GAS LINE PURGING

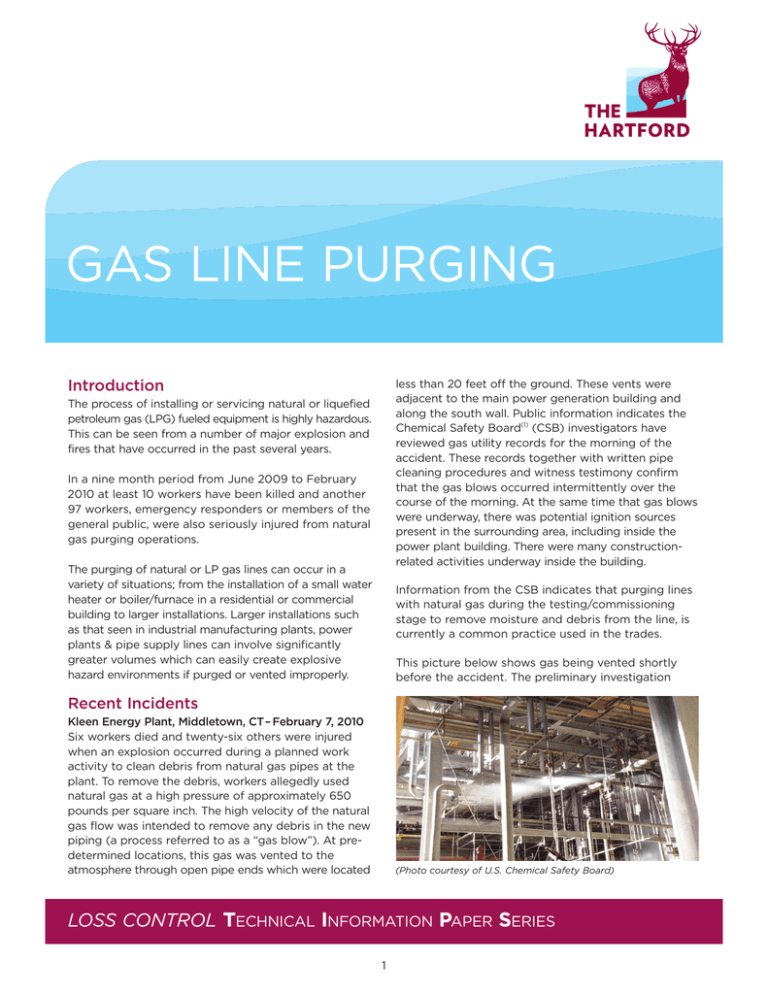

less than 20 feet off the ground. These vents were

adjacent to the main power generation building and

along the south wall. Public information indicates the

Chemical Safety Board(1) (CSB) investigators have

reviewed gas utility records for the morning of the

accident. These records together with written pipe

cleaning procedures and witness testimony confirm

that the gas blows occurred intermittently over the

course of the morning. At the same time that gas blows

were underway, there was potential ignition sources

present in the surrounding area, including inside the

power plant building. There were many constructionrelated activities underway inside the building.

Introduction

The process of installing or servicing natural or liquefied

petroleum gas (LPG) fueled equipment is highly hazardous.

This can be seen from a number of major explosion and

fires that have occurred in the past several years.

In a nine month period from June 2009 to February

2010 at least 10 workers have been killed and another

97 workers, emergency responders or members of the

general public, were also seriously injured from natural

gas purging operations.

The purging of natural or LP gas lines can occur in a

variety of situations; from the installation of a small water

heater or boiler/furnace in a residential or commercial

building to larger installations. Larger installations such

as that seen in industrial manufacturing plants, power

plants & pipe supply lines can involve significantly

greater volumes which can easily create explosive

hazard environments if purged or vented improperly.

Information from the CSB indicates that purging lines

with natural gas during the testing/commissioning

stage to remove moisture and debris from the line, is

currently a common practice used in the trades.

