TABLE 1: WIDTH TOLERANCES

advertisement

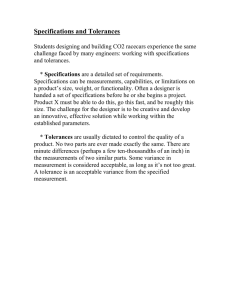

TABLE 1: WIDTH TOLERANCES DIMENSION NOMINAL DESIGN TOLERANCES FOR THE FOLLOWING TYPES OF DIMENSIONS (SEE ILLUSTRATIONS BELOW) NORMAL WIDTH WIDTH WIDTH EQUALS SUM OF SEVERAL SPACES (WIDER TOLERANCES REQUIRED) (NORMAL TOLERANCES) Dimension "W" (Fig. 1) is not affected by changes in the size of other width dimensions and is therefore easier to control. Dimension "W" (Fig. 2) is equal to the sum of the spaces "A", "B", "C" & "D". Changes in the size of any of the individual spaces affects the width dimension, thus making it harder to control. INCHES From ± To ± 0 1 .020 .030 1 2 .030 .045 2 4 .040 .060 4 6 .050 .075 6 10 .060 .090 10 15 .075 .100 15 20 .090 .125 20 24 .125 .150 NOTE: The nominal tolerances are design tolerances. Once a part has been developed, the running tolerances can usually be tighter than the design tolerances. Running tolerances normally must be ± the actual measurements obtained for development samples. Dimension "W" is not directly dependent on spaces "A" through "D" as the reference dimension "REF" can float. It is therefore easier to control than the "W" dimension in fig. 2 and NORMAL TOLERANCES CAN BE USED. Dimension "W" is equal to the sum of the spaces "A" + "B" +"C" +"D" and is directly affected by changes to these dimensions. It is therefore more difficult to control than the "W" dimension in fig. 1. and WIDER TOLERANCES ARE REQUIRED. (Dimension "E" in fig. 1 also is equal to the sum of the spaces.) 1" 3"E REF A B 1" C 1" 0" 1"D A W 3" B 1" C 1" 0" 1"D W 3" FIG. 1: NORMAL WIDTH FIG. 2: WIDTH =THE SUM OF SEVERAL SPACES 2 TABLE 2: LEG LENGTH & HEIGHT DESIGN TOLERANCES DIMENSION NOMINAL DESIGN TOLERANCES FOR THE FOLLOWING TYPES OF DIMENSIONS (SEE ILLUSTRATIONS BELOW) LEG LENGTH OR SINGLE SEGMENTS SUM OF SEVERAL SEGMENTS (NORMAL TOLERANCES) (WIDER TOLERANCES REQUIRED) HEIGHT Dimension "L" (Fig. 3) is for a single segment. The size of this segment is not dependent or affected by changes in the size of other dimensions and is easier to control. Dimension "C" (Fig. 4) is for two or more segments ("L"). Changes in the size of any of the individual segments affects this dimension. This type of dimension is harder to control. INCHES From To ± ± .125 .010 ----–– .125 .250 .015 .020 .250 .500 .020 .030 1.0 .025 .040 1.5 .030 .045 1.5 2.0 .040 .060 2.0 3.0 .045 .070 3.0 4.0 .050 .075 4.0 6.0 .060 ------- 6.0 8.0 .075 ------- 8.0 10.0 .090 ------- .500 1.0 NOTE: The nominal tolerances are design tolerances. Once a part has been developed, the running tolerances can usually be tighter than the design tolerances. Running tolerances normally must be ± the actual measurements obtained for development samples. Dimension "L" is for a single segment. It is not dependent or affected by changes in the size of other dimensions and easier to control than those in fig. 4. NORMAL TOLERANCES CAN BE USED. Dimension "C" is the sum of the segments "L" and is affected by changes in these dimensions. It is therefore more difficult to control "C" than the "L" dimensions in fig. 3. and WIDER TOLERANCES ARE REQUIRED. L 1"L 0" L 0"L C 1" 0" C 1" 1"L L 1" 0"L FIG. 3: LENGTH OR HEIGHT IS A SINGLE SEGMENT 3 FIG. 4: SUM OF SEVERAL SEGMENT LENGTHS TABLE 3: SPACE & GAP TOLERANCES DIMENSION NOMINAL DESIGN TOLERANCES FOR THE FOLLOWING TYPES OF DIMENSIONS (SEE ILLUSTRATIONS BELOW) SPACES & GAPS GAP OR SINGLE SPACE (NORMAL TOLERANCES) MULTIPLE SPACES (WIDER TOLERANCES REQUIRED) ADJUSTABLE GAP (TIGHTER TOLERANCES POSSIBLE) Dimensions "S" or "G" (Fig. 5) are not affected by changes in the size of other dimensions and are therefore easier to control. Dimensions "A", "B", "C" & "D" (Fig. 6) are multiple spaces that control width "W". The greater the number of spaces, the wider