Ge n-MOSFETs on Lightly Doped Substrates With High

advertisement

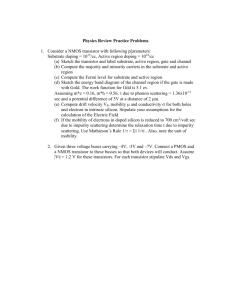

IEEE ELECTRON DEVICE LETTERS, VOL. 27, NO. 3, MARCH 2006 175 Ge n-MOSFETs on Lightly Doped Substrates With High- Dielectric and TaN Gate W. P. Bai, N. Lu, A. Ritenour, M. L. Lee, D. A. Antoniadis, Fellow, IEEE, and D.-L. Kwong, Senior Member, IEEE Abstract—In this letter, we report successful fabrication of Germanium n-MOSFETs on lightly doped Ge substrates with a and thin HfO2 dielectric (equivalent oxide thickness TaN gate electrode. The highest peak mobility (330 cm2 /V s) and saturated drive current (130 A/sq at – V) have been demonstrated for n-channel bulk Ge MOSFETs with an ultrathin dielectric. As compared to Si control devices, 2.5 enhancement of peak mobility has been achieved. The poor performance of Ge n-MOSFET devices reported recently and its mechanism have been investigated. Impurity induced structural defects are believed to be responsible for the severe degradation. =15 10 8 A) Index Terms—Ammonia treatment, germanium (Ge), hafnium oxide, high- dielectric, MOSFET. I. INTRODUCTION G e has been considered as the channel material in replacement of Si for future high-speed CMOS technology since it offers much higher carrier mobility than Si. Very promising results for bulk Ge p-channel MOSFETs with both high- dielectrics [1]–[4] and GeO N dielectric [5] have been demonstrated, with 2 hole mobility enhancement. Ge-on-insulator (GOI) devices also showed excellent performance [6]–[8]. Enigmatically, bulk Ge n-channel MOSFETs exhibited very poor performance. The drive currents of n-type devices were one to two orders lower than that of their p-type counterparts [2], [9], [10], even though the fabrication processes were almost identical [2], [5], [10]. Recently, improved characteristics of bulk Ge n-MOSFETs were reported, with plasma-PH treatment or AlN surface passivation [4]. However the cause of the poor performance of n-channel devices has not been clarified yet. In this letter, we report successful fabrication of Ge n-MOSFETs cm ) substrates. The poor Ge on lightly doped ( n-MOSFETs characteristics reported before might be ascribed to the severe degradation on the channel transport caused by impurities related structural defects near Ge surface. II. EXPERIMENT MOSFETs were fabricated on (100) oriented p-type Ge subcm). Ge wafers were precleaned using strates (Ga, Manuscript received September 13, 2005; revised December 22, 2005. This work was supported by the MARCO Materials, Structures and Devices Focus Research Center. The review of this letter was arranged by Editor B. Yu. W. P. Bai, N. Lu, and D.-L. Kwong are with the Microelectronics Research Center, Department of Electrical and Computer Engineering, University of Texas at Austin, Austin, TX 78758 USA (e-mail: baiwp@mail.utexas.edu). A. Ritenour, M. L. Lee, and D. A. Antoniadis are with the Microsystems Technology Laboratory, Massachusetts Institute of Technology, Cambridge, MA 02139 USA. Digital Object Identifier 10.1109/LED.2006.870242 cyclic HF dip method [11]. Rapid thermal NH anneal was performed at 450 C or 550 C for 2 min to form a stable interfacial layer between the Ge substrate and the high- dielectric [11]. 5 nm HfO film was then in situ deposited at 400 C by rapid thermal chemical vapor deposition using C H HfO precursor with or without introduction of O . 1500 TaN was reactively sputtered as the top electrode layer. Ring-type transistor structures were used in order to eliminate the need of isocm As was implanted lation. After gate patterning, at 40 keV, followed by 500 C 5 min source/drain (S/D) activation in a forming gas furnace. 200-nm Al was sputtered on both the frontside and the backside of the wafers for metallization. Finally, 300 C annealing was performed in forming gas for 30 min after S/D metal pattering. In addition, Ge n-MOS capacicm and tors on highly doped Ge p-substrates ( cm ) were also fabricated. Si control devices were fabricated for comparison. To achieve effective surface nitridation, NH annealing for Si devices was carried out at 700 C for 10 sec. S/D activation annealing was performed at 900 C for 30 s. III. RESULTS AND DISCUSSION The typical characteristics of Ge n-MOSFETs are displayed – in Fig. 1. Fig. 1(a) shows drain current-gate voltage characteristics. The off-current is orders lower than , which is due to the low substrate doping the on-current level and the narrow bandgap of Ge. Well-behaved drain – characteristics are shown in current–drain voltage Fig. 1(b). Fig. 1(c) shows the split capacitance–voltage (C–V) characteristics of these devices. 