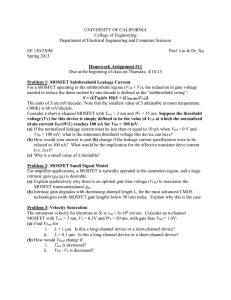

Characterization and Modeling of High-Switching

advertisement