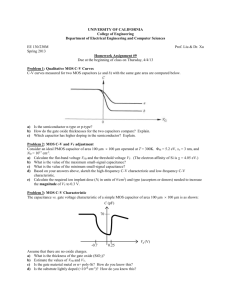

Investigation of oxide thickness dependence of Fowler

advertisement