SOLENOID VALVES

3/2

2

redundant, direct operated

basic flow, balanced poppet

1/4

U

Series

3

1

327

2

FEATURES

• The redundant solenoid valves are recommended for fail safe pilot applications

combining high flow, wide pressure range and absence of minimum operating

pressure

• When the redundant valve controls an actuator, the actuator remains in position

as long as one of the two solenoid valves (coils) is energized. To exhaust the

actuator both solenoids have to be de-energized

• PTFE rider rings and graphite-filled PTFE seals reduce friction and eliminate

sticking

• Coils used in metal enclosures have class H insulation materials

• Dedicated execution for low power

• Dedicated execution for extreme low ambient temperatures

• Peak voltage suppression diodes are standard in DC solenoids with metal

enclosures

• The solenoid valves satisfy all relevant EC Directives

• Environmental NACE compliant and certified vibration resistant in combination

with WSCR solenoids

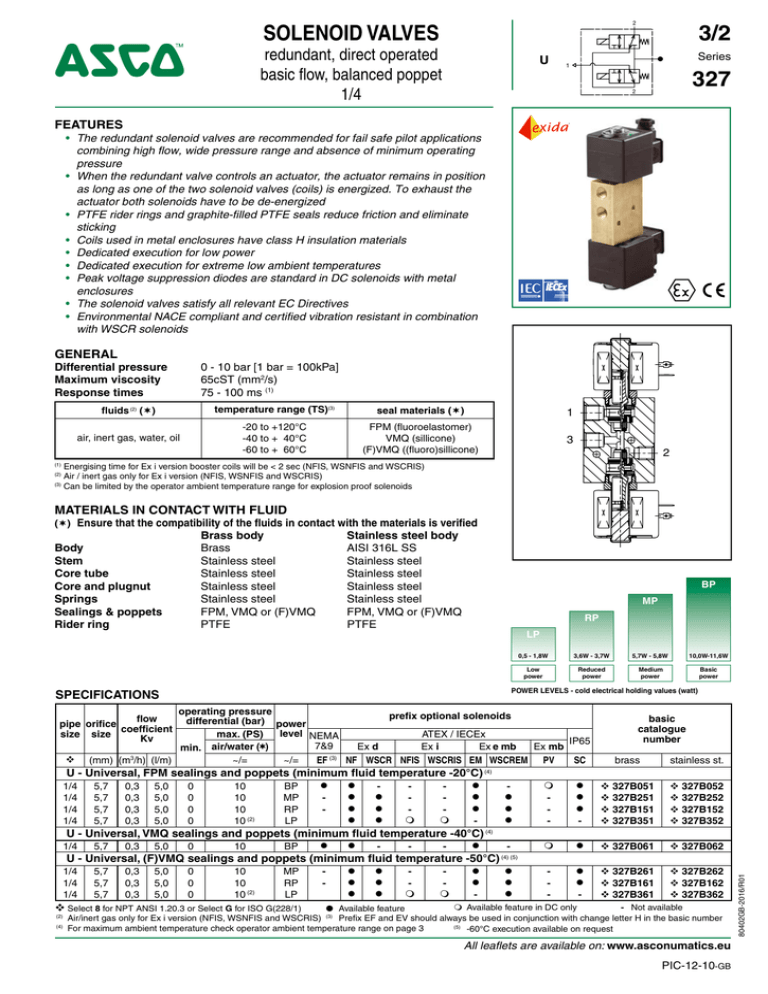

GENERAL

Differential pressure

Maximum viscosity

Response times

0 - 10 bar [1 bar = 100kPa]

65cST (mm2/s)

75 - 100 ms (1)

fluids (2) (¬)

temperature range (TS)(3)

seal materials (¬)

1

air, inert gas, water, oil

-20 to +120°C

-40 to + 40°C

-60 to + 60°C

FPM (fluoroelastomer)

VMQ (sillicone)

(F)VMQ ((fluoro)sillicone)

3

2

Energising time for Ex i version booster coils will be < 2 sec (NFIS, WSNFIS and WSCRIS)

(2)

Air / inert gas only for Ex i version (NFIS, WSNFIS and WSCRIS)

(3)

Can be limited by the operator ambient temperature range for explosion proof solenoids

(1)

MATERIALS IN CONTACT WITH FLUID

(¬) Ensure that the compatibility of the fluids in contact with the materials is verified

