POWERTRAIN SYSTEM S

Delphi Compact Modular Ignition Coils

Delphi Compact Modular Ignition Coils is an all-new family of innovative

ignition technology developed for modern engines. The coils do not require

rare earth magnets, thus enhancing application flexibility and mitigating the

potential for costly material price fluctuations. They offer manufacturers

wide design flexibility, compact size to help overcome packaging

constraints, lower cost versus conventional ignition coils, and impressive

performance and durability to meet the most stringent program

requirements.

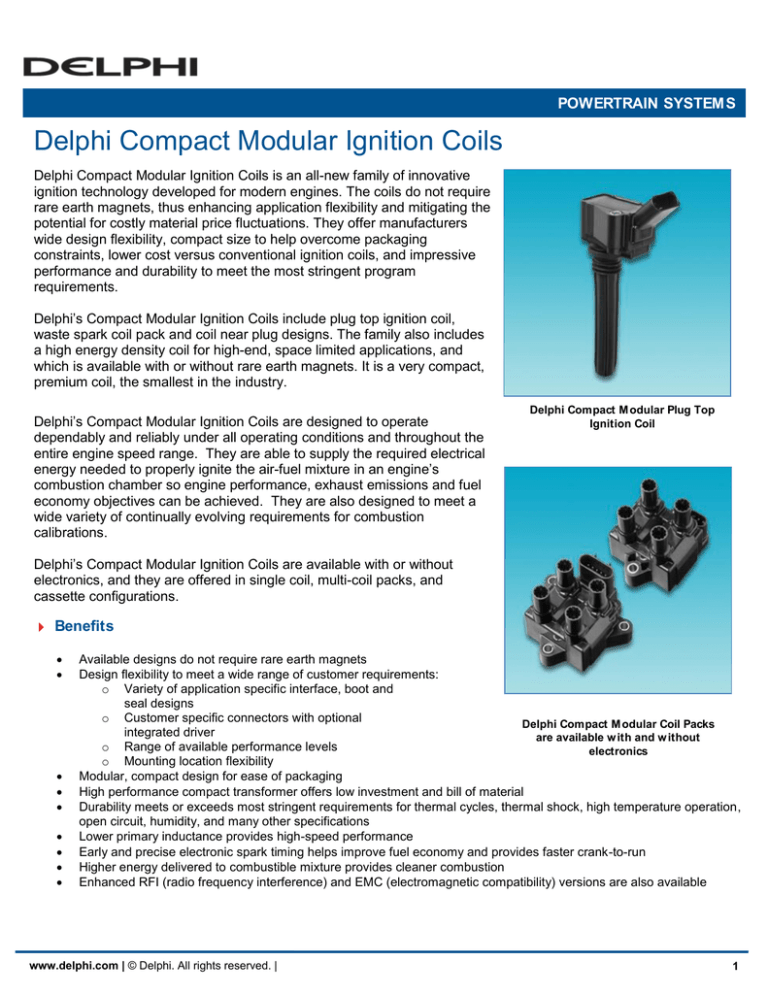

Delphi’s Compact Modular Ignition Coils include plug top ignition coil,

waste spark coil pack and coil near plug designs. The family also includes

a high energy density coil for high-end, space limited applications, and

which is available with or without rare earth magnets. It is a very compact,

premium coil, the smallest in the industry.

Delphi’s Compact Modular Ignition Coils are designed to operate

dependably and reliably under all operating conditions and throughout the

entire engine speed range. They are able to supply the required electrical

energy needed to properly ignite the air-fuel mixture in an engine’s

combustion chamber so engine performance, exhaust emissions and fuel

economy objectives can be achieved. They are also designed to meet a

wide variety of continually evolving requirements for combustion

calibrations.

