicle Production [units] Per Regional Sales Price Class per Segment 2013 2014 2015 2016 2017 2018 2019 2020 2013 2014 2015 2016 2017 2018 2019 2020 Large share of 48V applications in the Mid (e.g. Renault Clio, Ford Mondeo) and Premium (e.g. BMW 7 series, Smart Forfour) segment High share of German premium OEMs Entry: e.g. Renault Duster, Dacia Logan No share from Fiat (and it’s sub brands) forecasted until 2020 No share from Volkswagen projected Luxury: Porsche Macan, RollsRoyce Ghost Source: IHS Q3 2013 5 German OEMs are pushing for 48V The LV 148 standard defines a 48V power supply system including its functions and interfaces. The standard describes all relevant electrical requirements and test procedures for the new 48V components It is defined by the big 5 German automakers and shows a clear trend out of Europe to push 48V technology towards production. These five OEMs have been involved: Audi AG BMW AG Daimler AG Porsche AG Volkswagen AG AVL UK Expo 2014 / Ulf Stenzel 6 EU Past and Future Progress to meet the 2020 Target Overall the required rate of progress to the proposed 2020 targets is slightly greater (4.1%pa) than the rate that has already been achieved over the past five years (3.6%pa). However, these figures do not include the effect of flexibilities (i.e. supercredits) that effectively provide free grams. Carmakers are therefore even closer to achieving targets than the data suggests. The clear conclusion is that the 2020 target is achievable for makers of all types and sizes of cars with appropriate planning and introduction of fuel consumption reduction measures. Source: European Federation for Transport and Environment (T&E) AVL UK Expo 2014 / Ulf Stenzel 7 EU Taxes and Incentives for Mild Hybrids in Europe AVL UK Expo 2014 / Ulf Stenzel 8 Definition of Hybrids according to Legislation by Region From ECE R101: … means a vehicle,…. that, for the purpose of mechanical propulsion, draws energy from both of the following on-vehicle sources of stored energy/power: (a) a consumable fuel; (b) a battery, capacitor, flywheel/generator or other electrical energy/power storage device EU USA CHN JPN KOR 12V ST/ST SIN 12V ST/ST SIG w/o TA 12V ST/ST SIG with TA (1) (1) (2) (1) (1) (2) 48V Alternator (aux. supply only) 48V Mild HEV SIN…Start in Neutral SIG…Start in Gear TA… Torque Assistance (1) Yes, if energy storage is rechargeable (2) Yes, if rechargeable and kinetic energy converter AVL UK Expo 2014 / Ulf Stenzel 9 48V Main Drivers – Summary Reduction of CO2 emission to meet future emission legislation Comfort enhancement and new functions Production volume Less integration effort, weight & cost, compared to HV systems (safety, battery) 48V systems have the potential to fill the gap between state-of-the-art 12V Start/Stop systems and high voltage hybrid powertrains. Source: Bosch on „48V Power Supply“ Conference 2013 AVL UK Expo 2014 / Ulf Stenzel 10 Content 48V Market Situation & Needs 48V Powertrain Technologies and Challenges AVL’s Project Examples AVL UK Expo 2014 / Ulf Stenzel 11 12V/48V Electrical Architecture 48V High-Power Consumer EPS / EHPS eBooster … PTC Heater Electric Pumps El. AC Compressor ... Roll Stabilization 48V Boardnet 48V 48V Starter/Generator 48V Battery System Classic 12V Boardnet DC/DC 12V AVL UK Expo 2014 / Ulf Stenzel 12 E-Machine Integration The integration of the E-machine defines the recuperation potential; the engine drag torque reduces the amount of recuperative energy (P2 versus P1/BSG) Cost advantage high speed Emachine (BSG) versus high torque (ISG); high torque density leads to higher cost Integration cost & effort; package (ISG, P2), transmission modification (P2) Preferred system architectures, functionalities and the resulting cost to benefit ratios are depending on vehicle class & vehicle application AVL UK Expo 2014 / Ulf Stenzel 13 BSG Integration Challenges - Impact on Engine FEAD Design Belt Durability Variable Belt Tensioner Increase tension during cranking and boost (machine to engine) Increase tension during recuperation (engine to machine) Reduce tension during normal driving to reduce friction loss NVH Belt chirp during cranking Crankshaft Main Bearing Durability AVL UK Expo 2014 / Ulf Stenzel 14 Powertrain Key Components - BSG System Besides the main requirements (EM power & torque) as well as packaging constraints the supplier selection also to take care of cooling requirements and NVH 48V BSG systems vary across different supplier As an independent partner AVL can provide comparable and