Brass body

Brass

Stainless steel

Stainless steel

Stainless steel

Stainless steel

FPM, VMQ or (F)VMQ

PTFE

Body

Stem

Core tube

Core and plugnut

Springs

Sealings & poppets

Rider ring

Stainless steel body

AISI 316L SS

Stainless steel

Stainless steel

Stainless steel

Stainless steel

FPM, VMQ or (F)VMQ

PTFE

BP

MP

RP

LP

0,5 - 1,8W

3,6W - 3,7W

5,7W - 5,8W

10,0W-11,6W

Low

power

Reduced

power

Medium

power

Basic

power

POWER LEVELS - cold electrical holding values (watt)

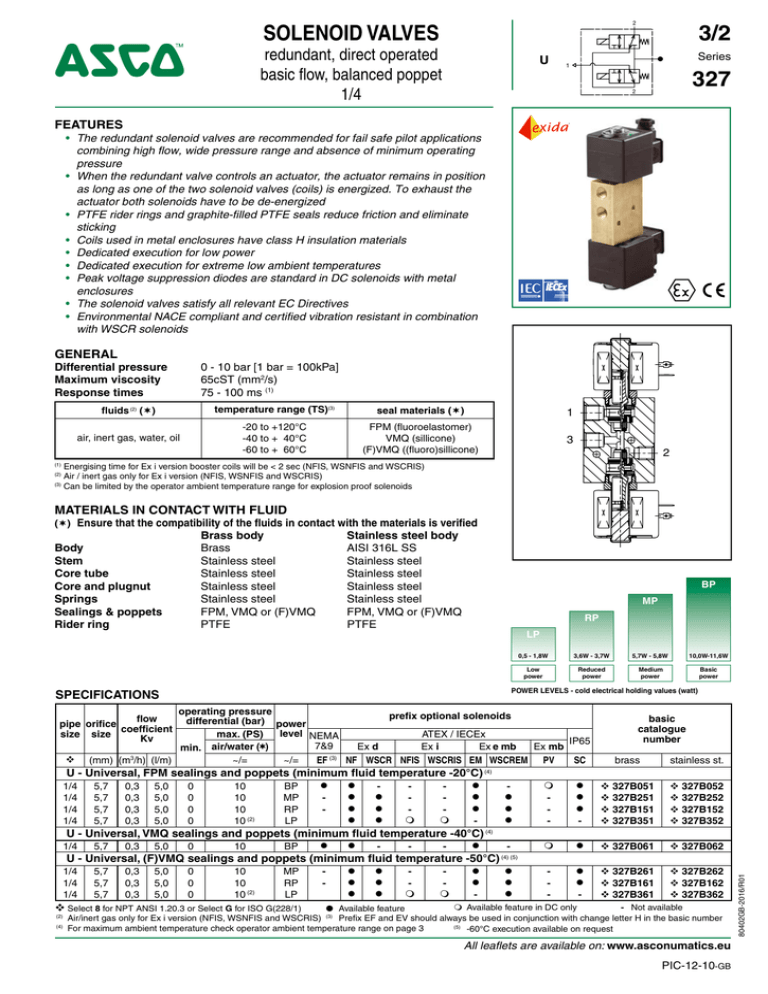

SPECIFICATIONS

operating pressure

prefix optional solenoids

differential (bar) power

level NEMA

ATEX / IECEx

max. (PS)

IP65

7&9

Ex d

Ex i

Ex e mb

Ex mb

min. air/water (¬)

(mm) (m3/h) (l/m)

~/=

~/=

EF (3) NF WSCR NFIS WSCRIS EM WSCREM PV

SC

flow

pipe orifice

coefficient

size size

Kv

basic

catalogue

number

brass

stainless st.

U - Universal, FPM sealings and poppets (minimum fluid temperature -20°C) (4)

1/4

1/4

1/4

1/4

5,7

5,7

5,7

5,7

0,3

0,3

0,3

0,3

5,0

5,0

5,0

5,0

0

0

0

0

10

10

10

10 (2)

BP

MP

RP

LP

-

-

-

-

327B051

327B251

327B151

327B351

327B052

327B252

327B152

327B352

-

327B061

327B062

-

-

327B261

327B161

327B361

327B262

327B162

327B362

U - Universal, VMQ sealings and poppets (minimum fluid temperature -40°C) (4)

1/4

5,7

0,3

5,0

0

10

BP

-

-

-

1/4

1/4

1/4

5,7

5,7

5,7

0,3

0,3

0,3

5,0

5,0

5,0

0

0

0

10

10

10 (2)

