Paper-Effect of impurities on the minority carrier lifetime of silicon

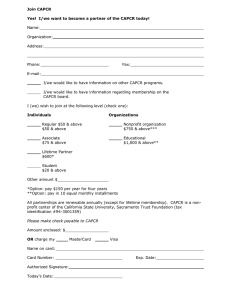

advertisement

22nd European Photovoltaic Solar Energy Conference, 3-7 September 2007, Milan, Italy EFFECT OF IMPURITIES ON THE MINORITY CARRIER LIFETIME OF SILICON MADE BY THE METALLURGICAL ROUTE 1 Arve Holt1, Erik Enebakk2 and Anne-Karin Soiland2 Institute for Energy Technology, P.O. Box 24, NO-2027 Kjeller, Norway, mailto:arve.holt@ife.no 2 Elkem Solar AS, P.O. Box 8040, NO-4675 Vågsbygd, Norway ABSTRACT: The objective of this study has been to investigate the relationship between the impurity level and the minority carrier lifetime of solar grade silicon made by the metallurgical route by Elkem Solar (ES). The wafers have been characterised by microwave photo conductance decay (µ-PCD), FeB-pair splitting and neutron activation analyses (NAA). The results of the minority carrier lifetime measurements show higher minority carrier lifetime of ES-wafers compared with results from wafers based on poly silicon material. A P-gettering processes has successfully been introduced, showing an average improvement by a factor larger than two. At [Fe] of about 1013 atoms/cm3 clustering starts to form in the red zone near the border of edge wafers. It is assumed that these clusters are electrically less active. This is supported by the increase of lifetime near the edge in the red zone. Most likely iron silicide clusters are formed. Keywords: defect engineering, P-gettering, annealing 1 INTRODUCTION One of the bottlenecks in order to ramp up the production of silicon solar cells and to reduce the price of solar panels further are the shortage of silicon feedstock of high enough quality. Traditionally feed stock for the silicon based solar cell industry has been produced through the silane or TCS route. However today several new methods for making silicon feedstock are under development. Elkem Solar (ES) has been focusing making solar grade silicon made by the metallurgical route [1]. The impurity concentration has been measured by neutron activation analyses (NAA). All the samples in this study were chemically polished at room temperature in a fresh CP4 solution consisting of 10 parts concentrated HNO3, 5 parts of concentrated CH3COOH and 2 parts 48% HF. Typically 15-20 microns were etched away on each side. The samples were then etched in a fresh piranha solution consisting of 3 parts of H2O2 and 10 parts of H2SO4. Before the P-gettering processing the samples were etched in a 5% HF solution prior to the process of spraying on the liquid diffusion source on both side of the samples. The diffusion source solvent was baked away by a heat treatment in an own for 10 minutes at 200 °C. In this study different temperature profiles in our belt furnace were used during P-gettering processing. After the gettering process the phosphorous rich surface layer was etched away by CP4 followed by a piranha etch. The objective of this study has been to investigate the relationship between the impurity level and the minority carrier lifetime of ES solar grade silicon and to compare the electrical properties of the wafers based on ES material with wafers based on material produced through the silane route. 2 EXPERIMENTAL SETUP For life time measurements the both front and back surfaces were passivated by going through a CP4 etch, piranha etch and a HF etch, followed by adding amorphous silicon on both sides by using PECVD technique [2,3]. Detailed mapping of lifetime of minority carriers have been studied at nine different positions in an ES edge block. In parallel wafers from an edge block produced from poly silicon by another manufacturer have also been investigated as a reference. The lifetime has been measured on as cut wafers and after different processing steps: i) temperature annealing, ii) emitter formation, and iii) high temperature gettering. 