ARTICLE IN PRESS

Available online at www.sciencedirect.com

Acta Materialia xxx (2009) xxx–xxx

www.elsevier.com/locate/actamat

Tensile and compressive behavior of gold and molybdenum

single crystals at the nano-scale

Ju-Young Kim, Julia R. Greer *

Materials Science, California Institute of Technology, Pasadena, CA 91125, USA

Received 12 May 2009; received in revised form 16 July 2009; accepted 17 July 2009

Abstract

In situ mechanical tests were carried out to measure the tensile behavior of single-crystalline face-centered cubic (fcc) gold (Au) and

body-centered cubic (bcc) molybdenum (Mo) nano-pillars with diameters between 250 and 1 lm, and to compare this with the compression results of these materials at the equivalent sizes. In Au, we observed similar tensile and compressive flow stresses at 10% strain

although strain-hardening in tension is somewhat more pronounced than it is in compression. In Mo, the amount of strain-hardening

in tension is significantly lower than that in compression, leading to a distinct tension–compression asymmetry in the flow stress at 5%

strain. The dissimilarities between tensile and compressive behavior in both crystals are discussed in terms of sample geometry constraints and dislocation behavior in bcc crystals.

Ó 2009 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Keywords: Tension test; Compression test; Plastic deformation; Tension–compression asymmetry

1. Introduction

Advances in load–displacement sensors and actuators,

as well as in micro-fabrication techniques, have enabled

the exploration of the mechanical properties of materials

at the sub-micron scale [1–7]. These efforts are driven by

the need for precise fabrication and reliable operation of

nano-scale devices, as well as by fundamental scientific

curiosity. Size effects in plasticity of single crystals have

been reported for nanoindentation and bending experiments, where they are attributed to the presence of severe

strain gradients [8–16], as well as in micro-pillar compression tests where the strain gradients are minimal [16–32].

Several years ago, Uchic et al. introduced a new

approach to evaluate the mechanical behavior of micronscale single crystals by uniaxially compressing micro-cylinders, fabricated by a focused ion beam (FIB), with a flat

punch tip in the nanoindenter [17,36]. This technique was

*

Corresponding author.

E-mail address: jrgreer@caltech.edu (J.R. Greer).

subsequently extended by Greer et al. to perform uniaxial

compression tests on Au nano-pillars with diameters below

1 lm [18]. Since then, many studies have convincingly demonstrated that both the yield strength and the flow stress

increase with decreasing sample size at the micron and

sub-micron scales [17–21,23,24,26–30,32,34,35]. Contrary

to these results based on testing FIB-fabricated samples,

no size effects were found in Mo alloy micro-columns prepared by chemically etching away the matrix of a directionally solidified NiAl–Mo eutectic, which attained theoretical

strength regardless of the sample size [22,25].

Several theories have been proposed to explain the

widely observed size effect in the compression of singlecrystalline face-centered cubic (fcc) nano-pillars. One such

theory is ‘‘hardening by dislocation starvation”, the main

premise of which is that pre-existing or newly generated

mobile dislocations escape the sample at the free surface

more quickly than they multiply [5,18,21]. This hypothesis

appears to be in agreement with the in situ transmission

electron microscopy (TEM) observations [27] and computational atomistic simulations [23,24,32]. Experimental

1359-6454/$36.00 Ó 2009 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

doi:10.1016/j.actamat.2009.07.027

Please cite this article in press as: Kim J-Y, Greer JR. Tensile and compressive behavior of gold and molybdenum single crystals at the

nano-scale. Acta Mater (2009), doi:10.1016/j.actamat.2009.07.027

ARTICLE IN PRESS

2

J.-Y. Kim, J.R. Greer / Acta Materialia xxx (2009) xxx–xxx

and computational studies of single-crystal Mo nano-pillar

compressions, however, showed that their deformation

mechanism is fundamentally different from that in fcc

nano-pillars. In body-centered cubic (bcc) metals, the screw

components of a dislocation loop are not restricted to any

single glide plane and can cross-slip on any other favorable

crystallographic plane in the course of its glide while the

motion of their edge counterparts is limited to a specific

plane. The reason for this discrepancy between these two

types of dislocations is that the mobility of screw dislocations in bcc metals is significantly lower than that of the

edge ones, estimated at 1:40 [66]. Furthermore, it was

recently reported that, based on dislocation dynamics simulations, even a single dislocation loop in a Mo nano-pillar

can replicate itself and leave behind debris in response to

the compressive applied stress [31]. Therefore, the dislocations in Mo nano-pillars are likely to have a higher residence time inside the pillar compared with fcc Au nanopillars, thereby significantly increasing the probability of

individual dislocation interactions, their multiplication,

and the formation of junctions, which subsequently serve

as new dislocation sources. This results in a different situation to that found in fcc nano-pillars, where the mobile dislocations are thought to escape at the free surface in

response to the applied compressive stress, leading to hardening by dislocation starvation [28–31].

