Installation Instructions

advertisement

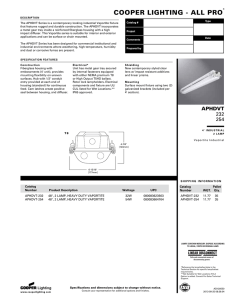

PHOENIX 7 INSTALLATION INSTRUCTIONS AND REPAIR PARTS LIST FOR HIGH PRESSURE SODIUM INTEGRAL BALLAST FLOODLIGHTS 120 VOLTS, 50-150 WATTS Models MSD 50HPS-120, MSD 70HPS-120, MSD 100HPS-120, MSD 150HPS-120 LAMPING MOUNTING Before lamping or re-lamping, make sure that power is turned off to the fixture. Vertical or horizontal mounting kits must be ordered with fixture. Insert one 1/2 inch (12mm) stainless steel bolt through the mounting hole provided in the mounting bracket and secure with appropriate lock washer and nut on the other side of the mounting fixture. When mounting on a maximum 1-3/4" OD pole or mast, a 1/4 inch (6mm) stainless steel Ubolt may be inserted in the holes provided in the bracket and To gain access to the lamp compartment, loosen 10 captive screws (Item 12) in the removable cover (Item 23). (Cover nearest 1/2 in. NPSI hole). DO NOT REMOVE BARRIER (Item 27). DO NOT REMOVE THE FIXED COVER (Item 22) WHICH HAS THE LAMP SOCKET ATTACHED TO IT. Screw lamp into socket. Reinstall removable cover (Item 23) and tighten 10 screws (Item 12) to 15 in-lbs. The fixture can be mounted and electric power connected. CAUTION 1. Operate fixture ONLY with PROPER lamp. The internal ballast in each fixture is designed to accommodate a specific wattage lamp. See LAMP RECOMMENDATIONS. 2. If the lamp fails, replace lamp or disconnect primary power to fixture within two weeks at the most. Otherwise, permanent damage to electrical components may result from high voltage pulses unique to High Pressure Sodium circuits. 3. Use protective gloves and safety eyeglasses when replacing lamps. the fixture secured with appropriate lock washers and nuts. NOTE: Mounting hardware isn't provided with fixture. If outer glass bulb is broken, turn off lamp and replace it promptly to avoid exposure to ultraviolet energy. Even with lamp outer glass enclosure broken, the arc tube may continue to fire. LAMP RECOMMENDATIONS Fixture Model No. Wattage Phoenix Part No. MSD-120-50HPS 50 4211300 MSD-120-70HPS 70 4212600 MSD-120-100HPS 100 4212700 MSD-120-150HPS 150 4212800 HORIZONTAL MOUNTING-USE KIT NO. 1090170 VERTICAL MOUNTING-USE KIT NO. 1090160 N5488100F-1 REPAIR PARTS LIST ITEM QTY. 1 2 End Cover Gasket 5005600 2 1 Socket Insulator 4052600 3 1 Black EPDM Grommet 5005500 4 3 Spacer 7523400 5 1 Reflector 2693901 6 1 Bracket For Capacitor & Ignitor 2310600 7 1 Mounting Bracket Vertical Mounting Mounting Bracket Horizontal Mounting 1090160 1090170 8 1 Cable Assembly 7508500 9 2 Threaded Rod 2694601 10 4 S.S. Hex Head Close-Acorn Nut, 6-32 6220200 11 2 S.S. Slotted Pan Head Machine Screw 6-32 x .25 6007700 12 20 S.S. Thread Forming Type B, Captive Screw, #8 x 1 6022300 15 1 S.S. Green Nut, hex 10-32 6203900 16 3 Threaded Rod 2694602 17 3 S.S. Hex Nut, 6-32 6201700 18 3 S.S. Split Lockwasher, #6 6312900 19 3 Cable Tie 4052200 20 1 Capacitor-Includes (3) Cable Ties, Item 19 50 Watt - (MSD 120 - 50 HPS) 70 Watt - (MSD 120 - 70 HPS) 100 Watt - (MSD 120 - 100 HPS) 150 Watt - (MSD 120 - 150 HPS) 1076100 1076200 1076300 1076400 21 1 Lamp Socket 4503700 22 1 Fixed Cover Kit (Lamp Socket Side) Including: Reflector, Gasket, and Label (Preassembled), (10) #8 x 1" Lg. Screws 1074900 23 1 Removable Cover Kit Including: Reflector and Gasket (Preassembled), (10) #8 x 1" Lg. Screws 1075000 24 1 Glass Kit With (2) Gaskets 1075100 25 2 Reflector - Includes (1) Gasket, Item 1 2693901 26 1 Ballast & Ignitor - Includes (3) Cable Ties, Item 19 50 Watt - (MSD 120 - 50 HPS) 70 Watt - (MSD 120 - 70 HPS) 100 Watt - (MSD 120 - 100 HPS) 150 Watt - (MSD 120 - 150 HPS) 1076800 1076900 1077000 1077100 27 1 Barrier 2701700 28 1 Screw, Thread Forming Type B #8 x 3/8 6021000 29 1 Nut U-Type #8 6241500 30 1 Washer, Flat 6302700 31 1 Washer, Terminal 6321100 32 1 Washer, Lock, External Toothed #10 6310400 N5488100F-2 DESCRIPTION PART NUMBER REPAIR PARTS ILLUSTRATION N5488100F-3 MS-120V 50-150W HPS Series Installation Instructions CAUTION All wiring should be done by licensed electricians in accordance with state and local codes plus National Electric Code (NEC) standards. Improper installation may result in serious injury. CAUTION Before cleaning, make sure the fixture is turned off. CLEANING WIRING When re-lamping, it is recommended that the glass on the fixture be cleaned to maintain fixture efficiency. This glass may be cleaned with any non-abrasive conventional glass cleaner. Before making any electrical connections, make sure that power is turned off to the incoming wires. The reflector should also be cleaned at this time. Use a soft cloth with warm, soapy water. Loosen ten screws (Item 21) in the removable cover (Item 23). (Cover nearest the 1/2 inch NPSI hole). Remove barrier (Item 27) for access to wiring compartment. AIMING - HORIZONTAL MOUNTING The wiring compartment now revealed contains a common wire and a 120 volt lead wire. They are labeled as such. Connect the appropriate incoming wires to these wires. Electrical fittings and conductors appropriate for the application and in compliance with accepted codes must be used. The green screw inside the compartment is grounded to the fixture and must be connected to a positive ground. DON'T CONNECT GREEN (GROUND) WIRE TO POWER SOURCE. When wiring is completed, reinstall the barrier, (Item 27). Reinstall the removable cover (Item 23). PHOENIX PRODUCTS COMPANY, INC. 8711 West Port Avenue ! Milwaukee, WI 53224 U.S.A. Phone: 414.973.3300 ! FAX: 414.973.3210 www.phoenixproducts.com N5488100F-4 Vertical aiming is achieved by loosening the two bolts which fasten the two mounting harps together. Re-tighten the bolts when the fixture is in the desired position. AIMING- VERTICAL MOUNTING Vertical aiming is accomplished by loosening the two bolts which fasten the mounting bracket to the fixture. Vertical travel is about 30 up and 100 down. Re-tighten the bolts when the fixture is in the desired position. The angle of the fixture can also be adjusted by loosening the mounting bolts in the mounting bracket, rotating the fixture to the desired angle and then re-tightening the bolts.