3 RESULTS AND DISCUSSIONS 3.1 Initial lifetime of samples before P-gettering The results for the lifetime of minority carriers in nine different positions in an ES edge block are shown in Table 1 and on a reference edge block in Table 2. Position one corresponds to samples at the bottom of the block and samples from position nine correspond to samples from the top of the block. The lifetime of the minority carriers has been characterised by microwave photo conductance decay (µPCD) method. The bulk [Fe] have been studied by FeBpair splitting by comparing the lifetime measurements before and after light soaking. The calculations where based on the equation Table 1: Initial lifetime of an ES edge block N Fe ! $ 1 1 ' )) = C µ "PCD && " % # before # after ( Pos 1 2 3 4 5 6 7 , where Cµ -PCD = 3.4 1013 µs/cm3 were used. Although the correctness of the C µ-PCD value is questionable, this method is useful to see the [Fe] variation across the wafer. 1155 ! (µs) 1,2 3 7,8 20,4 40,9 49,5 51,2 ! in bulk (µs) 1,5 4,4 11,3 29,7 62,1 72,8 77,0 ! edge zone (µs) 0,8 0,5 0,7 0,9 1,0 1,1 1,1 22nd European Photovoltaic Solar Energy Conference, 3-7 September 2007, Milan, Italy 8 9 60,2 54,6 90,5 80,0 It is therefore expected a negative gradient of the [Fe] all the way from the edge. 1,0 1,2 Table 2: Initial lifetime of a reference edge block Pos 1 2 3 4 5 6 7 8 9 ! (µs) 34 ! in bulk (µs) 59,2 ! edge zone (µs) 3,5 46 38 41 50 60 48 44 60,1 63,0 43 63 70 50 54 5,7 5,9 10,0 5,6 7,1 12 14 Both tables show three columns of results. The first column shows the average lifetime (!) of the sample. The second column shows the average lifetime of wafere without taking into account the contributions from the "red" edge zones shown in Figure 1 and in Figure 2. The third column gives an average value of the red zone before lifetime starts to increase significantly. Figure 2: A lifetime map of a sample from position 7 in the reference edge block. Figure 1: A lifetime map of a sample from position 7 of an ES edge block. Figure 3: Initial lifetime versus distance from the edge of an ES edge block As seen in Table 1 the lifetime increases from about 1 µs to about 90 µs when going from bottom to the top of the ES the edge block. This increase is not present in the reference block. In the latter case the lifetime shows a constant value of about 60 µs from bottom to top. Interestingly the lifetime in the ES block goes through a minimum in the red zone when going from the edge and inwards, shown in Figure 3. This effect is not observed in the reference block. The effect lower Fe concentration near the edge is suggested to be due to formation stable Fe defect clusters in matrix above a certain concentration. These clusters are shown to be stable during the light soaking process. The clustering near the edge may also explain the enhancement in lifetime near the edge in the red zone. The [Fe] has been measured by Fe-B pair splitting and the results show that the [Fe] goes through a maximum in the red zone shown in Figure 4. The clustering starts to occur at [Fe] just below 1013 atoms/cm3 where the peak in iron concentration is observed. In the reference block the iron concentration never reaches values higher than about 1012 atoms/cm3 in the red zone. Within the red zone of the reference block there is no maximum in the [Fe] observed. The red zone is formed due to in-diffusion of impurities like Fe from the crucible and crucible coating. The high concentration of iron in the red zone of the ES wafers may be caused by long annealing times during 1156 22nd European Photovoltaic Solar Energy Conference, 3-7 September 2007, Milan, Italy the crystallisation process and/or due to high impurity concentration in the crucible and/or crucible coating used. In other words the electrical properties of the red zone is process related and not related to the feedstock material. compared with the ES-wafers in this study. Figure 5: A lifetime map of a sample from position 7 of an ES edge block after P-gettering. Figure 4: [Fe] versus distance from edge of an ES edge block. 