SP A S I.A. Cop Thi Doh Thi abs Eng Soc this prin con Abs Qua dev

advertisement

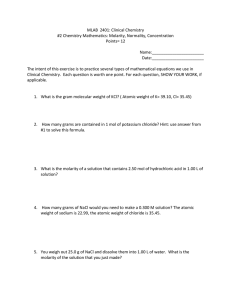

SPE 142755 AS Study of Seve eral Environmentally Frie endly Clay Stabilizers S I.A.. El-Monier, SPE, S and H.A. Nasr-El-Din, SPE, Texas s A&M Universsity Cop pyright 2011, Society of Pe etroleum Engin neers nference at M METS held in This paper was prepared for presentation at the SPE Projects and Facilities Challenges Con ha, Qatar, 13– –16 February 2011. Doh by b an SPE pro ogram comm ittee following g review of information con ntained in an p This paper was selected for presentation ntents of the paper have not been re eviewed by the Society o of Petroleum absstract submittted by the author(s). Con gineers and are a subject to o correction byy the author(s). The mate rial does not necessarily rreflect any po osition of the Eng ers, its officerrs, or memberrs. Electronic reproduction n, distribution, or storage o of any part of Socciety of Petroleum Enginee Engineers is p n consent of the t Society off Petroleum E prohibited. Pe ermission to rreproduce in thiss paper without the written nt is restricted act of not morre than 300 words; w The abstract m must contain d to an abstra illustrattions may nott be copied. T prin nspicuous ack knowledgmentt of SPE copyyright. con stract Abs Quaaternary aminee-based chemicals have been n used for maany years as cclay stabilizers. An Al/Zr-baased clay stabiilizer, A, was devveloped. It show wed great effeectiveness in mitigating m fines migration annd overcame thhe leaching efffect of HCl. In this study, Stabbilizer A was examined and its performan nce was compaared with two ccommercial cllay ones: tetram methyl ammonnium chloride andd choline chloriide. T The type of co ores (6 in. leng gth and 1.5 in. diameter) thatt were used is Berea sandstonne of 60-85 m md; mainly conntained 5 wt% kaoolinite. Variouss coreflood exp periments werre performed to o assess the e ffectiveness off each of the tthree stabilizerrs at 200 and 3000oF. Inductively y Coupled Plassma was used to t analyze the core c effluent too measure the cconcentrations of key cationss. During tetram methyl ammoniium chloride and a choline chlloride coreflooods, significannt amount of fiines were noteed in the core was noted durinng mixing of effluent samples, which means that these staabilizers were not effective. A bad odor oof ammonia w w HCl acid. Choline chlorride was effective at high conncentrations. S Stabilizer A showed good behhavior during chooline chloride with coreeflood experim ments, and prov ved to be betterr than the two commercial c staabilizers at low w concentrationns. Stabilizer A worked very welll, and no bad smell s or fines were w produced d. In addition, Stabilizer S A is an inorganic-bbased fluid, ennvironmentallyy friendly, and doees not have an ny smell; in co ontrast to quaternary amine chemicals. Unnlike previous Al-based stabbilizers (hydroxy aluminum soluutions), the new w stabilizer waas not removed d by HCl and no o decline in peermeability wass noted followiing HCl injectiion. Intrroduction Most of the amin ne-based clay stabilizers s worrk on the princciple of substiitution of catioonic species foor a sodium ioon in the clay nic species is generally g selectted such that itts hydrated vollume is less thaan that of the ssodium ion, ressulting in less lattiice. The cation sweelling when thee clay is exposed to aqueous fluids. Of the cationic speciees used, organiic quaternized amines (Himees and Vinson 19889; Patel at all. 1999) and potassium chlloride are favored. Potassiuum chloride hhas fallen out of favor duee to the high conncentration, typ pically greater than 3 wt% required for stab bilization, resul ulting in a highh level of unwaanted chloride concentration (Pattel 2009). Thee two most co ommon materiials currently in use are (2--hydroxyethyl)) trimethyl am mmonium chlooride (choline chlooride) and tetraamethyl ammonium chloride (TMAC). C Choline chloride is an ammo onium salt com mpound, (2-hyd droxyethyl) triimethyl ammonnium chloride.. It is readily bbiodegradable accoording to OEC CD-criteria. In atmosphere, ch holine chloridee will rapidly ddegrade accordding to a half life time of abbout 6.9 hours (Braaun 2004). Th he main advanttage of monocaationic aminess is the reducedd level of treaatment, typicallly 1 to 3 % ass compared