Proceedings of the 28th ASM Heat Treating Society Conference

October 20–22, 2015, Detroit, Michigan, USA

Copyright © 2015 ASM International®

All rights reserved

asminternational.org

Applying and Specifying Metallurgical Engineering in the Production

of Heavy Truck Axle Shafts

Steven C. Heifner, PE

Sypris Technologies, Inc., Louisville, KY, USA

Steven.Heifner@sypris.com; 502 774 6215

•

Abstract

The American Trucking Associations reports that “In 2014,

trucks moved 9.96 billion tons of freight, or 68.8%” of all

freight tonnage transported domestically. [1]. "Spending in the

U.S. logistics and transportation industry totaled $1.33 trillion

in 2012, and represented 8.5% of annual gross domestic product

(GDP)."[2] Truck axle shafts for decades have been made from

induction hardened carbon steel with 0.4% to 0.5% carbon.

Associated metallurgical engineering of steel procurements,

forging, processing, and applied machining, impacts axle shaft

production and performance. This paper, and the associated

presentation at the ASM 2015 Heat Treat Society (HTS)

Conference and Exposition, reviews metallurgical principles

and controls currently applied to heavy truck axle shaft use and

production in North America. Basic metallurgical engineering

principles and controls, as historically and currently applied and

specified, plus potential opportunities for increasing

engineering value optimization, are reviewed. In particular,

case depth, surface hardness, microstructure, grain size,

chemical compositional interactions, procurement, processing,

metallurgical and overall engineering characterizations and

achievement targets are discussed.

Engineering impacts people and the world we live in. The

designs and services provided by engineers require awareness,

impartiality, and equity. Engineers serve many masters,

including both our employers and our customers. In fact,

engineers serve the world. Heavy trucks, especially in North

America, and also around the globe, impact each of us every

day because transported freight makes our lives and our current

society possible.

The Heavy Truck Axle Shaft in Perspective to

the Entire Truck

There are many vehicles that travel the roads in North America.

“The Federal Highway Administration (FHWA) is an agency

within the U.S. Department of Transportation that supports

State and local governments in the design, construction, and

maintenance of the Nation’s highway system (Federal Aid

Highway Program).” “Through financial and technical

assistance to State and local governments, the Federal Highway

Administration is responsible for ensuring that America’s roads

and highways continue to be among the safest and most

technologically sound in the world.” [4] This includes oversight

of the vehicles that travel the highway system in North

America.

The Role of an Engineer

An engineer uses knowledge of science to create something

useful, typically something that can be sold. Engineers by

vocation are value oriented. Most engineers deal with

homogeneity in their designs and their associated creation and

application. Material and metallurgical engineers are more

focused on, and trained in, understanding imperfections and

performance limits in implementing and deploying engineered

solutions, such as truck axle shafts.

