GEM Plus - GE Industrial Solutions

REGIONAL OFFICES

NORTH

New Delhi

GE India Industrial Pvt. Ltd.

71/1, Shivaji Marg

New Delhi-110015

Ph: (011) 45052277/8

Fax: (011) 25928088

SOUTH

Bangalore

GE India Industrial Pvt. Ltd.

The Millenia, Level-6, Tower B

1 & 2, Murphy Road, Ulsoor

Bangalore-560008

Ph: (080) 41434000

Fax: (080) 41434199

WEST

Mumbai

GE India Industrial Pvt. Ltd.

361/362, Solitaire Corporate Park

M. Vasanji Road, Chakala

Andheri (E), Mumbai-400093

Ph: (022) 40101610

Fax: (022) 40101611

EAST

Kolkata

GE India Industrial Pvt. Ltd.

Horizon Building, 4th Floor

57, Chowringhee Road

Kolkata-700071

Ph: (033) 40034056

Fax: (033) 40034071

BRANCH OFFICES

Chandigarh

GE India Industrial Pvt. Ltd.

SCO No. 72 & 73, First Floor

Sector 8/C, Madhya Marg

Chandigarh-160008

Ph: (0172) 3982908-10

Fax: (0172) 3982905

Jaipur

GE India Industrial Pvt. Ltd.

448, 4th Floor, Ganapati Plaza

M.I. Road, Jaipur-302001

Ph: (0141) 5112802

Fax: (0141) 2389012

Lucknow

GE India Industrial Pvt. Ltd.

101, Ace Business Center

19, Vidhan Sabha Marg

Lucknow-226001

Ph: (0522) 3203808, 3012444/666

Fax: (0522) 4045909

Chennai

GE India Industrial Pvt. Ltd.

Temple Tower, 6th Floor

476, (New No. 672) Anna Salai

Nandanam

Chennai-600035

Ph: (044) 45070470-84

Fax: (044) 45070474

Coimbatore

GE India Industrial Pvt. Ltd.

No.36/6 & 7, 1st Floor

Ashirwad Building

D.B.Road, R.S. Puram

Coimbatore-641002

Ph: (0422) 4393520 / 4393529

Cochin

GE India Industrial Pvt. Ltd.

Mayur Business Center & Motel

Chittur Road, Pullepadi Junction

Cochin-682035

Ph: (0484) 2364139

Fax: (0484) 4031400

Hyderabad

GE India Industrial Pvt. Ltd.

5-2-45, Hyderbasti, RP Road

Near Gujarati High School

Secunderabad-500003

Ph: (040) 27543162, 66311264

Fax: (040) 66339272

Ahmedabad

GE India Industrial Pvt. Ltd.

405-406, Kirtiman Complex

Kinariwala House, Behind Citibank

Off C.G. Road, Ahmedabad-380006

Ph: (079) 65427385/55427389

Fax: (079) 26460637

Pune

GE Money Financial Services Limited

Shop No. 405-410, 4th Floor

City Point, Dhole Patil Road

Pune-411001

Mob: +91 9850867507

Works:

GE India Industrial Pvt. Ltd.

Plot No. 42/1 & 45/14

Electronic City - Phase II

Bangalore-560100

Ph: (080) 41113000

Fax: (080) 28528469/552

We are committed to continuous development and improvement of our products and the specifications are subject to change without notice. For product availability and latest prices, please contact GE Sales Team.

For any further information, visit us at http://www.geindustrial.com

g and General Electric are registered trade marks of General Electric Co. USA ©

HO:

GE India Industrial Pvt. Ltd.

The Millenia, Level-6, Tower B

1 & 2, Murphy Road, Ulsoor

Bangalore-560008

Ph: (080) 41434000

Fax: (080) 41434199

Email: query@ge.com

Toll Free No:

18001024343

Customer Care: gecustomer.care@ge.com

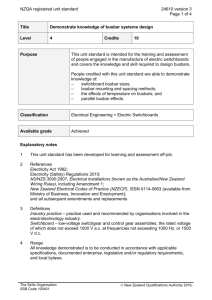

GEM Plus

Custom-Built Low Voltage

Switchboard System

MCC’S - PCC’S

Draw-out & fixed.

