Nails - TIMBERtech

advertisement

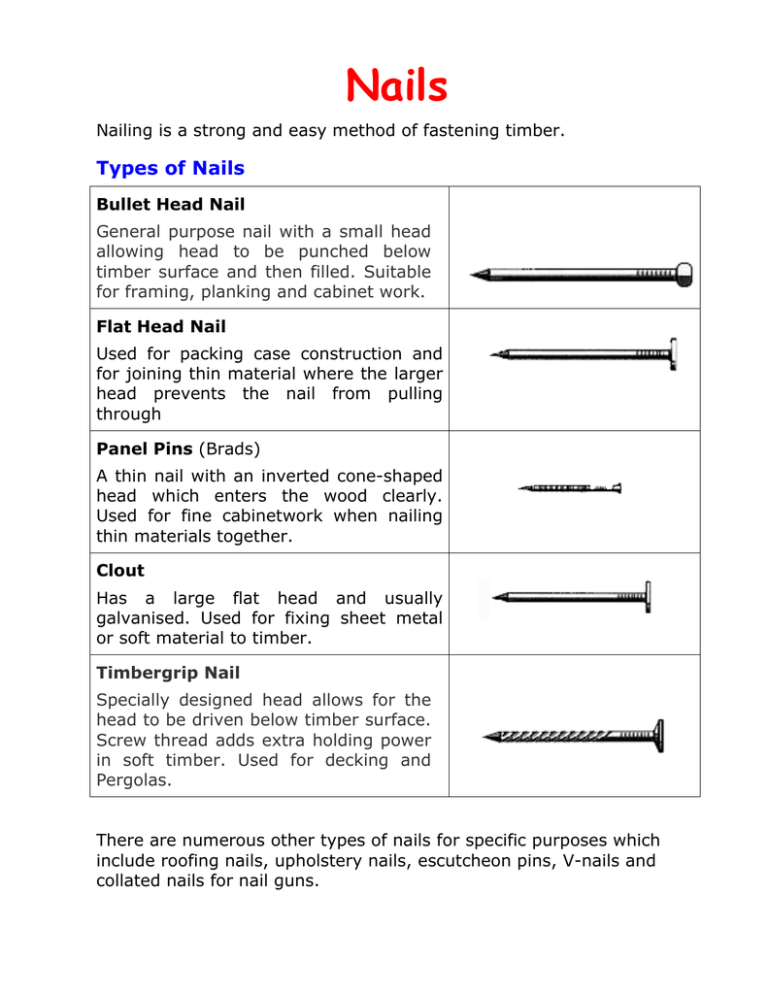

Nails Nailing is a strong and easy method of fastening timber. Types of Nails Bullet Head Nail General purpose nail with a small head allowing head to be punched below timber surface and then filled. Suitable for framing, planking and cabinet work. Flat Head Nail Used for packing case construction and for joining thin material where the larger head prevents the nail from pulling through Panel Pins (Brads) A thin nail with an inverted cone-shaped head which enters the wood clearly. Used for fine cabinetwork when nailing thin materials together. Clout Has a large flat head and usually galvanised. Used for fixing sheet metal or soft material to timber. Timbergrip Nail Specially designed head allows for the head to be driven below timber surface. Screw thread adds extra holding power in soft timber. Used for decking and Pergolas. There are numerous other types of nails for specific purposes which include roofing nails, upholstery nails, escutcheon pins, V-nails and collated nails for nail guns. Ordering Nails When ordering nails the following information should be stated: • Type:- refers to the shape of the head or use • Length:- may range from 12mm – 150mm • Diameter:- refers to the diameter of the shank • Metal:- steel (bright), brass etc • Coating:- (if applicable) galvanised, zinc plated, florentine • Quantity:- in kilograms – new blister packs sold by number For more information http://www.otter.com.au/nails_hints.php Nailing Length of Nail When choosing the nail length take into consideration the type of timber being used (softwood or hardwood). In most applications the plain shank nail should be 2-3 times longer than the timber being held, always nailing the lighter timber to the heavier. A longer nail should be selected if nailing into end grain. Driving Nails Nails should be driven with the hammer until the head projects about 3mm above the surface and then driven just below with a nail punch, so that work may be planed and the hole stopped up with putty or filler Quite often nails bend while driving because the hammer glances off the head of the nail. This may be prevented by removing all traces of glue, oil or dirt from the face of the hammer by rubbing it on a piece of fine abrasive paper. Dovetail Nailing Dovetail nailing grips both pieces of wood better than hammering the nails straight into the work. as the diagram shows, the nails are angled towards each other and this makes it a little more difficult for the two pieces of wood to be pulled apart. A punch can then be used to tap the heads of the nail slightly below the surface of the wood. This is a typical use of nail in a school workshop. Often panel pins are used in this way. Skew Nailing Skew nailing is used where the timber thickness or position prevents normal nailing methods from being used. It is recommended to use a punch for the last portion of nailing to avoid damage to the timber. Removing Nails Use nail pincers or a claw hammer Scrap should be used under the pincers or claw hammer to prevent bruising and to aid leverage. Prevention of Splitting When nailing near edges or ends, splitting be prevented by drilling a hole of shank diameter. Another trick is to blunt the end of the nail with the hammer before driving. When to pre-drill: When nailing into dense hardwood (e.g. Red Gum) pre-drilling will be required in order to avoid nails bending. Use a drill approximately 2/3 the diameter of the nail, this allows for all nails to be driven in plumb, maintains holding power and minimizes the risk of bending nails which may cause unsightly marks on the timber. Collated Nails Various types of collated nails are used in a range of portable air nailers. The picture shows a typical nailer whose magazine is loaded with a strip of collated nails. The slant magazine on this model allows ease of nailing in corners. The nails for different types of nailers may be collated and held together with plastic strips, paper strips or wire ties. Some nailers are designed with magazines that hold coils of collated nails. Coils are usually either plastic collated or wire collated. Nail sizes for the model shown range from 38mm to 65mm. Other coil nailers can be loaded with nails up to 83 mm in length.