This picture below shows gas being vented shortly

before the accident. The preliminary investigation

Recent Incidents

Kleen Energy Plant, Middletown, CT– February 7, 2010

Six workers died and twenty-six others were injured

when an explosion occurred during a planned work

activity to clean debris from natural gas pipes at the

plant. To remove the debris, workers allegedly used

natural gas at a high pressure of approximately 650

pounds per square inch. The high velocity of the natural

gas flow was intended to remove any debris in the new

piping (a process referred to as a “gas blow”). At predetermined locations, this gas was vented to the

atmosphere through open pipe ends which were located

(Photo courtesy of U.S. Chemical Safety Board)

LOSS CONTROL TECHNICAL INFORMATION PAPER SERIES

1

LOSS CONTROL TECHNICAL INFORMATION PAPER SERIES

Gas Line Purging

control the release of purged gases. The purged fuel

gas was vented indoors into the utility room, which

was ventilated by an exhaust fan. Over 200 people

who had no role in the installation were in the building

when the natural gas found an ignition source and

exploded at approximately 11:25 a.m.

report from the U.S. Chemical Safety and Hazard

Investigation Board (CSB) indicate the explosion was

the result of venting a significant volume of natural

gas (estimated at 400,000 cubic feet of gas) to the

outdoors, but within an employee work area, during

the purging of the main gas line. Any ignition source

present (i.e. welding, portable heaters, electrical

equipment, static electricity, etc.) would be able to

initiate the explosion.

Other Similar Incidents

• During the construction of a 30 story hotel in 2008

in San Diego, an explosion injured 14 workers and

damaged 3 levels of the building. CalOSHA cited a

contractor for not venting from an enclosed space

and failure to test for flammable gases.

ConAgra Slim Jim Plant, Garner, NC – June 9, 2009

A major natural gas explosion heavily damaged the

ConAgra Slim Jim meat processing factory in Garner,

North Carolina. Four workers died in the resulting

explosion & building collapse, there were at least 71

injuries and a large section of the building collapsed.

Approximately 18,000 pounds of ammonia was

released causing an evacuation of personnel. This

release also resulted in a toxic exposure to emergency

response personnel and the general public. Resulting

environmental damage occurred from the large

ammonia release.

• In 2007 two plumbers in Cheyenne, WY were

severely burned during the purging of natural gas

into the interior of a new hotel under construction.

The workers stated they were unable to smell the

“odorized” gas as it filled the room.

• In 1999 at a Ford power plant in Dearborn, MI six

people were killed, 38 injured and $1 billion in property damage occurred. A gas pipe being removed

from service was purged into a boiler.

• 1997 in Cary, NC a worker attempted to purge air

from a natural gas line into a laundry room during a

startup of a commercial dryer. Six workers injured,

and a partial roof collapse occurred.

Problem Identified

• The purging of lines with natural gas during the

testing/commissioning stage to remove moisture

and debris (known as gas blows) from the line, is

currently a common practice used in the trades.

Many times this gas may be vented into interior or

restricted spaces that do not allow the gas to freely

disperse that result in a concentration buildup.

CONAGRA PLANT, GARNER, NC

(Photo courtesy of U.S. Chemical Safety Board)

• During the “firing” of equipment fueled by natural

or LP gas it is common to purge the fuel supply line

near the equipment. This often results in flammable

gas being vented in an enclosed area as the air is

purged from the line. These locations are typically

confined and have many potential ignition sources.

The accident occurred during the installation of a new

fuel gas-fired industrial water heater in an interior utility room of the plant. Five days prior to the accident, a

new section of three-inch steel piping – which would

provide natural gas to the heater – was tied into a sixinch natural gas supply line located on the roof. The

new natural gas piping ran horizontally over 120 feet

along the roof and then descended into the utility

room. The water heater manufacturer, was attempting

to purge the new gas line by using natural gas to

directly displace the air. This was done by removing

threaded fittings, creating one or more pipe openings

near the heater. The worker then opened a valve to

• Historically workers have relied on the sense of smell

to be able to detect the presence of the flammable

gas. A chemical odorant (T-butyl mercaptan) is

typically manually added to natural and LP gas.

