Experimental Investigation of Draft Tube Flow of an Axial Turbine by

advertisement

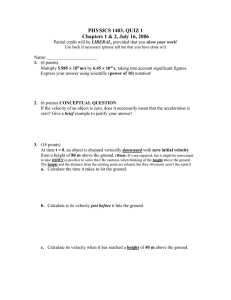

3rd IAHR International Meeting of the Workgroup on Cavitation and Dynamic Problems in Hydraulic Machinery and Systems, October 14-16, 2009, Brno, Czech Republic Experimental Investigation of Draft Tube Flow of an Axial Turbine by Laser Doppler Velocimetry Philippe GOUIN Laboratory of Hydraulic Machinery, Laval University, Quebec, Canada Claire DESCHENES Laboratory of Hydraulic Machinery, Laval University, Quebec, Canada Monica ILIESCU Laboratory of Hydraulic Machinery, Laval University, Quebec, Canada Gabriel Dan CIOCAN Laboratory of Hydraulic Machinery, Laval University, Quebec, Canada ABSTRACT This paper presents the current results of an experimental study of the draft tube flow in a propeller turbine by Laser Doppler Velocimetry. Aiming to assess the impact of radial velocity on flow behaviours, measurement campaigns were performed in the draft tube to acquire two velocity components at the outlet and three components at the inlet. A characteristic setup for measuring the three components of the velocity field is presented. Details regarding the positioning system and rotating optical access design are given and the uncertainty issues are discussed. Time averaged velocity profiles are presented for both inlet and outlet sections of the draft tube and correlations are established between them. KEYWORDS Axial hydraulic turbine, draft tube flow, LDV, radial velocity, velocity profiles 1. INTRODUCTION Draft tube flow is studied to a great extent in hydraulic turbines as this part plays a crucial role in the energy recovery of the machines. Incoming flow to the draft tube induces unstable operation and diminution of its energy recovery, which has a considerable effect on the efficiency of low head turbines. Many numerical studies are thus dealing with these complex flows while fewer studies aim to address the lack of good validation data, both facing interesting challenges. While the radial velocity is often put aside, 3rd IAHR International Meeting of the Workgroup on Cavitation and Dynamic Problems in Hydraulic Machinery and Systems, October 14-16, 2009, Brno, Czech Republic this paper intends to present briefly a method to acquire three velocity components at draft tube inlet and to focus on measurement results in terms of the impact of velocity distribution at the draft tube inlet on the outlet velocity profiles. Other experimental studies involving 3D-LDV measurements were performed notably by Ciocan et al. [4]. In the scope of this paper, the experimental study of draft tube flow involves measurements on an axial turbine model. The propeller turbine model is characterised by 24 stay vanes and 24 guide vanes, a runner with six fixed blades, an intake and an asymmetric draft tube both with a central pier. It is also defined by a specific speed of 0.424. The runner blades being fixed, the runner does not guarantee optimal flow downstream except for best efficiency point. Moreover, the asymmetry triggered in the semi-spiral casing is conveyed downstream in the draft tube whose optimisation gets laborious. The draft tube investigated is characterised by two channels decentred from runner axis which are subject to flow rate unbalance. 2. EXPERIMENTAL TOOLS Three measurement campaigns were performed to acquire the data. Laser Doppler Velocimetry, which measures the velocity of a fluid by detecting the frequency shift between a laser source and scattered light from tracer particles, was used for its non-intrusiveness and reliability [3]. The LDV system used in the study (Dantec Dynamics) allows simultaneous measurement of two velocity components. Silver coated hollow glass spheres of 10 µm were used as seeding particles throughout the study. Tab.1. shows the measured components and section for the three campaigns with some LDV parameters. Laser Wavelength Beams diameter Beams separation Focal length Meas. volume diam. Meas. volume length 5.8W Argon-Krypton 488 / 514.5 nm 1 mm ± 0.02 39 mm ± 0.02 400 or 1000 mm 189 or 238 µm 3.97 or 6.33 mm Campaign # - Section Measured components 1 - Inlet 2 - Outlet 3 - Inlet Cz, Cθ Cx, Cz Cz, Cr* LDV focal length (mm) 400 400 or 1000 400 Samples per spatial point 60000 10000 60000 Tab.1 LDV characteristics and measurement campaigns 3. MEASUREMENT SECTIONS For the outlet section, two series of measures were necessary to obtain the velocity field near the exit plane in the two channels. On each of them, measurements were made on a grid of 10 x 23 points covering 95% of the cross-section. The transversal velocity component was put aside as the model structure did not allow acquiring it without major modifications. Fig.1 illustrates the measurement plane, located at 0.02·RRef upstream the outlet, also pointing out the runner rotation direction and the global coordinate system. The reference radius (RRef) corresponds to the runner radius. In order to acquire velocities on these grids, the LDV probe is