to 2 [SPE 142755] inorganic salts. Most of them have limited application due to temperature stability, strong odors, toxicity or lower level of inhibition. Table 1 summarizes the chemistry, functionality, and some shortcomings of choline chloride (Patel 2009). Patel et al. (2007) showed that the main disadvantage of choline chloride is the low level of inhibition and solid tolerance. Tetramethyl ammonium chloride (TMAC) is a quaternary ammonium salt with the chemical formula [(CH3)4N]Cl. It is used as a KCl substitute temporary clay stabilizer. TMAC's main advantage over potassium chloride is the treatment rates that can be accomplished, typically the product is recommended at 3 wt%. Theoretically, TMAC is the most efficient quaternized amine. The main drawback of TMAC is its odor (Himes and Vinson 1989). However, the chemistry, functionality, and some shortcomings of TMAC are given in Tables 1 and 2, which indicate that TMAC fails in the toxicity tests (Patel 2009). Poelker (2008) introduced new chemicals denoted A4819 and A4840, He compared them with the conventional TMAC and claimed that the three stabilizers had acceptable level of mitigation, however the permeability his results showed that there was a reduction in permeability during the tap water injection. Smith et al. (2006) showed that TMAC provided temporary protection because the small cations, which were used to replace the sodium cations, are themselves quickly replaced, once flow from well is re-established. Sharma and Sharma (1994) mentioned that polymers containing quaternary ammonium salts, hydrolysable metal ions such as zirconium oxychloride, and hydroxyl aluminum have three potential disadvantages: 1) charge neutralization does not prevent mechanical particle dislodgment at high flow rates, 2) they provide temporary treatment since polyvalent ions tend to desorb over times, and 3) some chemicals used are relatively expensive. They developed a new technique, Surface Adsorption Polymerization (SAP) process, for fines stabilization using polymerizable ultra-thin films. Thomas et al. (1976) showed the effect of chemical treatment on clay migration problem using SEM techniques. They claimed that unlike hydroxyl aluminum solution, zirconium is not removed by acid and can be applied effectively in acid. On the contrary, Himes et al (1991) showed that the treatments by hydroxyl aluminum and zirconium oxychloride need to retreat after acidizing and have restriction to non carbonate containing sandstone formations (Coppell et al, 1973). They also presented a new clay treatment for low permeability sandstones. His (1984) presented an evaluation of clay control additives for matrix acidizing operations. He proved experimentally that zirconium oxychloride overall performance slightly better than other organic polymer typed additives. However, some rapid permeability loss following acid treatments was observed for cores treated by zirconium oxychloride. Haskin (1976) reviewed hydroxy aluminum treatments. From field experience, a precipitation may form if hydroxyl aluminum contacts large negatively charged organic anions. This may cause formation damage. El-Monier and Nasr-El-Din (2010) presented Stabilizer A, Al/Zr-based clay stabilizer, which is part of a new generation of metal polymers for use in various oilfield applications. It is 100% inorganic and displays very low toxicity as compared to commonly used clay stabilizers such as quaternary amine compounds. Table 3 gives the toxicological and chronic/reproductive data for stabilizer A. Coreflood studies were conducted on this chemical. It was proved that Stabilizer A is effective as a clay stabilizer, and it can work up to 300oF. HCl did not dissolve much of it, unlike the previous Al-based and Zr-based clay stabilizers such as hydroxyl aluminum and zirconium oxychloride solutions. Previous studies claimed that TMAC and choline chloride are environmentally friendly and are effective in inhibiting clay swelling in a down-hole formation for well stimulation and stabilizing clay-containing formation (Afton 1994; Shimizu 1998). Peolker et al. (2008) claimed that the effectiveness of the conventional TMAC, despite the reduction in permeability that was noticed following the stabilizer injection. Environmental issues were introduced in the previous sections, and it is obvious that there is a