However, perception can be subjective, and some

individuals can become desensitized after prolonged

exposure (resulting in the inability to recognize the

2

LOSS CONTROL TECHNICAL INFORMATION PAPER SERIES

Gas Line Purging

odor). In addition the effect of “odor fade” is now

being recognized. This can occur on new pipe

installations and can react to remove the odorant

effectiveness. The odorant manually added during

the distribution process has the potential to be

omitted by human error.

Emergency Actions

Following the ConAgra explosion investigation the

CSB in September 2009 issued a Safety Bulletin

entitled Dangers of Purging Gas Piping into Buildings.

Five key lessons learned were identified in this bulletin:

1. Purging new or existing gas piping into buildings

can be highly hazardous due to the possible accumulation of gas above the lower explosive limit

(LEL)(3) and the associated danger of fire and explosion. Wherever practicable, directly vent purged

gases to a safe location outdoors, away from people and ignition sources. This can be done using a

temporary hose or piping or permanently installed

vent pipes, depending on the facility design.

• All potential ignition sources are not effectively isolated or at times these sources can not be isolated

(i.e. static electricity or lightning).

• The recognition of the inherent hazards of gas

purging operations has been weak as evidenced by

number of explosion incidents in recent years.

• The current regulatory codes do not adequately

address the required safety measure when purging

newly installed, modified or serviced fuel gas systems.

2. Purging indoors should only be done in limited

circumstances where purging outdoors is not

practicable. In such cases:

Regulatory Standards/References

• Nonessential personnel should be evacuated;

The regulatory standards that apply to the installation

of natural and LP gas installation are covered under

voluntary consensus codes developed by several

organizations. These codes are commonly adopted as

regulations by various states or local municipalities

across the United States. The agency/associations and

codes are shown below:

• All ignition sources should be controlled or

eliminated;

• Ventilation should be adequate to maintain the

gas concentration well below the lower explosive

limit at all times.

• The National Fire Protection Association (NFPA)

publishes the National Fuel Gas Code (NFPA 54/

ANSI Z223.1).

3. Never rely on odor alone to detect releases of fuel

gases. An odorant(4) is typically added to fuel gases,

such as natural gas and propane, to warn workers

and consumers of releases. However, the perception

of odor is highly subjective and varies from one

person to another. People also become desensitized

to odor during prolonged exposures. Additionally,

new gas pipes and containers can react with or

otherwise remove the odorant, an effect known as

“odor fade.”

• The American Gas Association (AGA) publishes a

technical guide entitles Purging Principles and

Practice.

• The NFPA and AGA jointly publish the National Fuel

Gas Code Handbook.

• The International Code Council (ICC) also has the

International Fuel Gas Code.

4. Always use combustible gas detectors(5) to monitor

the gas concentration during purging operations. To

provide the most accurate information about combustible gas levels, sampling should be conducted

frequently or continuously at appropriate locations.(6)

Additional Mandatory Standards apply to industry

under the Occupational Safety and Heath Administration,

such as:

• Occupational Safety and Heath Administration

(OSHA) regulates LPG under 29 CFR 1910.110.

5. Ensure personnel involved in gas purging operations are fully trained and knowledgeable about safe

gas venting practices, the proper use of gas detectors, and the danger of relying on the sense of smell

alone to detect gas releases. Include training on the

problem of odor fade in new gas piping systems.

• OSHA also regulates flammable gases under 29 CFR

1910.119 where processes involve a flammable liquid

or gas on site in one location, in a quantity of 10,000

pounds or more.(2)

3

LOSS CONTROL TECHNICAL INFORMATION PAPER SERIES

Gas Line Purging

On February 4, 2010 just three days before the Kleen

Energy Plant explosion, the CSB voted to approve 2

urgent recommendations that national fuel gas codes

be changed. These changes are needed to improve

safety when gas pipes are being purged (cleared of

air) during maintenance or installation of new piping.

2009-12-I-NC-UR2

Incorporate the revised gas purging provisions of

the National Fuel Gas Code, consistent with CSB recommendation 2009-12-I-NC-R1, into the International

Fuel Gas Code.

