EYSX Expanded Fill Sealing Fittings

advertisement

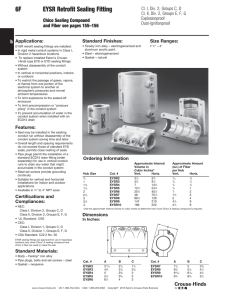

Cl. I, Div. 1 & 2, Groups B,c,o• Cl. II, Oiv. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl.lll EYSX Expanded Fill Sealing Fittings Accessories Page BF-11 Explosionproof Oust-lgnitionproof BF-5 ; 1 t t 0 CROUSE-HINDS• 1 Applicat ion: EYSX Expanded Fill Sealing Fittings: • restrict the passage of gases, vapors or flames from one portion of the electrical installation to another at atmospheric pressure and normal ambient temperatures • limit explosions to the sealed-off enclosure • limit preoompression or "pressure piling" in conduit systems • provide 40% wire fill capacity to allow uninterrupted runs in a conduit system Sealing fittings are required : • at each entrance to an enclosure housing an arcing or sparking device when used in Class I, Division 1 and 2 hazardous locations. To be located as close as practicable and, in no case, more than 18" from such enclosures • at each entrance of 2" size or larger to an enclosure or fitting housing terminals, splices or taps when used in Class I, Division 1 hazardous locations. To be located as close as practicable and, in no case, more than 18" from such enclosures • in conduit systems when leaving Class I, Division 1 or 2 hazardous locations • in cable systems when the cables either do not have a gas/vaportight continuous sheath or are capable of transmitting gases or vapors through the cable core when those cables leave the Class I, Division 1 or 2 hazardous locations Features: EYSX Expanded Fill Sealing Fittings provide: • a 40% wire fill capacity for expanded fill sealing • large openings with threaded closures to provide easy access to conduit hubs for making dams • integral bushings in conduit hubs to protect conductor insulation from damage • taper-tapped hubs to ensure ground continuity • minimum turning radius EYSX Expanded Fill Sealing Fittings are available for installation in both horizontal or vertical positions. Certifications and Compliances: Vertical or horizontal femal e NEC/CEC: EVSX11- EYSX81 Class I, Division 1 and 2, Groups B,C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class Ill EYSX9, EVSX10, EVSX1 SA- EYSX10 SA Class I, Division 1 and 2, Groups C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class Ill • UL Standard: 886 • CSA Standard: C22.2 No. 30 EYSX Expanded Fill Sealing Fittings For Sealing in Vertical o r Horizontal Positions Hub Size Y.! Y.! o/4 o/4 1 1 11/4 1'!4 1 '~ 1Y.! 2 2 2 '12 2Y.! 3 3 3'~ 3Y.! 4 4 NOTE: Sealing fittings are approved for use in hazardous locations only when Chico"' X fiber and Chico A sealing compound are used to make the seal. Female Hub Cat. # EYSX11 * EYSX1 SA EYSX2l* EYSX2 SA EYSX31 EYSX3SA EYSX41 EYSX4 SA E:YSX51 EVSX5 SA EYSX61 EYSX6SA EYSX71 EYSX7 SA EYSX81 EYSX8 SA EYSX9* EVSX9 SA EYSX10* EYSX10SA NPT Turning Size 1 1'!4 A 3 11/16 4o/16 5'1\s 6'14 1 '~ 6114 1h % 2 Blh 2 Y.! 9o/t6 g:y. 3 3 1;2 11 1116 4 11 '!16 :f; With plug cover removed. Dimensions • Bodies - Feraloyo Iron alloy and/or ductile iron • Closures - Fera/oy iron alloy and/or steel Standard Finishes: • Feraloy iron alloy and ductile iron A electrogalvanized and aluminum acrylic paint • Steel - electrogalvanized Options: 1Y.! Radius 11/4 13!4 1% 2:Y16 1231.J2 2o/1s 2o/1s 3 3 4 1/< 4% 5114 6 Y.! 61;2 3o/1s 3Y'ls:f; 3 11Asi 4 191.J2:j: 4191.J2:f; t See Certifications and Compliances for classsification of each product. * Feralo)"" :j: With cover removed. Standard Materials: • Copper-free aluminum bodies and enclosures B / Size Ranges: • 1!.!"