10.8 equivalent oxide thickness (EOT) was extracted from the inversion C–V measurement considering the quantum effect [12]1. The capacitance increase V and on the inversion on the accumulation C–V at V is caused by the narrow bandgap of Ge C–V at and the lightly doped substrate, which make the p-n junction between S/D and channel more conducting under reverse bias. Gate leakage (I–V) characteristics [inset of Fig. 1(c)] demonV. strate extremely low leakage current of 0.64 mA/cm at The nonzero at zero is due to trapping/detrapping current and/or dielectric relaxation current [13]. The dependence of the and at V on the channel peak transconductance length (L) of these devices is shown in Fig. 2(a). In linear region, , where is the total resistance, is the S/D series resistance, is the measured drain W is the channel width, 1CV simulation program available online at: http://www.device.eecs. berkeley.edu/qmcv/ 0741-3106/$20.00 © 2006 IEEE 176 IEEE ELECTRON DEVICE LETTERS, VOL. 27, NO. 3, MARCH 2006 Fig. 2. (a) Dependence of peak transconductance (left y axis) and drive current at V = 2 V (right y axis) on MOSFET channel length. The peak G and I data were obtained from the I –V plots. Due to the degradation of drive current resulted from S/D series resistance, 30% correction at low field and 53% correction at high field were made in calculation of mobility by using I –V data of L = 20 m devices. (b) Extracted electron mobility as a function of effective electrical field for Si control n-MOSFETs ( ) and bulk Ge with different surface treatment and HfO deposition: 550 C NH + HfO without O ; 550 CNH + HfO with O ; 450 C NH + HfO without O . } Fig. 1. (a) I –V , (b) I –V , and (c) split C–V characteristics for Ge n-MOSFET devices on lightly doped substrates with 550 C NH surface treatment and non-O HfO deposition. Inset of (c): I–V characteristics for these Ge n-MOSFETs. current, and is the ideal (non- ) drain current per square. The intercepts on y axis of Fig. 2(a) indicate significant , which is possibly caused by insufficient implantation dose and/or poor ion activation at 500 C. To accurately calculate the electron mobility was extracted . The by data and the mobility was extracted by using integrated inversion charge (obtained from split C–V measurements). Electron mobility as a function of the effective field is shown in Fig. 2(b). Compared to Si control devices, 2.5 enhancement of peak mobility (330 cm /V s) is achieved for Ge n-MOSFETs. Considering the 2 higher intrinsic electron 1 o mobility in bulk Ge than in Si, this higher enhancement of the channel mobility implies that nitrogen incorporation into the interface of Ge devices brings less channel scattering and mobility degradation than that for Si devices. Different surface treatments and dielectric deposition methods have led to different device performance on channel transport, as shown in Fig. 2(b). The devices treated with higher temperature (550 C) NH annealing and non-O HfO deposition exhibit the highest mobility (330 cm /V s). Deposition of HfO with the introduction of O degrades the channel transport characteristics with a peak mobility of 283 cm /V s. Devices with 450 C NH treatment show the worst peak mobility of 230 cm /V s. NH treatment at higher temperature and non-O dielectric deposition can form a more stable interlayer with more nitrogen and less oxygen incorporated [14], [15]. This helps to prevent the formation of poor quality GeO interlayer [16], [17] and results in better channel transport characteristics. In Table I we summarize the recent published data for bulk Ge n-MOSFETs and p-MOSFETs, respectively [1]–[5], [9], [10]. One noticeable fact is that the doping level of the substrate used BAI et al.: Ge n-MOSFETs ON LIGHTLY DOPED SUBSTRATES WITH HIGH- DIELECTRIC AND TaN GATE SUMMARY WORK; DATA; I 177 TABLE I (a) BULK Ge p-MOSFET RESULTS AND (b) BULK Ge n-MOSFET RESULTS PUBLISHED RECENTLY. NOTE: # REPRESENTS THIS N IN [9] WAS ESTIMATED FROM THE MINIMUM CAPACITANCE IN C–V MEASUREMENTS; EOT IN [1], [2], [5], [10] ARE CET IN [2], [4] ARE VALUES AT V –V = 1:2 V. THE RECENT RESULTS OF GOI DEVICES ARE NOT INCLUDED