Delphi Compact M odular Plug Top

Ignition Coil

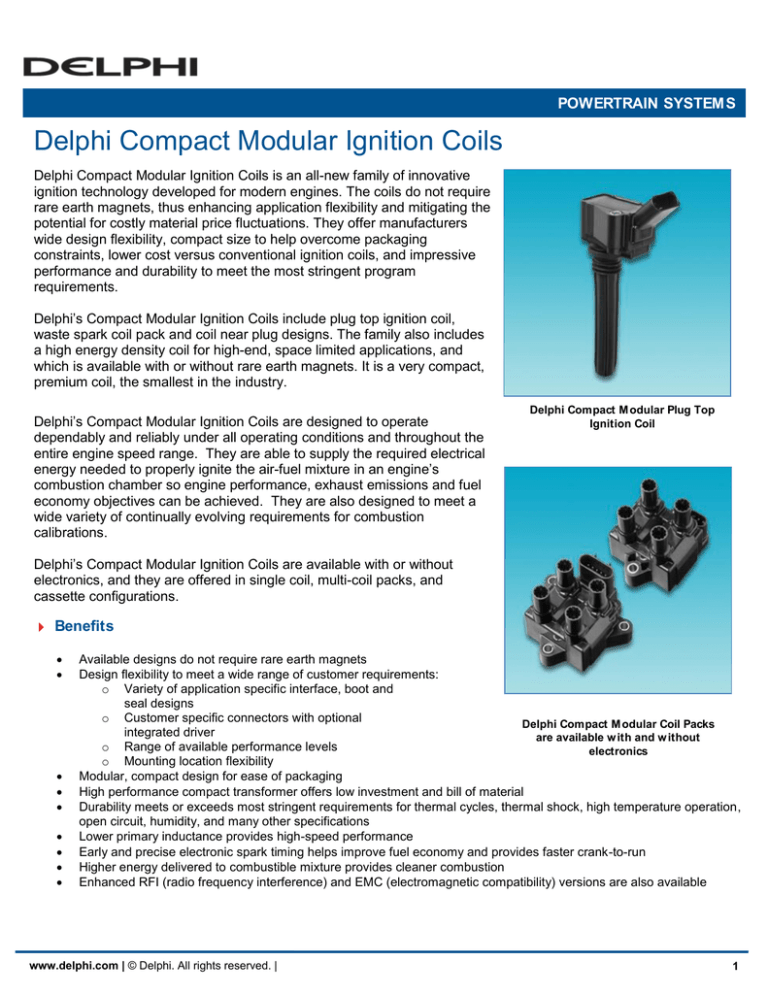

Delphi’s Compact Modular Ignition Coils are available with or without

electronics, and they are offered in single coil, multi-coil packs, and

cassette configurations.

Benefits

Available designs do not require rare earth magnets

Design flexibility to meet a wide range of customer requirements:

o Variety of application specific interface, boot and

seal designs

o Customer specific connectors with optional

Delphi Compact M odular Coil Packs

integrated driver

are available w ith and w ithout

o Range of available performance levels

electronics

o Mounting location flexibility

Modular, compact design for ease of packaging

High performance compact transformer offers low investment and bill of material

Durability meets or exceeds most stringent requirements for thermal cycles, thermal shock, high temperature operation,

open circuit, humidity, and many other specifications

Lower primary inductance provides high-speed performance

Early and precise electronic spark timing helps improve fuel economy and provides faster crank-to-run

Higher energy delivered to combustible mixture provides cleaner combustion

Enhanced RFI (radio frequency interference) and EMC (electromagnetic compatibility) versions are also available

www.delphi.com | © Delphi. All rights reserved. |

1

Delphi Compact Modular Ignition Coils

Typical Applications

Delphi Compact Modular Ignition Coils are designed for automotive

gasoline, ethanol, ethanol-blended fuel, and compressed natural gas

(CNG) engines. The coils are designed to meet virtually any customer

package requirement, including:

Stand-alone coil or coil and igniter package

Coil with multiple pin connector capability

Coil assembly with or without high voltage leads

Availability

Delphi's Compact Modular Ignition Coils will begin production in 2014.

Engineering samples are available to qualified vehicle manufacturers.

Contact Delphi for additional information.

Delphi Compact M odular Coil Near Plug

Performance Advantages

Delphi Compact Modular Ignition Coils are built of sturdy materials and designed for long-term durability and

reliability. They feature cost-effective designs and are produced by smart manufacturing processes that enable

successful implementation across a wide range of engine applications. Delphi offers manufacturers a complete

systems integration approach to ignition systems development. Every step of the ignition process is analyzed,

including the creation, transmission, timing and delivery of the ignition spark energy. This strategy provides an

optimized ignition system tailored to customer requirements.

Typical Performance Specifications

Metric

Operating Ambient Temperature Range

Primary Current

Usec Under Load 25 pF

Usec Under Load 25 pF // 1 mΩ

Usec Maximum in Idle State

Spark Current Range (1000 V Zenner)

Spark Duration Range (1000 V Zenner)

Secondary Energy (1000 V Zenner)

Performance

-40°C to 140°C

Application specific.

40 kV

33 kV

47 kV

84 mA to 200 mA

1.67 ms to 2.6 ms

Without magnets: Up to 90 mJ (130 mJ at boost mode)

With magnets: Up to 125 mJ (190 mJ at boost mode)

The Delphi Advantage

Delphi has a deep understanding of ignition systems and the combustion process. We offer the benefits of more

than 100 years’ experience in ignition systems and we build millions annually. We offer a low cost, global

manufacturing footprint and the most comprehensive line of ignition systems in the industry. Our ignition

products excel in performance, quality and durability. We provide advanced and innovative technologies

designed to help our customers meet the market challenges of the future.

As a global leader in engine management systems technology, Delphi can help manufacturers meet emissions

requirements, improve fuel economy and enhance performance. Delphi is a source for high value solutions and

our systems expertise is built into every product. Delphi’s flexible engineering approach encourages

collaboration. And, Delphi has a thorough understanding of markets around the world and a global network of

resources.

www.delphi.com | © Delphi. All rights reserved. |

2