To gain further insight into the origins of size effects and

their influence on the deformation mechanisms operating

in nano-scale crystals, we performed uniaxial tension tests

on Au and Mo single crystals with the dimensions equivalent to some of the previously reported nano-pillar compression results [18,28,29]. To date, there have not been

extensive reports on the tensile behavior of materials at

the micron and sub-micron scales because this type of

deformation has not yet been widely utilized due to the

absence of commercial in situ mechanical testing equip-

ment, as well as to the challenges associated with sample

preparation [37–45]. Recently, Kiener et al. reported a

new method to measure tensile behavior of single crystals

at the micro- and nano-scales [46], in which tension samples were fabricated by using FIB, and mechanical testing

was performed inside a scanning electron microscope and

a transmission electron microscope [47].

In this work we present the results of in situ uniaxial tensile testing of nano-scale samples fabricated similarly to the

nano-pillars for the compression testing, i.e. by using FIB

to directly shape the samples from the bulk single crystals.

The tension tests were conducted in a custom-built in situ

mechanical tester, SEMentor, comprising a scanning electron microscope (FEI Quanta 200, FEI Company, Hillsboro, OR, USA) and the dynamic contact module

(DCM) of the nanoindenter (Agilent Corp., Oak Ridge,

TN, USA) inserted into a free port in the scanning electron

microscope and equipped with a custom-fabricated conductive diamond tension/compression grips, as shown in

Fig. 1. The nanoindenter motion is restricted to be along

the axes, so gripping of the tensile samples is accomplished

by adjusting the 3D movement of the sample stage while

tracking the motion in the microscope. In addition, it is

possible to measure precise length change in gauge section

during testing by in situ scanning electron microscopy

(SEM) images. The procedures of sample preparation

and testing are described in detail in the next section.

We find that the tensile stress–strain behavior of h1 0 0ioriented single-crystalline Au and Mo samples with sample

sizes between 250 nm and 1 lm are significantly different

from one another, further supporting the argument that

different plasticity mechanisms operate in these crystals at

the nano-scale. We investigate the influence of the constraints posed by the sample geometries on strain-hardening and dislocation-based factors responsible for the

tension–compression asymmetry in bcc crystal structure.

Fig. 1. Pictures of the SEMentor (SEM + Nanoindenter) and the inside of chamber.

Please cite this article in press as: Kim J-Y, Greer JR. Tensile and compressive behavior of gold and molybdenum single crystals at the