FOR COMPARISON BECAUSE THE SURFACE DOPING LEVELS OF GOI SUBSTRATES WERE UNCLEAR OF j j for p-MOSFET fabrication is at the range from to cm . For the n-MOSFETs which exhibited poor percm . formance, the substrate doping level is above Poor dopant activation and high S/D series resistance might be one possible cause since S/D activation might need different activation conditions for different types of substrates. However, is much less than the difthe saturation drain voltage and the threshold voltage ference of the gate-source bias , as shown in – plots in [2] and [10], revealing the presence of severe channel carrier scattering instead of poor S/D contact. Whang et al. [4] reported improved characteristics of Ge n-MOSFETs. We notice that the p-substrate used in their cm . The experiment is at a doping concentration of saturated drive current of n-MOSFETs is almost the same as the p-type counterparts, indicating the degradation in n-type devices still existed. Significant improvements on both peak mobility and saturated drive current have been achieved in our experiment by using the substrate at lower doping level cm ). The substrate doping concentration seems ( to play a key role in the poor n-MOSFETs performance reported recently. The much more severe degradation of drive currents with increased substrate doping, as compared with Si devices, indicates that besides the Coulomb scattering by ionic impurities there exists some other scattering mechanism. Fig. 3 shows high-frequency C–V and I–V characteristics of Ge n-MOS capacitors fabricated on two highly doped p-subcm and cm ) with identical strates ( process conditions. Their almost identical I–V characteristics indicate the same dielectric properties on both substrates. While, devices fabricated on the substrate of cm exhibited abnormal C–V, i.e., low-frequency shape in the inversion region even at 1-MHz measurement frequency. In most semiconductors indirect recombination is the dominant Fig. 3. High-frequency (1 MHz) C–V and I–V (inset) characteristics of Ge n-MOS capacitors fabricated on p-substrates with doping concentration of 4 10 cm and 2 4 10 cm . 550 C NH surface treatment and HfO deposition with O were carried out for these devices. 2 2 recombination process [18]. The generation/recombination rate (R) is proportional to the doping concentration. Thus, the C–V measurements in the inversion region should not depend on the bulk doping level according to the high/low C–V criterion [19], for high-frequency C–V and i.e., for low-frequency C–V, where is the substrate doping concentration, is the intrinsic carrier concentration, is the minority carrier lifetime ( =1/R), and is the measurement frequency. Therefore, there must be other surface recombination processes that significantly reduce when the substrate doping level is sufficiently high. Considering the high diffusion coefficient of Ga in Ge and the self-diffusion coefficient of Ge (which is three and five orders of magnitude higher than that in Si, respectively), a possible degradation mechanism is that the highly doped Ga impurities may form diffusion-induced dislocations [20] or other structural 178 IEEE ELECTRON DEVICE LETTERS, VOL. 27, NO. 3, MARCH 2006 defects near the substrate surface. These defects in turn will enhance the atom diffusion and help to form more defects [21]. The dramatically increased defects near surface lead to severe additional scattering on the channel carriers and significantly reduce the carrier mobility. These surface defects can also act as the generation/recombination centers of minority carriers, enhancing surface recombination process and reducing the lifetime of minority carriers. Consequently minority carriers can response to small signals even at pretty high measurement frequency when the doping level is sufficiently high. IV. CONCLUSION We have demonstrated the characteristics of Ge n-MOSFETs fabricated on lightly doped substrates. Ge devices exhibited 2.5X enhancement of peak electron mobility compared to Si control devices. Less oxygen incorporation in the interfacial layer improved the channel transport characteristics. The poor performance of Ge n-MOSFETs reported recently is possibly attributed to impurity induced structural defects near substrate surface, which significantly increase the channel scattering and reduce the minority lifetime when the substrate doping level is