mounted on a traverse system with degrees of freedom in y and z directions. The laser propagates through an optical access whose quality is crucial; both the parallelism and finish of the window surfaces must meet optical quality standards and the alteration of the hydraulic profile minimized. For the inlet section, the first measurement campaign gathered information on axial and tangential velocities at the inlet section, on three diameters over three cross-sections of the conical diffuser, where asymmetric profiles were obtained [2]. This campaign used a traverse system in translation only, aligned with the runner axis. The radial velocity, more challenging to acquire, is subject to restrictive hypotheses in 3rd IAHR International Meeting of the Workgroup on Cavitation and Dynamic Problems in Hydraulic Machinery and Systems, October 14-16, 2009, Brno, Czech Republic many numerical studies although it was identified as a key component in draft tube simulations [1, 5]. It is also part of the circumferential non-uniformities and contributes to dynamic phenomena taking place downstream the runner. These issues motivated to push forward with the acquisition of this component in the third measurement campaign. Fig.1. Measurement sections and main turbine components Considering the available measurement area of the system that will be presented afterwards, the available data of the first campaign (see Tab.1 – right) and the interference of the system with the draft tube, the measures where made on four radiuses with 41 points each, on one cross section of the conical diffuser bellow the runner. The angles of the radiuses with the positive x axis are 33.5°, 213.5°, 273.5° and 337.5°. Fig.2 illustrates the position of the radiuses with respect to the reference coordinate system. This configuration of the conical diffuser and the access window was used for the radiuses 2 and 3. In order to acquire the radiuses 1 and 4, the conical diffuser was rotated of 120° counter-clockwise. Fig.2. Rotating access measurements radius position and LDV configuration 3rd IAHR International Meeting of the Workgroup on Cavitation and Dynamic Problems in Hydraulic Machinery and Systems, October 14-16, 2009, Brno, Czech Republic 4. METHODOLOGY As the LDV system measures two components perpendicular to the laser propagation direction, getting directly the radial velocity component on different radial locations means moving the LDV probe parallel to the measured radius. With the parallelism constraint on the optical access, this method would imply an unacceptable modification of the hydraulic profile in the conical section concerned. The method proposed in this paper is overcoming this problem by performing the measure through a fixed location rotating optical access. For each spatial position measured, the optical access window angle varies and so the angle of the absolute velocity components perceived. The probe is oriented so the axial component is measured as validation with the first campaign. The other component acquired (Cr*) corresponds to a projection of the r-θ velocity vector on planes proper to each position of the optical access. Successive measurement campaigns then provide two dependent partial velocity vectors that can be combined through planar rotation to compute Cr on each spatial position. The equations system includes Cr, Cθ in the reference coordinate system, Cr* in the optical access coordinate system and the angle β between the two systems. Fig.3 illustrates the coordinate system rotation in one point. One can observe that for the third campaign to be sufficient to get Cr from this coordinate rotation, Cr* has to be in the r-θ plane. Otherwise, a third partial velocity vector would be required to solve the equations system and no common velocity component (i.e. Cz) would be available to validate the results. Fig.3. Measured velocity components in the local reference frame of the translational (left) and rotational (right) configuration 5. MECHANICAL DESIGN One of the challenges of this method is to position the probe with respect to the optical access, and the optical access with respect to the reference coordinate system. For all spatial positions, the probe has to be kept perpendicular to the window surfaces at a distance fixed by the optical path of the LDV beams to the measurement point. The realisation of such an experimental setup is constraining and sensitive to many parameters. The design developed in this study will be presented briefly. In order to allow the rotation of the window on the measurement plane while preventing leaks, a spherical joint similar to a ball valve was conceived to be mounted on the acrylic conical diffuser of the model. A fixed frame insures sealing with the conical diffuser and squeezes the joint in place by means of two teflon rings. The frame is made of two threaded parts that allow adjusting the squeeze on the joint, which has to be sufficiently tight for sealing and loose enough to allow rotation. A shouldered cylindrical glass window is inserted in the spherical joint and pressed on an o-ring by a threaded tubular part. Fig.4 illustrates the rotating optical access assembly. 