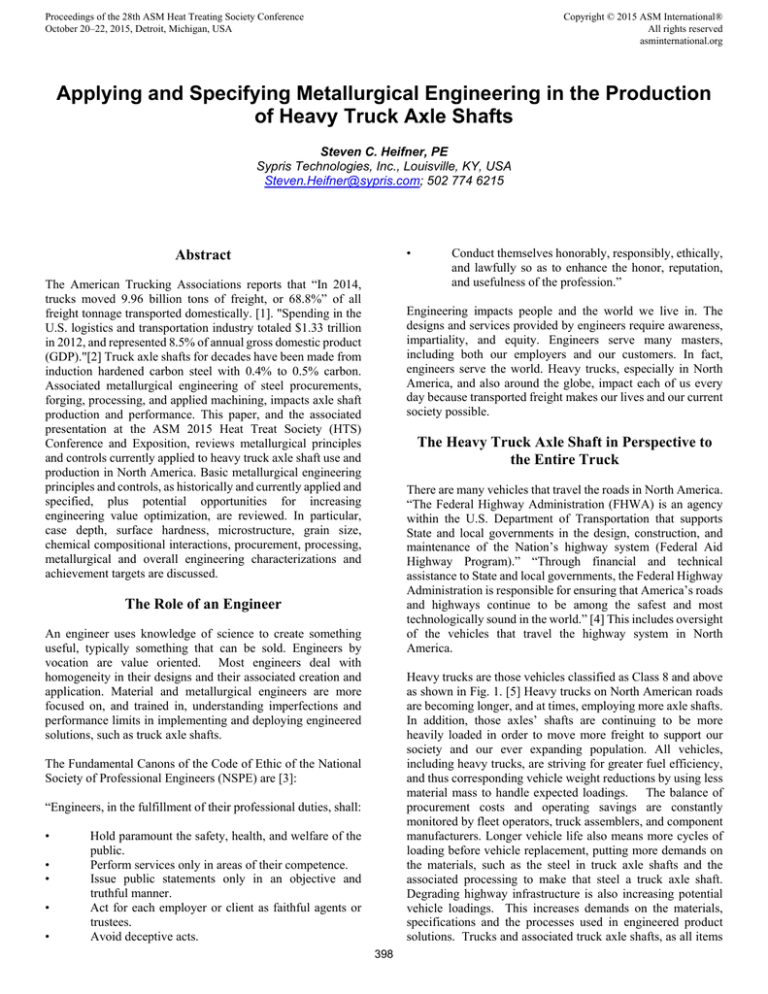

Heavy trucks are those vehicles classified as Class 8 and above

as shown in Fig. 1. [5] Heavy trucks on North American roads

are becoming longer, and at times, employing more axle shafts.

In addition, those axles’ shafts are continuing to be more

heavily loaded in order to move more freight to support our

society and our ever expanding population. All vehicles,

including heavy trucks, are striving for greater fuel efficiency,

and thus corresponding vehicle weight reductions by using less

material mass to handle expected loadings. The balance of

procurement costs and operating savings are constantly

monitored by fleet operators, truck assemblers, and component

manufacturers. Longer vehicle life also means more cycles of

loading before vehicle replacement, putting more demands on

the materials, such as the steel in truck axle shafts and the

associated processing to make that steel a truck axle shaft.

Degrading highway infrastructure is also increasing potential

vehicle loadings. This increases demands on the materials,

specifications and the processes used in engineered product

solutions. Trucks and associated truck axle shafts, as all items

The Fundamental Canons of the Code of Ethic of the National

Society of Professional Engineers (NSPE) are [3]:

“Engineers, in the fulfillment of their professional duties, shall:

•

•

•

•

•

Conduct themselves honorably, responsibly, ethically,

and lawfully so as to enhance the honor, reputation,

and usefulness of the profession.”

Hold paramount the safety, health, and welfare of the

public.

Perform services only in areas of their competence.

Issue public statements only in an objective and

truthful manner.

Act for each employer or client as faithful agents or

trustees.

Avoid deceptive acts.

398

in our economic driven society, need to continually become less

wasteful and generate more value.

system adopted in Nazi Germany. Standardized transportation

is a major component of military readiness, and has become

increasingly more critical to commercial success and value

creation since the Roman Empire.

The Industrial Revolution harnessed steam to do work, and that

work included movement. One aspect of that movement

became transportation. Metal was needed to harness and direct

the power of steam into useful work. Iron, and then steel,

became ever more in demand, in particular for railroad tracks,

railroad wheels, and railroad axles. The application of

metallurgy, in many forms, was critical to transportation

progress. As is currently the case with heavy truck axles, getting

more life from each railroad axle, was an economic necessity.

Steel processing techniques used to make railroad axles were

subsequently transferred to motor transportation designs as road

networks grew. These road networks, and vehicles using them,

became increasingly to the rapidly expanding North American

economy after World War 2.