GEM Plus

Custom-Built Low Voltage Switchboard System

When we designed the new modular GEM Plus system, our customers were involved right from the beginning. Based on customer needs assessed from the derived target market segment, the new

GEM Plus provides significantly increased flexibility, reliability, security, expandability, aesthetics, and value for money.

GEM Plus type tested factory built assemblies are designed and manufactured in accordance with the highest quality of the national/international standard applicable to low voltage equipment.

The comprehensive range of GEM Plus system applications varies from withdrawable and fixed power control centers with air circuit breakers, motor control centers in fully draw-out, semi drawout and fixed version for motor starter application, distribution panels in draw-out and fixed version.

The equipment can be executed with a three or four phase busbar with maximum safety level for the operator.

GE, the General Electric is a world-renowned innovator and supplier of systems and components for low voltage switchgear, power distribution & industrial automation.

GE draws on this wealth of background Knowledge in designing and manufacturing of low voltage switchgear for its global and local customers.

GE Energy - Industrial Solutions, comprehensive portfolio of LV & MV Business solutions includes:

Salient Features of GEM Plus:

• Using a relatively few standard components it is possible to construct a custom build switchboard

• The versatility of the modular system makes it easy & quick assembly, extension and site modifications

• Standardized drawout modules are fully interchangeable

• Self locking of drawout modules after insertion

• Plugin terminals for semi drawout and sliding terminals for fully drawout control contacts

• Non-hygroscopic fire retardant barriers and DMC/SMC moulded insulators for increased safety

• Vertical busbars designed for 4 pole plug in system to provide drawout neutral isolation

• Interleaving busbar system is adopted for higher rated switchboards

• Spacious horizontal busbar chamber for better heat dissipation MCC’S - PCC’S

Draw-out & fixed.

Components Equipments Motors

GEM Plus

Custom-Built Low Voltage Switchboard System

When we designed the new modular GEM Plus system, our customers were involved right from the beginning. Based on customer needs assessed from the derived target market segment, the new

GEM Plus provides significantly increased flexibility, reliability, security, expandability, aesthetics, and value for money.

GEM Plus type tested factory built assemblies are designed and manufactured in accordance with the highest quality of the national/international standard applicable to low voltage equipment.

The comprehensive range of GEM Plus system applications varies from withdrawable and fixed power control centers with air circuit breakers, motor control centers in fully draw-out, semi drawout and fixed version for motor starter application, distribution panels in draw-out and fixed version.

The equipment can be executed with a three or four phase busbar with maximum safety level for the operator.

GE, the General Electric is a world-renowned innovator and supplier of systems and components for low voltage switchgear, power distribution & industrial automation.

GE draws on this wealth of background Knowledge in designing and manufacturing of low voltage switchgear for its global and local customers.

GE Energy - Industrial Solutions, comprehensive portfolio of LV & MV Business solutions includes:

Salient Features of GEM Plus:

• Using a relatively few standard components it is possible to construct a custom build switchboard

• The versatility of the modular system makes it easy & quick assembly, extension and site modifications

• Standardized drawout modules are fully interchangeable

• Self locking of drawout modules after insertion

• Plugin terminals for semi drawout and sliding terminals for fully drawout control contacts

• Non-hygroscopic fire retardant barriers and DMC/SMC moulded insulators for increased safety

• Vertical busbars designed for 4 pole plug in system to provide drawout neutral isolation

• Interleaving busbar system is adopted for higher rated switchboards

• Spacious horizontal busbar chamber for better heat dissipation MCC’S - PCC’S

Draw-out & fixed.

Components Equipments Motors

Applications

Buildings, Machinery And Processes

Commercial

• Small and large offices

• Warehouses

• Shopping malls

• Schools

• Hospitals

• Airports

• Railway stations

Utilities

• Power Plants [Thermal, Hydro & Nuclear]

• Oil & Gas on and off shore

• Petrochemical

• Water treatment plants

• Waste management

• Telecommunications

Industrial

• Printing

• Paper

• Machinery

• Pharmaceutical

• Automotive & pulp

• Chemical industry

• Marine

• Steel

• Cement

• Fertilizer

• Sugar

Electrical Data

Rated operating voltage

Rated frequency

Rated insulation voltage

Degree of pollution

Rated current [Aluminum Busbars]:

Rated current

Rated peak withstand current

Rated short-time withstand current

Rated current [Copper Busbars]:

Rated current

Rated peak withstand current

Rated short-time withstand current

Forms of separation - le lpk lcw

Ue

Ui le / Ith lpk lcw

415V AC

50 / 60 Hz

660V

3 up to 4000 A up to 132 kA up to 65 kA up to 6300 A up to 250 kA up to 100 kA form 3b optional, up to form 4

Mechanical Data

Degree of Protection According to IEC60529 - External from IP 30 to IP 54;

Internal from IP 2X

Steel Components Frame

Internal Partitions

Door & Covers

2mm Thick CRCA

1.5mm Thick CRCA

1.5mm Thick &

2mm Thick as optional

Plastic components

Surface Protection

Busbar

BB Supports

Shrouds

Other components

DMC/SMC/FRP

FRP / PVC

Nylon 6 / PC

Epoxy Powder Coated as per client’s requirement

Aluminium /Copper as per client’s requirement

Standards

Type tested switchgear assemblies (TTA) IS:8623; IEC:60439-1.

Applications

Buildings, Machinery And Processes

Commercial

• Small and large offices

• Warehouses

• Shopping malls

• Schools

• Hospitals

• Airports

• Railway stations

Utilities

• Power Plants [Thermal, Hydro & Nuclear]

• Oil & Gas on and off shore

• Petrochemical

• Water treatment plants

• Waste management

• Telecommunications

Industrial

• Printing

• Paper

• Machinery

• Pharmaceutical

• Automotive & pulp

• Chemical industry

• Marine

• Steel

• Cement

• Fertilizer

• Sugar

Electrical Data

Rated operating voltage

Rated frequency

Rated insulation voltage

Degree of pollution

Rated current [Aluminum Busbars]:

Rated current

Rated peak withstand current

Rated short-time withstand current

Rated current [Copper Busbars]:

Rated current

Rated peak withstand current

Rated short-time withstand current

Forms of separation - le lpk lcw

Ue

Ui le / Ith lpk lcw

415V AC

50 / 60 Hz

660V

3 up to 4000 A up to 132 kA up to 65 kA up to 6300 A up to 250 kA up to 100 kA form 3b optional, up to form 4

Mechanical Data

Degree of Protection According to IEC60529 - External from IP 30 to IP 54;

Internal from IP 2X

Steel Components Frame

Internal Partitions

Door & Covers

2mm Thick CRCA

1.5mm Thick CRCA

1.5mm Thick &

2mm Thick as optional

Plastic components

Surface Protection

Busbar

BB Supports

Shrouds

Other components

DMC/SMC/FRP

FRP / PVC

Nylon 6 / PC

Epoxy Powder Coated as per client’s requirement

Aluminium /Copper as per client’s requirement

Standards

Type tested switchgear assemblies (TTA) IS:8623; IEC:60439-1.

Certifications

Operational Safety, Quality and Availability

The fulfillment of all instructions of IS: 8623 / IEC:60439-1 assures a basic level for personnel and system protection. With GEM Plus, GE exceeds these levels as a standard. The GEM Plus low voltage switchboard system has been subjected to extensive type tests in compliance with the standards.

In order to ensure the highest possible degree of safety,

GE continues to conduct tests as a continuous development program.

The results of these tests are applicable to the various low voltage switchgear and control gear assemblies

(TTA) in accordance with IS: 8623 / IEC:60439-1

Our continuous improvement in quality and productivity is driven through lean six sigma ways.

Our manufacturing unit is one of the certified EHS

Global Star facility.

Motor Control Centers

GEM Plus MCC’s are used to control electric motors and other equipments from a central location, or power is to be distributed to equipments safely and reliably. The MCC’s are available in Single Front and Double Front or

Back-to-Back.

GEM Plus MCC’s are sheet steel modular construction and each vertical section is segregated with metallic barriers and are supplied in fully drawout, semi drawout and fixed version. Each panels are extendable both side and can be coupled to breaker panels having higher depth either side. Double bended doors and covers ensure the torsion free and self adhesive gaskets make the panels dust and vermin proof.

Nomenclature of MCC’s [Single & Double Front]

BUSBAR CHAMBER

FEEDER UNITS G1

FEEDER UNITS G1

FEEDER UNITS G4

FEEDER UNITS G5

FEEDER UNITS G6

540

810

FRONT VIEW

270

KICK PLATE

510

SIDE VIEW [S/F]

510 510

1020

SIDE VIEW [D/F]

Certifications

Operational Safety, Quality and Availability

The fulfillment of all instructions of IS: 8623 / IEC:60439-1 assures a basic level for personnel and system protection. With GEM Plus, GE exceeds these levels as a standard. The GEM Plus low voltage switchboard system has been subjected to extensive type tests in compliance with the standards.