On February 24, 2010 a NFPA panel voted to move

forward with the CSB’s recommendations to make gas

purging practices safer. Currently the National Fuel

Gas Code Committee has not approved the language

for a temporary interim amendment (TIA). The committee is working towards consensus language and

expects to release a draft TIA for public review in the

near future.

The first recommendation was directed to the National

Fire Protection Association (NFPA), the American Gas

Association (AGA) and the Chair of the NFPA 54/ANSI

Z223.1 Committee.

2009-12-I-NC-UR1

Enact a Tentative Interim Amendment as well as permanent changes to the National Fuel Gas Code (NFPA

54/ANSI Z223.1) to require that during the purging of

fuel gas piping at industrial, commercial, and public

facilities:

Lessons Learned

Training

All personnel should be properly trained in:

1. Lockout-Tagout

2. Safe Gas Purging Techniques

3. Hazard Identification

4. Use of Gas Monitoring Equipment

a. Purged fuel gases shall be directly vented to a

safe location outdoors, away from personnel and

ignition sources

b. If it is not possible to vent purged gases outdoors,

purging gas to the inside of a building shall be

allowed only upon approval by the authority having

jurisdiction(7) of a documented risk evaluation and

hazard control plan. The evaluation and plan shall

establish that indoor purging is necessary and that

adequate safeguards are in place such as:

Lockout – Tagout

1. Any potential ignition source should be identified

and isolated in the proximity of the work area. All

flames or potential ignition sources within proximity

should be de-energized and locked out. Use the

standard lockout-tagout protocols required under

OSHA 1910.

• Evacuating nonessential personnel from the

vicinity of the purging;

2. Just closing and locking out the fuel line may not

be enough. Has the line been purged of the fuel

gas inside. (see purging section on page 5)

• Providing adequate ventilation to maintain the

gas concentration at an established safe level,

substantially below the lower explosive limit; and

3. Fuel supplies in some cases upstream may also

need to be secured and locked out. This may also

require the installation of blinds in the fuel supply

line in some situations.

• Controlling or eliminating potential ignition

sources.

c. Combustible gas detectors are used to continuously monitor the gas concentration at appropriate

locations in the vicinity where purged gases are

released.

(SPADE BLIND WITH LOCKOUT DEVICE)

d. Personnel are trained about the problems of odor

fade and odor fatigue and warned against relying

on odor alone for detecting releases of fuel gases.

The second recommendation was directed to the

International Code Council (ICC) and the Chair of the

International Fuel Gas Code Committee.

BLANK (OR BLIND)

4

LOSS CONTROL TECHNICAL INFORMATION PAPER SERIES

Gas Line Purging

The Tentative Interim Amendment (2009-12-I-NC-UR1)

issued by the Chemical Safety Board states that if it is

not possible to vent flammable gas outside then it

shall only be allowed when approved by the Authority

Having Jurisdiction(7) of a documented risk evaluation

and hazard control plan. If it is not possible to purge

to a safe outside location then interior purging should

only be done with very careful planning.

Purging

1. Gas blows (or the purging) of pipe to remove

contaminant or debris should be done using nonflammables that are inert such as air (not pure

oxygen), carbon dioxide or nitrogen. This reduces

the risk of fire or explosion. These gas blows have

risks associated:

• Possible high pressure discharges to clean out

the line. Where is the discharge point? This point

should be located in an isolated area away from

contact with personnel, equipment and buildings.

• Develop a written Purging Plan that addresses:

– Employee training

– Lockout-tagout of ignition sources and fuel

source minimization

– The purging process

– Monitoring of flammable gases (and oxygen levels)

– Minimizing exposure to non-essential personnel

– Evacuation/emergency response

• These discharges should be outside in a well

ventilated area that allows quick dispersion of

gas concentration or buildup.

• Caution needs to be used with inert gases.