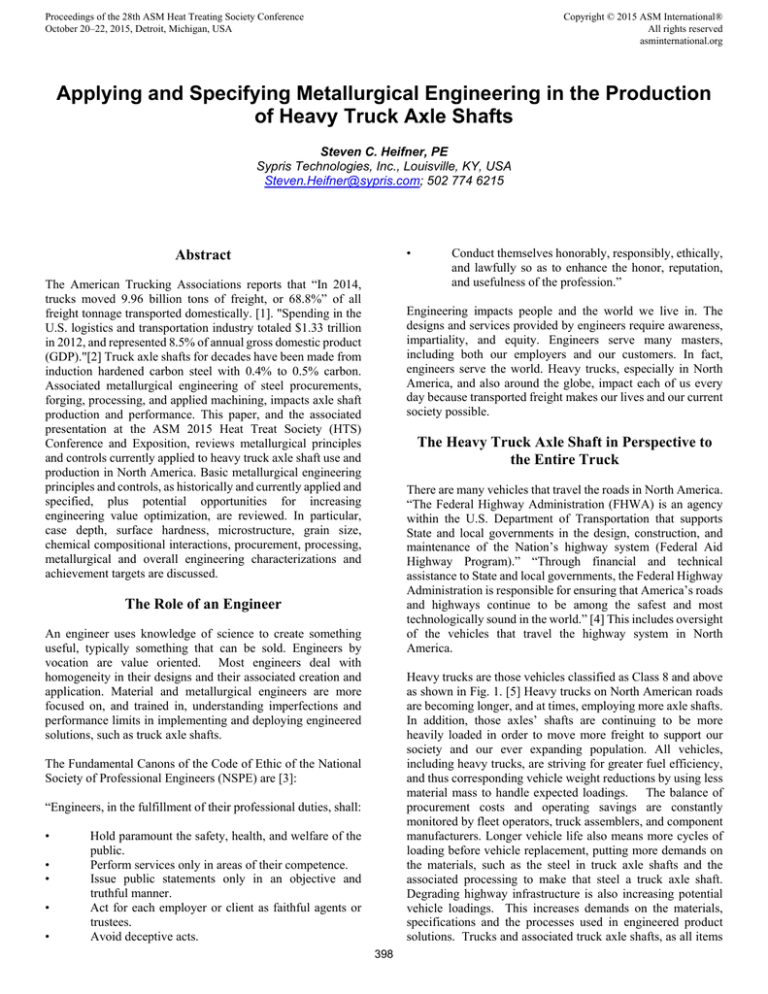

Making a Truck Axle

In the past fifty (50) years, since the creation of the US

Interstate Highway System, the manufacture and processing of

steel trucks axle shafts has changed very little. The process

involves procuring steel, forging a spline on one end and a

wheel connecting flange on the other end. The forging is then

machined as necessary and induction hardened and tempered to

obtain optimal material performance properties in the axle

shaft. The outer fibers of the axle shaft experience the greatest

torsional stress, thus a hardened martensitic case with a ductile

pearlite and ferrite, or bainite, core is created through induction

hardening heat treatment. This process flow is illustrated in Fig.

2.

Figure 1: Federal Highway Administration (FHWA) Vehicle

Classifications graphic;

http://onlinemanuals.txdot.gov/txdotmanuals/tri/images/FHW

A_Classification_Chart_FINAL.png

Without an axle, one wheel has little value, and a pair of wheels

has even less. Specified standard axle widths were a critical

component of the success of the Roman Empire. If you wanted

to drive a Roman road, your wheels needed to fit into the road

ruts created by the standard axle widths of previous travelers.

These same axle widths greatly influenced the first railroads

centuries later. However, it also led to businesses working with

engineers to create various track widths, or gauges, to

monopolize and control freight transportation in selected areas

along particular lines of commerce.

INPUT

Raw Material (Steel)

Cut or Shear to Working Size

Forge Spline

Forge Flange

Scale Removal - Blasting

Machining

Induction Hardening

Tempering

Straightening

Axle Shaft Shipment

OUTPUT

This plethora of railroad gauges, and the freight chaos and

associated economic waste it caused, led to development of

road width standards during the previous century by

governmental predecessors of the current Federal Highway

Administration. Specifications, or standards, did not exist prior

to invention of the typewriter, subsequently put to use during

World War 1 to help create safe housing for armament workers.

Production was being lost when temporary housing collapsed

killing workers, and discouraging new workers from coming

forward. Great value was associated with these first typewritten

specifications regarding worker housing which soon expanded

throughout the military, and in the coming decades into all

aspects of North American and world business, especially after

World War 2. The interstate highway system concept was a

post-war import to North America modeled on the standardized

Figure 2: Process Map for Making a Truck Axle Shaft.

Raw Material

Steel is a relatively inexpensive material that can be easily

altered in shape by forging, modified by machining into a

particular dimensional design, and heat treated as necessary to

optimize material performance and engineering usefulness.

154X plain carbon steel is the primary material used to make

399

heavy truck axle shafts in North America. At times, more

carbon is added, or other alloying elements modified, often

altering the hardenability to an H or RH grade. Hardenability is

important because it allows induction heat treatment to give the

outer fibers of the axle shaft the strength desired.

composition of the material, the grain size, and the severity of

quench. It is important to note that the maximum achievable

hardness in steel is determined by carbon content while

hardenability is determined by the alloy chemistry, which also

includes carbon. Hardenability is key to achieving the desired

case depth in a heavy truck axle shaft, and will be discussed

more in the Induction Hardening section of this paper.

As with most steel in use in the world today, the steel material

now being produced and in use is recycled steel scrap processed

by a mini-mill using electric arc furnace (EAF) steel processing.

Steel is the most recycled material in the world today, however

this recycling is concentrating tramp and residual elements in

the steel product being produced, increasing material

hardenability potential over the past five decades, and thereby

at times impacting subsequent axle shaft processing activities.

Micro alloyed and high strength low alloy steels (HSLA) are

created by using these same tramp and residual elements.

