JOB NAME

TYPE

TI-51030

BALLAST, CAPACITOR, AND

IGNITOR DATA

BALLASTS

All HID lamps are negative resistance light sources (this means that once the arc is initiated, the lamp’s resistance continually decreases as current increases; for all

practical purposes, the lamp becomes a short circuit). They require a support device (ballast), that limits the lamp and line current when voltage is applied, to prevent

the lamp from being destroyed.

In addition, the ballast provides the lamp with proper voltage to reliably start and operate the lamp throughout its rated service life. If a transformer is integral to the

ballast circuit, it modifies the available supply voltage to provide the voltage required for the lamp.

A distinction must be made between lag circuit and lead circuit ballasts. The lamp current control element of a lag circuit ballast consists of an inductive reactance in

series with the lamp. The current control element in lead circuit ballasts consists of both inductive and capacitive reactances in series with the lamp; however, the net

reactance of such a circuit is capacitive in mercury and metal halide ballasts, and inductive in high pressure sodium ballasts.

High pressure sodium (HPS) lamps are greatly different than the mercury or metal halide lamps. Mercury and metal halide lamps maintain a relatively stable voltage

drop across the arc tube throughout its life (wattage is also essentially constant) with aging being reflected only in lamp lumen depreciation, decreasing light output.

The HPS lamp is a dynamic device with performance changing as the lamp ages. The arc tube voltage rises with usage; therefore, the wattage and lumen output

change with age. The early experience will be low wattage performance, low lumen output, and fewer footcandles being generated on the work task. When the

lamps start to mature, the arc tube voltage rises toward its nominal design level, the lumen output and resulting footcandle levels will approach the calculated or

desired levels. As the lamp continues to mature, the wattage levels continue to increase until the power supply-voltage limits have been reached, at which time

the lamp will extinguish or “drop out.” Cooling of the extinguished lamp permits its voltage requirement to lessen so that it may restrike and operate until it again

exceeds the available power supply voltage. This cycling of “strike-burn-drop out-cool-strike-burn-drop out” is typical of lamps which have reached near end of life.

These lamps will ultimately fail to cycle or restrike and must be replaced.

BALLAST SELECTION CONSIDERATIONS

• Is the application industrial or other?

• What is the nominal line voltage experience? Is it generally controlled with 5%? Does it swing by as much as 10%?

Is it most frequently high voltage or low voltage?

• Will the higher starting currents of reactor ballasts work a hardship? Most starting currents never exceed operating currents?

• Consider costs of equipment. Initial, operating and maintenance.

Normal power factor reactor units have no capacitors and lower initial costs.

Regulated ballasts have higher initial, operating and maintenance costs.

• Do extreme voltage conditions exist–either high, low, or varying (line dips)–which

could be better controlled by a premium cost magnetic regulated ballast?

112

• Is line voltage generally controlled to a reasonable level where CWA-CWI will

perform at less cost?

BALLAST CIRCUITRY

There are many different types of ballasts used with different lamps. Within a lamp

type, ballasts vary with lamp wattage and regulation changes in line voltage. Better

regulation generally results in higher cost. The different types of HID ballasts are:

REACTOR BALLAST (R) (120V ONLY)…provides limited regulation by way of an

air gap in the coil. Depending on the light source used, it may require a starter to

supply the high voltage pulse necessary to start the lamp. Day-Brite uses the normal

power factor (NPF) only, although it is available in high power factor (HPF).

Advantages

Disadvantages

• Least costly to manufacture

• Lowest ballast losses–least wasted energy

• Least costly to operate and maintain

• Light weight

• Provides good wattage regulation on

systems that control the voltage within ± 5%

CWA**

105

LAMP WATTS (%)