consistent component characterization AVL UK Expo 2014 / Ulf Stenzel 15 48V Electrical Load Migration – Impact on eStorage 12V DC 12V 48V DC DC 48V DC >10 Ah 6 Ah SG SG CO2 reduction only Electrical Load Migration Start/Stop, Boost, Recuperation Chassis Control, Climate Comfort, Engine Components Electrification, eBooster, etc… AVL UK Expo 2014 / Ulf Stenzel 16 Powertrain Key Components – eStorage System 12V Conv. Micro 48V Mild >>48V Mild 200-800V Full PHEV EV Flooded Lead Acid Enhanced Flooded Strong effort in the Lead Acid enhancement of advanced carbon Carbonadded addedVRLA to meet 48V requirements VRLA Lead Acid + UCap could be an interim solution Lead Acid + UCap Migration from High Voltage to 48V with Li-Ion Ideally carry over modules from high power Li-ion HV battery packs Li-ion NiMH ? Source: Adapted from Dr. Menahem Anderman (2013) Legend: AVL UK Expo 2014 / Ulf Stenzel Dominating Potential Candidate 17 48V Li-Ion Battery Technology Roadmap Lithium Titanate (LTO) The cell performance varies across cell technologies Lithium Iron Phosphate (LFP) Lithium Nickel Manganese Oxide (NMC) 2013 2020 Specific Energy 100 90 80 70 60 Specific Power 50 Costs Source: AVL internal benchmarking (averaged values) 40 30 20 10 0 Safety Lifetime Performance AVL UK Expo 2014 / Ulf Stenzel NMC LFP LTO NMC & LFP cathode materials fulfil current 48V automotive requirements in terms of performance and safety and will be the dominating Lithium-ion technologies in 48V applications LTO (lithium titanate oxide) anodes show excellent life, low temperature performance, safety but lead to high system costs 18 Overview 48V Main Functions AVL UK Expo 2014 / Ulf Stenzel 19 ADV. 48V FUNCTIONALITIES IN LEGAL CYCLES – NEDC Hybrid States 120 100 80 60 40 20 0 200 400 v [k m /h ] 0 600 t [s] 800 1000 50 40 30 20 10 0 0 AVL UK Expo 2014 / Ulf Stenzel 50 100 150 200 t [s] 20 ADV. 48V FUNCTIONALITIES IN LEGAL CYCLES – FTP Hybrid States 60 40 20 0 0 500 1000 1500 2000 2500 t [s] Hybrid States 90 80 70 60 v [km/h] v [km/h] 80 50 40 30 20 10 0 2000 AVL UK Expo 2014 / Ulf Stenzel 2050 2100 2150 2200 2250 t [s] 2300 21 Content 48V Market Situation & Needs 48V Powertrain Technologies and Challenges AVL’s Project Examples AVL UK Expo 2014 / Ulf Stenzel 22 The “TWINS”: 12V and 48V LC Super Hybrid NEDC CO2 Emission [g/km] 180 160 140 120 100 80 60 40 20 0 Acceleration 0 - 100 kph [s] 12 -12% -18% 18 % -24% Potential Similar for further Performance improvement 10 8 6 4 2 0 1,8-litre TSI 1,4-litre TSI with Start/Stop LC Super Hybrid AVL UK Expo 2014 / Ulf Stenzel 48V Mild HEV Concept 1,8-litre TSI 1,4-litre TSI with LC Super Hybrid 48V Mild HEV Start/Stop Concept 23 48V Advanced Lead Carbon Battery Diesel Hybrid Prototype Project Overview Features: 48V mild hybrid with Belt Starter Generator (BSG) & electric supercharger (VES) • +20% Power • -15% CO2 Engine update for BSG Controls / Operating Strategy Demo Vehicle Built & Calibration Engine & Vehicle AVL UK Expo 2014 / Ulf Stenzel Belt Starter Generator E-Booster Lead Acid Battery 24 AVL Engineering Project History since 2002 Concept Study Concept Study „100mpg“ 48V Market evaluation 48V Demo Vehicle Start/Stop 12V SRM BSG Conti VW Touran 42V Mild Hybrid Testing Comp. Dev. Case Study „Affordable Hybrid“ <60V JAC Refine 14+x Micro/Mild Hybrid Start / Stop 12V Engine durability testing „Beltless Engine“ 42V Mild Hybrid Eco Target 42V Mild Hybrid Start/Stop 14V + X BSG +AMT. JAC Binyue BSG Demo vehicle Drive Benchmark 42V Mild Hybrid Start/Stop 12V Start / Stop BSG 12V Battery performance testing EV Demo 42V SW Dev. 42V Mirco / Mild Hybrid LC Super Hybrid 12V BSG + eCharger AT Start / Stop 48V LC Super Hybrid BSG+switched CS pulley 48V BSG + eCharger BISG SW dev. 48V Start/Stop ALABC Pack Dev. 14V + X 48V Li-Ion Batt Pack Dev. BSG + UCap 48V 48V Mirco / Mild Hybrid 12V BSG Micro Hybrid Engine Start / Stop 2003 AVL UK Expo 2014 / Ulf Stenzel 2005 2007 2009 2013 25 Summary In 2020 almost all Mild HEV’s produced from European OEMs are 48V Systems. German OEMs are pushing towards 48V Implementation of new 48V HEV functions into an existing platform requires a systematic approach and an independent holistic view on the powertrain architecture and components Interdependencies between components need to be fully understood to avoid undesirable impact on: …Emissions and fuel consumption …Performance …Drivability / comfort …Energy mgmt. / charge balance AVL UK Expo 2014 / Ulf Stenzel 26 Thank you for your Attention! AVL UK Expo 2014 / Ulf Stenzel 27