the tolerances should be for the individual spaces. Dimension "G" (Fig. 7) can be adjusted by moving the top leg up or down instead of having to change dimension "S". If this is allowable, tighter tolerances are possible. ± ± INCHES From To ± .060 .080 15 % -------- -------- .080 .125 10% -------- -------- .125 .250 10% -------- .015 .250 .500 .025 .030 .015 .025 .035 .020 .500 1.0 1.0 2.0 .030 .045 .020 2.0 3.0 .040 .050 -------- 3.0 4.0 .045 .060 -------- NOTE: The nominal tolerances are design tolerances. Once a part has been developed, the running tolerances can usually be tighter than the design tolerances. Running tolerances normally must be ± the actual measurements obtained for development samples. Dimensions "A" + "B" +"C" +"D" are multiple spaces that control the width "W". The greater the number of spaces, the more difficult it is to control the "W" dimension and to hold all the individual spaces within spec. WIDER TOLERANCES ARE REQUIRED for the spaces as well as the width. S 0" S 0" S SINGLE SPACES A G 0" G B 1" C 1" 0" 1"D W 3" GAPS FIG. 5: SINGLE SPACES & GAPS FIG.6 7: MULTIPLESPACES SPACES FIG : MULTIPLE 4 EXAMPLE OF AN ADJUSTABLE GAP 0"S 0" G 0"G 0"G If the part is designed with the space "S" slightly greater than the gap "G", the top leg can be moved up or down slightly to adjust the gap dimension while running the part. MINIMUM GAP SIZE Do not specify gaps less than .060" as a jig must be placed inside of gap to support the legs. The wider the leg, the larger the gap should be as thicker jigs must be used for deeper gaps. 1/8 APPROX 0" GAPS FOR THIN INSERTS If paper or thin flexible inserts are used, set the gap at .060" and add a small thin bead as shown. .030" APPROX. 0" 0"G CONTROL OF OVERLAP During development, if this leg is running short and the width of the slot is running toward the max., standard SPC practice is to lengthen this leg to insure sufficient overlap of the insert. If a minimum overlap is required, this should be specified. INFORMATION ABOUT INSERT & REQUIRED FIT Specify the width, thickness and material of the insert and indicate how it is to be inserted into the slot such as: • Insert slides in from the end, • Insert flexes and is inserted from the front, • Insert must slide up into the top gap and then drop into the bottom gap. The bottom leg can normally be shorter. 0" 0" GAP PROBLEMS WITH DEPTH & FLATNESS 0" DEPTH LEG HEIGHT TOP GAP 0" 0" BOTTOM GAP This design makes it difficult to control the depth as the several leg heights won't be the same. This also makes it difficult to get flat bottom and top surfaces. STACKED GAPS CAUSE PROBLEMS This is an example of "Stacked Gaps". It is difficult to adjust the gap size, as whatever is done to the top gap usually affects the bottom gap. Larger tolerances may be required, especially if there are a series of gaps as shown. Changes in the adjacent gaps makes it difficult to control the gap dimension. FIG. 7: GAP DESIGN 5 TABLE 4: ANGLE DESIGN TOLERANCES DIMENSION LENGTH OF SHORT LEG INCHES NOMINAL DESIGN TOLERANCES FOR THE FOLLOWING TYPES OF DIMENSIONS (SEE ILLUSTRATIONS BELOW) NORMAL TOLERANCES TIGHT TOLERANCES See FIG 8:ANGLE TOLERANCES below and FIG. Tight tolerances should only be used for simple 9: PROBLEMS IN MEASURING ANGLES on the shapes such as angles and channels. See FIG 8:ANGLE TOLERANCES below and FIG. 9: next page. PROBLEMS IN MEASURING ANGLES on the next page. ± ± .25 5° 4° .50 4° 3° .75 3° 2° 1.0 2° 1.5° 1.5 2° 1.5° 2.0 1.5° 1° 3.0 & Up 1° .75° 4" 3" 2" 1"1" 0" X LINEAR DISPLACEMENT OF SHORT LEG DUE TO CHANGE IN ANGLE "A" 45° A SPECIFIED ANGLE Angles for plastic extrusions are normally controlled by forming plates and jigs as the part is being run. It is usually difficult to move a leg only a few thousandths in order to correct for the