In order to ensure the highest possible degree of safety,

GE continues to conduct tests as a continuous development program.

The results of these tests are applicable to the various low voltage switchgear and control gear assemblies

(TTA) in accordance with IS: 8623 / IEC:60439-1

Our continuous improvement in quality and productivity is driven through lean six sigma ways.

Our manufacturing unit is one of the certified EHS

Global Star facility.

Motor Control Centers

GEM Plus MCC’s are used to control electric motors and other equipments from a central location, or power is to be distributed to equipments safely and reliably. The MCC’s are available in Single Front and Double Front or

Back-to-Back.

GEM Plus MCC’s are sheet steel modular construction and each vertical section is segregated with metallic barriers and are supplied in fully drawout, semi drawout and fixed version. Each panels are extendable both side and can be coupled to breaker panels having higher depth either side. Double bended doors and covers ensure the torsion free and self adhesive gaskets make the panels dust and vermin proof.

Nomenclature of MCC’s [Single & Double Front]

BUSBAR CHAMBER

FEEDER UNITS G1

FEEDER UNITS G1

FEEDER UNITS G4

FEEDER UNITS G5

FEEDER UNITS G6

540

810

FRONT VIEW

270

KICK PLATE

510

SIDE VIEW [S/F]

510 510

1020

SIDE VIEW [D/F]

Compartment and trays

Overall Dimensions of GEM Plus MCC’s

Busbar Rating

Up to 1250A

1600A

2000~4000A

Height mm

2460/2220

2460/2220

2460/2220

Width mm

SF / DF

810

810

810

Depth mm

S/F D/F

510

690

1020

1020

690

1020

1020

1200

1020 1020

1200 1350

Cable Entry

Bottom

Top

Bottom

Top

Bottom

Top

Outgoing with-drawable units

Drawout units are provided with spring loaded incoming power contact connecting the unit to vertical busbars and outgoing contact for the cables. Each drawout unit comprises the following locking devices:

• An automatic door interlock, which prevents the door being opened when the switch is in the ON position.

• A latch, to prevent the unit from being dropped accidentally if removed too quickly.

• Plug-in / sliding contact block features available to enable remote control and signaling.

• A test position is also available whenever required to facilitate testing of control circuits with functional interlock without energizing the power unit.

The trays are provided with guides and low friction sliding devices which can smoothly insert and withdraw along with the guide rails.

Outgoing non-drawable units

In this design feeder components are fitted directly into the cubicle and both power and control terminals are in fixed version.

270

810

540

CONTROL CONTACT

PLUG-IN

VERTICAL BUSBAR

INCOMING POWER TRMNL

RACKING SPINDLE

540

810

270

SECTIONAL VIEW S/F

EXTENSION BUSBAR

FOR CABLE TERMINATION

OUTGOING POWER

TERMINALS

CONTROL CONTACT

SLIDING

OUTGOING POWER TRMNL

VERTICAL BUSBAR

INCOMING POWER TRMNL

RACKING SPINDLE

540

810

270

SECTIONAL VIEW D/F

EXTENSION BUSBAR

FOR CABLE TERMINATION

OUTGOING POWER

TERMINALS

CONTROL CONTACT

SLIDING

The withdrawable compartments are of standard sizes G1, G2, G3, G4, G5 and G6 being multiple of G1 which is 120mm high. One panel front can accommodate maximum of 17 such basic units of G1 size, the trays in case of fixed module G1 to G17 can be selected based on the feeder type. Every compartment is provided with a hinged door and a FRP/PVC barrier in between the vertical busbar and tray.

Main Busbar system

The main / horizontal busbars are located in a separate compartment at the top of the switchboard. The spacious horizontal busbar compartment has a degree of protection of IP 54 for upto 1600A and IP 42 for above rating. The phase bars and neutral bar are available for current ratings from 500 up to 4000A with

Al and 6300A with Cu. They are secured by SMC/DMC busbar supports and can be easily extendable on both sides. Unique arrangement of interleaving system is adopted for higher rated panels to not only achieve better dynamic and thermal withstand capacity but also to reduce temperature rise.

