Current Reset Fault Indicators

Use Single- or Three-Phase Current Reset Fault Indicators

to Reduce Outage Times

Improve system reliability by quickly identifying and isolating

faulted underground cable sections.

Features and Benefits

Reduce Outage Times

Quickly and efficiently find faults on underground systems.

Improve Service Crew Productivity

Reduce maintenance and operating costs by reducing fault-finding

time. Remote displays eliminate the need to open the enclosure to

check the fault indicator’s status.

Enhance Visibility

Improve viewing with a highly visible, reflective red target or a

combination target and BEACON® LED display. The combination

display’s target portion will continue to indicate faults even after

the end of the battery’s life.

Communicate Status

Use the optional auxiliary contact to provide status indication

to a SCADA input.

Install Easily

Spring-loaded clamps enable quick installation with standard

hotline tools.

Making Electric Power Safer, More Reliable, and More Economical ®

General Description

Options

Current Reset Fault Indicators use continuous load current to

automatically reset and to maintain the energy required to respond

to a fault. Each unit includes:

• Current Sensing Unit

Senses the load and fault currents on the conductor.

• Spring Clamp Assembly

An integral split-core type transformer enables line crews to

install the unit with standard hot line tools.

• Visual Display

A reflective red target and/or a flashing red LED display

maximizes visibility during day and night.

• Weatherproof Housing

Withstands high temperatures and high moisture environments.

UV-stabilized polycarbonate housing is compact and lightweight.

Time Current Curve

• “IR” Inrush Restraint

• “A” Auxiliary Contact

• “DT” Delayed Trip (24 ms)

• “LC” Low-Current Reset (1.5 A)

• “3” Three-Phase Reset

• “N” Nonreplaceable C Battery (BEACON models only)

• “W” Window Mounting Kit (“L” display only)

Cable Preparation and Installation

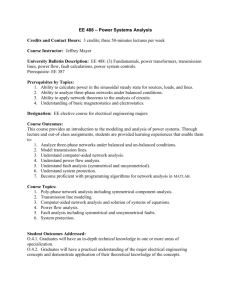

TIME CURRENT CURVE FOR FAULT INDICATOR

Peak Amperes

in Multiples of

Nominal Trip

Rating

4.0

3.5

3.0

2.5

2.0

1.414

1.0

0.0

0.0

1.0

0.5

1.5

2.0

Time in Milliseconds

Option 1

Option 2

Option 3

SEL recommends double-back concentric neutral training, Option 1.

Options 2 and 3, which depict installation of the FCI directly over the

semicon, are also acceptable methods.

Underground Application

Line crews find the location of faults by isolating

the section of line between the last tripped (red)

fault indicator and the first untripped (white)

fault indicator.

Normally

open point

Fault Location

Tripped

Fault Indicator

Untripped

Fault Indicator

Fuse

Operational Specifications

Power Source

Mechanical Target—Load Current

LED Display

Replaceable Battery (standard)—

1200 flashing hours (2.4 Ah, 3.6 V

Lithium AA cell)

Nonreplaceable Battery (optional)—

3000 flashing hours (8.5 Ah, 3.6 V

Lithium C Cell)

Nominal Trip Rating

100 to 1200 A

Maximum Fault Current

25 kA for 10 cycles at 60 Hz

Trip Rating Tolerance

±10% at the calibrated OD

Mounting Diameter Ranges

0.75" to 2.10" (1.9 cm to 5.3 cm); larger

clamp options available

Trip Response Time

1 ms at trip rating (24 ms optional)

Submersibility

15 ft (4.6 m)

Reset

Automatic at minimum current

Housing

UV-stabilized polycarbonate

Minimum Current Reset

3 A standard, 1.5 A optional

Display Options

Reflective red target

Transformer Core

Vinyl-coated silicon steel

Typical Reset Time

25 seconds at 10 A and above

Combination target and BEACON LED

Three-Phase Reset

Automatically resets to the normal

untripped condition when current in

each phase exceeds 3 A

Tamperproof Bolt or BEACON Bolt

Inrush Restraint

Prevents false indication during reclosing

operations in situations when the inrush

current exceeds the nominal trip value

Inrush restraint response time: 300 ms

Temperature Range

—40° to +85°C

Dimensions

4.0 in

10.16 cm

INDICAT

OR

ULT

FA

N

N

5.2 in

13.21 cm

M

A

DE

IN

US

A U.S. & FO

GN

REI

PA

2.5 in

6.35 cm

TS

3.7 in

9.39 cm

BEACON Remote

“L” Display

2.5 in

6.35 cm

3.5 in

8.89 cm

RA

ZE

TO

EIT

RIE

MADE IN USA

U.S. & FOREIGN PATENTS

S

2.14 in

5.44 cm

SCHW

2.1 in

5.33 cm

CRSRTT

Trip Testing Tool

Test and manually trip

energized CR Fault Indicators.

R

EN

GIN

EERING

LA

BO

Standard Remote

“V” Display

2.5 in

6.35 cm

4.0 in

10.16 cm

2.98 in

7.57 cm

3.5 in

8.89 cm

MA

DE

IN

A∅

INDI

CA

C∅

2.1 in

5.33 cm

U SA

R

TO

1.5 in

3.81 cm

Tamperproof

Bolt Display

Magnet

2.5 in

6.35 cm

Three-Phase

Remote “4” Display

0.65 in

1.65 cm

Sold separately.

SEL Current Reset Fault Indicators

Ordering Information

Choose from the following options to complete the part number (example: 3 C R L 0 4 0 0 W ).

Phase Selection

Single-Phase

1

Three-Phase

3

Fault Indicator Type

Current Reset

BEACON® Current Reset

Type of Display

Integral Target Display

Standard Remote “V” Display

BEACON Remote “L” Display

Tamperproof Bolt Display

Three-Phase Remote “3” Display

BEACON Three-Phase Remote “4” Display

Nominal Trip Rating (contact factory for other ratings)

100 A

200 A

400 A

600 A

800 A

1000 A

1200 A

Options*

Inrush Restraint

Auxiliary Contact

Delayed Trip (24 ms)

Low Current Reset (1.5 A)

Three-Phase Reset Requirement

(not required on “3” or “4” displays)

Nonreplaceable C Battery (BEACON models only)

Window Mounting Kit (“L” Display only: included

with “V” Display)

CR

BCR

I

V

L

B

3

4

0100

0200

0400

0600

0800

1000

1200

IR

A

DT

LC

3**

N

W

* Not all options are available in all combinations.

** Only available on three-phase fault indicators.

Related Products

Type CRD Fault Indicator

Current reset technology coupled with the largest target display

in the industry (8.2 cm2) provides a solution for overhead and

underground applications.

Commitment to Quality

Five-year warranty, no questions asked.

Field application assistance available.

© 2009—2011 by Schweitzer Engineering Laboratories, Inc. All rights reserved. PF00046 • 20110209