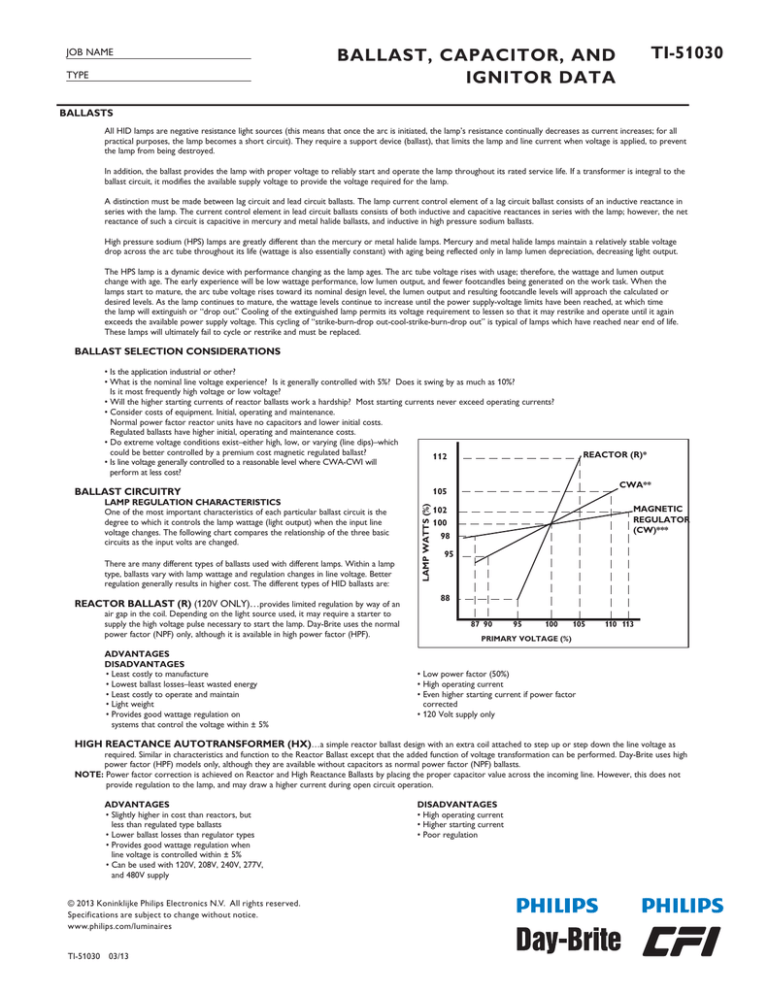

LAMP REGULATION CHARACTERISTICS

One of the most important characteristics of each particular ballast circuit is the

degree to which it controls the lamp wattage (light output) when the input line

voltage changes. The following chart compares the relationship of the three basic

circuits as the input volts are changed.

REACTOR (R)*

MAGNETIC

REGULATOR

(CW)***

102

100

98

95

88

87 90

95

100

105

110 113

PRIMARY VOLTAGE (%)

• Low power factor (50%)

• High operating current

• Even higher starting current if power factor

• corrected

• 120 Volt supply only

HIGH REACTANCE AUTOTRANSFORMER (HX)…a simple reactor ballast design with an extra coil attached to step up or step down the line voltage as

required. Similar in characteristics and function to the Reactor Ballast except that the added function of voltage transformation can be performed. Day-Brite uses high

power factor (HPF) models only, although they are available without capacitors as normal power factor (NPF) ballasts.

NOTE: Power factor correction is achieved on Reactor and High Reactance Ballasts by placing the proper capacitor value across the incoming line. However, this does not

provide regulation to the lamp, and may draw a higher current during open circuit operation.

Advantages

• Slightly higher in cost than reactors, but

• less than regulated type ballasts

• Lower ballast losses than regulator types

• Provides good wattage regulation when

line voltage is controlled within ± 5%

• Can be used with 120V, 208V, 240V, 277V,

and 480V supply

© 2013 Koninklijke Philips Electronics N.V. All rights reserved.

Specifications are subject to change without notice.

www.philips.com/luminaires

TI-51030 03/13 Disadvantages

• High operating current

• Higher starting current

• Poor regulation

BALLAST, CAPACITOR, AND IGNITOR DATA

TI-51030

CONSTANT WATTAGE AUTOTRANSFORMER (CWA)…combines the best features of the High Reactance and Magnetic Regulator Ballasts. Regulation is good,

power factor is high, and losses are not excessive. A variation of the CWA called the Peak Lead Auto Regulator Ballast is used exclusively for Metal Halide lamps. The

HPS Auto Regulator would also be included in this family of ballasts.

Advantages

Disadvantages

• High power factor (over 90%) and low operating current

• More expensive than Reactor type ballast

• Good regulation–permits and responds favorably to line voltage

• Slightly larger in size and weight than

variations of up to +5% or –10%

Reactor Ballast

• Starting current is even lower than operating current

• Costs less than magnetic regulator

• Provides good regulation of lamp wattage, especially in nominal and

below normal systems

• Ballast losses are less than for magnetic regulator

• Available for all standard voltages

REGULATOR (ISOLATED SECONDARY)–“MAGNETIC REGULATOR” BALLAST (REG-LAG)…also known as Constant Wattage Ballast (CW), is a three

winding ballast similar in design to the older mercury ballast design, but provides regulation with line voltage variation of + or – 10% from nominal. It has an isolated

primary and secondary which transforms voltage and feeds power to the lamp through a reactor section (3rd winding). It also has a capacitor in the circuit for wattage

control and is a HPF device. It provides better lamp wattage control than the other designs, but with the disadvantage of the highest ballast losses, the highest operation

costs, and the highest manufacturing costs. This ballast is generally not necessary for systems operating at near normal line voltage.

Advantages

Disadvantages

• High power factor (over 90%)

• Heavier and larger than other ballasts

• Excellent line voltage regulation, it is responsive to systems that operate

• Most expensive of all types of ballasts

normally in extremely high or extremely low line voltage situations–in the

“near to ± 10%” range

• Low operating current and lower starting current

• Isolated secondary reduces danger of electrical shock

• At nominal voltage, its volts/watts trace is quite like the performance of a Reactor Ballast

• Provides better lamp regulation

ISOLATED REGULATOR BALLAST (CWI)…similar to the Auto Regulator Ballast in performance. The Isolated Regulator Ballast electrically isolates the lamp socket and

capacitor from the line. The Magnetic Regulator Ballast also isolates the lamp circuit from the line and additionally improves lamp wattage regulation, but may cause an

increase in input watts.