3.2 Lifetime of samples after P-gettering In this case the samples were diffused at 890°C for 20 minutes, after which the temperature was abruptly lowered to 800°C in order to slow down the P diffusion and then gradually ramped down to 700°C during one hour[4]. The resulted sheet resistance after diffusion showed about 30"/square. The results of the lifetime after gettering at different positions in the ES edge block is shown in Table 3 in columns named ! (µs), ! in bulk (µs), and ! edge zone (µs). The results from the reference block is also given in the column named !ref(µs). Table 3: Lifetime after P-gettering for ES Edge block Pos 1 2 3 4 5 6 7 8 9 ! (µs) 86,7 117,8 130,6 134,7 136,9 163,7 178,5 170,4 !ref(µs) 88 76 79 83 77 81 85 70 51 ! in bulk (µs) 105,0 145,0 153,0 164 170 201 221 ! red zone (µs) 24,5 24,7 24,4 27,1 23,5 25,8 24,7 202 26,5 Figure 6: A lifetime map of a sample from position 7 in the reference edge block after P-gettering. Interestingly for the reference samples, the red zone area is completely removed after the P gettering process, while for ES material the red zone has been reduced dramatically. Figure 5 shows a lifetime map of an ES sample and Figure 6 shows an example from a reference block. As seen from the results above, the P-gettering process improves the lifetime dramatically for the ES material. In the bulk the average lifetime increases from about 70 to 170 µs. However in the regions with low lifetime initially there is not observed any improvements after the gettering process, seen by comparing Figure 1 and Figure 5. Improved lifetime after gettering has been shown by many and most recently by Tan et al. [5], Bentzen et al.[6] and by P. Manshanden and L. Geerligs[7]. However these studies shows overall lower lifetime values Figure 9 shows line profiles before and after P-gettering from position 2 of an ES edge block. As seen from the figure the red zone after gettering of the ES material reflects the area where clustering of defects have occurred. However note the remaining red zone area has been proved with more than an order of magnitude. Line 1157 22nd European Photovoltaic Solar Energy Conference, 3-7 September 2007, Milan, Italy profiles of the lifetime from the edge are shown in Figure 7. 3.4 Annealing The lifetime has been studied after annealing at different temperatures. The results of the annealing studies are shown in Figure 9 for one position in the ES edge block. Also included are the results from the initial and P-gettered wafer at the same position. As shown, the effect after annealing is highest in the temperature range 500-600 °C. This improvement has also previously been reported by others [8]. However in this study the Pgettering process shows much higher improvement with respect on lifetime. This is the case both in the red zone region and in the bulk region not contaminated during crystallisation. Interestingly the lifetime profiles shows two peaks in the red zone part after annealing. This may be due to different cluster regimes. At 600 °C this effect is largest. Figure 7: Lifetime versus distance from the edge of an ES edge block after gettering 3.3 P-gettering at different temperatures P-gettering has been preformed at different temperatures both for the ES and the reference material for 150 minutes. The results are shown in Table 4 and in Figure 8. At 800-900 °C the effect of gettering is highest with more than doubling of the lifetime performance. Pgettering also in this case has the largest impact on the wafers based on ES material. Table 4: Results of lifetime measurements given in !s from P-gettering processes at different temperatures 700 °C 800 °C 900 °C 890°C * ESm 50 118 129 159 ESr 3,8 6,4 16,3 25,8 Refm 59 106 110 81 * Temperature ramps and hold times equal to the set-up described in section 3.2. Figure 9: Lifetime profiles after annealing at different temperatures from position 2 of an ES edge block The results of lifetime measurements on the reference block after annealing at different temperatures are shown in Figure 10. In this case annealing shows best results at the lowest temperature. Note also the presence the red zone also after annealing. Figure 8: Lifetime profiles after P-gettering at different temperatures from position 5 of an ES edge block. Figure 10: Lifetime profiles after annealing at different temperatures of a reference edge block. 