sufficiently high. REFERENCES [1] C. O. Chui, H. Kim, D. Chi, B. B. Triplett, P. C. McIntyre, and K. C. Saraswat, “A sub-400 C germanium MOSFET technology with high- dielectric and metal gate,” in IEDM Tech. Dig., 2002, pp. 437–440. [2] A. Ritenour, S. Yu, M. L. Lee, N. Lu, W. Bai, A. Pitera, E. A. Fitzgerald, D. L. Kwong, and D. A. Antoniadis, “Epitaxial strained germanium p-MOSFETs with HfO gate dielectric and TaN gate electrode,” in IEDM Tech. Dig., 2003, pp. 433–436. [3] N. Wu, Q. Zhang, C. Zhu, D. S. H. Chan, M. F. Li, N. Balasubramanian, A. Chin, and D. L. Kwong, “Alternative surface passivation on Germanium for metal-oxide-semiconductor applications with high- gate dielectric,” Appl. Phys. Lett., vol. 85, pp. 4127–4129, 2004. [4] S. J. Whang, S. J. Lee, F. Gao, N. Wan, C. X. Zhu, J. S. Pan, L. J. Tang, and D. L. Kwong, “Germanium p- & n-MOSFETs fabricated with novel surface passivation (plasma-PH and thin AlN) and TaN/HfO gate stack,” in IEDM Tech. Dig., 2004, pp. 307–310. [5] H. L. Shang, H. Okorn-Schmidt, K. K. Chan, M. Copel, J. A. Ott, P. M. Kozlowski, S. E. Steen, S. A. Cordes, H.-S. P. Wong, E. C. Jones, and W. E. Haensch, “High mobility p-Channel germanium MOSFETs with a thin Ge oxynitride gate dielectric,” in IEDM Tech. Dig., 2002, pp. 441–444. [6] T. Tezuka, S. Nakaharai, Y. Moriyama, N. Sugiyama, and S.-I. Takagi, “Selectively-formed high mobility SiGe-on-Insulator pMOSFETs with Ge-rich strained surface channels using local condensation technique,” in VLSI Symp. Tech. Dig., 2004, pp. 198–199. [7] D. S. Yu, A. Chin, C. C. Laio, C. F. Lee, C. F. Cheng, W. J. Chen, C. Zhu, M.-F. Li, W. J. Yoo, S. P. McAlister, and D. L. Kwong, “3D GOI CMOSFETs with novel IrO (Hf) dual gates and high- dielectric on 1P6M-0.18 um-CMOS,” in IEDM Tech. Dig., 2004, pp. 181–184. [8] H. Shang, J. O. Chu, S. Bedell, E. P. Gusev, P. Jamison, Y. Zhang, J. A. Ott, M. Copel, D. Sadana, K. W. Guarini, and M. Ieong, “Selectively formed high mobility strained Ge PMOSFETs for high performance CMOS,” in IEDM Tech. Dig., 2004, pp. 157–160. [9] C. O. Chui, H. Kim, P. C. McIntyre, and K. C. Saraswat, “A germanium NMOSFET process integrating metal gate and improved hi-K dielectrics,” in IEDM Tech. Dig., 2003, pp. 437–440. [10] H. Shang, K.-L. Lee, P. Kozlowski, C. D’Emic, I. Babich, I. Babuch, E. Sikorski, M. Ieong, H.-S. P. Wong, and W. Haensch, “Self-aligned n-channel germanium MOSFETs with a thin Ge oxynitride gate dielectric and tungsten gate,” IEEE Electron Device Lett., vol. 25, no. 2, pp. 135–137, Feb. 2004. [11] W. P. Bai, N. Lu, J. Liu, A. Ramirez, D.-L. Kwong, D. Wristers, A. Ritenour, L. Lee, and D. Antoniadis, “Ge MOS characteristics with CVD HfO gate dielectrics and TaN gate electrode,” in VLSI Symp. Tech. Dig., 2003, pp. 121–122. [12] K. Yang et al., “Quantum effect in oxide thickness determination from capacitance measurement,” in VLSI Symp. Tech. Dig., 1999, pp. 77–78. [13] W. Luo, D. Sunardi, Y. Kuo, and W. Kuo, “Stress Testing and Characterization of high- Dielectric thin films,”, 2003 IRW final report. [14] E. P. Gusev, H. Shang, M. Copel, M. Gribelyuk, C. D’Emic, P. Kozlowski, and T. Zabel, “Microstructure and thermal stability of HfO gate dielectric deposited on Ge(100),” Appl. Phys. Lett., vol. 85, pp. 2334–2336, 2004. [15] S. Van Elshocht, B. Brijs, M. Caymax, T. Conard, T. Chiarella, S. De Gendt, B. De Jaeger, S. Kubicek, M. Meuris, B. Onsia, O. Richard, I. Teerlinck, J. Van Steenbergen, C. Zhao, and M. Heyns, “Deposition of HfO on Germanium and the impact of surface pretreatments,” Appl. Phys. Lett., vol. 85, pp. 3824–3826, 2004. [16] R. S. Johnson, H. Niimi, and G. Lucovsky, “New approach for the fabrication of device-quality Ge/GeO /SiO interfaces using low temperature remote plasma processing,” J. Vac. Sci. Technol., vol. A 18, pp. 1230–1233, 2000. [17] R. P. H. Chang and A. T. Fiory, “Inversion layers on germanium with low-temperature-deposited aluminum-phosphorus oxide dielectric films,” Appl. Phys. Lett., vol. 49, pp. 1534–1536, 1986. [18] B. G. Streetman and S. Banerjee, Solid State Electronic Devices. Englewood Cliffs, NJ: Prentice-Hall, 2000, p. 117. [19] E. H. Nicollian and J. R. Brews, MOS Physics and Technology. New York: Wiley, 1982. [20] B. Tuck, Introduction to Diffusion in Semiconductors. Stevenage, U.K.: Peregrinus, 1974, p. 213. [21] B. I. Boltaks, Diffusion in Semiconductors: Infosearch Ltd., 1963, ch. VI.