nano-scale. Acta Mater (2009), doi:10.1016/j.actamat.2009.07.027

ARTICLE IN PRESS

J.-Y. Kim, J.R. Greer / Acta Materialia xxx (2009) xxx–xxx

2. Experiments

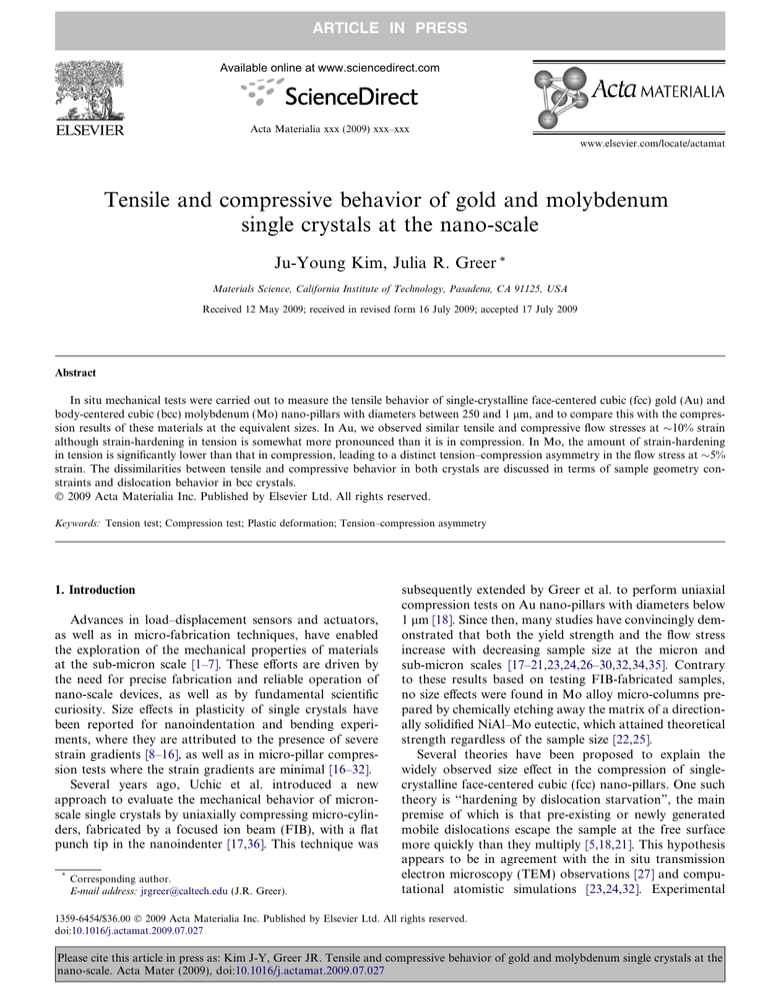

Tension samples with rectangular cross-sections were

milled out of the well-annealed and electropolished (1 0 0)

Au and Mo crystals by using the FIB. For comparison purposes, the bulk samples used to produce the nano-scale tension samples for this study are the same physical pieces as

used in Refs. [28,29]. A series of sample fabrication steps

and mechanical test procedures are illustrated in Fig. 2.

In the course of fabrication, we first use top-down ion

beam patterning to define a thin lamella with a thickness

between 250 and 1 lm, width between 2.5 and 3 lm, and

height greater than 5 lm. To minimize the taper generally

associated with this procedure, we etch each side of the

lamella at a tilt angle of ±0.6° rather than at the commonly

used orthogonal beam direction. By using this approach,

we are able to produce vertical lamellae with only a slight

amount of tapering, all localized at the top, as shown in

Fig. 2a. In the subsequent fabrication steps, we create the

‘‘shoulders” from the top section of the lamella by which

the sample is gripped, so that the gauge section beginning

at 1.5 lm below the top is nearly orthogonal to the bottom of the bulk samples. We refine the final shape by tilting

the ion beam angle and milling the sample almost parallel

to the bulk sample surface and nearly normal to the lamel-

3

lae (4° angle between surface and ion beam). Fig. 2b

shows an image of a typical dog-bone-shaped tension sample fabricated by using the described procedure. To minimize the possible generation of a surface oxide layer,

mechanical tests were performed immediately after sample

fabrication in the SEMentor under vacuum.

To perform the mechanical tests, we also fabricated the

compression/tension grips from a conductive diamond

nanoindenter tip by the use of ion-assisted etching during

FIB. The grips are composed of: (1) a through-hole for

gripping the tensile sample shoulders, (2) a V-shaped notch

in the bottom platen to ensure stable gripping of samples of

various sizes, and (3) a flat bottom for compression tests.

The inner side walls have a slope of 20° to establish a stable

contact with the sample, whose shoulders are also inclined

by 20° from the vertical axes. Fig. 3 shows SEM images of

the tension/compression grips. During the mechanical

tests, the grips are first lowered into a crater in the bulk

sample positioned behind the actual sample, which is then

gradually brought into the through-hole by the lateral

motion of the microscope stage. All tension tests were

conducted at a constant nominal displacement rate of

2 nm s1. By assuming volume conservation during plastic

deformation, true stress r was evaluated as r = PL/A0L0

where P is the measured force, L is the instantaneous gauge

length, A0 is the initial cross-sectional area, and L0 is the

initial length. True strain e was calculated as e = ln(L/

L0). The gauge length L was evaluated instantaneously

by the ‘‘length change” data collection channel together

with the measurements from SEM images collected during

the test.

3. Results

Fig. 4 shows several compressive stress–strain curves of

h1 0 0i-oriented Au and Mo nano-pillars, with the former

obtained in the course of the present work and the latter

taken from Ref. [29]. Tensile curves for the same materials

are shown in Fig. 5. The ‘‘effective diameter” of the rectanqffiffiffiffiffiffiffiffiffiffiffiffi

gular cross-sectional tension samples is d eff ¼ p4 d 1 d 2 ,

Fig. 2. Procedures making dog-bone-shaped tension sample: (a) side view

of thin lamella and (b) tension sample. Final FIB millings were conducted

using ion current of 50 pA at 30 kV ion acceleration voltage.

where d1 and d2 are the width and thickness of the rectangular cross-section measured by front and side SEM

images.