Hot rolled steel is the primary material used to make heavy

truck axle shafts, but at times, turned and polished steel is

requested by customers. Such attention to surface condition is

a fatigue design consideration. If crack initiation can be

delayed, fatigue life of the truck axle shaft will be extended.

Fatigue cracks can initiate on the outer fibers of the axle shaft,

or at the internal case-core interface when the internal torsional

shear stress level exceeds material strength of the internal nonhardened core material (as explained by Greg Fett [13]).

In North America, ASTM A29 [7], along with other referenced

ASTM standard specifications, are universally employed for

steel production. Other parts of the world have similar national

or regional standards, but also often embrace ASTM standards.

Each ladle of steel made is assigned a heat code by the steel

mill. A certified material test report (CMTR) from a typical

steel mill reports: procurement references, applicable

specifications, dimensional information, reduction ratio, ladle

chemistry (ASTM A29), calculated Jominy hardenability

(ASTM A255 [8]), microcleanliness (ASTM E45 [9]), grain

size (ASTM E112 [10]), possibly but not typically mechanical

properties (ASTM A370 [11]), general and specific comments

per procurement requirements, approval signatures, and

processing dates.

Failures within the spline or flange are material condition issues

controllable by, and thus the responsibility of, the axle shaft

manufacturer. Failures in the shaft body and associated

transition areas are typically associated with shock loadings

during vehicle operation. A shock load is a sudden and powerful

force applied against a component that can cause the component

to crack and the halves to separate from each other. An example

of this would be, spinning wheels that suddenly find traction.

Damage occurs because a shock load overstresses the axle shaft

beyond its material strength, and this can damage or destroy the

shaft immediately or shortly later. Often an axle shaft damaged

by a shock load will continue to operate but then fatigue fail

some time later after accumulating more cyclic stresses.

Finding a rough, crystalline finish on failure surface of

fractured axle shaft is indicative of an axle shaft damaged by a

shock load. Thus, axle shaft failures can be progressive or

immediate.

Steel chemistry can include the following elemental checks: C,

Mn, P, S, Si, Al, Cu, Ni, Cr, Mo, Sn,, N, V, Cb, B, Ca, W, Ti,

Pb, Co, As, Sb, Zr, and Bi. C, Mn, P, S, Si, Al, M and Fe, are

the primary components of steel composition. The other noted

elements are tramp or residual items. Aluminum content is a

critical alloy necessary to create a killed steel with a consistent

prior austenitic grain size of 5 or finer historically[6], and

currently observed to be in the range of a grain size of 7 to 9

which is associated with improved steel cleanliness, and other

steel making, process controls.

Progressive failure is cracking of a shaft following the initial

shock followed by crack growth and torsional fatigue failure.

Immediate failure is from a single sudden shock; i.e. a torsional

shear failure. Shock load failures are initiated by the vehicle

operators, not the material condition of the axle shaft. If the

resulting axle shaft fracture is at a 45-degree angle to the axle

shaft centerline, that fracture is called a torsional tensile failure

because of an additional axle shaft loading dimension. Early life

axle shaft failure events can also include crack initiation during

axle shaft straightening, quench cracks during induction

hardening, or insufficient case depth achieved during induction

hardening.

In addition, it is typical to calculate and report the DI or ideal

diameter. As explained so well by Daniel H. Herring [12]: “A

quantitative measure of a steel’s hardenability is expressed by

its DI, or ideal diameter, value. This abbreviation comes from

the French phrase “diamètre idéal” and refers to the largest

diameter of steel bar that can be quenched to produce 50%

martensite in its center. The quench rate of the bar is assumed

to be infinitely fast on the outside; that is, it has sufficient

quench severity so the heat removal rate is controlled by the

thermal diffusivity of the metal and not the heat transfer rate

from the steel to the quenchant. Typically, water or brine

provides these infinitely fast quench conditions. The larger the

ideal diameter value, the more hardenable is the steel.” “DI

values are an excellent means of comparing the relative

hardenability of two materials as well as determining if it is

possible to harden a particular cross section (or ruling section)

of a given steel”. DI values are influenced by the chemical

Typically, axle shaft failures occur at the transition from flange

to the shaft body, or less often, at the transition from the shaft

body to the spline. These transition failure sites are desirable

because they act as fuses protecting the rest of the truck

transaxle. A high residual stress state in the outer fibers of the

axle shaft is strong mitigator of fatigue crack initiation, and

early fatigue failure. Balancing axle shaft strength and axle

shaft toughness, that is, the impact or shock resistance of that

axle shaft, is necessary to achieve performance and prevent

failure of a given heavy truck axle shaft. Well-controlled

400

processing of the starting raw material is necessary to achieve

the axle shaft’s full performance potential.