3rd IAHR International Meeting of the Workgroup on Cavitation and Dynamic Problems in Hydraulic Machinery and Systems, October 14-16, 2009, Brno, Czech Republic Dimensioning of this mechanism is subject to a compromise between the resulting measurement area and the modification of the hydraulic profile. As first constraint, the diameter of the window is given by the maximum laser beams separation. Also given a minimum distance between the teflon rings (related to the diameter of the joint) to insure adequate joint sealing, the angular stroke of the joint is primarily function of the sphere diameter. On the other hand, covering a wider angle also requires a greater modification of the hydraulic profile. In the present context, a sphere diameter of 0.21·RRef procured a stroke of 40°. Fig.4. Rotating optical access assembly To position the optical access and the probe, a specific mechanism was also designed, based on the traverse system used in the other experimental campaigns. Aiming to be precise and easy to align, the system uses a linear actuator to guide another one in rotation around the access window rotation axis. Both actuators are characterised by a precision of 0.02 mm, traduced in a 0.0014° angular precision for the mobile motor position. The second linear actuator is supported by two circular motion guides and is fixed to the threaded tubular part showed on the left of Fig.4. This mechanism allows the probe to be moved perpendicularly to the window and both the window and the probe to be rotated for each measurement point. Fig.5 shows a picture of this system used in the third experimental campaign. Fig.5. LDV experimental setup for measurement of the radial velocity component at the runner outlet 3rd IAHR International Meeting of the Workgroup on Cavitation and Dynamic Problems in Hydraulic Machinery and Systems, October 14-16, 2009, Brno, Czech Republic 6. LIMITATIONS AND UNCERTAINTY The method presented so far is subject to some specific issues. First, the alignment process of the LDV system results in an uncertainty on the spatial position of each measurement point. In the case of the rotating optical access calibration, the position of the system has to be precisely adjusted regarding more degrees of freedom than usual. Misaligned laser beams can result in phase shift, spatial shift and crosscontamination of velocity components [3]. The fact that two measurement campaigns were made, and therefore two alignment processes, implies that this uncertainty is increased. Simultaneous acquisition of the two vectors by means of a three components LDV system would allow verifying the coincidence of the laser beams on the same spatial point thus reducing the number of necessary alignments to one, but would also augment the relative uncertainty because of the low amplitude of the third component [4]. On the other hand, common 3D-LDV systems, unless using two 2D probes and four laser wavelengths, allow measurement of three components without the possibility to validate each of them directly. Performing two 2D campaigns allowed to validate the axial velocity and to insure good orientation between the measured components. Furthermore, the principal uncertainty issue in computing Cr is related to the angle β used in the coordinate system rotation from the optical access reference to the global reference. One can note that for a specific measurement point where β is 0°, the radial velocity Cr is obtained directly from Cr*. At the opposite, a value of β close to 90° leads to a value of Cr* similar to Cθ without much information on Cr. Increasing the angle β results in progressively amplifying the uncertainty on the radial velocity computed; Tab.2 gives the resulting radial velocity error for an initial error of 1% on measured velocities (Cr* and Cθ). The impact of these issues tends to increase in low velocity or recirculation regions, for which the relative error inherent to the LDV system increases significantly. Also, operating conditions such as flow rate, head and temperature are subject to fluctuations. The actual conditions from one campaign to the other are then affected by variations of less than 1% on the model efficiency and the unit speed (n11) value. β (°) Relative error (%) 0 1.00 20 1.42 40 2.14 60 3.73 80 11.43 Tab.2. Effect of angle β on the radial velocity accuracy 7. RESULTS In the scope of this study, nine operating regimes are covered by each experimental campaign, combining three different net heads and seven wicket gate openings. In the context of this paper, the operating conditions presented are listed in Tab.3. Time averaged data will be presented for all spatial points of the inlet and outlet sections. Lengths and velocities are normalized with respect to the runner reference radius RRef, and the mean velocity in the reference section CRef, respectively. # 8 3* 4 5 6 Q11 (m3/s) 