- 4" Copyright• 2000 Cooper Industries, Inc. Cl. I, Div. 1 & 2, Groups A,B,C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl.lll Condulet®Sealing Fittings Bf-2 1 ( Accessories Page BF-9 r 1 0 CROUSE·HINDS ' t Application: EYS and EZS sealing fittings: • restrict the passage of gases, vapors or flames from one portion of the electrical installation to another at atmospheric pressure and normal ambient temperatures • limit explosions to the sealed· off enclosure • limit precompression or " pressure piling" in conduit systems Sealing fittings are required: • at each entrance to an enclosure housing an arcing or sparking device when used in Class I, Division 1 and 2 hazardous locations. To be located as close as practicable and, in no case, more than 18" from such enclosures • at each entrance of 2" size or larger to an enclosure or fitting housing terminals, splices or taps when used in Class I, Division 1 hazardous locations. To be located as close as practicable and, in no case , more than 18" from such enclosures • in conduit systems when leaving Class I, Division 1 or Division 2 hazardous locations • in cable systems when the cables either do not have a gas/vaportight continuous sheath or are capable of transmitting gases or vapors through the cable core when those cables leave the Class I, Division 1 or Division 2 hazardous locations Features: EYS and EZS sealing fittings include: • minimum turning radius • large openings with threaded closures to provide easy access to conduit hubs for making dams • integral bushings in conduit hubs to protect conductor insulation from damage • taper-tapped hubs to ensure ground continuity EYS sealing fittings are available for installation in either vertical only or in both horizontal or vertical positions. Vertical fem al e EZS sealing fittings for installation at any angle; the covers with opening for sealing compound can be properly positioned to accept the compound. Vertical male& female Explosionproof Dust-lgn itionproof Vertical or horizontal female Vertical or horizontal male& female Standard Materials: • Bodies - Feralo}"' iron alloy and/or ductile iron • Closures - Fera/oy iron alloy and/or steel • Removable nipples - steel Standard Finishes: • Feraloy iron alloy and ductile iron - electrogalvanized and aluminum acrylic paint • Steel - electrogalvanized EYS Options: For Sealing in Vertical Positions Only • Copper-free aluminum bodies, nipples and enclosures- see listings Hub Size Size Ranges: • V.t - 'h o/4 1 6" Certifications and Compliances: Female Hub Cat.# EYS1* EYS2* EYS3* Male& Female Hub Cat.# EYS16* EYS26* EYS36* Approximate Internal Volume in Cubic Inches 1 2 3% For Sealing in Vertical or Horizontal Positions NEC/CEC: • EYS1-3, 11·31, 1~36, 116·316 Class I, Division 1 & 2, Groups A,B,C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class Ill • EYS41·101, 416-1016 Class I, Division 1 & 2, Groups B,C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class Ill • EYS29, 4-o14, 46-o146 EZS1 , 16·86 Class I, Division 1 & 2, Groups C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class Ill Hub Size Y2 :y. 1 1114 Ph 2 2\12 3 3%. 4 Fem al e Hub Cat.# EYS1 1* EYS21* EYS31* EYS41 EYS51 EYS61 EYS71 EYS81 EYS91 EYS101 Male& Female Hub Cat.# EYS116* EYS216* EYS316* EYS416 EYS516 EYS616 EYS7t6 EYS816 EYS916 EYS1016 Approximate Internal Volume in Cubic Inches Vertical Horizontal 1 1 2 2 3 3o/4 6 8 10% 19 25 \12 56 72 95 121/4 22¥1 30 64 \12 82 110 NOTE: Sealing fittings are approved for use in hazardous locations only when Chico~ X fiber and Chico A sealing compound are used to make the seal. • UL Standard: 886 • CSA Standard: C22.2 Dimensions EYS 1 Series Size 1h o/4 1 a 39/)2 3 1o/1 6 4o/1s EYS 11 Series 11/4 11h 1% Turning Radius 1% 129/)2 2% 2:Y16 27As 3 3% 41,4 4% 51/4 6 1h 7% t 23h2 2 1/ 16 2o/1s 2 1\1\s 3o/16 37/161: 311!161: 4 19h2t 5 11h2t b a 3 1 Vt6 3 11116 4o/1s 11/4 Turning Radius 1%2 1 \12 1% H-4 H11 2:Y16 27/16 3 3Yl 4'14 4% 5'14 123hz 2\1\s 2o/16 211/16 3o/1s 3 71161: 3 1 \1\ st b EYS4 Series 11/4 11h 2 21h 3 31h 4 5 6 5 \1\ s 5 1h 6V. 7 1h 81;2 9o/16 93/4 11 1116 121/a 5\1\s 5% 6V. 7% 8th 93116 9% Copyright" 2000 Cooper Industries, Inc. * Available in copper-free aluminum - 10 order, add suffi< SA lo Cat. No. t With cover removed.