MP

RP

LP

-

-

Select 8 for NPT ANSI 1.20.3 or Select G for ISO G(228/1)

(2)

(4)

Available feature in DC only

- Not available

● Available feature

Air/inert gas only for Ex i version (NFIS, WSNFIS and WSCRIS) (3) Prefix EF and EV should always be used in conjunction with change letter H in the basic number

(5)

For maximum ambient temperature check operator ambient temperature range on page 3

-60°C execution available on request

All leaflets are available on: www.asconumatics.eu

PIC-12-10-GB

80402GB-2016/R01

U - Universal, (F)VMQ sealings and poppets (minimum fluid temperature -50°C) (4) (5)

SERIES 327

PRODUCT SELECTION GUIDE

PREFIX TABLE

1

E

E

E

N

P

S

W

N

W

W

W

W

W

W

W

prefix

description

2 3 4 5 6 7

F

Explosionproof - NEMA 7, 9 - Zinc plated steel conduit

V

Explosionproof - NEMA 7, 9 - 316 SS conduit

M

Waterproof IP66/67 - Metal enclosure (EN/IEC 60079-7,-18 and -31)*

E T

Threaded conduit/hole (M20 x 1,5)

F

Flameproof - Aluminium (EN/IEC 60079-1, 60079-31)*

V

Encapsulated epoxy moulded (EN/IEC 60079-18)*

C

Solenoid with spade plug connector (EN/IEC 60730)

P

Waterproof IP67 - Metal enclosure

F

I S

I.S. with Aluminium IP67 enclosure (EN/IEC 60079-11+31)*

S

Waterproof IP67 - 316 SS enclosure

S C R

Flameproof 316L SS (EN/IEC 60079-0+1+31)*

S C R E M

Increased Safety / Encapsulated 316L SS (EN/IEC 60079-0+7+18+31)*

S C R I S

Intrinsically Safe 316L SS (EN/IEC 60079-0+11+31)*

S E M

Waterproof IP66/67 - 316 SS enclosure (EN/IEC 60079-7,-18 and -31)*

S N F I S

I.S. with 316L SS IP67 enclosure (EN/IEC 60079-11+31)*

S N F

Flameproof - 316L SS (EN/IEC 60079-1, 60079-31)*

T

Threaded conduit (1/2" NPT)

H C

Class H - Battery charging circuit

X Other special constructions

power level

LP RP MP BP

-

-

SUFFIX TABLE

suffix

1 2 3 4 5

N V

V

C O

description

FPM (fluoroelastomer) and parts cleaned for oxygen service

FPM (fluoroelastomer)

Epoxy coating on all external surfaces

power level

LP RP MP BP

● Available feature

Available feature in DC only

-Not available

* ATEX/IECEx valves using these solenoids are approved according to EN 13463-1 (non electrical)

(1)

Functional Safety certification is not applicable with this feature

STEP 1

Select basic catalogue number,

including pipe thread indentification

letter. Refer to the specifications table

on page 1.

Example: 8327B051

STEP 2

Select prefix (combination). Refer to

the specifications table on page 1 and

the prefix table on page 2, respect the

indicated power level.

Example: NF

STEP 3

Select suffix (combination) if required.

Refer to the suffix table on page 2,

respect the indicated power level.

Example: CO

STEP 4

Select voltage. Refer to standard

voltages on page 3.

Example: 230V / 50/60 Hz

STEP 5

Final catalogue / ordering number.

Example:

NF 8327B051 CO 230V / 50/60 Hz

ORDERING EXAMPLES VALVES:

SC

WSEMT

NFET

WSEM

NF

WSCR

EM

PV

EF

OPTIONS & ACCESSORIES

spare part kit no.(2)

~/=

C123670

C123670

C131237

C131237

C132251

C132251

C132253

C132253

C132251

C132251

C132253

C132253

C132443

C132443

C132444

C132444

mounting

bracket

Select 8 for NPT ANSI 1.20.3 or select G for ISO G(228/1)

Standard prefixes/suffixes are also applicable to kits

Mounting holes in body

(2)

All leaflets are available on: www.asconumatics.eu

12-10-2

327B051

327B052

327B051

327B052

327B261

327B152

327B251

327B062

327H152

CO

CO

CO

CO

CO

CO

24V / DC

24V / DC

230V / 50/60 Hz

24V / DC

24V / DC

24V / DC

230V / 50/60 Hz

24V / DC

240V / 50/60 Hz

prefix (3)

pipe thread

basic number (3)

voltage

suffix

ORDERING EXAMPLES KITS¬:

WS

EM

PV

EF

prefix

basic number

C131237 (4)

C123670

C131237

CO

C123670

suffix

Prefix EF and EV should always be used in conjunction with

change letter H in the basic number

(4)

Basic kit number applies to SC coil construction

¬

Because of the nature of redundant valves (2x solenoid) the

spare part kits have to be ordered 2x

(3)

80402GB-2016/R01

catalogue

number

SC 327B051

SC 327B052

SC 327B061

SC 327B062

SC 327B151

SC 327B152

SC 327B161

SC 327B162

SC 327B251

SC 327B252

SC 327B261

SC 327B262

327B351

327B352

327B361

327B362

8

G

G

G

8

G

8

8

G

SERIES 327

EXPLANATION OF TEMPERATURE RANGES OF SOLENOID VALVES

Valve temperature range

Operator ambient temperature range

Total temperature range

The valve temperature range (TS) is determined by the selected seal material, the temperature

range for proper operation of the valve and sometimes by the fluid (e.g. steam)

The operator ambient temperature range is determined by the selected power level and the

safety code

The temperature range of the complete solenoid valve is determined by the limitations of both

temperature ranges above

ELECTRICAL CHARACTERISTICS

Coil insulation class H

Electrical safety IEC 335

Standard voltages (1)

DC (=) 24V - 48V; Allowable voltage variation ± 10%

AC (~) 24V - 48V - 115V - 230V/50/60Hz; Other voltages are available on request

prefix

option

operator

power ratings

ambient

inrush holding hot/cold temperature

~

~

=

range

(VA) (VA) (W)

(W)

(C°)(1)

electrical

enclosure

protection

(EN 60529)

safety code

replacement coil / kit

~

=

230V/50/60 Hz

24V/DC

type(2)

Basic power (BP)

SC

WP/WS

NF/WSNF

EM/WSEM

PV

EF/EV

10,0

10,0

10,0

10,0

12,0

10,0

10,0

10,0

10,0

12,0

10,0

10,0

10,0

10,0

12,0

9,0/11,2

9,0/11,2

9,0/11,2

9,0/11,2

9,0/11,2

9,3/11,6

-40 to +55

-40 to +55

-60 to +40/60

-40 to +40

-40 to +55

-40 to +52/40

EN 60730

EN 60730

II2G Ex d IIC Gb T6/T5, II2D Ex tb IIIC Db

II2G Ex e mb IIC Gb T3, II2D Ex tb IIIC Db

II2G Ex mb IIC Gb T4, II2D Ex mb IIIC Db

NEMA type 7 and 9

IP65, moulded

IP67, steel /SS

IP66/67, alu./SS

IP66/67, steel /SS

IP67, moulded

NEMA 4X

123664-017

400915-017

400915-017

400915-017

276002-058D

400425-142

400913-142

400913-142

400913-142

- (3)

238714-006D

01

03

05

03

07

08

5,8

5,8

5,8

5,8

5,8

5,8

5,2/5,7

5,2/5,7

5,2/5,7

5,2/5,7

5,2/5,7

5,2/5,7

-40 to +90

-40 to +90

-60 to +40/75

-60 to +90

-60 to +60/75/90

-40 to +40/75

EN 60730

EN 60730

II2G Ex d IIC Gb T6/T5/T4, II2D Ex tb IIIC Db

II2G Ex d IIC Gb T6/T4, II2D Ex t IIIC Db

II2G Ex e mb IIC Gb T6/T4, II2D Ex tb IIIC Db

II2G Ex e mb IIC Gb T5/T4, II2D Ex tb IIIC Db

IP65, moulded

IP67, steel /SS

IP66/67, alu./SS

IP66/67, SS

IP66/67, SS

IP66/67, steel /SS

400924-297

400921-297

400921-297

400962-297

400962-297

400921-297

400923-442

400914-442

400914-442

400961-442

400961-442

400914-442

02

04

05

06

06

04

3,2/3,6

3,2/3,6

3,2/3,6

3,2/3,6

3,2/3,6

3,2/3,6

-40 to +55

EN 60730

-40 to +55

EN 60730

-60 to +60

II2G Ex d IIC Gb T6, II2D Ex tb IIIC Db

-60 to +40/60/90 II2G Ex d IIC Gb T6/T5/T4, II2D Ex t IIIC Db

-60 to +40/60/90 II2G Ex e mb IIC Gb T6/T5/T4, II2D Ex tb IIIC Db

-40 to +40/55

II2G Ex e mb IIC Gb T6/T5, II2D Ex tb IIIC Db

Medium Power (MP)