In order to balance all these factors, forgers need a greater

processing temperature range than heat treaters, typically plus

or minus 50oF [20 oC], or even plus or minus 100oF [50 oC].

Reducing allowed variances, such as processing temperature, or

material inputs (such as a grain size) can be done, but at a cost

and after repeated forging production process rebalancing.

Spline Forging

Raw material is sheared or cut to length, then one end is heated

and forged for some distance (short or long; 3” [ 70 mm ] to 12”

[ 300 mm ]) to be subsequently machined and then splined by

rack rolling or hobbing, to form a spline for insertion into the

transaxle. Forging involves heating metal and striking to form

a desired product. Such metal working, or blacksmithing, has

formed the foundation of metallurgy for centuries. Making a

spline does not take much metal movement, especially

compared to forming the flange, but the principles and material

property limitations are the same. The steel needs to be hot

enough to flow but not so hot to damage or burn the steel.

Blacksmiths judged the formability by its heated color with

their eyes, today we have pyrometers and electronic logic

systems. 154X steel is typical forged between 1800oF [ 1000 oC

]and 2250oF [ 1280 oC ]. Heating 154X steel above 2300oF [

1300 oC ] begins to damage the steel by insipient melting.

Above about 1550oF [ 900 oC ] the ferrite and pearlite

microstructure of the bar transforms to austenite. Alloying,

temperature, and time at temperature impact the metal grain

size. 154X is a fine grained, aluminum killed steel. Forgers

want the metal to flow easily and welcome higher temperature

levels (in addition to fine grained steel).

Flange Forging

The other end of this cut bar is forged into a wheel flange.

Flange formation on a truck axle shaft from a rolled steel bar

takes more metal movement than creating the spline end. Metal

can be moved only so far during each processing hit. While

spline ends are created in one or two hits, flange formation

typically takes 3 to 5 hits, or passes. During each hit the metal

comes in connect with the die, or anvil, losing heat at the contact

surface. In addition, atomic friction during metal movement

creates adiabatic energy somewhat increasing internal metal

temperature. Thus a somewhat non-uniform starting heated

zone on a bar end is becoming even more non-uniform in each

subsequent forging process step.

The piece being forged cannot get too hot. This can result in

insipient melting (burning) of the steel. Neither can it get too

cold and critically slow metal flow. The metallurgy throughout

the flange being formed is impacted by these temperatures and

flows in relation to time. Fortunately, computer modeling is

helping us to better understand these temperatures and flows in

an engineering perspective rather than our historic

blacksmithing perspective.

Forging engineers strive with their process design to create a

desired property and dimensional output. By balancing their

starting raw material, with subsequent processing activities.

This finally results in the deployment of a high quality axle in a

truck driving safely down the road. This balancing requires

understanding, specifying and applying sound metallurgical

principles in the forging operation.

154X steel heated above 1750oF [1000 oC] is fully austenitic

and flows readily in the forging die. After forging, the piece is

typically slow cooled in still air to form a ferrite and pearlite

microstructure with an associated hardness of 20 to 30 HRC.

The pearlitic/ferritic microstructure is desired for subsequent

machining and induction hardening.

1800oF [1000 oC] and 2250oF [1280 oC] is a rather wide

temperature range. Heat treaters typically strive to maintain

plus or minus 25oF [10 oC] during processing operations. The

benefits of reducing variances to standardize output is well

known in our modern Six Sigma world. Higher temperatures

require more energy to achieve, and energy is an ever escalating

cost. However, forging at lower temperatures loads the forging

equipment more with associated potential equipment damage

and repair costs, decreasing value creation. Also, steel expands

differently at different temperatures thermally thereby

impacting the forging die sizing necessary to achieve the final

desired dimensional product output. Precision dimensional

forging can reduce subsequent machining and associated costs,

creating production system value. Achieving temperature

uniformity in the portion of the bar being forged is impacted by

the metal chill effect created by the rest of the unheated baron

one side of the bar heat zone. and more exposed surface area at

the cut end (end effect). There are temperature variances

throughout the heated zone being forged. All this balancing

impacts metallurgical properties through the heated zone during

forging and during (and after) subsequent cooling.

Scale Removal - Blasting

In addition, to moving metal at temperature during forging, the

heated surface of the hot zone is also interacting with the

surrounding atmosphere forming an oxide scale. More

temperature at the surface leads to more scale formation, and

also potentially carbon migration and decarburization at the

heated surface. Scale may or may not break free during each

subsequent forging pass, including the heating prior to forging.