Horizontal auxiliary supply system

Auxiliary supply system busbars are located in the HBB chamber separated from HBB, Up to 12 Nos. auxiliary bars with a current rating of 50A are available.

Vertical distribution busbar system

GEM Plus MCC with drawout/fixed outgoing units vertical busbars are branched from the main busbar system. The vertical busbars are located behind the equipment modules. Vertical busbars are available for current rating from 630A to 1440A. VBB are covered with FRP/PVC feeder shrouds having the opening only for the incoming terminals. Safety shutters are available optionally.

Earth busbar system

GEM Plus switchboards are supplied with a horizontal earth busbar 50x10mm Al or 50x6mm Cu and a vertical earth busbar 20x5mm runs along with the height of the cable alley in drawout panels and is connected to the main horizontal earth busbar. Each drawout modules are fitted with a spring loaded scraping earth which make first and break last for safety to operating personnel.

Cable-entry compartment

A separate, lockable cable-alley compartment, along with the entire height of the feeder compartment, is provided at the righthand side for power and control cable termination. On the side wall, cable ladders are available for cable clamps. The cable-alley compartment is isolated from the feeder compartments.

The standard cable-alley compartment width is 270 mm. The compartment is provided with an undrilled, removable gland plate at the bottom of the cubicle.

Compartment and trays

Overall Dimensions of GEM Plus MCC’s

Busbar Rating

Up to 1250A

1600A

2000~4000A

Height mm

2460/2220

2460/2220

2460/2220

Width mm

SF / DF

810

810

810

Depth mm

S/F D/F

510

690

1020

1020

690

1020

1020

1200

1020 1020

1200 1350

Cable Entry

Bottom

Top

Bottom

Top

Bottom

Top

Outgoing with-drawable units

Drawout units are provided with spring loaded incoming power contact connecting the unit to vertical busbars and outgoing contact for the cables. Each drawout unit comprises the following locking devices:

• An automatic door interlock, which prevents the door being opened when the switch is in the ON position.

• A latch, to prevent the unit from being dropped accidentally if removed too quickly.

• Plug-in / sliding contact block features available to enable remote control and signaling.

• A test position is also available whenever required to facilitate testing of control circuits with functional interlock without energizing the power unit.

The trays are provided with guides and low friction sliding devices which can smoothly insert and withdraw along with the guide rails.

Outgoing non-drawable units

In this design feeder components are fitted directly into the cubicle and both power and control terminals are in fixed version.

270

810

540

CONTROL CONTACT

PLUG-IN

VERTICAL BUSBAR

INCOMING POWER TRMNL

RACKING SPINDLE

540

810

270

SECTIONAL VIEW S/F

EXTENSION BUSBAR

FOR CABLE TERMINATION

OUTGOING POWER

TERMINALS

CONTROL CONTACT

SLIDING

OUTGOING POWER TRMNL

VERTICAL BUSBAR

INCOMING POWER TRMNL

RACKING SPINDLE

540

810

270

SECTIONAL VIEW D/F

EXTENSION BUSBAR

FOR CABLE TERMINATION

OUTGOING POWER

TERMINALS

CONTROL CONTACT

SLIDING

The withdrawable compartments are of standard sizes G1, G2, G3, G4, G5 and G6 being multiple of G1 which is 120mm high. One panel front can accommodate maximum of 17 such basic units of G1 size, the trays in case of fixed module G1 to G17 can be selected based on the feeder type. Every compartment is provided with a hinged door and a FRP/PVC barrier in between the vertical busbar and tray.

Main Busbar system

The main / horizontal busbars are located in a separate compartment at the top of the switchboard. The spacious horizontal busbar compartment has a degree of protection of IP 54 for upto 1600A and IP 42 for above rating. The phase bars and neutral bar are available for current ratings from 500 up to 4000A with

Al and 6300A with Cu. They are secured by SMC/DMC busbar supports and can be easily extendable on both sides. Unique arrangement of interleaving system is adopted for higher rated panels to not only achieve better dynamic and thermal withstand capacity but also to reduce temperature rise.

Horizontal auxiliary supply system

Auxiliary supply system busbars are located in the HBB chamber separated from HBB, Up to 12 Nos. auxiliary bars with a current rating of 50A are available.