The tensile curves for Au show discrete strain bursts

during plastic flow and size effects similar to those in compression. Some of the key characteristics of the tensile

behavior of Au compared with compressive are: (1) the

average extent of individual strain bursts is shorter, (2)

strain bursts occur more slowly, and (3) the amount of

strain-hardening with increasing strain is relatively large.

Since all tests were performed at the same data acquisition

rate of 25 Hz, the relative speed of a strain burst can be

determined by the number of data points captured in it.

The tensile stress–strain curves of Mo are shown in

Fig. 5b and appear to have a similar plasticity signature

to the Mo compressive curves. Notable in the Mo tensile

Please cite this article in press as: Kim J-Y, Greer JR. Tensile and compressive behavior of gold and molybdenum single crystals at the

nano-scale. Acta Mater (2009), doi:10.1016/j.actamat.2009.07.027

ARTICLE IN PRESS

4

J.-Y. Kim, J.R. Greer / Acta Materialia xxx (2009) xxx–xxx

Fig. 3. FIB machined conductive diamond grip for in situ tension and compression tests.

Fig. 4. Typical stress–strain curves in compression of (a) Au and (b) Mo

with some intentional unloading and reloading segments [27]. Note that

the strain scales (x-axis) in (a) and (b) are different.

curves is that the amount of strain-hardening is significantly lower than that in compression.

Fig. 6 shows SEM images of the remaining bottom parts

of some typical post-tension samples. Numerous slip lines

along multiple crystallographic orientations are clearly

seen on the surface of the Au samples, with severe plastic

Fig. 5. Typical stress–strain curves in tension of (a) Au and (b) Mo. Note

that the strain scales (x-axis) in (a) and (b) are different.

deformation localized close to the middle of the gauge

length via necking, as shown in Fig. 6a. Fig. 6b shows that

the necking is initiated at the location of a large slip event,

after which the subsequent plastic deformation is localized

at the neck until rupture. We observe the top parts of the

tensile samples to be somewhat bent and/or rotated, likely

due to the gripping constraints. The post-tension fracture

Please cite this article in press as: Kim J-Y, Greer JR. Tensile and compressive behavior of gold and molybdenum single crystals at the

nano-scale. Acta Mater (2009), doi:10.1016/j.actamat.2009.07.027

ARTICLE IN PRESS

J.-Y. Kim, J.R. Greer / Acta Materialia xxx (2009) xxx–xxx

5

Fig. 6. SEM images showing (a) multiple slip lines in Au, (b) bending after severe deformation in Au, (c) Au sample drawn down to a point before rupture,

(d) Mo fracture surface after quick necking and rupture.

surface of Au, shown in Fig. 6c, indicates that the sample

was drawn down to nearly a point before rupture, a behavior typical for the highly ductile metals. The fracture

surface of a Mo tensile sample (Fig. 6d) clearly shows the

presence of fewer, wider-distributed slip lines after the

deformation compared with Au post-tension samples.

Also, unlike Au, the necking and subsequent rupture in

Mo occur rapidly, on the order of several seconds.

Fig. 7 shows the plot of the flow stresses attained for

both types of deformation at 10% strain normalized by

the ideal axial strength of Au [48] and the sample size on

a log–log scale. We observe a strong size effect for both

compression and tension, with no distinguishable difference

in the attained flow stresses between the two types of deformation. To elucidate the possible effects of different geometries between tension and compression samples, we also

show the flow stresses of tensile sample geometries that

were pre-compressed to 4% before conducting tension

experiments. These three points appear to be contained

within the same general distribution of flow stresses as a

function of size.

On the contrary, there is a significant difference in the

flow stresses between these two types of deformation in

Mo, as shown in Fig. 8b. While the measured yield

strengths in tension and compression agree with each other

well (Fig. 8a), the flow stresses measured at 5% strain in

tension are clearly lower than those in compression. In

Fig. 8a and b, the yield strengths and flow stresses were

normalized by the ideal axial strength of Mo [48]. We chose

to report 5% strain for Mo (rather than 10% as is the case

for Au) because the fracture strains of Mo in tension and

compression are generally lower than 10%. Average flow

stresses in tension attain about 60% of those in compression for the entire range of strain.

4. Discussion

Fig. 7. Flow stresses in compression and tension for Au at 10% strain

normalized by the ideal strength of Au.