0.7905 1.2945 1.3862 1.2762 1.3155 n11 (RPM) 124 124 124 120 130 Guide vanes opening 17° 33° 38° 33° 33° Relative efficiency 62.8 % 100.0 % 99.1 % 100.1 % 97.6 % Fig. Id. 17° 33°Hnom 38° 33°Hmax 33°Hmin Tab.3. Operating conditions analysed (* nominal point) 3rd IAHR International Meeting of the Workgroup on Cavitation and Dynamic Problems in Hydraulic Machinery and Systems, October 14-16, 2009, Brno, Czech Republic The effect of varying the wicket gates opening at constant head on the radial and axial velocity profiles is shown in Fig.6. The 33° opening at nominal head, best efficiency point, leads to relatively uniform profiles with a narrow stalled region bellow the hub, as one can observe on left side of Fig.6. A minor velocity deficit is notable over radius 2 (θ = 213.5°) and attests of a slight flow unbalance towards positive x axis. A similar tendency can be observed in radial velocity profiles, as radius 2 presents a wider negative velocity region in the center of the section. One could interpret this tendency as the combined effect of the upstream velocity non-uniformities and the draft tube elbow. Fig.6 (right side) illustrates radial velocity profiles for radiuses 2 and 4 in nominal (33°Hnom) and overload (38°) operating conditions. The radial asymmetry is found for both conditions, with greater velocity in the overload case. Fig.6. At constant head: (Left) Axial velocity profiles, 33° opening at nominal head. (Right) Radial velocity profiles, radii 2 and 4, at best efficiency point and overload, at nominal head Fig.7 illustrates axial and circumferential velocities measured over radius 2, for the first three operating conditions. Closer to the design hypothesis of pure axial velocity, the nominal condition profiles are generally in between the two others. At partial load, a major recirculation region (up to R/RRef = 0.53) is clearly visible in the center of the section, deflecting the flow towards the outer wall where high axial and tangential velocities are found. Best efficiency point exhibits low tangential velocities and no recirculation. Overload condition also shows a uniform axial profile but a major counter-rotating region in the center, associated with a vortex downstream the runner. This structure is also visible on Fig.6 (right) with the increased modulus of the radial velocity in this region. The opening of the overload conditions being closer to the nominal 33° than the partial load 17° opening, the efficiency at overload is not greatly diminished. The impact of these inlet flow behaviours can be investigated through the axial velocity contours at the outlet section presented in Fig.8. The blurred contour lines identify zero velocity boundaries; the header of each graph displays the operating condition and the integrated flow rate over the two measured areas referenced to the operating condition. Similarly to the inlet section and although a flow rate unbalance is measured, the best efficiency operating condition (center) leads to quite uniform velocity distributions on both draft tube channels. Overload condition (top-left) exhibits a slightly more balanced flow repartition between the channels but also a low velocity region in the center of the left channel. 3rd IAHR International Meeting of the Workgroup on Cavitation and Dynamic Problems in Hydraulic Machinery and Systems, October 14-16, 2009, Brno, Czech Republic Fig.7. Axial and tangential velocity profiles at the draft tube inlet for constant head, radius 2 Fig.8. Axial velocity contours at the draft tube outlet. Header: Integrated flow rate over each measured area 3rd IAHR International Meeting of the Workgroup on Cavitation and Dynamic Problems in Hydraulic Machinery and Systems, October 14-16, 2009, Brno, Czech Republic The presence of such structure implies higher velocity gradients, higher turbulence thus lower draft tube energy recovery which can contribute to lower the efficiency of the whole machine (see Tab.3). Partial load condition (bottom-left) results in even more irregular distributions with one major recirculation zone near the pier in both channels. One can presume that this recirculation and the resulting flow unbalance arise from the interaction between the central recirculation at the inlet section, the draft tube elbow and the pier. Now considering a fixed wicket gate opening of 33°, the effect of varying the unit speed (n11) can be analysed through operating conditions 5, 3* and 6. As illustrated by Fig.9, similar profiles are obtained for the three operating conditions, with variations in amplitude. Also implying a slight flow rate augmentation, the increase of the runner rotating speed with respect to the net head is traduced at the draft tube inlet section by an augmentation of the tangential velocity and the radial velocity (decreasing the flow tendency to converge towards the center). This variation also affects the axial velocity, reducing in the central half of the section and increasing near the outer wall. As for operating conditions previously