great confusion about these two chemicals. On the other hand, the effectiveness of these chemicals was not clear as clay stabilizers. In general, a clay stabilizer should provide equal or superior return of permeability in core flow studies as compared with effective solutions. Core flow studies were not presented in the literature for these two chemicals. Therefore, core flood studies were conducted on Berea sandstone cores to investigate the effectiveness of tetramethyl ammonium chloride and choline chloride. The performance of Stabilizer A was compared with these two commercial clay stabilizers up to 300oF. Inductively Coupled Plasma (ICP) was used to analyze the core effluent to measure the concentrations of key cations. Materials Clay stabilizer, Stabilizer A, was obtained as an aqueous solution, and its physical properties are given in Table 4. 5 wt% NaCl solutions were filtered through 1 µm filter paper. 15 wt% HCl was used in addition to 0.3 vol% corrosion inhibitor (CI). Type of cores was Berea sandstone (1.5 in. diameter, and 6.0 in. length); Table 5 gives the mineralogy of Berea sandstone as was determined using XRD technique. Each solution was prepared by mixing for 30 minutes with a magnetic stirrer. All clay stabilizer solutions were prepared in 5 wt% NaCl. A schematic diagram of the core flood setup is shown in Fig. 1. It included a core holder and three transfer vertical vessels that were connected in parallel to the core holder; the first vessel can be loaded with a maximum of 2 liter of the brine, the second can be loaded with a maximum of 2 liter of the DI water, and the third can be loaded with a maximum of 1 liter of the stabilizer or the HCl solution. Properties of the prepared solutions were measured and are given in Table 6. Injection rate was kept constant at 5 [SPE 142755] 3 cm3/min. This rate was selected because it did not cause mechanical fines migration. Berea sandstone cores were dried and saturated with 5 wt% NaCl overnight for pore volume (PV) calculations. A new core was used in each experiment. A confining pressure of 1,500 psi was applied and the back pressure was 1,000 psi. Samples of the core effluent were collected during all experiments. Instruments To evaluate the properties of Stabilizer A, tetramethyl ammonium chloride, choline chloride and their solutions, various apparatus were used. Orion 370 PerpHecT Ross Electrode was used to measure the pH. Thermo Scientific Orion 950 ROSS FAST QC™ Titrator was used to measure the concentration of HCl in the core effluent. The density was measured using DMA 35N portable density meter. Capillary viscometer (Cannon Ubbelohde viscometer, size 1) was used to determine the viscosity of Stabilizer A and acid solutions. Inductively Coupled Plasma (WinLab32 ICP software) was used to determine the concentrations of key cations in the core effluent samples. Results and Discussion Effectiveness of Clay Stabilizers at 2 wt% Concentration The general procedure for the coreflood experiments was as follows: injection of 5 wt% NaCl to measure the initial core permeability, then 2 PV of the stabilizer solution. At the end, DI water was injected. El-Monier and Nasr-El-Din (2010) optimized the concentration of Stabilizer A and showed the great effect of 2 wt% Stabilizer A on mitigating fines migration as shown in Fig. 2, where no increase in the pressure drop across the core was noted during the DI water injection up to 300oF. They also tested the effect of 15 wt% HCl on the performance of this stabilizer, and it worked very well, and the leaching effect was not significant. Core effluent samples were collected and showed no Al and Zr through the analysis of the Inductively Coupled Plasma (ICP). They proved that Stabilizer A was effective due to the presence of trivalent cation Al+3 and tetravalent cation Zr+4, which reduced Debye’s length, increased the electrostatic attraction force in the electric double layer between ions, and shielded the negative charge of clays (Masliyah and Bhattacharjee 2006). In aqueous solutions, Zr salts hydrolyze to form polynuclear ions that perform as ions of much higher charges. Because of the high positive charge, the zirconium polynuclear ion is probably several million times stronger as a clay stabilizer than the conventional calcium and potassium salts (Veley 1969). Therefore, injecting low salinity