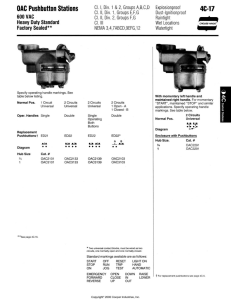

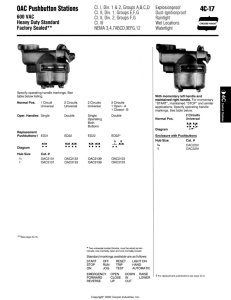

EMP and EMPS Barrel Assemblies

advertisement

EMP and EMPS Barrel Assemblies Cl. I, Div. 1 & 2, Groups B.C.D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. Ill NEMA7BCD,9EFG,12 Dimensions Pg. 4C-24 Explosionproof Dust-lgnitionproof Raintight Wet Locations 4C-23 Group 2: For custom-built control panels and System 4 Control Stations. Illuminated pushbutton** jrf , «* Long Assembly Cat. # Diagram •• r®-] a!* fti* 120V* pilot light EMP0090t i 120V* pilot light EMP0098t i • • •• *-'VS Maintained Contact Pushbutton Diagram Long Assembly Down Up Cat. # A1 J A2 . Two-position selector switch, key operated Diagram Position 1 A1 MAM. A2 • • A1 MAM. 0 1 MAM. A2 • • B2 • • Key Removal Both positions Left only Right only Short Assembly Cat. # EMPS0491 EMPS0492 EMPS0493 Both positions AI •.• BI ••• Left only A2 »Sr B2 w1* Right only EMPS0591 EMPS0592 EMPS0593 Position 2 AI •.• A2 " Standard Assembly Cat. # EMP0491 EMP0492 EMP0493 EMP0591 EMP0592 EMP0593 Three-position selector switch, key operated Key Short Assembly Standard Assembly Removal Cat. # Cat. # All EMPS0691 EMPS0692 EMPS0693 EMPS0694 EMPS0791 EMPS0792 EMPS0793 EMPS0794 EMP0691 EMP0692 EMP0693 EMP0694 EMP0791 EMP0792 EMP0793 EMP0794 EMPS0891 EMPS0892 EMPS0893 EMPS0894 EMP0891 EMP0892 EMP0893 EMP0894 Diagram Position 1 A l MAM. A2 • • Al MAM. BI •*-!* A2 • • B2 • • A1 •.• Bl MAM. A2 W*» B2 • • Position 2 Position 3 A1 •)• A2 • • A1 «|» B1 »|« A2 V^ B2^7 Al MAM. 81 MAM. A2 • • B2 • • AI •,• A2 *** Center only Left only Right only All Center only At •.• BI ••• Left only A2 *>t B2 ^W Right only All Center only AI MAM. BI »!» Left only A2 • . B2 V^ Right on|y * Other voltages available. Information on request. t Colors available: red, green, amber, clear, blue. See table on page 4C-21. ** LED pilot light can be furnished in place of standard incandescent pilot lamp. Add suffix LED after color symbol. Copyright" 2000 Cooper Industries, Inc. A1 A2 EMP098 EMP Panel Mounted Pushbutton Stations Selector Switches, Pilot Lights and Combinations Cl. Cl. Cl. Cl. Factory Sealed NEMA3,7CD,9EFG,12 I, Div. 1, Groups C,D I, Div. 2, Groups B,C,D II, Div. 1, Groups E,F,G II, Div. 2, Groups F,G Cl. Ill Explosionproof Dust-lgnitionproof Raintight Wet Locations 4C-19 Application: EMP panel mounted pushbutton stations, selector switches, pilot lights and combinations are used: • together with instruments, gauges and meters all mounted on a panel of sheet steel or other suitable material in the fabrication of control boards • in areas made hazardous due to the presence of flammable vapors, gases or highly combustible dusts • in corrosive locations • indoors at petroleum refineries, chemical and petrochemical plants and other process industry facilities where similar hazards exist EMP43 Features: • Compact enclosures which require a minimum of panel space, making them ideally suited for flow chart control boards • Enclosures made in single, two and three gang sizes • Accurately ground; wide flange on both body and cover for flame-tight joint • Only the device operators and pilot lights protrude through the panel. Enclosures are behind the panel so that conduit and wiring is concealed • Pilot lights are relamped from the front of the panel by unscrewing the knurled jewel assembly • Mounting made easy - a 1W diameter hole is drilled for each threaded barrel and any panel up to % thick can be used; locking nuts clamp the assemblies to the panel and permit alignment with conduit and other fittings behind the panel • Furnished with vertical through feed hubs 1" size • Units are factory sealed for Class I, Division 1 and 2, Groups C and D. Standard Materials: • Bodies and covers - Feraloy" iron alloy • Threaded barrels - copper-free aluminum • Operating shafts - stainless steel • Single pushbutton and selector switch operators - phenolic • Double pushbutton operators - copper-free aluminum Certifications and Compliances: • NEC/CEC: Class I, Division 1, Groups C,D Class I, Division 2, Groups B,C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III • NEMA/EEMAC: 3, 7CD, 9EFG, 12 • UL Standard: 698 • CSA Standard: C22.2 No. 30 Options: • The following special options are available from factory by adding suffix to Cat. No.: Suffix to be Added to Encl. Cat. # Description Lockout on single pushbutton operator only. Locks normally closed contacts in open position Three-position selector switches with modified operation: Momentary contact clockwise operation, spring return to center, maintained contact counter-clockwise operation S634 Momentary contact counter-clockwise operation, spring return to center, maintained contact clockwise operation S635 Pilot lights for circuit voltages up to 600 volts maximum (standard voltage range 110-125) Combination of devices other than those listed can be supplied LED pilot lights in place of standard incandescent pilot lamps Standard Finishes: Dimensions (inches) • Feraloy iron alloy - electrogalvanized and aluminum acrylic paint • Copper-free aluminum - barrels, black anodized; operators, natural • Stainless steel - natural • Phenolic - natural Dimensions are approximate, not for construction purposes. Style 1 Electrical Rating Ranges: • Pushbutton stations and selector switches: heavy duty 600vac maximum • Pilot lights: 110 to 600vac Copyright 2000 Cooper Industries, Inc. Styles S153 See Listings Specify LED EMP and EMPS Barrel Assemblies 4C-24 Explosionproof Dust-lgnitionproof Raintight Wet Locations Cl. I, Div. 1 & 2, Groups B.C.D Cl. II, Div. 2, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. Ill NEMA3,7BCD,9EFG Dimensions (inches)* NOTE: All barrel assemblies are W-14 NPSM thread size. EMPS 049 4 13/16 EMP 049 513/16 * U «- * 3/ie • !»• i *| p 3/16 1 FCT; <= I «= I h ft Threaded *~ length ~*" • 2I/4 • ,6 EMP 009 * 25/8 Turn d 'r ^=RL ex h " fiSBlH ^^11^ [» 3/ieH » _i '" . -rV __ Threoded "- length Bi&TlL 2 3/16 * length ~ |_ ' "I - _ i rM> *" j j^JMPS049l3/4__i> EMP 049 2 3/4 ^ 1_ J 2 1/16 Turn die I ; _ *-3/l6 Threaded ~ length ' ' •^3^— : «^_lc Sf" ^ 1 : f F I \ 5 1 Threaded length 2 1/4 FH |5= TTF= 1 J= ' L_l dia |] ffTp^ i—L.T 2 5/8 Lj^J3 ^; "; •) EMP0090 3/I6 -"tr ^ih1- J * Threaded length fUPf. 0491 5 9/16 EMP 049 6 5 / 8 "' 1 Rlh^ UJp : 1 tji*tJH L ., Threaded 23 /,6 « [•-3/I > 3/16 -•] k--» » "" 2 5/8 f \+l**-* , 3/I6 E VIP-EMPS019 T i-, '-. ttrr EMP098 3/16—J *--*] k-3/16 T m 3/I6 EMPS OI9 2 I/4 EMPOI93I/4 j_ •• EMPSOI9 5I/8 EMP OI9 6 I/8 | ^3-uI I [ JC ) 2^6 ^ "" EMPS 039 1 1/4f EMP 039 2 1/4 2 3/16 Threaded length ~*" ^EMPS 029 1 1/4 I EMP 029 2 I/4 2 5/|6_ »| 63/16 " w ~75i~ W U . ' • „ 4 *" EMP-E MPS029 3/l6-»j «--» EH/IP-EMPS039 2 1/16 i ? Turn i : " IT -H k 3/I6 2 5/8 fjl 3= ,, * 3/ tfl | EMP-EMPSi049, 059, 069, 079, 089 EMP S 039 4 7/8 EMP 039 5 3/4 b^C «j p- 3/16 ^ r« 3/I6 S 1 EMPS0295I/8 EMP0296I/8 37/ 3/I6 3/I6-" . . —«j 7/8 Ien9th 19 •— £ MPS 049I I I/4 E MP 049I 2 I/4 EMP-EMPS0491, 0591, 0691, 0791,0891 Series 3/16—H U--^ |*-3/l6 1 M 1" l~ i ' c_ 1 / 7 F !•—HJ-" length t EMP0098 * Dimensions are apprDximate, not for construction purposes. Copyright" 2000 Cooper Industries, Inc.