Nitrogen can be used to reduce the risk of fire

or explosion but it also can make the atmosphere

in and around the equipment hazardous for

humans to breathe(7). It’s not toxic as it makes up

78% of the air we breath but it can displace the

air we breathe as the inert concentration levels

rise. If the concentration of oxygen is reduced to

below 19.5% a person could become unconscious

and die from lack of sufficient oxygen.

• Have the written plan reviewed and approved by the

Authority Having Jurisdiction.

Hazard Identification

Break down the purging task to identify all potential

hazards by a job hazard analysis (JHA) process.

3 steps are involved in the development of a JHA.

(see attachment)

• High pressure gas blows or purging can cause

catastrophic failure of pipe, valves or fittings.

Pipe, valves, fittings, gauges, etc. should all be

designed for the pressures that are intended. If

not, precautions need to be taken to keep the

pressures within design parameters or to isolate

(i.e. via the installation of line blinds or blanks).

1. Creating a step by step task analysis to complete

the job.

2. Identify all the potential hazards associated with

each task step.

3. List the methods of control for each of the hazards

identified.

2. When purging of pipe for the purpose of displacing

air or other gas within the pipe and replacing it

with fuel gas (natural or LP) extreme caution is

required due to the fuel gas that is charged into the

system escaping into the atmosphere. This purging

should be directed outdoors in a well ventilated

space that is free from all ignition source hazards.

Monitoring

Checking

for layers

of gas

at various

levels

• A temporary pipe or hose could be used to

purge from the source to a safe outside area.

When locating the purge discharge take into

consideration the physical properties of the gas

being purged.

• For gas heavier than air consider low spots or

depressions where heavier gas vapors will settle.

Consider the effects of weather on dispersion of

the gas being purged. The gas should be rapidly

dispersed and not exceed 10% of the LEL.

Whether performing a

gas blow or a purging

operation (inside or outside) with flammable gas

a potential exists for an

accumulation of gas at

an explosive level. The

only safe means to monitor for flammable gas

concentrations is with a

reliable combustible gas

detector(6).

Combustible gas detectors should be rated

intrinsically safe by a

5

LOSS CONTROL TECHNICAL INFORMATION PAPER SERIES

Gas Line Purging

5. Combustible gas detectors measure combustible/

flammable gas concentration in the atmosphere,

which is indicated on the device as a percentage of

the lower explosive limit (LEL).

certifying organization such as Underwriters

Laboratory (UL®) or Factory Mutual (FM®). They also

should be calibrated and serviced per the manufacturer

instructions. Employee training in the proper use of

this equipment is required. Following the manufacturer’s

instructions is crucial to hazard identification.

6. The evaluation of appropriate locations for combustible gas monitoring should include consideration

of the purge location, characteristics of the gas

(lighter or heavier than air), stratification or mixing

of the gas, and existing ventilation. See the

International Society for Automation (ISA) RP 12.13,

Recommended Practice for the Installation,

Operation, and Maintenance of Combustible Gas

Detection Instruments (2003) and the American

Petroleum Institute (API) 2009, Safe Welding,

Cutting, and Hot Work Practices in the Petroleum

and Petrochemical Industries (2002).

Testing should be done frequently and at predetermined locations during the purging process. At any

time if the gas concentration exceeds 10% of the LEL,

the purging process should be immediately stopped.

For More Information

For additional information specific to your need,

please contact your Hartford loss control consultant,

or visit us at www.thehartford.com.

7. The NFPA defines the Authority Having Jurisdiction

(AHJ) as an “organization, office, or individual

responsible for enforcing the requirements of a

code or standard, or for approving equipment,

materials, an installation, or a procedure” such as a

local fire marshal or building official. NFPA 654,

Standard for the Prevention of Fire and Dust

Explosions from the Manufacturing, Processing, and

Handling of Combustible Particulate Solids, 2006

Edition, 654-6. Where it is not possible to implement safety controls, NFPA standards can grant

decision-making authority over exceptions to safety

requirements to the authority having jurisdiction.

Footnotes

1. The Chemical Safety Board (CSB) is an independent federal agency charged with investigating

industrial chemical accidents. The CSB conducts

root cause investigations of chemical accidents at

fixed industrial facilities.