fluids after the stabilizer solution will not induce fines migration, and will not affect the electrical charge of naturally occurring clay platelets in the formation. Coreflood experiments of 2 wt% TMAC were investigated at 200 and 300oF, it followed the same procedure as that used with Stabilizer A, at 200oF, Fig. 3 shows that there was an increase in the pressure drop across the core during fresh water injection. Fines in the core effluent samples were also noted, which indicate fines migration problems. TMAC induced fines migration and was not effective. This might be because TMAC used as a KCl substitute temporary clay stabilizer, which means that they are themselves quickly replaced once flow from the well is re-established. Similar results were obtained at 300oF. These results indicate that this stabilizer is not effective at 2 wt% and temperatures of 200 and 300oF/ At 200oF as shown in Fig. 4, there was an increase in the pressure drop across the core during the DI water injection and fines were noticed in the core effluent samples. This means that the permeability of the core declined. This is because choline chloride is a monocationic clay stabilizer, which acts as a temporary clay stabilizer and can be easily removed once the flow of DI water is resumed, and it has low level of inhibition. It was also noticed that soaking the core for one hour and resuming the flow made the pressure drop to increase, which indicates that more damage can be created after shutting the experiment for a short period. Although the claims of previous work for its effectiveness, 2 wt% choline chloride was not effective and induced fines migration problems. Effectiveness of Clay Stabilizers at 4 wt% Concentration 2 wt% of choline chloride and TMAC did not show good potential for mitigating fines problems. These chemicals were tested again at higher concentration of 4 wt% at 200oF to make sure from their ability to stabilize the fines in the core. The same procedure was followed, and the results were obtained as shown in Figs. 5 and 6 for 4 wt% TMAC and 4 wt% choline chloride, respectively. It can be concluded that TMAC still introduces damage to the formation, where fines were noted in the core effluent and the pressure drop across the core was increased. In case of 4 wt% choline chloride, fines problems were mitigated and no increase in the pressure was created. This means that 4 wt% choline chloride was effective and enough to prevent fines migration. Effect of HCl Acid More tests were conducted to investigate the effect of HCl on the stabilizers under study. After treating the cores with 2 wt% of the clay stabilizers at 200 and 300oF, the stabilizer was left for 1 hour for soaking inside the core holder for each experiment separately, then injection of DI water was resumed to make sure that the stabilizer was still working and to obtain stabilization in the pressure drop. 15 wt% HCl plus 0.3 vol% CI was injected after DI water injection and followed again by DI water injection to 4 [SPE 142755] examine the leaching effect of HCl on the three clay stabilizers at 200 and 300oF. Figs. 7 through 11 showed the results of these experiments. During the injection of HCl with the cores that were treated by the stabilizers, the same fluctuation in the pressure drop across the cores was noticed. After HCl injection, the pressure drop decreased due to the injection of DI water, and the permeability enhanced as given in Table 7. Hence, Stabilizer A was still effective even after HCl injection as the pressure drop did not increase due to the enhancement that was introduced by HCl by the dissolution of minerals. Samples were collected and core effluent analysis will be presented later. An enhancement was noticed also in the cases of choline chloride and TMAC due to HCl stimulation. The increase in pressure during HCl injection was due to the release of CO2. Berea cores contain carbonate minerals, which were dissolved by HCl, and released CO2. Solubility of CO2 decreased as the concentration of CaCl2 increased in water. That increase in the pressure drop diminished during the injection of DI water. Analysis of Core Effluent Samples of the core effluent were collected during each experiment, and Al, Zr, Fe, Ca, and Mg were analyzed. Inductively Coupled Plasma (ICP) was used to measure the concentrations of the different