We report the following key observations of the tensile

deformation of the Au nano-crystals: (1) flow stresses

attained at 10% strain in tension are similar to those in

compression, showing no tension–compression asymmetry,

and (2) shorter, slower discrete strain bursts and more pro-

Please cite this article in press as: Kim J-Y, Greer JR. Tensile and compressive behavior of gold and molybdenum single crystals at the

nano-scale. Acta Mater (2009), doi:10.1016/j.actamat.2009.07.027

ARTICLE IN PRESS

6

J.-Y. Kim, J.R. Greer / Acta Materialia xxx (2009) xxx–xxx

Fig. 8. (a) Yield strengths and (b) flow stresses at 5% strain in

compression and tension for Mo both normalized by the ideal strength of

Mo.

nounced strain-hardening occur in tension compared with

compression. These features are discussed in more details

in Section 4.1 in the context of constraints posed by the

sample geometry. On the contrary, while the measured

yield strengths of Mo in tension agreed well with those in

compression, the amount of strain-hardening in tension is

significantly lower than that in compression, resulting in

attaining only 60% of the compressive flow stresses at

5% strain. Factors responsible for the tension–compression asymmetry caused by the crystal structure of bcc metals and the non-planar dislocation core structure are

discussed in Section 4.2.

4.1. Au: more pronounced strain-hardening in tension

compared with compression

During uniaxial deformation, an individual slip event

induces a shear offset of the top part of the sample with

respect to the loading axis. Since our experiments are

performed on crystals oriented for the activation of multiple slip systems, h0 0 1i, the deformation is characterized

by the creation of multiple slip steps ubiquitously populated along the pillar surface. If the deformation results

in the creation of only fine and symmetrical slips steps,

these offsets cancel each other out, retaining the integrity

of the cylindrical specimen shape. Despite the nominal

multi-slip orientation, it is not uncommon for a large slip

event to occur preferentially on a single set of planes due

to the stochastic nature of the dislocation avalanches [49–

52]. When the top of the sample is constrained by the nanoindenter grips, this results in destruction of the symmetry

and in the creation of the bending and rotation moments

in addition to the uniaxial force. It has been suggested that

during nano-pillar compressions, additional strengthening

may arise from the lateral constraint of the loading shaft,

as well as by the friction between the pillar top and the

nanoindenter flat tip [33,53–55]. Complementary to these

experimental findings, Deshpande et al. showed in their dislocation dynamics simulations that the generation of a

bending force due to the constraints posed on the sample,

preventing it from rotation, results in the formation of geometrically necessary dislocations (GNDs), and thereby

causing additional hardening [32]. Therefore, the constraints caused by the grips in uniaxial tests at nano-scale

are a likely cause of additional hardening effects.

The difference in the constraints posed by the nanoindenter tip in tension vs. compression could, therefore, be a

source of the dissimilarities in the post-yield strain-hardening behavior of Au between these two deformation paths.

In this work, the tension and compression tests on Au were

conducted by using the same testing method at a nominal

constant displacement rate of 2 nm s1. As shown in

Fig. 3a, the strain bursts associated with slip events in compression occur very rapidly, preventing the instrument

from responding at the same speed because of the limited

feedback rate between measured force and the nominal

constant displacement rate algorithm. This may cause an

instantaneous break of full contact between the tip and

the pillar top, causing the feedback loop algorithm to send

a signal to lower the force in the strain burst range. During

this break, the top part of the pillar may be offset from the

bottom part due to the instantly reduced friction between

the tip and the top of the pillar. In tension, however, the

strain bursts occur much more slowly than in compression,

as shown in Fig. 5a, since during these tests the full contact

between the grips and the pillar shoulders is maintained,

and the sample is restricted from forming an offset and

from rotation. Despite maintaining a full contact with the

sample in tension, the constraining effects of the grips during tension may cause an even higher degree of strengthening compared with compression. During the tensile tests,

the grips are in contact with the bottom of the pillar shoulders. The contact area between the grips and the sample,

therefore, is larger than it is in compression, where only

the flat top area of the nano-pillar is in contact with the

tip. Thus, the constraints associated with tensile testing

Please cite this article in press as: Kim J-Y, Greer JR. Tensile and compressive behavior of gold and molybdenum single crystals at the

nano-scale. Acta Mater (2009), doi:10.1016/j.actamat.2009.07.027

ARTICLE IN PRESS

J.-Y. Kim, J.R. Greer / Acta Materialia xxx (2009) xxx–xxx

could be much stronger than they are in compression since

both shoulder ends at some distance from the center of the

loading axis are constrained during tension tests. To evaluate the effects of the tension sample geometry on the

mechanical behavior, we compressed the tension samples

with effective diameters of 1 lm and compared the results

with those for compression of cylindrical pillars of

900 nm diameter. These stress–strain curves, shown in

Fig. 9, are similar to one another up to 8% strain, but

upon further compression the tensile samples exhibit more

pronounced strain-hardening than the compressive ones.