Vertical distribution busbar system

GEM Plus MCC with drawout/fixed outgoing units vertical busbars are branched from the main busbar system. The vertical busbars are located behind the equipment modules. Vertical busbars are available for current rating from 630A to 1440A. VBB are covered with FRP/PVC feeder shrouds having the opening only for the incoming terminals. Safety shutters are available optionally.

Earth busbar system

GEM Plus switchboards are supplied with a horizontal earth busbar 50x10mm Al or 50x6mm Cu and a vertical earth busbar 20x5mm runs along with the height of the cable alley in drawout panels and is connected to the main horizontal earth busbar. Each drawout modules are fitted with a spring loaded scraping earth which make first and break last for safety to operating personnel.

Cable-entry compartment

A separate, lockable cable-alley compartment, along with the entire height of the feeder compartment, is provided at the righthand side for power and control cable termination. On the side wall, cable ladders are available for cable clamps. The cable-alley compartment is isolated from the feeder compartments.

The standard cable-alley compartment width is 270 mm. The compartment is provided with an undrilled, removable gland plate at the bottom of the cubicle.

Power Control Centers

GEM Plus PCC’s are used as main LT switchboards for distribution and control of power. The PCC panels are offered either in single tire or two tire configuration. PCC’s are suitable for coupling with single front and double front MCC’s to make the switchboard as PMCC.

GEM Plus PCC’s are sheet steel modular construction, each PCC’s are provided with segregated compartment for safety i.e. Metering chamber, Circuit breaker chamber and Relay chamber, each sections having its own doors.

Double bended doors and covers ensure the torsion free and self adhesive gaskets make the panels dust and vermin proof.

Spacious bottom cable space are provided and are also suitable for either cable or busduct entry from top/bottom. For single core cables, aluminium gland plates are provided to eliminate the magnetic effect.

Barriers are provided between the incoming and outgoing terminals of ACB for added safety.

BUSBAR CHAMBER

NOMENCLATURE OF PCC's [SINGLE TIRE]

METERING CHAMBER

BREAKER CHAMBER

RELAY CHAMBER

600 / 810 / 960

FRONT VIEW

330 /480/ 690

1350 / 1500 / 1710

SIDE VIEW [D/F]

1020

BREAKER CHAMBER

BUSBAR CHAMBER

NOMENCLATURE OF PCC's [TWO TIRE]

BREAKER CHAMBER

RELAY CHAMBER

870

FRONT VIEW

330 / 480

1350 / 1500

SIDE VIEW [D/F]

1020

Overall Dimensions of GEM Plus PCC’s

Busbar Rating

Up to 630A

800~1250A

1600A

2000~4000A

Two tire

Up to 1250A

Two tire

2000A

Height mm

2460

2460

2460

2460

2460

2460

Width mm

PCC

600

600

810

810

960

870

870

I/C & O/G

1020

1350

1350

1710

1500

1500

Depth mm

B/C

1350

1350

1350

1710

I/C Busduct

Entry

1350

1500

1500

1710

Power Control Centers

GEM Plus PCC’s are used as main LT switchboards for distribution and control of power. The PCC panels are offered either in single tire or two tire configuration. PCC’s are suitable for coupling with single front and double front MCC’s to make the switchboard as PMCC.

GEM Plus PCC’s are sheet steel modular construction, each PCC’s are provided with segregated compartment for safety i.e. Metering chamber, Circuit breaker chamber and Relay chamber, each sections having its own doors.

Double bended doors and covers ensure the torsion free and self adhesive gaskets make the panels dust and vermin proof.

Spacious bottom cable space are provided and are also suitable for either cable or busduct entry from top/bottom. For single core cables, aluminium gland plates are provided to eliminate the magnetic effect.

Barriers are provided between the incoming and outgoing terminals of ACB for added safety.