cations. During Stabilizer A, TMAC, and choline chloride injection, the concentrations of Al, Zr, total Fe, Ca, and Mg were zero in the core effluent. This indicates that during the stabilizer injection up to 300oF, Stabilizer A worked very well and attached to the grain surfaces where no Al or Zr was observed in the core effluent samples during its injection. No Al or Zr was present originally in TMAC and choline chloride clay stabilizers, and no Al was leached from the core. Figs. 12 through 19 show the elemental analysis of these coreflood experiments during HCl injection at 200oF. It can be shown that during the corefloods at 200oF, Al was noticed in the core effluent samples during HCl injection. This means that HCl leached a considerable amount of Al, which could be due to the Al contained in the stabilizer itself, or the Al minerals in clays and feldspars. During the HCl injection period in TMAC and choline chloride, a considerable amount of Al was leached by HCl, and this is because of the Al minerals in clays and feldspars. Al had higher values in case of Stabilizer A during HCl injection because of the Al contained originally in the stabilizer. High amounts of total Fe, Ca, and Mg were noticed during HCl injection in the three cases of clay stabilizers because of the dissolution effect of iron containing minerals, and carbonate minerals from calcite and dolomite. No Zr was noticed up to 300oF in the core effluent samples. At high concentration, 4 wt% of TMAC and choline chloride, it can be seen that the amount of Al cations was much less than the concentration at 2 wt%. Applying material balance on the Al coming out in the core effluent, the following results were obtained and presented in Table 8: at 200oF, the amount of Al in the core effluent of 2 wt% Stabilizer A experiment was due to the Al contained in the stabilizer itself and in the core minerals, and it equals 130 mg. The amount of Al in the core effluent of the 2 wt% TMAC experiment equals 64 mg, which was due to the Al in the core minerals only. This means that the Al remained in the core due to stabilizer A itself was 56 wt%. At 300oF, the amount of Al remained inside the core due to Stabilizer A was 78 wt%. This confirms that HCl could not remove much of the Al contained in Stabilizer A. Besides, no Zr was noticed in the core effluent, which confirms that no Zr was leached by HCl. The amount of Al in the core effluent of the 2 wt% choline chloride experiment equals 10.8 mg, which was due to the Al in the core minerals only. This means that the Al remained in the core due to stabilizer A itself based on the choline chloride experiment at 200oF was 20 wt%. Again, no Zr was noticed in the core effluent. It was also noticed that the concentrations of the different cations that were leached by HCl in case of choline chloride is much less than the other two clay stabilizers, but still higher concentration of choline chloride is required to stabilizer the clays in the cores. Conclusions Three environmentally friendly clay stabilizers were examined in the present study. The effect of 15 wt% acid on the treated cores was also studied. Based on the results obtained, the following conclusions can be drawn: 1. Stabilizer A worked very well up to 300oF and no fines were observed in the core effluent. 2. TMAC was not effective where fines were induced after injecting DI water. 3. Choline chloride was not effective at 2 wt%, however it worked very well at higher concentrations. 4. Zr was not leached by HCl after Stabilizer A injection. 5. HCl leached Al from the treated cores however, no decline in permeability was noted. Nomenclature LC50 (50% lethal concentration) = LD50 = NOEC (no observed effect concentration) = The concentration of a chemical in air or of a chemical in water which causes the death of 50% of a group of test animals The amount of a chemical, given all at once, which causes the death of 50% of a group of test animals. The test concentration immediately below the lowest tested concentration with statistically significant adverse effect. [SPE 142755] 5 IC25 = Chronic LOEC (Lowest Observed Effect Concentration) Chronic MATC (maximum acceptable toxicant concentrations) = = IC stands for inhibition concentration. The IC25 is also a calculated percentage of effluent. It is the level at which the organisms exhibit 25 percent reduction