This scale impacts the ability of a pyrometer to correctly

measure the surface temperature of a heated piece of metal.

Also, this scale impacts subsequent machinability of this forged

product, therefore this oxide scale is typically removed by steel

grit blasting after forging, which adds cost. Scale can also be

removed with high pressured water spray as well. Preventing

scale by forging in an inert atmosphere has been considered and

attempted, but adding an inert atmosphere also adds significant

cost.

Shot peening rather than shot blasting can add residual stresses

at the surface of a truck axle shaft, dramatically improving

401

fatigue performance, however the extra time and shot loading

associated with peening adds substantial cost.

depth for induction processes than published in hardenability

curves because more and quicker cooling is available. As

explained by M.A. Grossman in 1942 [15], and as documented

and specified within Table 5 of ASTM A255 [8], achievable

surface hardness is limited by material carbon content that

during initial contact with quench media almost instantaneously

forms martensite at the outer surface. Hardness achievement

away from the spline declines with distance because the

location at depth cannot cool as fast (soley by conduction)

because the cooling quench media is at the outer surface

(allowing for both conduction and convective cooling). Thus a

case depth profile in a heavy truck axle shaft is created.

Engineers use their knowledge to create something useful,

something valuable, that a customer is willing to purchase,

however the physical world limits what can and cannot be done

for reasonable cost. The level of scale removal, or surface

cleaning, must be agreed upon and specified by impacted

parties. Customers are unwilling to absorb additional cost

unless a performance benefit is achievable and demonstrated.

Thus the level of scale removal required and specified is

dependent on the economic value associated with that scale

removal.

Conduction transfers energy, as represented by temperature,

into a part, and conduction must transfer energy back out from

inside the part during quench cooling. As with forging, it is

desirable to heat a part enough to austenite the microstructure

(above about 1550ºF [900 oC]) sufficiently to allow the outer

case to transformation to austenite while limiting temperature

and associated heating exposure and phase transformation in

the core. Maintaining the lowest austenization temperature

possible also makes cooling, or quenching, the heated axle shaft

easier and correspondingly less costly than a process requiring

additional heat exchangers, cooling towers, and fluid

management.

Machining

The cleaned forging now must be altered into the final

dimensional configuration envisioned by the transaxle design

engineers.

Material properties variances can impact

subsequent processing such as machining, but the 154X steel

heavy truck axle shaft raw material is readily processed using

standard machining tools and techniques. It will not be

attempted in this paper to cover these standard machining

techniques.

Machining tolerances must take into consideration subsequent

processing. Induction hardening heat treatment in the next

processing step (along with subsequent tempering) will alter

part dimensions due to thermal expansion. Most significantly

the axle shaft will become longer during hardening. Spline and

other dimensions are affected to a much lesser extent. So once

again understanding, applying, and specifying material

properties is critical to axle shaft processing. The metallurgical

engineer must work with both the design engineer and the

production engineer to achieve system balance and the desired

dimensional outcome.

It is important to have an axle shaft core hard enough to oppose

applied torsional stresses that decreases from maximum at the

outer surface to zero stress at the center of the core, with no

quench cracks to act as fatigue initiation sites. Over hardening

the core does not benefit axle shaft performance, but under

hardening at the core-case interface can limit axle shaft

performance as it can becomes a fatigue crack initiation site.

Certain customers request greater hardness levels, especially in

transition zones, to ensure sufficient case depth hardness and

associated material strength. Others expect no heat exposure in

the core. Verification of hardness currently requires destructive

testing (sectioning). Destructive testing is a lagging, not a

leading, indicator, that your induction hardening heat treatment

process is working and producing good parts. This raises the

question, where should a hardened axle shaft be tested? How

many hardness tests are necessary, and need to be

correspondingly specified? Sample quality and preparation is

critical for obtaining meaningful hardness measurements.

Testing has a cost, and more testing than is statistically required

has decreasing value and reduces profits unnecessarily.

Induction Hardening

Heavy truck axle shaft processing time after forging, is 80%

machining and 20 % induction hardening. Induction hardening

creates a strong, hard case over a more ductile, softer inner core.

Induction hardening changes a 154X heavy truck axle shaft

surface hardness from 20 to 30 HRC to 50 to 60 HRC. Hardness

achieved decreases from the surface to the core of the shaft,

however the induction hardening pattern also varies

longitudinally. There is hardening flare into the flange, that

transitions into the shaft body, which transitions again into the

spline before running out at, or slightly before, the end of the

spline. The transitions zones, as previously mentioned, can vary

slightly or significantly from adjacent hardened zones if

hardening operations are not carefully managed.

