PA CAZ Testing Protocol 1. Record outdoor ambient air temperature

advertisement

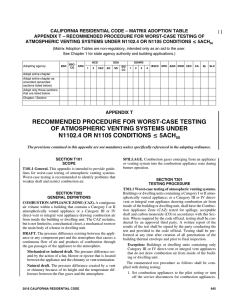

PA CAZ Testing Protocol 1. Record outdoor ambient air temperature. 2. Zero out gas leak detector and Carbon Monoxide Meter in outdoor ambient air. 3. Check all gas and fuel lines for leaks and make required repairs before performing CAZ test. Continue to monitor for the presence of combustible gasses during inspection. 4. Start with all exterior doors, windows and fireplace damper(s) closed. Set all combustion appliances to the pilot setting or turn off at the service disconnect, including: Boiler, Furnace, Space Heaters and Water Heater and any other device that can depressurize the structure. With the structure in this configuration, measure and record the base pressure of the combustion appliance zone WRT outside. 5. Establish the worst case CAZ by turning on the dryer, all exhaust fans and exhaust devices and any other device that can depressurize the structure. Close any interior doors that make the CAZ pressure more negative. Turn on the air handler fan, if present and leave on if the pressure in the CAZ becomes more negative, and then recheck the door positions. Measure the total change in pressure in the CAZ WRT the outside subtract the baseline pressure and record the net pressure difference CAZ WRT outside. Record this net pressure difference as “Worst Case Depressurization”. 6. Compare net pressure difference to chart (CAZ depressurization Limits). If CAZ does not meet depressurization limits, recommend outside air be brought into to CAZ. Determine what is depressurizing the CAZ (i.e. whole house fan). Recommend that the device not be used until depressurization problem is corrected. Version: Feb 2012 1 PA CAZ Testing Protocol 7. Before and during the Spillage, draft and Carbon Monoxide tests, monitor the ambient CO in the breathing zone. Abort the test if the ambient CO level exceeds 35ppm. Turn off the appliance, ventilate the space and evacuate the structure. The structure may be reentered once ambient CO levels have gone below 35ppm. The appliance must be repaired and the problem corrected prior to completing the combustion safety diagnostics. 8. While under worst case CAZ start the heating appliance, beginning with the smallest BTU rated appliance first and using a smoke bottle, test for Spillage at the draft diverter. The appliance should not spill more than 60 seconds. If spillage ends within 60 seconds measure draft. 9. Follow the Protocol for Draft Testing to check draft after the draft diverter for gas, and before the barometric draft damper on oil. • • • • • Protocol for Draft Testing Measure draft pressure in the flue WRT CAZ of all heating and hot water combustion appliances at Steady State operating conditions. (Steady-StateOnce flue gas temperature has stabilized) Gas Appliances: Atmospheric or Natural Draft (70%): Drill a 5/16th inch hole after the draft diverter in the center of the longest, straightest, accessible section of the vent connector. Measure the draft in the center of the vent connector. Record the draft measurement. When the test is complete, seal the hole with High Temperature RTV silicone caulk, cover with aluminum tape or metal plug. Induced Draft (80%) furnaces: Draft measurement shall be taken downstream of the inducer motor. The preferred location for CO testing is the same hole used for draft testing. Holes for Draft and CO testing shall be drilled using a 5/16 inch drill bit. When test is complete: Seal the hole with High Temperature RTV silicone caulk, cover with aluminum tape or threaded metal plug. Version: Feb 2012 2 PA CAZ Testing Protocol • If the vent is a double walled “B”-Type vent: Completely seal the inner liner with High Temperature RTV silicone caulk and a 5/16 inch threaded plug made of stainless steel or… Seal interior hole with RTV silicone and cover exterior hole with UL listed aluminum tape. • Sealed Combustion or Power Vented appliances or water heaters (90% +): No draft measurement required. Recommend Technician confirm draft at the vent termination. If it is unsafe to access vent termination due to the height of the roof or weather conditions. Access flue products by drilling a 5/16” hole in the flue gas exhaust pipe and plug by tapping and installing a threaded brass or stainless steel plug into hole. Oil Appliances: • Natural draft oil fired hot air, hot water, steam boilers and oil fired water heaters: Measure draft by drilling a 5/16” hole in the flue gas exhaust pipe a minimum of 18” from the breech of the heating appliance and before the barometric damper. No closer than 2 times the vent diameter from anything that will cause turbulence such as an elbow. When testing is complete: Seal hole with High Temperature RTV silicone caulk, cover the hole with aluminum tape or metal plug. Based on Draft Testing, compare results to “Minimum Worst-Case Draft” Chart based on outdoor temperature. 10. With the appliance at Steady State measure the CO level before combustion gasses are diluted. The CO level should not exceed 100ppm or the Manufacturers Specifications. If CO exceeds these levels a clean and tune is required. 11. Repeat steps 8, 9 and 10 for each Combustion appliance located in the Combustion Appliance Zone. 12. Perform steps 8, 9 and 10 with all appliances operating at the same time. 13. If the appliance passes: Spillage, Draft and CO under “Worst Case” Conditions skip step 14 and go to step 15. 14. If the appliance fails Spillage or Draft under “Worst Case” conditions turn off the appliance, exhaust fans and exhaust devices, open interior doors and allow the vent to cool before retesting. When the vent is cool to the touch: Measure the pressure in the CAZ WRT outside and compare to Baseline measurement taken in step 4 to ensure that the CAZ is restored to “Natural Conditions”. Retest Spillage, Draft and CO under “Natural Conditions”. Repeat for each appliance, allowing the vent to cool between each test. Test Again with all appliances operating. 15. Make recommendations or complete work order for repairs based on test results. Version: Feb 2012 3