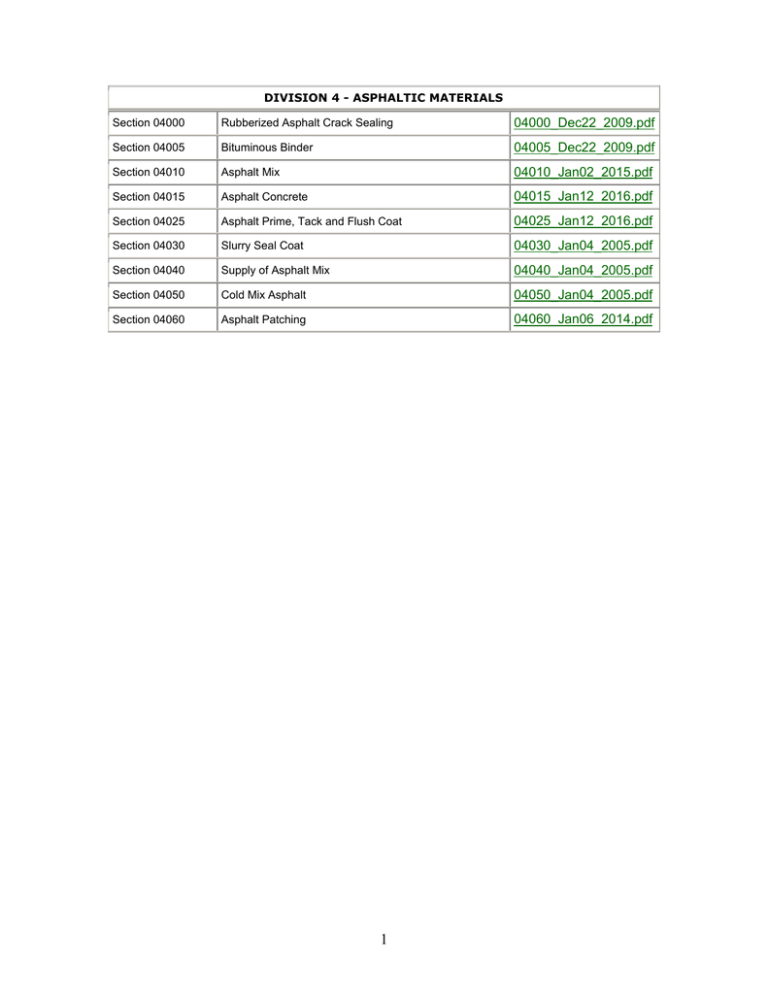

DIVISION 4 - ASPHALTIC MATERIALS Section 04000 Rubberized

advertisement