Induction hardening scanners incorporate electrical,

mechanical, and fluid systems to create a magnetic field, and

then move a part through that field to austentize/heat the part

and then quench/cool the part to produce a martensitic

surface/case, while limiting phase transformations in the part’s

core. This is a complex balancing act. As previously noted,

reducing variances aids process control, however the raw

material, the forging, the machining, and now the induction

scanner operation itself are all sources of potential variance.

Hardenability curves present potential achievable hardness

during a Jominy end quench [14], and thus are one dimensional.

Induction scanners for truck axle shafts operate in two

dimensions, during a single-shot induction hardening operation,

or three dimensions, during a two-turn coil induction scanning

operation. Designers demand greater than average hardness at

402

Should a hardening operation be adjusted to compensate for

previous variances, or should the previous variances be

eliminated so the hardening operation can remain constant? If

one axle shaft fit all vehicles it might be a single hardening

operation, but this is not reality. Unique solutions are costly to

create and maintain, and actually introduce more variance into

any system. Ideally a heavy truck axle shaft of consistent

construction and dimensions is moved through a consistent

magnetic field, heated and then cooled, to create a consistent

metallurgical and dimensional output..

Heavy truck axle shafts are heavy (45 to 65 pounds each), and

packing for shipment must be designed to control this weight

and also protect the axles hafts, especially the spline and flange

design interfaces. Finished parts can be exposed to the elements

before and during shipment and in storage, and can begin

rusting. Customers expect any and every delivered axle shaft to

be ready use directly upon receipt or whenever there is a need

to use that axle shaft. Adding rust protection may add value or

be just an added cost to and a shaft that has also been forged,

machined, and hardened.

Tempering

Axle Shaft Insertion into Trucks and Society

During induction hardening, the micro expansion of martensitic

needles created in the case impart a beneficial compressive

residual surface stress. Untempered martensite, however, is

susceptible to environmental hydrogen and can be subject to

catastrophic fatigue failure. Blunting the lath martensite needles

through tempering is typically employed. Part exposure to a

temperature of 300oF [200 oC] to 500oF [300 oC] for one to one

and half hours minimum is typically specified to temper a steel

heavy truck axle shaft. This hold time is based upon the heater

treat’s maxim of one hour per inch of thickness. Heavy truck

axle shafts are usually 1-7/8” [ 47 mm ] in shaft diameter, and

usually no greater than 2-1/4” [ 57 mm ]in diameter, with

hardened case depths typical 0.5” [ 12 mm ] thick, up to 0.7” [

18 mm ] thick. Having a case depth thickness less than an inch

may allow for lesser temper hold times to achieve a desired

temper. Higher tempering temperatures and longer hold times

will reduce 154X mechanical properties slightly, therefore the

lowest temperature and time exposure is considered a potential

cost savings and value generator. In addition, induction

hardening in-process controls occur directly after hardening

rather than after tempering so the production line is not

excessively idled, (or not generating parts or value). Warm

parts are easier to straighten (if required) during the next axle

shaft processing step.

Finished axle shafts are typically shipped to a transaxle

assembler, who may or may not be the final truck assembler.

Trucks are ubiquitous to our societal and economic existence.

We have invested in roads and must have vehicles to travel

those roads to deliver almost everything that makes our lives

possible. Engineering is a team activity. We must work with

others to make our solutions work. Making things work better

is what value is all about.

Conclusions

Metallurgical engineering value concepts and knowledge

applied during today's production of heavy truck axle shafts

include:

Steel is a relatively inexpensive material that be easily

altered in shape by forging, modified by machining

into a particular dimensional design, and induction

hardened as necessary to optimize material

performance and engineering usefulness.

Customers, are unwilling to absorb additional costs

unless a performance benefit is achievable and

demonstrated. Trucks and associated truck axle shafts

need to continually become more value generating and

less wasteful.

Most engineers deal with homogeneity in their designs

and their placement in the world. Material and

metallurgical engineers are more focused on and

trained in understanding imperfections and

performance limits in implementing and deploying

engineered solutions, such as truck axle shafts.

Hardenability is key to achieving the desired case

depth in a heavy truck axle shaft. Controlling this, and

other metallurgical and process inputs can assure a

consistent output. There is no value in performing

surface hardness verification tests during axle shaft

production.

Aluminum content is necessary to create a killed steel

with a consistent prior austenitic grain size of 5 or

finer. It is unclear how additional grain size

specification requirements impacts truck axle shaft

performance and usefulness.