linear displacement "X" shown in the illustration. The legs also move laterally and vertically a small amount due to the extruder surging or due to air drafts as the part is being formed. When legs are short, a small linear displacement changes the angle significantly. This is why the angular tolerance (in degrees) that can be held increases as the length of the short leg decreases. For a 1° change in an angle, the linear displacement for a 1" long leg is only .017". This jumps to .070" for a 4" long leg. FIG. 8: ANGLE TOLERANCES 6 This is a drawing of a part. All the legs are perfectly straight and it is easy to measure the angles. The legs on plastic extrusions are not perfectly straight but are usually curved slightly as shown below. Note the difference in the measurement at "A" compared to that at "B". For all practical purposes, the angle between the legs is at 120° and the measurement at "A" is correct. Sometimes it is better to use linear measurements as shown below to control angles. A B 120° 120° 60° 113° 60° 1" 1" 2" 2" FIG. 9: PROBLEMS IN MEASURING ANGLES 2" 2" 1" 1"1" Angles for plastic extrusions are normally controlled by forming plates and jigs as the part is TABLE 5: FABRICATION TOLERANCES being run. It is usually difficult to move a leg only a few thousandths in order to correct for the linear displacement "X" shown in the illustration. The +/- .008 HOLE SIZE legs also move laterally and vertically a small amount due to the extruder surging or due to air +/- .031 EDGE TO FIRST HOLE drafts as the part is being formed. When legs are 0" X short, a small linear displacement changes the DISPLACEMENT +/- .031 HOLE TOLINEAR HOLE LOCATION angle significantly. This is why the angular OF SHORT LEG DUE TO tolerance (inLENGTH degrees)TOLERANCE that can be held increases as VARIES W/ LAST HOLE TO EDGE CHANGE IN ANGLE "A" the length of the short leg decreases. For a 1° 45° A SPECIFIED ANGLE +/- .031in an angle, the linear displacement for a 1" NOTCH WIDTH & HEIGHT change long leg is only .017". This jumps to .070" for a 4" long leg. FIG. 8: ANGLE TOLERANCES 7 FIG. 10: DEGREES OF DIFFICULTY EASY DIFFICULT EASY DIFFICULT BEST EASY CAUSES BOW ALMOST IMPOSSIBLE DIFFICULT IMPOSSIBLE DETAILS 8 DIMENSIONING W DIMENSION NOT PARALLEL TO POINTS BEING MEASURED (OK FOR OVERAL DRAWING DIMENSION BUT DIFFICULT TO MEASURE OK A B OUTSIDE TO INSIDE DIMENSIONS (A & B) DIFFICULT TO MEASURE W DIMENSIONS FORM INTERSECTION OF GEOMETRICAL POINTS (DIMENSION OK AS REFERENCE DIMENSION BUT NOT MEASURABLE DATUM LINE DIMENSIONING (NORMALLY CAN MEASURE, BUT NOT WHAT WANT TO MEASURE) 9 FACTORS AFFECTING TOLERANCES • TOLERANCES DEPENDENT UPON COMPLEXITY OF THE PART IF MANY SEGMENTS MORE DIFFICULT TO HOLD TOLERANCES IF SIMPLE PART CLOSER TOLERANCES CAN BE HELD • CHANGING PROCESS CONDITIONS AMBIENT TEMPERATURE CHANGES IN MATERIAL FROM BATCH TO BATCH • OPERATOR DEPENDENT -- MANY MANUAL ADJUSTMENTS • DIE DESIGN GUIDELINES FOR USING TOLERANCE TABLES • TOLERANCES ARE NOMINAL • BEST TO USE DIMENSIONS THAT CAN BE MEASURED DIRECTLY • START WITH DIMENSIONS AFFECTING FIT WITH MATING PARTS • TRY TO LIMIT NUMBER OF DIMENSIONS WITH TOLERANCES • USE REFERENCE DIMENSIONS WHERE POSSIBLE SPC DEFINITION OF REFERENCE DIMENSION REFERENCE DIMENSIONS USED IN DIE DESIGN REFERENCE DIMENSION CHECKED DURING DEVELOPMENT THICKNESS • NORMALLY SPECIFY NOMINAL THICKNESS EXPECT THICKNESS VARIATIONS • NOMINALLY -- TO .090" ± 10%, OVER .090" ± 8% • WHERE REQUIRED -- SPECIFY MIN OR MAX FOR PARTICULAR AREA RADII • NORMALLY NOT TRUE RADII --DIFFICULT TO MEASURE DIRECTLY • USE RADIUS GAUGES WHEN NEED TO MEASURE • WHEN TOLERANCES REQUIRED SEE TABLE 2 (SINGLE SEGMENT) LENGTH • NORMALLY ± 1/16" • FACTORS AFFECTING LENGTH CONTROL LENGTH, LINE SPEED CHANGE IN LENGTH DUE TO TEMPERATURE --SPC TO DESTINATION 10