This is consistent with the more pronounced strain-hardening in tension and indicates that sample geometry is likely

to be the main cause for a more pronounced strain-hardening in tension.

The constraint may also depend on the lateral stiffness

of the loading shaft and on the friction between the grips

and the sample [33,53–55]. Since both tension and compression data in this study were obtained by the same type

of mechanical tester, the differences in the constraint

caused by the variation in lateral stiffness of the loading

shaft are not likely to play a significant role in observing

higher/lower flow stresses. The difference in the sample

cross-sections (circular vs. rectangular) may also contribute

to the differences in yield and plastic flow, as described in

detail in Ref. [56]. However, the flow stresses of the circular

and rectangular cross-section Au samples in tension are

consistent with one another [56], and the dissimilarity

between the tensile and compressive stress curves in Au

may be due, in part, to a different sample geometry aspect.

The gauge section of the tensile samples does not have an

immediate contact with the grips since the sample is being

held by its shoulders, while during compression, the pillar

top is directly in contact with the tip. The cross-sectional

area at the top of the shoulders is much larger than that

in the gauge section, resulting in a sharp shear stress gradi-

Fig. 9. Stress–strain curves in compression of tension samples with top

grip part and pillars.

7

ent at their interface. As the dislocations glide in their slip

planes in the course of deformation, they are likely to pile

up against this interface, increasing the stress necessary to

apply in order to move other mobile dislocations through

the piled-up array and thus causing additional strain-hardening. On the other hand, in the pillar compressions the

contact between the pillar top and the flat punch indenter

tip does not restrict dislocation motion, as evidenced by

the presence of multiple slip lines generously distributed

along the pillar height as well as in the compressed pillar

tops [28,29]. Kiener et al. inferred the presence of these dislocation pile-ups near the gauge section-grip interface in

their post-tension Cu samples by measuring the local crystal misorientations via electron backscatter diffraction

(EBSD) [46]. These authors also reported that the additional hardening effect due to the tensile sample geometry

vanishes when the aspect ratio (gauge length to width) is

greater than 2. All samples in this study have aspect ratios

between 3 and 10, suggesting that hardening via dislocation

pile-ups near the interface is unlikely to be the main source

of strain-hardening of Au in tension.

4.2. Tension–compression asymmetry of Mo

Unlike in Au, there is a significant amount of tension–

compression asymmetry in Mo, as shown in Fig. 8b. This

is typical of bulk bcc crystals, which exhibit tension–compression asymmetry in flow stresses because the {1 1 1}

planes perpendicular to the primary slip directions h1 1 1i

are not mirror planes in the crystal structure [57,58]. If

the operating slip planes in a bcc crystal were confined only

to {1 1 0}, which are mirror planes, the flow stresses in tension and compression would be equivalent. However, SEM

images of the post-deformation Mo samples in Fig. 6d and

Ref. [29] indicate that crystallographic slip does not, in

fact, occur along a single family of primary slip planes,

but rather along multiple ones, for example {1 1 0},

{1 1 2}, {1 2 3}, and so on. Activating slip on multiple

families of slip planes even in the high-symmetry, h0 0 1i,

orientation used in the tests is consistent with the reported

non-Schmid behavior of bcc crystals [57], as the respective

Schmid factors for the {1 1 0}, {1 1 2}, and {1 2 3} planes

are 0.41, 0.47, and 0.46 when the loading axis is oriented

along [1 0 0] and the slip direction is h1 1 1i.

We believe that one of the key factors in the observed

tension–compression asymmetry in Mo could be the a/6

h1 1 1i transitions in the twinning and anti-twinning sense

on {1 1 2} slip planes [57–64]. This phenomenon can be

induced in bcc crystals by applying shear stresses in opposite directions: the local crystal environment created by

twinning is more stable than that produced by the antitwinning deformation, leading to the application of higher

(lower) stresses during plastic deformation. The Peierls

stresses acting along the twinning and anti-twinning directions in Mo, as calculated by atomistic simulations, are

reported to be 0.017l and 0.053l, respectively, where l is

the shear modulus [65]. The Peierls stresses are calculated

Please cite this article in press as: Kim J-Y, Greer JR. Tensile and compressive behavior of gold and molybdenum single crystals at the

nano-scale. Acta Mater (2009), doi:10.1016/j.actamat.2009.07.027

ARTICLE IN PRESS

8

J.-Y. Kim, J.R. Greer / Acta Materialia xxx (2009) xxx–xxx

for 0 K to take into account the intrinsic effect of crystal

structure without thermal contribution. The difference in

the Peierls stresses along the twinning and anti-twinning

directions in Mo can be negligible above the critical temperature; however, the critical temperature of Mo is

472 K [64], well above the RT.

Another critical factor in the deformation path-dependent strength in Mo could be the critical resolved shear

stress (CRSS) associated with tension vs. compression,

caused by the non-planar a/2 h1 1 1i screw dislocation

cores when components other than the glide shear stress

are present [60–64]. The shear stress component (s) perpendicular to the slip direction is always positive for tension,

which facilitates dislocation glide on (

101) planes by lowering the corresponding Peierls barrier. Analogously, s is

always negative for compression, inhibiting slip on this

plane and thus requiring the application of higher stresses.