BUSBAR CHAMBER

NOMENCLATURE OF PCC's [SINGLE TIRE]

METERING CHAMBER

BREAKER CHAMBER

RELAY CHAMBER

600 / 810 / 960

FRONT VIEW

330 /480/ 690

1350 / 1500 / 1710

SIDE VIEW [D/F]

1020

BREAKER CHAMBER

BUSBAR CHAMBER

NOMENCLATURE OF PCC's [TWO TIRE]

BREAKER CHAMBER

RELAY CHAMBER

870

FRONT VIEW

330 / 480

1350 / 1500

SIDE VIEW [D/F]

1020

Overall Dimensions of GEM Plus PCC’s

Busbar Rating

Up to 630A

800~1250A

1600A

2000~4000A

Two tire

Up to 1250A

Two tire

2000A

Height mm

2460

2460

2460

2460

2460

2460

Width mm

PCC

600

600

810

810

960

870

870

I/C & O/G

1020

1350

1350

1710

1500

1500

Depth mm

B/C

1350

1350

1350

1710

I/C Busduct

Entry

1350

1500

1500

1710

REGIONAL OFFICES

NORTH

New Delhi

GE India Industrial Pvt. Ltd.

71/1, Shivaji Marg

New Delhi-110015

Ph: (011) 45052277/8

Fax: (011) 25928088

SOUTH

Bangalore

GE India Industrial Pvt. Ltd.

The Millenia, Level-6, Tower B

1 & 2, Murphy Road, Ulsoor

Bangalore-560008

Ph: (080) 41434000

Fax: (080) 41434199

WEST

Mumbai

GE India Industrial Pvt. Ltd.

361/362, Solitaire Corporate Park

M. Vasanji Road, Chakala

Andheri (E), Mumbai-400093

Ph: (022) 40101610

Fax: (022) 40101611

EAST

Kolkata

GE India Industrial Pvt. Ltd.

Horizon Building, 4th Floor

57, Chowringhee Road

Kolkata-700071

Ph: (033) 40034056

Fax: (033) 40034071

BRANCH OFFICES

Chandigarh

GE India Industrial Pvt. Ltd.

SCO No. 72 & 73, First Floor

Sector 8/C, Madhya Marg

Chandigarh-160008

Ph: (0172) 3982908-10

Fax: (0172) 3982905

Jaipur

GE India Industrial Pvt. Ltd.

448, 4th Floor, Ganapati Plaza

M.I. Road, Jaipur-302001

Ph: (0141) 5112802

Fax: (0141) 2389012

Lucknow

GE India Industrial Pvt. Ltd.

101, Ace Business Center

19, Vidhan Sabha Marg

Lucknow-226001

Ph: (0522) 3203808, 3012444/666

Fax: (0522) 4045909

Chennai

GE India Industrial Pvt. Ltd.

Temple Tower, 6th Floor

476, (New No. 672) Anna Salai

Nandanam

Chennai-600035

Ph: (044) 45070470-84

Fax: (044) 45070474

Coimbatore

GE India Industrial Pvt. Ltd.

No.36/6 & 7, 1st Floor

Ashirwad Building

D.B.Road, R.S. Puram

Coimbatore-641002

Ph: (0422) 4393520 / 4393529

Cochin

GE India Industrial Pvt. Ltd.

Mayur Business Center & Motel

Chittur Road, Pullepadi Junction

Cochin-682035

Ph: (0484) 2364139

Fax: (0484) 4031400

Hyderabad

GE India Industrial Pvt. Ltd.

5-2-45, Hyderbasti, RP Road

Near Gujarati High School

Secunderabad-500003

Ph: (040) 27543162, 66311264

Fax: (040) 66339272

Ahmedabad

GE India Industrial Pvt. Ltd.

405-406, Kirtiman Complex

Kinariwala House, Behind Citibank

Off C.G. Road, Ahmedabad-380006

Ph: (079) 65427385/55427389

Fax: (079) 26460637

Pune

GE Money Financial Services Limited

Shop No. 405-410, 4th Floor

City Point, Dhole Patil Road

Pune-411001

Mob: +91 9850867507

Works:

GE India Industrial Pvt. Ltd.

Plot No. 42/1 & 45/14

Electronic City - Phase II

Bangalore-560100

Ph: (080) 41113000

Fax: (080) 28528469/552

We are committed to continuous development and improvement of our products and the specifications are subject to change without notice. For product availability and latest prices, please contact GE Sales Team.

For any further information, visit us at http://www.geindustrial.com

g and General Electric are registered trade marks of General Electric Co. USA ©

HO:

GE India Industrial Pvt. Ltd.

The Millenia, Level-6, Tower B

1 & 2, Murphy Road, Ulsoor

Bangalore-560008

Ph: (080) 41434000

Fax: (080) 41434199

Email: query@ge.com

Toll Free No:

18001024343

Customer Care: gecustomer.care@ge.com