Straightening

Ideally, straightening any axle shaft would never be necessary,

however, exposing hot metal to a cooling solution can cause

part warping. The non-uniform application of cooling solutions

or quench to a non-uniform heat surface is a major contributor

to warping. Excessive warping or distortion will compromise

the transaxle design and its operating efficiency and cannot be

allowed to compromise the axle shaft or the vehicle. Improper

straightening can also crack the outer surface and create fatigue

initiation sites. Non-destructive inspection, such as magnetic

particle inspection, of straightened parts is sometimes

mandated. Such inspection is time (and value) consuming.

Preparation for Shipment

The heavy truck axle shaft is now complete, however it has

generated no value until it is sold and delivered to a customer.

Sometimes customers require their axle shafts to be blasted

again after induction hardening, and sometimes they do not.

403

If fatigue initiation can be delayed, fatigue life of the

truck axle shaft should be extended. Improper

straightening, and other processing missteps, can

create fatigue initiation sites limiting axle life.

Non-destructive inspection, such as magnetic particle

inspection, is time and value consuming. When

specified, one must consider how this non-destructive

inspection is improving axle shaft performance.

Dimensional achievement in balance with achievable

metallurgical properties is required during axle shaft

forging. Forgers need a greater processing temperature

range than heat treaters.

Destructive testing is a lagging, not a leading

indicator, of metallurgical quality.

[3] National Society of Professional Engineers (NSPE), 1420

King Street, Alexandria, Virginia 22314 , phone number

703 684 2800; “Code of Ethics” webpage;

http://www.nspe.org/resources/ethics/code-ethics.

[4] U.S Department of Transportation, Federal Highway

Administration website; http://www.fhwa.dot.gov/about/.

[5] Traffic Recorder Instruction Manual, Texas Department of

Transportations, Released February 01, 2012, Appendix A:

Vehicle Classification Using FHWA 13-Category Scheme;

http://onlinemanuals.txdot.gov/txdotmanuals/tri/images/F

HWA_Classification_Chart_FINAL.png.

[6] Mishra, B., Steelmaking Practices and Their Influence on

Properties, Metals Handbook Desk Edition, ASM

International, 1998, p. 174–202.

[7] ASTM A29 / A29M-12e1, Standard Specification for

General Requirements for Steel Bars, Carbon and Alloy,

Hot-Wrought, ASTM International, West Conshohocken,

PA, 2012, www.astm.org.

[8] ASTM A255-10(2014), Standard Test Methods for

Determining Hardenability of Steel, ASTM International,

West Conshohocken, PA, 2014, www.astm.org.

[9] ASTM E45-13, Standard Test Methods for Determining

the Inclusion Content of Steel, ASTM International, West

Conshohocken, PA, 2013, www.astm.org.

[10] ASTM E112-13, Standard Test Methods for Determining

Average Grain Size, ASTM International, West

Conshohocken, PA, 2013, www.astm.org.

[11] ASTM A370-14, Standard Test Methods and Definitions

for Mechanical Testing of Steel Products, ASTM

International, West

Conshohocken,

PA, 2014,

www.astm.org.

[12] Herring, D.H, "THE HEAT TREAT DOCTOR:

Fundamentals of Heat Treating: Ideal Diameter," Industrial

Heating,

September

1,

2005,

page

18-20,

IndustrialHeating.com.

[13] Fett, G.A., Induction Case Hardening of Axle Shafts,

Induction Heating and Heat Treatment. Vol 4C, ASM

Handbook, ASM International, 2013, p 160–172.

[14] Kirkaldy, J.S., Quantitative Prediction of Transformation

Hardening in Steels, Heat Treating, Vol 4, ASM

Handbook, ASM International, 1991, p 20–32.

[15] Grossman, M. A., Hardenability Calculated from

Chemical Composition, AIME Transactions, Vol 150,

1942, pp. 227–259.

Acknowledgments

My friend, Matt Yaksic, for expanding my knowledge

regarding forgings.

My company, Sypris Technologies, for supporting my

professional association and involvement with ASM

International and the Heat Treat Society.

References

[1] "Trucking Revenues Top $700 Billion for the First Time

According to New Report” press release from American

Trucking Associations, 950 North Glebe Road, Suite 210,

Arlington, VA 22203-4181, dated May 11, 2015;

http://www.trucking.org/article.aspx?uid=70210058bb81-44df-a565-492f899fc139.

[2] U.S Department of Commerce, SELECTUSA website,

“The Logistics and Transportation Industry in the United

States" webpage; http://selectusa.commerce.gov/industrysnapshots/logistics-and-transportation-industry-unitedstates.html.

404