in a biological measurement such as reproduction or growth. It is calculated statistically and used in chronic toxicity testing. The upper end of MATC range is represented by the lowest test concentration that has statistically significant effect. The MATC is an estimated toxic threshold concentration falling between the highest concentration showing no effect and the next highest concentration showing a toxic effect when compared to the controls References Afton, C.W. and Gabel, R.K. 1994. Clay Stabilizers. US Patent No. 5,342,530. Braun, C. 2004. Experimental SIDS Initial Assessment Report for SIAM 19. Berlin, Germany, 19-22 October. UNEP Publication. El-Monier, I.A., and Nasr-El-Din, H.A. 2010. A New Environmentally Friendly Clay Stabilizer. Paper SPE 136061 presented at the SPE Production and Operations Conference and Exhibition held in Tunis, Tunisia, 8–10 June. Haskin, C.A. 1976. A Review of Hydroxy-Aluminum Treatments. Paper SPE 5692 presented at the SPE International of AIME Symposium on Formation Damage Control held in Houston, Texas, 29-30 January. Himes, R.E. and Vinson, E.F. 1989. Fluid additives and Method for Treatment of Subterranean Formations. U.S. Patent No. 4,842,073. Himes, R.E., Vinson, E.F., and Simon, D.E. 1991. Clay Stabilization in Low-Permeability Formations. SPE Prod Eng, 6 (3): 252258. His, C.D. 1984. Evaluation of Clay Control Additives for Matrix Acidizing. Paper SPE 13086 presented at the SPE Annual Technical Conference and Exhibition held in Houston, Texas, 16-19 September. Masliyah, J.H, and Bhattacharjee, S. 2006. Electrokinetic and Colloid Transport Phenomena. New Jersey. A John Wiley & Sons, Inc. Patel, A.D. 2009. Design and Development of Quaternary Amine Compounds: Shale Inhibition with Improved Environmental Profile. Paper SPE 121737 presented at the SPE International Symposium on Oilfield Chemistry held in The Woodlands, Texas, 20-22 April. Patel, A.D., Stamatakis, E., Young, S, and Friedheim, J. 2007. Advances in inhibitive Water-Based Drilling Fluids-Can They Replace Oil-Based Muds? Paper SPE 106476 presented at the SPE International Symposium on Oilfield Chemistry held in Houston, Texas, 28 February-2 March. Patel, A., Thaemlitz, C.J., McLaurine, H.C. and Stamatakis, E. 1999. Drilling Fluid Additives and Method for Inhibiting Hydration. U.S. Patent No. 5,908,814. Poelker, D.J. 2008. Drilling Polyamine Salts As Clay Stabilizing Agents. U.S. Patent No. 2008/0108523 A1. Shimizu, S. 1998. Method of manufacturing tetramethyl ammonium hydroxide. US Patent No. 4572769. Sharma, B.G., and Sharma, M.M. 1994. Polymerizable Ultra-Thin Films: A New Technique for Fines Stabilization. Paper SPE 27345 presented at the SPE International Symposium on Formation Damage Control held in Lafayette, Louisiana, 7-10 February. Smith, C., Oswald, D., and Daffin, M.D. 2006. Clay Control Additive for Wellbore Fluids. US Patent No. 2006/0289164 A1. Thomas,R.L., Crowe, C.W., and Simpson, B.E. 1976. Effect of Chemical Treatment upon Formation Clays is Revealed by improved SEM Techniques. Paper SPE 6007 presented at the SPE Annual Fall Technical Conference and Exhibition held in New Orleans, Louisiana, 3-6 October. Veley, C.D., 1969. How Hydrolyzable Metal Ions React with Clays to Control Formation Water Sensitivity. JPT, 21 (9): 11111118. 6 [SPE 142755] Ta able 1─Monoccationic Amin e Shale Stabillizers (Patel 20009) Structture/Compositiion Function/Limitation HS&E/Toxxicity pH and Tem mperature Marine toxiicity, Limitattions bad odoor Name N (T TMAC) Cholin ne Chloride C Compatibility w with additives lim mitation in shaale inhibition, ammoniaa odor Material TMA AC Choline Ch hloride Material TMA AC Biodegradaable, non-toxicc to marinee Table 2─To oxicity of Catiionic Amines ( Patel 2009) Co oncentration L LC50 7 lb b/bbl in GM#7 <110,000 >500,0000 ppm SPP Conccentration Microotox 2% 0.900% Table 3─ ─ Toxicological Data of Sta abilizer A (El-M Monier and N Nasr-El-Din 20010) Acute A Data Rat LD50, mg/kg m Fathead min nnow 96-hour LC L 50, mg/l Fathead min nnow acute NO OEC, mg/l 3775 825 603 Chronic/R Reproductive D Data Ceriodaphniia dubia Chron nic NOEC, mg//l Ceriodaphniia dubia Chron nic MATC, mg/l Ceriodaphniia dubia Chron nic LOEC, mg//l Ceriodaphniia dubia Chron nic IC25, mg/l 3.8 5.3 7.5 5.1 Table 4─Properties 4 of the Stabilizzers as Receivved Stabilizer A Density at 77oF, g/cm3 