The Reflective Surface of the MAGIC Telescope

advertisement

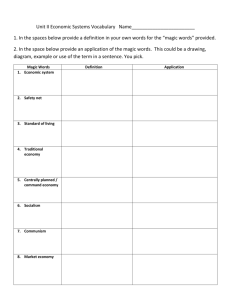

The Reflective Surface of the MAGIC Telescope Michele Doro on behalf of the MAGIC Collaboration University of Padova & INFN michele.doro@pd.infn.it 6th RICH - Trieste, Italy 15-20 October, 2007 Overview Part I: The MAGIC detector Part II: The Reflective Surface Overview on the IACT technique Demands Mirror Tests and measurement MAGIC I problem MAGIC II upgrade Overview on future 15-20 Oct 2007 M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 2 PART 1 The MAGIC Telescope The MAGIC Telescope Collaboration of 22 institutes (mostly European) ~150 physicists Installation completed 2003, fully-operating since fall 2004 ~50 publications on journals Currently on III-year cycle of scientific-observations 15-20 Oct 2007 M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 4 The IACT technique Physics of the atmospheric showers: Cosmic rays (protons, heavier Z, electrons, photons) hit the upper atmosphere Interactions create cascade of billions of particles: Charged particles in turn emit Cherenkov light: Electromagnetic shower (e+,e-,γ) Hadronic shower (π0, π±, e+,e-,γ) Blueish flash ~2ns duration ~1º aperture Cherenkov cone reaches the ground Circle of ~120m radius Effective telescope area ~ 104-5 m2 15-20 Oct 2007 M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 5 Imaging Technique Light is reflected on a multi-pixel camera (576 total) Image is ellipsoid 396 central PMT 1 inch 180 outer PMT 1.5 inch Pointing to the centre for gammas Randomly distributed for hadrons Study of the image gives information on primary particle The reflective surface must ensure a PSF possibly smaller than the pixel size 15-20 Oct 2007 M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 6 Physics program Pulsars AGNs GRBs SNRs ? Origin of Cosmic Rays Cold Dark Matter 15-20 Oct 2007 Quantum Gravity effects cosmological γ-Ray Horizon M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 7 MAGIC II Currently a second telescope is being built Stereoscopic MAGIC I + II will have increased performance: 15-20 Oct 2007 Structurally a clone of MAGIC I Each system adopted new enhanced solutions Better telescope than MAGIC I Increased angular resolution Increased energy resolution Increased flux sensitivity Inauguration 21/09/2008 M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 8 Many challenging solutions Reflector and mirrors: Drive Lacquer-coated enhances photon conversion of PMT Operation with moonlight Signal transmission 15-20 Oct 2007 Faster repositioning ever achieved Camera World largest dish diameter 17m Light undercarriage made of CFRP All aluminium mirrors with sandwich structure and diamondmilled surface Active mirror control Ultra-fast acquisition (2GhZ) Optical transmission instead of coaxial M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 9 PART 2 MAGIC reflective surface Brief History 2001-2004 MAGIC I mirrors are designed, tested and installed 732 INFN mirrors (76%) 224 MPI mirrors (24%) 2005-06 MAGIC I Upgrade of the design Substitution of damaged mirrors MAGIC I MAGIC II 2006- MAGIC II mirrors 1m2 Aluminium mirrors (INFN) 2 1m Glass mirrors (INAF) 15-20 Oct 2007 M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 11 Mirror Technical Demands Lightweight Mirror Shape Rigidity Insulation Mounting Optical quality 15-20 Oct 2007 Telescope must rotate fast and then mirrors need to be as light as possible Mirrors profile is spherical Each mirror has different radius of curvature because reflector profile is parabolic (f=17m) Avoid oscillations due to wind Avoid bending during tracking Sometimes strong rains and snows Also high humidity Strong UV light Coupling with actuators of Active Mirror Control Easy mounting and substitution Maximize reflectivity Minimize reflected spot size M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 12 The Reflector Parabolic profile Huge dimension demands tessellation of the surface Radius of curvature changes according to position 15-20 Oct 2007 preserve temporal structure of the shower slightly increased aberrations So-called average radius used (mean of paraboloid principal radii ) 34 to 36.5 meters radius range M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 13 Shape Large reflector area (~234m2) requires to tessellate the surface Geometry of the mirror tile Size 15-20 Oct 2007 Past used solutions: round, hexagonal Solution: MAGIC has square mirrors to minimize empty regions and easier production Construction reasons Aberrations Solution: MAGIC I has 0.5m side, MAGIC II has 1m side (2x) mirrors M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 14 Materials Established experience with glass mirrors (astronomy) for other IACTs AlMgSi0.5 plate 1-2cm thick glass layer Aluminized for reflectivity Protection some drawbacks Hexcell Usual large weight Difficulty of producing different focal lengths Al-box Mounting and laser 15-20 Oct 2007 Idea of the full-aluminium sandwich Al-alloy surface Al-box Hexcell honeycomb structure Diamond-milling of the surface M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 15 Assembly 1 The sandwich is assembled with the use of the aeronautic glue 3M™ AF163-2K The sandwich in then inserted between two verystiff aluminum-moulds 2 Plane for MAGIC I Already curved for MAGIC II and everything is put into a plastic vacuum-bag Autoclave curing 5 bar pressure 120º temperature MAGIC II Result is the raw-blank 15-20 Oct 2007 3 35m M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 16 Diamond-milling 3 A diamond mills the surface To give spherical shape, rotation on two axis Mirror rotates around optical axis