6. Conclusions

We have performed uniaxial tension and compression

tests on single-crystalline Au and Mo h0 0 1i-oriented

nano-pillars with effective diameters between 250 and

1 lm. By analyzing their plastic flow in tension and compression, we report the following findings:

1. Flow stresses attained in Au at 10% strain are equivalent for tension and compression despite the somewhat

more pronounced amount of strain-hardening in tension

compared with compression.

2. The strain-hardening in Au tension is likely due to the

constraints imposed by the nanoindenter grips: the loading axis is likely to be more constrained by the nanoindenter tip in tension than it is in compression, and this

constraint can introduce geometrically necessary dislocations into the structure, which, in turn, enhance

strain-hardening.

3. The amount of strain-hardening in the tensile deformation of Mo is significantly less pronounced than it is in

compression, resulting in a significant tension–compression asymmetry: the flow stresses attained in tension

comprise only 60% of those in compression. We postulate that the two key reasons for this asymmetry in bcc

crystals at the nano-scale may be (i) the differences in

the Peierls stress in twinning vs. anti-twinning deformations, and (ii) a strong dependence of CRSS on the nonglide applied stress tensor components.

References

[1]

[2]

[3]

[4]

[5]

Nix WD. Metall Trans A 1989;20:2217.

Arzt E. Acta Mater 1998;46:5611.

Oliver WC, Pharr GM. J Mater Res 1992;7:1564.

Schuh CA. Mater Today 2006;9:32.

Nix WD, Greer JR, Feng G, Lilleodden ET. Thin Solid Films

2007;515:3152.

[6] Zhu TT, Bushby AJ, Dunstan DJ. Mater Technol 2008;23:193.

[7] Uchic MD, Shade PA, Dimiduk DM. Annu Rev Mater Res

2009;39:1–8.

[8] Fleck NA, Hutchinson JW. Adv Appl Mech 1997;33:295.

[9] Stolken JS, Evans AG. Acta Mater 1998;46:5109.

[10] Fleck NA, Muller GM, Ashby MF, Hutchinson JW. Acta Metall

Mater 1994;42:475.

[11] Nix WD, Gao H. J Mech Phys Solids 1998;46:411.

[12] Swadener JG, George EP, Pharr GM. J Mech Phys Solids

2002;50:681.

[13] Feng G, Nix WD. Scripta Mater 2004;51:599.

[14] Kim JY, Lee BW, Read DT, Kwon D. Scripta Mater 2005;52:353.

[15] Durst K, Backes B, Franke O, Göken M. Acta Mater 2006;54:2547.

[16] Kim JY, Kang SK, Lee JJ, Jang JI, Lee YH, Kwon D. Acta Mater

2007;55:3555.

[17] Uchic MD, Dimiduk DM, Florando JN, Nix WD. Science

2004;305:986.

[18] Greer JR, Oliver WC, Nix WD. Acta Mater 2005;53:1821.

[19] Dimiduk DM, Uchic MD, Parthasarathy TA. Acta Mater

2005;53:4065.

[20] Volkert CA, Lilleodden ET. Philos Mag 2006;86:5567.

[21] Greer JR, Nix WD. Phys Rev B 2006;73:245410.

[22] Bei H, Shim S, Pharr GM, George EP. Scripta Mater 2007;57:397.

[23] Rabkin E, Nam HS, Srolovitz DJ. Acta Mater 2007;55:2085.

[24] Tang H, Schwarz KW, Espinosa HD. Acta Mater 2007;55:1607.

[25] Bei H, Shim S, Pharr GM, George EP. Acta Mater 2008;56:4762.

[26] Frick CP, Clark BG, Orso S, Schneider AS, Arzt E. Mater Sci Eng A

2008;489:319.

[27] Shan ZW, Mishra RK, Syed Asif SA, Warren OL, Minor AM.

Nature Mater 2008;7:115.

[28] Brinckmann S, Kim JY, Greer JR. Phys Rev Lett 2008;100:155502.