1.4494 pH 2..9 Viscosity at 77oF, cP 96 125,,560 Al Concentrration, ppm Zr Concentration, ppm 38,2270 bilizer TMAC Stab Density at 77oF, g/cm3 pH Viscosity at 77oF, cP Stabilizerr Choline Chlooride Density at 77oF, g/cm3 pH Viscosity at 77oF, cP 1.0018 8..9 16 1.009 7..5 19 Resultss Fail Pass Resultss Fail [SPE 142755] 7 Table 5─Minarology of Berea Sandstone Mineral Concentration, wt% Quartz 86 Kaolinite 5 Feldspar 3 Chlorite 2 Calcite 2 Dolomite 1 Illite 1 Table 6─Properties of the Solutions Used in the Core flood Experiments Brine 5 wt% NaCl: density at 77oF, g/cm3 1.033 viscosity at 77oF, cP 1.05 pH 7.7 DI water: density at 77oF, g/cm3 0.998 viscosity at 77oF, cP 0.95 pH 7.0 2 wt% Stabilizer A prepared in 5 wt% NaCl: density at 77oF, g/cm3 1.049 viscosity at 77oF, cP 1.08 pH 4.2 2 wt% Stabilizer TMAC prepared in 5 wt% NaCl: density at 77oF, g/cm3 1.032 viscosity at 77oF, cP 1.063 pH 7.3 2 wt% Stabilizer choline chloride prepared in 5 wt% NaCl: density at 77oF, g/cm3 1.034 viscosity at 77oF, cP 1.055 pH 8.0 4 wt% Stabilizer choline chloride prepared in 5 wt% NaCl: density at 77oF, g/cm3 1.035 viscosity at 77oF, cP 1.05 pH 7.2 4 wt% Stabilizer TMAC prepared in 5 wt% NaCl: density at 77oF, g/cm3 1.032 viscosity at 77oF, cP 1.03 pH 7.5 15 wt% HCl: density at 77oF, g/cm3 1.075 viscosity at 77oF, cP 1.9 pH 0 Table 7─Permeability at the End of the Coreflood Experiments at 200oF Coreflood Experiments Initial Core Final Core Permeability, md Permeability, md 2 wt% Stabilizer A test 66.7 75.9 2 wt% Stabilizer TMAC test 86 84.4 4 wt% Stabilizer TMAC test 64 62 2 wt% Stabilizer choline chloride test 81.5.4 117 4 wt% Stabilizer choline chloride test 65 96 8 [SPE 142755] Table 8─Al amount remained in the core after the experiments Coreflood Experiment Al Remained, % 56 Stabilizer A at 200oF based on TMAC 20 Stabilizer A at 200oF based on choline chloride [SPE E 142755] 9 Fig. 1─C Coreflood Settup. Pressure Drop Across the Core, psi 10 00 2 wt% % Stabilizer A in 5 wt% NaC Cl 8 80 6 60 5 wt% % NaCl DI water 4 40 2 20 0 0 5 10 15 Cumu ulative Injec cted Volum me, PV Fig. 2─Pressure drop across th he core of 2 wtt% Stabilizer A at 200oF ass a function off the cumulativve injected voolume at a flow w rate = 3 5 cm m /min. 10 [SPE 142755] Pressure Drop Across the Core, psi 100 2 wt% % Stabilzer TMAC T in n 5 wt% NaC Cl 80 DI water 5 wt% % NaCl 60 40 20 0 0 2 4 6 8 10 Cumulative Inje ected Volum me, PV Fig. 3─Pressure drop across th he core of 2 wtt% TMAC at 200oF as a fun nction of the ccumulative injjected volumee at a flow 3 ratee = 5 cm /min. Fines were noticed n in the samples s after 0.5 PV of watter injection. 150 Pressure Drop, psi 120 Soaking for 1 hr 2 wt% Choli 2 wt% Stabiine Chloride lzer TMAC in 5 wt% % NaCl % NaCl in 5 wt% 90 60 5 wt% w NaCl DI water w 30 0 0 5 10 15 20 Cumulative Injected Volume, V PV he core of 2 wtt% choline ch hloride at 200o F as a functioon of the cumu ulative injected volume at Fig. 4─Pressure drop across th 3 a flow rate = 5 cm m /min. Fines were noted in n the core efflu uent samples aafter 0.5 PV of water injectiion. [SPE E 142755] 11 250 Pressure essu e Drop, op, ps psi 200 4 wt% TMAC C prepared in 5 wt% % NaCl 150 DI water 5 wt% NaC Cl 100 50 0 0 3 6 9 1 12 15 Cumulativ ve Injected Volume, V PV Fig. 5─Pressure drop across th he core of 4 wtt% TMAC at 200oF as a fun nction of the ccumulative injjected volumee at a flow 3 ratee = 5 cm /min. Fines were noticed n in the samples s after 1 PV of waterr injection. 150 Pressure Drop, psi 120 4 wt% Ch holine Chloriide prepared in 5 wt% Na aCl 90 60 5 wt% NaC Cl DI water w 30 0 0 3 6 9 12 Cumulative Injected Volume, V PV Fig. 6─Pressure drop across th he core of 4 wtt% choline ch hloride at 200o F as a functioon of the cumu ulative injected volume at 3 a flow rate = 5 cm m /min. 12 [SPE 142755] Pressure Drop Across the Core, psi 100 15 wt% HCl 80 60 DI water 40 DI water 20 0 14 18 22 26 Cumulative Injected Volume, PV Fig. 7─Pressure drop across the core during 15 wt% HCl injection at 200oF as a function of the cumulative injected volume at a flow rate = 5 cm3/min after 2 wt% Stabilizer A treatment. Pressure Drop Across the Core, psi 100 15 wt% HCl 80 60 DI water DI water 40 20 0 14 18 22 26 Cumulative Injected Volume, PV Fig. 8─Pressure drop across the core during 15 wt% HCl injection at 200oF as a function of the cumulative injected volume at a flow rate = 5 cm3/min after 2 wt% TMAC treatment. [SPE 142755] 13 400 15 wt% HCl 350 Pressure Drop, psi 300 250 200 DI water DI water 150 100 50 0 15 20 25 30 Cumulative Injected Volume, PV Fig. 9─Pressure drop across the core during 15 wt% HCl injection at 200oF as a function of the cumulative injected volume at a flow rate = 5 cm3/min after 4 wt% TMAC treatment. 