Machine axis rotates tilted and diamong at distance d Adjustable R curvature In the MAGIC reflector around 20 different bins of radius of curvatures are needed The mirror gets the reflective properties 15-20 Oct 2007 M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 17 Coating The aluminium must be protected against environment Solutions Solution adopted: quartz because of costs and transparency in 300-700nm The width must be optimized for positive interference in the wavelength where Cherenkov light is peaked (blue) 15-20 Oct 2007 Diamond chemical vacuum deposition (CVD) Al2O3 anodization SiO2 vacuum deposition Width ~ 100 nm Measurement of the roughness gives 4nm on average M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 18 Testing the quality - Reflectivity The reflectivity was measured in the Cherenkov range (200-800nm) using: MAGIC I: Reflectivity is correctly peaked at 400nm (close to peak of the Cherenkov spectrum) Average reflectivity around 80-85% MAGIC II: 15-20 Oct 2007 Perkin-Elmer device (mirror must be cut and put inside the machine) Spectro-photometer (local measure on 3x3cm2 of surface) Mantained the same qualities M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 19 Testing the quality - Spot Size Mirror is put at twice the focal length (~35m) and illuminated with point-like bright source Analysis of the CCD image: LED MAGIC I mirror 15-20 Oct 2007 d90 ~ 10mm at the camera distance So-called “d90”= diameter containing 90% of the focused light d90 = spot size It is not a measure of reflectivity due to difficulties in estimating scattered light LED MAGIC II mirrors d90 ~ 5mm Better of factor 2 BEST RESULT! M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 20 Panel & AMC Major difference between MI and MII mirrors are grouped into panels of 4 (3 in some cases) Panel is also Al-sandwich (20kg) Inter-alignment and fixing Single mirror host AMC for MII The back of the panel hosts the actuators for the Active Mirror Control AMC moves panel to re-adjust the focussing to correct small bending during the tracking Use of laser 15-20 Oct 2007 M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 21 MAGIC I experience Main problem with mirrors installed in MAGIC I after two years from installation Substituted around 100 mirrors (~10%) 15-20 Oct 2007 Humidity was entering from edge of top plate of the mirrors Condensation into water Ice formation and bubbles Due to strong rigidity, deformation is local and mirror maintains reflective area Re-designed mirrors for insulation Test for large mirrors Now problem seems solved M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 22 Reflector performance monitor Reflector performance can be monitored Reflector PSF, now stable <11mm Single mirror abs.reflectivity SBIG CCD at the centre of the reflector, observe a star and the camera at the same time All mirror focussed:PSF One mirror focussed and others defocussed: single mirror reflectivity M. Garczarczyk Phd Thesis 2007 ~11mm SPOT Inner PMT 15-20 Oct 2007 M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 23 Upgrade on MAGIC I Improved design 15-20 Oct 2007 Thinner skin and pre-shaped box: the mould is not spherical and the rawblank comes out already with ~35m curvature Larger top-plate and gluing of the edge with 3M™ DP190 External heater to avoid coupling between plastic and aluminium M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 24 MAGIC II Al-mirrors Basically an extension of MAGIC I-upgraded mirror: Increased honeycomb width resulted in increased rigidity: Larger upper plate with respect to box Use of aeronautic glue DP190 for insulation No internal heater Curvable box Best spot size due to more accurate diamond milling of the surface MAGIC I MAGIC II 15-20 Oct 2007 M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 25 MAGIC II MAGIC II will have Upgrade to 1m2 facet Technologically achievable Less number of items Decreased weight and direct coupling to active mirror control No-need of inter-alignment Drawback: 15-20 Oct 2007 144 m2 of INFN-Padova mirrors 104 m2 of INAF-Brera mirrors Less approximating the parabola: increased aberrations, nevertheless the coma aberration dominates for tilted incidence M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 26 MAGIC II Glass mirrors A thin glass sheet (1-2 mm) is elastically deformed so to retain the shape imparted by a mould having convex profile. If the radius of curvature is large, the sheet can be pressed against the mould using the vacuum suction. On the deformed glass sheet (under vacuum force) is glued an honeycomb structure that provide the structural rigidity. Then a second glass sheet is glued on the top to create a sandwich. After releasing the vacuum, on the concave side is deposited a reflecting design for their mirrors coating (Aluminum) and a thin protective coating (Quartz) 15-20 Oct 2007 M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 27 Summary and outlook 15-20 Oct 2007 MAGIC II mirrors production is already on the production-line Technique gave excellent results in term of light concentration Insulating problems seem solved Price is decreased wrt to MAGIC I, nevertheless is still main drawback: 2.8k€/m2 can be a problem for third generation IACTs Scale production can decrease costs or find other techniques (glass) M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 28 Back-up slides Results http://tevcat.uchicago.edu/ Around 50 publications on journals ~21 VHE source observed (6 MAGIC discoveries!) 7 new analysis techniques 23 technical papers Observed sources: 12 = extragalactic 9 = galactic 15-20 Oct 2007 M.Doro - The Reflective Surface of the MAGIC Telescope - RICH 2007 30