analyzed, asymmetry is found in radial velocity profiles of Fig.9 (right). A wider negative velocity region in the center of the section is still present over radius 2. Also, the decrease in tangential velocity associated with lower unit speed (n11) leads to the apparition of a narrow counter rotating region close to R/RRef = 0.23. Fig.8 (top-right, center and bottom-right) presents the axial velocity contours at the outlet section for the constant wicket gate opening analysis. Witnessing the similarity and uniformity of the nominal (33°Hnom) and maximum head (33°Hmax) velocity profiles, what one can note is the flow rate unbalance of the minimum head operating condition (33°Hmin). The slightly higher flow rate and the outward tendency of the inlet flow of this operating condition could trigger such unbalance that develops in the draft tube elbow and at the pier. The resulting higher velocity region in the bottom right corner of the right channel, the stalled region in the left channel and the high velocity gradients associated with them contribute to lower the draft tube energy recovery which possibly lower the model efficiency (see Tab.3). Fig.9. At constant opening: (Left) Axial and tangential velocity profiles, radius 2. (Right) Radial velocity profiles, radii 2 and 4. 3rd IAHR International Meeting of the Workgroup on Cavitation and Dynamic Problems in Hydraulic Machinery and Systems, October 14-16, 2009, Brno, Czech Republic 8. CONCLUSION Current results of the study of the draft tube flow in a propeller turbine by Laser Doppler Velocimetry were presented in this paper. A method to acquire three velocity components at draft tube inlet using a rotating optical access has been presented, the radial velocity being obtained by the combination of two partial velocity vectors. It is found that the method is subject to specific uncertainty issues regarding the LDV system calibration and the radial velocity computation. Time averaged results were presented at draft tube inlet for three velocity components and at draft tube outlet for two components. Results at the outlet section show varied distributions, from clearly asymmetric with high velocity gradients to best efficiency point uniform profiles. Inlet velocity profiles asymmetry and diversity have been witnessed. Recirculation in the central region, secondary flows, counter rotating regions and converging radial velocity in the central half of the section were identified. Future analysis of the radial velocity component at draft tube inlet is expected to give more details on the impact of this component and of asymmetry on numerical simulations of the draft tube flow. 9. ACKNOWLEDGEMENTS The authors would like to thank the participants of the Consortium on Hydraulic Machines for their support and contribution to this research project: Alstom Hydro Canada, Andritz Hydro LTD, Edelca, Hydro-Quebec, Laval University, NRCan, Voith Hydro Inc. Our gratitude goes as well to the Canadian Natural Sciences and Engineering Research Council who provided funding for this research. 10. REFERENCES [1] Payette, F.-A., De Henau, V., Dumas, G., Sabourin, M.: Sensitivity of draft tube flow predictions to boundary conditions. IAHR - 24th Symposium on Hydraulic Machinery and Systems. Foz de Iguazu, Brasil, 2008 [2] Gagnon, J.-M., Deschênes, C., Ciocan, G.D., Iliescu, M.: Numerical simulation and experimental investigation of the flow in an axial turbine. IAHR - 24th Symposium on Hydraulic Machinery and Systems. Foz de Iguazu, Brasil, 2008 [3] Tropea C., Yarin A., Foss J., (Eds.): Springer Handbook of Fluid Mechanics. 2007. pp. 296-309 [4] Ciocan G.D., Avellan F., Kueny J.-L.: Optical Measurement Techniques for Experimental Analysis of Hydraulic Turbines Rotor - Stator Interaction. Proceedings of the ASME Fluids Engineering Division Summer Meeting, Boston, Massachusetts, USA, June 11-15, 2000 [5] Page M., Giroux A.-M.: Turbulent Flow Computations in Turbine 99 Draft Tube with CFXTASCflow, FIDAP and FINE/Turbo. Turbine 99 – Workshop 2. The second ERCOFTAC Workshop on Draft Tube Flow. Vattenfall Utveckling AB, Älvkarleby, Sweden, June 17-20, 2001 11. NOMENCLATURE Cx, Cy, Cz (m/s) Velocity components LDV Laser Doppler Velocimetry 3rd IAHR International Meeting of the Workgroup on Cavitation and Dynamic Problems in Hydraulic Machinery and Systems, October 14-16, 2009, Brno, Czech Republic in the global reference frame; Cr, Cθ, Cz (m/s) Radial, tangential and axial velocity components; Cr* (m/s) Radial velocity in the local coordinate system of the rotating optical access; Cref (m/s) Mean velocity in the reference section of the machine Hmin, Hnom, Hmax(m) Minimum, nominal and maximum head of the operating conditions Radial position with respect to the runner axis Rref (m) Runner reference radius; x, y, z (m) Cartesian position relatively to the reference coordinate system; β (°) Angle between rotating access and reference coordinate systems θ (rad) Circumferential position with respect to positive x axis n11 (rpm) Unit speed R (m)