[29] Kim JY, Greer JR. Appl Phys Lett 2008;93:101916.

[30] Schneider AS, Clark BG, Frick CP, Gruber PA, Arzt E. Mater Sci

Eng A 2009;508:241.

[31] Weinberger CR, Cai W. Proc Natl Acad Sci USA 2008;105:14304.

[32] Deshpande VS, Needleman A, Van der Giessen E. J Mech Phys Solids

2005;53:2661.

[33] Raabe D, Ma D, Roters F. Acta Mater 2007;55:4567.

[34] Kim JY, Jang D, Greer JR. Scripta Mater 2009;61:300.

[35] Rao SI, Dimiduk DM, Parthasarathy TA, Uchic MD, Tang M,

Woodward C. Acta Mater 2008;56:3245.

[36] Uchic MD, Dimidik DA. Mater Sci Eng A 2005;400:268.

[37] Hemker KJ, Sharpe Jr WN. Annu Rev Mater Res 2007;37:93.

[38] Gianola DS, Eberl C. JOM 2009;61:24.

[39] Read DT, Dally JW. J Mater Res 1993;8:1542.

[40] Sharpe Jr WN, Yuan B, Edwards RL. J Microelectromech Syst

1997;6:193.

[41] Sharpe Jr WN, Jackson KM, Hemker KJ, Xie Z. J Microelectromech

Syst 2001;10:317.

[42] Huang HB, Spaepen F. Acta Mater 2000;48:3261.

[43] Read DT, Cheng YW, Keller RR, McColskey JD. Scripta Mater

2001;45:583.

[44] Espinosa HD, Prorok BC, Peng B. J Mech Phys Solids 2004;52:667.

[45] Son D, Kim JJ, Kim JY, Kwon D. Mater Sci Eng A 2005;406:274.

[46] Kiener D, Grosinger W, Dehm G, Pippan R. Acta Mater

2008;56:580.

[47] Oh SH, Legros M, Kiener D, Dehm G. Nature Mater 2009;8:95.

[48] Ogata S, Li J, Hirosaki N, Shibutani Y, Yip S. Phys Rev B

2004;70:104104.

[49] Dimiduk DM, Woodward C, LeSar R, Uchic MD. Science

2006;312:1188.

[50] Parthasarathy TA, Rao SI, Dimiduk DM, Uchic MD, Trinkle DR.

Scripta Mater 2007;56:313.

[51] Ng KS, Ngan AHW. Acta Mater 2008;56:1712.

[52] Rinald A, Peralta P, Friesen C, Sieradzki K. Acta Mater 2008;56:511.

[53] Maaß R, Van Petegem S, Grolimund D, Van Swygenhoven H, Kiener

D, Dehm G. Appl Phys Lett 2008;92:071905.

[54] Kiener D, Grosinger W, Dehm G. Scripta Mater 2009;60:148.

[55] Kiener D, Motz C, Dehm G. Mater Sci Eng A 2009;505:79.

Please cite this article in press as: Kim J-Y, Greer JR. Tensile and compressive behavior of gold and molybdenum single crystals at the

nano-scale. Acta Mater (2009), doi:10.1016/j.actamat.2009.07.027

ARTICLE IN PRESS

J.-Y. Kim, J.R. Greer / Acta Materialia xxx (2009) xxx–xxx

[56] Brinckmann S, Kim JY, Jennings AT, Greer JR. Int J Multiscale

Comput Eng 2009;7:187–94.

[57] Hirth JP, Lothe J. Theory of dislocations. 2nd ed. New York: John

Wiley and Sons; 1982.

[58] Seeger A, Hollang L. Mater Trans 2000;41:141.

[59] Hull D, Bacon DJ. Introduction to dislocations. Oxford: Butterworth;

1984.

[60] Duesbery MS, Vitek V. Acta Mater 1998;46:1481.

9

[61] Seeger A. Mater Sci Eng A 2001;254:319–21.

[62] Gröger R, Bailey AG, Vitek V. Acta Mater 2008;56:5401.

[63] Gröger R, Racherla V, Bassani JL, Vitek V. Acta Mater

2008;56:5412.

[64] Gröger R, Vitek V. Acta Mater 2008;56:5426.

[65] Rao SI, Woodward C. Philos Mag 2001;81:1317.

[66] Lawley A, Gaigher HL. Philos Mag 1964;10:15.

Please cite this article in press as: Kim J-Y, Greer JR. Tensile and compressive behavior of gold and molybdenum single crystals at the

nano-scale. Acta Mater (2009), doi:10.1016/j.actamat.2009.07.027