1158 22nd European Photovoltaic Solar Energy Conference, 3-7 September 2007, Milan, Italy At [Fe] of about 1013 atoms/cm3 clustering starts to form in the red zone near the edge of the sample. It is assumed that these clusters are electrically less active. This is supported by the increase of lifetime near the edge in red zone. Most likely iron silicide clusters are formed. 3.5 NAA analyses Neutron activation analyse has been used to determined the bulk impurity level. Samples from two blocks have investigated one centre block from ES and one reference edge block made from poly silicon. The results from the study are shown in Table 5. Low temperature annealing improves the material in certain regions. However P-gettering overall gives better results. Except for the [Na] and the [Co], the overall impurity concentration is higher for the ES material. Please also note the reference block is also contaminated from the crucible and coating since it is an edge block. Even though, the measured lifetime is higher for the ES material. This may due to presence of other elements causing internal gettering. These inclusions are currently being investigated. By comparing NAA and FeB-pair splitting measurements only 0.1 % of the present Fe atoms are solved as free interstitial atoms. Almost all the Fe impurities present are passivated, bonded around defects or in defect clusters or are present in form of silicide particles. 5 Table 5 Impurity concentration given in atoms/cm measured by using NAA. ESB ESC EST RefB RefC RefT Fe 4.8e14 5.3e14 5.2e14 4.2e14 1.9e14 1.8e14 Cu 4.3e15 4.1e15 4.1e15 4.4e15 2.6e15 3.0e15 Cr 3.8e13 4.9e13 3.7e13 6.6e13 2.5e13 2.9e13 Co 1.2e13 7.3e12 1.8e13 5.5e12 4.1e12 4.6e12 Sb 5.2e12 2.8e12 1.5e12 1.4e12 2.2e12 2.2e12 Zn 5.1e13 4.5e13 6.1e13 4.3e13 2.6e13 3.3e13 As 4e13 5.2e13 7.2e13 1.7e13 2.3e13 4.3e13 Na 3.8e13 4.3e13 6.5e13 4.5e13 5.9e13 3.5e13 4 REFERENCES 3 [1] C. Zahedi. et. al., "Solar grade silicon from metallurgical route " PVSEC-14, Bangkok, (2004) 26-30 [2] A. Bentzen, A. Ulyashin. A. Suphellen, E. Sauar, D. Grambole, D.N. Wright, E.S. Marstein, B.G. Svensson, and A. Holt, "Surface passivation of silicon solar cells by amorphous silicon/silicon nitride dual layers", Technical Digest of the 15th International Photovoltaic Science and Engineering Conference, (2005) 31 [3] A.G. Ulyashin, A. Bentzen, S. Diplas, A.E. Gunnaes, A. Olsen, B.G. Svensson, A. Suphellen, E.S. Marstein, A. Holt, D. Grambole, E. Sauar, " Hydrogen release and defect formation during heat treatments of SiNx:H/a-Si:H double passivation layer on c-Si substrate" Proc. WCPEC-4 , IEEE, (2006)1354-1357 CONCLUSIONS The results of the minority carrier lifetime measurements show higher minority carrier lifetime of ES-wafers compared with results from wafers based on poly silicon material. Furthermore a P-gettering processes has successfully been introduced, showing on average a further improvement by a factor larger than two times, shown in Figure 11. [4] A. Bentzen, E. S. Marstein, R. Kopecek, and A. Holt, "Phosphorus diffusion and gettering in multicrystalline silicon solar cell processing " Proceedings of the 19th European Photovoltaic Solar Energy Conference, Paris, France, (2004) 935 [5] J. Tan, D. Macdonald, N. Bennett, D. Kong, and A. Cuevas, " Dissolution of metal precipitates in multicrystalline silicon during annealing and the protective effect of phosphorus emitters" Applied Physics Letter P91 (2007) 043505 [6] A. Bentzen, A. Holt, R. Kopecek, G. Stokkan, J. S. Christensen, and B. G. Svensson, "Gettering of transition metal impurities during phosphorus emitter diffusion in multicrystalline silicon solar cell processing" , Journal of Applied Physics, 99:093509, 2006 [7] P. Manshanden and L. Geerligs, "Improved phosphorous gettering of multicrystalline silicon", Sol. Energy Mater. Sol. Cells 90 (2006) 998 [8] A.A. Istratov, T. Buonassisi , M.D. Pickett , M. Heuer, E.R. Weber, "Control of metal impurities in “dirty” multicrystalline silicon for solar cells", Materials Science and Engineering B 134 (2006) 282–286 Figure 11: Bulk lifetime of minority carriers before and after gettering at different positions of both the ES and reference edge block. 1159