SC

WP/WS

NF/WSNF

WSCR

WSCREM

EM/WSEM

5,8

5,8

5,8

5,8

5,8

5,8

5,8

5,8

5,8

5,8

5,8

5,8

Reduced Power (RP)(4)

SC

WP/WS

NF/WSNF

WSCR

WSCREM

EM/WSEM

3,7

3,7

3,7

3,7

3,7

3,7

3,7

3,7

3,7

3,7

3,7

3,7

3,7

3,7

3,7

3,7

3,7

3,7

IP65, moulded

IP67, steel /SS

IP66/67, alu./SS

IP66/67, SS

IP66/67, SS

IP66/67, steel /SS

- (4)

- (4)

- (4)

- (4)

- (4)

- (4)

400923-042

400914-242

400914-242

400961-242

400961-242

400914-242

02

04

05

06

06

04

IP66/67, alu./SS

IP66/67, SS

IP66/67, SS

IP66/67, alu./SS

IP66/67, SS

IP66/67, alu./SS

- (5)

- (5)

- (5)

- (5)

- (5)

- (5)

400914-542

400961-542

400961-542

429013-001

429013-001

429013-001

05

06

06

05

06

05

Low Power (LP)(5)

NF/WSNF 1,85

WSCR

1,85

WSCREM 1,85

NFIS (6)

0,5

WSCRIS

0,5

WSNFIS

0,5

1,85 1,85 1,5/1,8 -60 to +55

1,85 1,85 1,5/1,8 -60 to +55

1,85 1,85 1,5/1,8 -60 to +55

0,5 0,5

0,5

-40 to +60

0,5 0,5

0,5

-40 to +60

0,5 0,5

0,5

-40 to +60

Temperature range can be limited by sealings

AC (~) limited to 127V/50/60Hz or 125V/DC

- Not available

II2G Ex d IIC Gb T6, II2D Ex tb IIIC Db

II2G Ex d IIC Gb T6, II2D Ex t IIIC Db

II2G Ex e mb IIC Gb T6, II2D Ex tb IIIC Db

II2G Ex ia IIC T6 Gb, II2D Ex tb IIIC Db

II2G Ex ia IIC T6 Gb, II2D Ex tb IIIC Db

II2G Ex ia IIC T6 Gb, II2D Ex tb IIIC Db

(1)

(2)

(4)

(5)

Refer to the dimensional drawings on page 4 and 5

Only available in 24V/DC

(3)

(6)

Multiple coil kits are available under ATEX/IECEx, contact us

Shall be protected against any impact or friction, see the

installation conditions given in the I&M sheet

ELECTRICAL CONNECTIONS

prefix

SC

WP, WS, EM, WSEM, NFIS, WSNFIS, WSCRIS

connection

Spade plug connector with cable gland EN175301-803A (ISO 4400) for cables

with an outer diameter from 6 to 10 mm

M20 plastics cable gland for cables with an outer diameter from 7 to 12 mm.

WSCREM

M20 316 SS cable gland for cables with an outer diameter from 7,2 to 11,7 mm.

NF, WSNF, WSCR, NFTIS, WSNFTIS

1/2" NPT threaded cable entry. Enclosures are supplied without cable gland

NFET, WSNFET, NFETIS, WSNFETIS

M20 x 1,5 threaded cable entry. Enclosures are supplied without cable gland

80402GB-2016/R01

All leaflets are available on: www.asconumatics.eu

12-10-3

SERIES 327

ADDITIONAL OPTIONS

●

●

●

●

●

Direct mount / pad mount construction according to NAMUR recommendations

Ex mb/mD (prefix "PV") solenoid can be supplied with various cable lengths

Compliance with "UL", "CSA" and other local approvals available on request

Special moulded-in solid state components for peak voltage suppression and/or rectification (four diode bridge)

-60°C execution available on request

INSTALLATION

●

●

●

●

●

●

●

●

●

Multi language installation/maintenance instructions are included with each valve

The solenoid valves can be mounted in any position without affecting operation

The mounting holes are provided in the valve body

Threaded pipe connection identifier is 8 = NPT (ANSI 1.20.3); G = G (ISO 228/1)

Declarations of conformity are available on request

Ex e mb Prefix "EM" and Ex ia Prefix "NFIS/WSCRIS"execution: solenoid enclosure has a cable gland with integral strain relief

for cables with an o.d. from 7 to 12 mm and is provided with an internal and external connection facility for an earthing or

bonding conductor

Ex d Prefix "NF/WSNF/WSCR" enclosure is provided with a 1/2" NPT threaded entry hole, M20 x 1,5 (prefix "ET") is optional.