Advantages

• Provides good wattage control with up to ± 10% line voltage shift–excellent wattage control in lines that operate near normal

• Cost less than Magnetic Regulator ballast, but slightly more than CWA

• Ballast losses are less than for Magnetic Regulator ballast, but slightly more than CWA

HID lamps have several electrical characteristics that have important effects on ballasts:

STARTING VOLTAGE…Mercury Vapor and most Metal Halide lamps incorporate integral starting electrodes which allow the lamps to start at relatively low voltages in

ambient temperatures ranging above –20 F (–29 C).

High Pressure Sodium lamps require separate electronic starting devices (ignitors) which deliver a high voltage pulse to establish the arc. (The pulse repeats each

cycle with a maximum pulse width of 15 microseconds.) Once the lamp arc is established, the ignitor drops out of the circuit.

STARTING CURRENT…is the initial current available to the lamp during warm-up. If the current is in­cor­rect, the lamp may never come up to rated operating performance and/

or lamp life may be affected.

OPERATING CURRENT…is the rated current flow under normal conditions once the lamp arc has been established and is performing at rated levels. Most ballast types

have starting currents less than operating currents. Care should be taken when loading circuits to base load calculations on the higher of the two current ratings.

Normal power factor ballasts have higher starting currents than operating currents. Fuses, circuit breakers, and photoelectric control switches must be sized to

accommodate the highest current.

OPERATING VOLTAGE…Mercury Vapor and Metal Halide lamp operating voltage remains relatively constant throughout rated life, although lamp manufacturing

tolerances can allow for as much as plus/minus 10% variance from nominal. Depending on the type of ballast being used, lamp wattage may vary considerably.

High Pressure Sodium lamp operating voltage rises continually, from initial installation until end of life. HPS ballasts are designed to satisfy the increased voltage

requirements of the lamp through-­out rated life. As an example, a 400W HPS lamp nominally starts at 100 volts and increases to 140 volts at end of life.

OPERATING WATTAGE…HID lamps operate at rated wattage only if the lamp voltage and supply voltage is nominal. Lamp wattage and lamp life will be affected if either of

these vary from nominal.

CURRENT CREST FACTOR…is the ratio of peak to RMS value. The crest factor of a true sine wave is 1.41. Input voltage to a ballast may be close to a sine wave, but the

secondary voltage wave shape in the inductive and capacitive type ballast is distorted, and their crest factors are higher than 1.41. The most commonly used ballasts

(Constant Wattage, and Constant Wattage Auto­transformer) have crest factors of about 1.8. Some Metal Halide and HPS ballasts approach 1.65­.

Lamp manufacturers’ published lumen maintenance data is based on lamps operated on a standard reactor (1.41 CF) ballast in the laboratory. Tests indicate that ballasts

with higher crest factors may result in depreciation of lumen output, typically due to electrode degradation.

BALLAST REGULATION…is the ability of a ballast to control lamp wattage when subjected to line voltage variation. Consideration should be given to line voltage variations

expected on a given electrical system where HID lamps are used. Most new power distribution systems are designed to provide plus/minus 3% of nominal voltage. Some

systems, especially older ones, may have variances up to plus/minus 10% from nominal. Usually, the cost of a ballast rises with the degree of regulation provided. The

better the regulation, the higher the cost. Ballast regulation can also refer to regulation of lamp wattage with variations in lamp voltage. In this sense, a Reactor (CWA)

is better than a Magnetic Regulator (Reg-Lag).

PRIMARY DROPOUT REGULATION…All power distribution systems experience dips and peaks in line voltage as well as other transient conditions. Well-regulated

systems seldom see voltage fluctuations of 20% or more. Be sure to check the primary dropout voltage rating of the ballast if the voltage variations are of concern.

Voltage dips in excess of this rating may cause the lamps to extinguish and recycle.

POWER FACTOR…(the phase between voltage and current) is the ratio of line watts to line volts x line amps, expressed in a percentage. A high power factor (HPF) ballast

must have a power factor of at least 90% at nominal line voltage and lamp wattage. Usually as the lamp and capacitors age, the power factor will drop below 90%.

CAPACITORS

Capacitors are used as a power factor correcting or current regulating device and provide the control necessary to ensure proper lamp and ballast operation. Different

wattages, voltages, and ballast types require a variety of different capacitor values. The ballast I.D. label specifies the microfarad and voltage rating needed to operate

properly. If the capacitor is incorrectly wired, improper operation of the fixture as well as other component failure could result.

IGNITOR

These devices are utilized to provide the proper voltage and energy to start the lamp. Predominantly used with HPS lamps as well as some Metal Halide sources. May

provide up to 4000 volt spikes.

Philips Lighting Company

© 2013 Koninklijke Philips Electronics N.V. All rights reserved.

Philips Lighting Company

200 Franklin Square Drive

Specifications are subject to change without notice.

281 Hillmount Road

Somerset, NJ 08873

www.philips.com/luminaires

Markham ON, Canada L6C 2S3

Phone: 855-486-2216

Phone: 800-668-9008

TI-51030 03/13