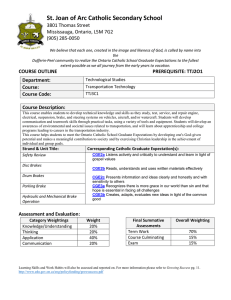

Cam Brakes and Automatic Slack Adjusters

advertisement