150 15 wt% HCl Pressure Drop, psi 120 90 DI water DI water 60 30 0 20 25 30 35 Cumulative Injected Volume, PV Fig. 10─Pressure drop across the core during 15 wt% HCl injection at 200oF as a function of the cumulative injected volume at a flow rate = 5 cm3/min after 2 wt% choline chloride treatment. 40 14 [SPE 142755] 150 Pressure Drop, psi 120 15 wt% HCl 90 60 DI water DI water 30 0 12 15 18 21 24 27 30 Cumulative Injected Volume, PV Fig. 11─Pressure drop across the core during 15 wt% HCl injection at 200oF as a function of the cumulative injected volume at a flow rate = 5 cm3/min after 4 wt% choline chloride treatment. 6000 TMAC in 5et% NaClNaCl at 200F TMAC 5 wt% Stabilizer in 5wt% 5 wt%NaCl NaCl Stabilizer A in 200F----choline 5 wt% NaCl choline chlordie chloride atin200F Al Concentration, ppm 5000 15 wt% HCl 4000 3000 DI water 2000 DI water 1000 0 20 21 22 23 24 25 Cumulative Injected Volume, PV Fig. 12─Al concentration in the effluent of 2 wt% Stabilizer A, TMAC and choline chloride at 200oF corefloods during HCl injection. [SPE 142755] 15 60000 Stabilizer DI water at room T TMAC in 5tmac wt%inNaCl Stabilizer A at NaCl T=200F Stabilizer A in inbrine 5 wt% Choline 5 wt%inNaCl Stabilizerchloride choline in chloride brine at T=300F Total Fe Concentration, ppm 50000 15 wt% HCl 40000 30000 20000 DI water DI water 10000 0 20 21 22 23 24 25 Cumulative Injected Volume, PV Fig. 13─Total Fe concentration in the effluent of 2 wt% Stabilizer A, TMAC and choline chloride at 200oF corefloods during HCl injection. 60000 Stabilizer in DI water at room ------T TMAC intmac 5 wt% NaCl Stabilizer at T=200F StabilizerAAininbrine 5 wt% NaCl choline chloride in 5 wt%in NaCl Stabilizer choline chloride brine at T=300F Ca Concentration, ppm 50000 15 wt% HCl 40000 30000 DI water DI water 20000 10000 0 20 22 24 26 Cumulative Injected Volume, PV Fig. 14─Ca concentration in the effluent of 2 wt% Stabilizer A, TMAC and choline chloride at 200oF corefloods during HCl injection. 16 [SPE 142755] 12000 Stabilizer in DI water at room T-------TMAC intmac 5 wt% NaCl Stabilizer at T=200F StabilizerAAininbrine 5 wt% NaCl Choline chloride in 5 wt% NaCl at T=300F Stabilizer choline chloride in brine Mg Concentration, ppm 9000 15 wt% HCl DI water DI water 6000 3000 0 20 22 24 Cumulative Injected Volume, PV Fig. 15─Mg concentration in the effluent of 2 wt% Stabilizer A, TMAC and choline chloride at 200oF corefloods during HCl injection. 1000 TMAC a--------------t 200F TMAC5et% in 5 NaCl wt% NaCl Al Concentration, ppm cholinechloride chlordie in 5 wt% NaCl choline at 200F 800 15 wt% HCl 600 400 DI water DI water 200 0 20 21 22 23 24 25 Cumulative Injected Volume, PV Fig. 16─Al concentration in the effluent of 4 wt% TMAC and choline chloride at 200oF corefloods during HCl injection. [SPE 142755] 17 60000 Stabilizer in DI water at room T TMAC intmac 5 wt% NaCl Choline chloride in 5 wt% NaClat T=300F Stabilizer choline chloride in brine Total Fe Concentration, ppm 50000 15 wt% HCl 40000 30000 DI water 20000 DI water 10000 0 20 21 22 23 24 25 Cumulative Injected Volume, PV Fig. 17─Total Fe concentration in the effluent of 4 wt% TMAC and choline chloride at 200oF corefloods during HCl injection. 60000 Stabilizer tmac DI water at room ------T TMAC in 5 wt%inNaCl choline chloride 5 wt%inNaCl Stabilizer choline in chloride brine at T=300F Ca Concentration, ppm 50000 40000 30000 DI water 15 wt% HCl DI water 20000 10000 0 20 22 24 Cumulative Injected Volume, PV Fig. 18─Ca concentration in the effluent of 4 wt% TMAC and choline chloride at 200oF corefloods during HCl injection. 18 [SPE 142755] 12000 oF T-------Stabilizer in DI water at room TMAC in tmac 5 wt% NaCl at 200 o Choline chloride in 5 wt% atT=300F 200 F Stabilizer choline chloride in NaCl brine at Mg Concentration, ppm 9000 DI water 15 wt% HCl DI water 6000 3000 0 20 22 24 Cumulative Injected Volume, PV Fig. 19─Mg concentration in the effluent of 4 wt% TMAC and choline chloride at 200oF corefloods during HCl injection.