2. Except for hydrocarbon fuels used solely for workplace consumption as a fuel (e.g., propane used for

comfort heating, gasoline for vehicle refueling), if

such fuels are not a part of a process containing

another highly hazardous chemical covered by 29

CFR 1910.119.

3. The LEL, also known as the Lower Flammable Limit

(LFL), is defined as “that concentration of a combustible material in air below which ignition will not

occur.” Recommended Practice for Handling

Releases of Flammable and Combustible Liquids

and Gases, NFPA 329 (2005).

8. CSB identified 85 nitrogen asphyxiation incidents

that occurred in the workplace between 1992 and

2002. Eighty people were killed and 50 were

injured. Source USB Safety Bulletin No. 2003-10-B |

June 2003

4. Natural gas is primarily composed of methane, an

odorless and colorless gas. In order to heighten

an individual’s ability to detect natural gas, small

quantities of odorant are added. T-butyl mercaptan

(typically described as having a “skunk-like” odor),

is one such odorant.

Sources

Various U.S. Chemical Safety Board, available public

Investigation and Safety Bulletin information

The information provided in these materials is intended to be general and advisory in nature. It shall not be considered legal advice. The Hartford

does not warrant that the implementation of any view or recommendation contained herein will: (i) result in the elimination of any unsafe conditions

at your business locations or with respect to your business operations; or (ii) will be an appropriate legal or business practice. The Hartford

assumes no responsibility for the control or correction of hazards or legal compliance with respect to your business practices, and the views

and recommendations contained herein shall not constitute our undertaking, on your behalf or for the benefit of others, to determine or warrant

that your business premises, locations or operations are safe or healthful, or are in compliance with any law, rule or regulation. Readers seeking

to resolve specific safety, legal or business issues or concerns related to the information provided in these materials should consult their

safety consultant, attorney or business advisors. All information contained herein is as of September 2011.

© September 2011 The Hartford Financial Services Group, Inc., Hartford, CT 06155 All Rights Reserved

6

LOSS CONTROL TECHNICAL INFORMATION PAPER SERIES

Gas Line Purging

PURGING JOB HAZARD ANALYSIS

TASK NAME:

LOCATION:

DATE:

EQUIPMENT BEING PURGED:

TASK STEP

HAZARD

7

CONTROL

LOSS CONTROL TECHNICAL INFORMATION PAPER SERIES

Gas Line Purging

PURGING CHECKLIST

The below sample checklist is not all-inclusive and should be used as a means to help monitor your worksite.

YES

Has a Purging – Job Hazard Analysis been completed?

Have all fuel line sources been identified?

Have all fuel lines not required for the purging operation

been secured and locked out?

Are line blanks or blinds required to safely isolate fuel lines,

fitting, gauges?

Is the purging discharge line located outside away from

personnel, equipment & buildings? If No, a written Gas Purging

Plan should be developed.

Could high pressure discharge direct gases or foreign objects

towards personnel, equipment & buildings?

Is inert gas being used as the purging medium? If Yes

a.) Will oxygen levels be monitored to maintain adequate

concentration between 19.5% and 23.5%?

Will purging operation involve a flammable gas?

Will the flammable gas purged settle into low areas where

there are uncontrolled ignition sources?

Has the written Gas Purging Plan been communicated to

and approved by the local Authority Having Jurisdiction?

Have all non-essential personnel been evacuated to a safe

location from the purging operations?

Are reliable combustible gas meters being used to sample

for gas concentrations?

Have employees using the combustible gas meters been

trained on their use?

Have the combustible gas meters been properly calibrated

and tested per the manufacturer specifications?

Have all employees been specifically trained in safe procedures

for the gas purging operations?

Is a temporary hose or line required to direct the purged gas

to safe locations outside of the building?

Has emergency response personnel (Fire Department, EMS, etc.)

been notified of the gas purging activities planned?

Are additional ventilation sources required to maintain gas

concentrations within acceptable levels?

Have all potential ignition sources been isolated, de-energized

and locked-out?

COMPLETED BY:

DATE:

8

NO

NOTES