These are supplied without cable gland

All DC solenoids with metal enclosure are provided with switch-off peak voltage suppression diodes

To comply with IEC 61508 (SIL) the valves must be provided with a specific exhaust protector (as shown on page 6) or equal

DIMENSIONS (mm), WEIGHT (kg)

TYPE 01:

TYPE 02:

Epoxy moulded

SC: IEC 335 / ISO 4400

Epoxy moulded

SC: IEC 335 / ISO 4400

327B051 / B052 / B061 / B062

327B151 / B152 / B161 / B162 / B251 / B252 / B261 / B262

360°

360°

TYPE 03:

TYPE 04:

Metal, epoxy coated / AISI 316 SS

WP / WS: IEC 335

EM / WSEM: EN/IEC 60079-7+18+31

Metal, epoxy coated / AISI 316 SS

WP / WS: IEC 335

EM / WSEM: EN/IEC 60079-7+18+31

327B051 / B052 / B061 / B062

327B151 / B152 / B161 / B162 / B251 / B252 / B261 / B262

360°

360°

All leaflets are available on: www.asconumatics.eu

12-10-4

80402GB-2016/R01

SERIES 327

DIMENSIONS (mm), WEIGHT (kg)

TYPE 05:

TYPE 06:

Aluminium, epoxy coated / AISI 316L SS

NF / WSNF

: EN/IEC 60079-1, 60079-31

NFIS / WSNFIS : EN/IEC 60079-11, 60079-31

AISI 316L SS

WSCR

: EN/IEC 60079-0, 60079-1, 60079-31

WSCREM : EN/IEC 60079-0, 60079-7, 60079-18,

EN/IEC 60079-31

WSCRIS : EN/IEC 60079-0, 60079-11, 60079-31

327B051 / B052 / B061 / B062 / B151 / B152 / B161 / B162 /

B251 / B252 / B261 / B262 / B351 / B352 / B361 / B362

D

A

E

327B152 / B162 / B252 / B262 / B352 / B362

B

G

F

H

Ø5,5

C

2

1

3

12

36

27

37

TYPE 07:

TYPE 08:

Epoxy encapsulated

PV: EN/IEC 60079-18

Epoxy encapsulated

EF and EV: NEMA type 7, 9 / ICS-6 ANSI

327B051 / B052 / B061 / B062

327H001 / H002 / H011 / H012

01

02

03

04

05

05

06

07

08

SC

SC

WP, WS, EM, WSEM

WP, WS, EM, WSEM

NF, WSNF

NF, WSNF, NFIS, WSNFIS

WSCR, WSCREM, WSCRIS

PV

EF, EV

power level

A

B

C

D

E

F

G

H

weight

BP

MP/RP

BP

MP/RP

BP/MP/RP

LP

MP/RP/LP

BP

BP

45

50

76

76

97

97

92

45

50

91

86

86

90

135

145

137

97

97

205

194

194

201

248

268

252

171

173

93

97

120

120

102

102

116

72

77

65

68

82

82

54

54

75

67

51

66

59

61

63

160

170

161

45

122

23

23

23

23

101

111

103

121

62

102

97

97

100

23

23

23

23

23

1,55 kg

1,65 kg

1,60 kg

1,70 kg

4,70 kg

4,90 kg

3,10 kg

1,70 kg

1,70 kg

80402GB-2016/R01

type prefix/option

All leaflets are available on: www.asconumatics.eu

12-10-5

SERIES 327

SECTIONAL DRAWING

2

A

3

1

1

3

2

Schematic presentation of

the redundant valve

B

Execution : Reduced Power

Bracket kit no.: C139824

contains: Stainless steel

304 SS screws and bracket

All leaflets are available on: www.asconumatics.eu

12-10-6

PIC-12-0010-GB -- Availability, design and specifications are subject to change without notice. All rights reserved.

80402GB-2016/R01

NF/WSNF

MOUNTING BRACKET