Rebar Splicing: Development Length for High Strength Concrete

advertisement

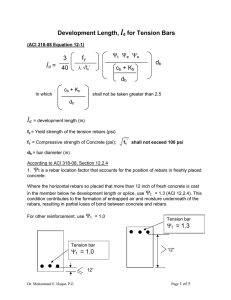

REBAR SPLICING SOLUTIONS ENGINEERING BULLETIN #8 SEPTEMBER 2015 Determining the Proper Development Length for Lap Splicing High Strength Concrete Reinforcement Developing the proper lap length of concrete-embedded rebar is crucial for obtaining the rebar’s full tensile capacity. If the overlap distance is less than the defined development length (i.e. the minimum lap length required), the bar will pull out of the concrete. According to ACI 318, the development length is based on the attainable average bond stress over the length of embedment of the reinforcement. The development length is a function of the steel bar yield stress, the concrete compressive strength, the distance between the bar and the edge of the concrete (“clear cover”), and the bar diameter. The process for determining the development length of ASTM A1035/A1035M Grade 100 rebar is consistent with conventional reinforcing steel grades with slight changes to the applicable equations. In 2010, the American Concrete Institute (ACI) published the ITG-6R-10 “Design Guide for the Use of ASTM A1035/A1035M Grade 100 Steel Bars for Structural Concrete,” which guides engineers to safely design structures using ASTM A1035/A1035M up to a yield strength of 100 ksi. The ACI ITG-6R-10 slightly modified the equations in ACI 408R-03 “Bond and Development of Straight Reinforcing Bars in Tension” for both confined and unconfined ASTM A1035/A1035M Grade 100 rebar. The modified equations for the development length per ACI ITG-6R-10 are shown below: ACI ITG-6 Equation (10-1) ACI ITG-6 Equation (10-5) Where: ld = fy = f’c = φ = ω = α = βc = λ = db = cb = Κtr = development length (also splice length), (inches) yield strength of bar (psi) specified concrete compressive strength (psi) strength reduction factor (0.80) factor reflecting benefit of large cover/spacing perpendicular to controlling cover/spacing ≤ 1.25 bar location factor (1.3 for top reinforcement and 1.0 for all other locations) coating factor (1.5 for coated bars and 1.0 for uncoated bars) lightweight aggregate factor (1.3 for lightweight aggregate and 1.0 for normal weight aggregate) diameter of bar (inches) spacing or cover dimension for spliced reinforcing bar transverse reinforcement index The table below shows the calculated development length of ASTM A1035/A1035M steel reinforcing bars based on the formula above for bars #3 through #11 and a range of concrete compressive strengths (3,000 psi to 12,000 psi). Development Length* (inches) Concrete Compressive Strength (psi) Bar Size 3,000 4,000 5,000 6,000 7,000 8,000 9,000 10,000 11,000 12,000 3 17.8 16.4 15.3 14.5 13.8 13.3 12.8 12.4 12.0 11.7 4 23.7 21.8 20.4 19.3 18.5 17.7 17.1 16.5 16.1 15.6 5 29.7 27.3 25.5 24.2 23.1 22.2 21.4 20.7 20.1 19.5 6 35.6 32.7 30.6 29.0 27.7 26.6 25.6 24.8 24.1 23.5 7 42.3 38.9 36.4 34.5 32.9 31.6 30.5 29.5 28.6 27.9 8 54.3 49.9 46.7 44.2 42.2 40.5 39.1 37.8 36.7 35.7 9 67.8 62.3 58.3 55.2 52.7 50.6 48.8 47.3 45.9 44.7 10 84.3 77.4 72.5 68.6 65.5 62.9 60.7 58.7 57.0 55.5 11 101.9 93.7 87.7 83.0 79.2 76.1 73.4 71.0 69.0 67.1 Where: fy = 100,000 psi f’c = 3,000 to 12,000 psi φ =0.80 α =1.0 βc =1.0 λ =1.0 c = 2 inches ω =1.0 Κtr = 1.0 (for simplification) *The table calculations are based on a specific design example for illustrative purposes. The design engineer is responsible for applying the development length formula to the given design per ACI ITG-6R-10. MMFX STEEL CORPORATION 2415 Campus Drive, Suite 100, Irvine, CA 92612 • Phone (949) 476-7600 Toll Free: (866) 466-7878 • www.mmfx.com FINAL_20150911f ¯ REBAR SPLICING SOLUTIONS ENGINEERING BULLETIN #8 SEPTEMBER 2015 Mechanical Couplers Made for Use with the ChromX ASTM A1035/A1035M Grade 100 Steel Reinforcing Bars Various types and styles of couplers specified by the structural design engineer are available from the coupler manufacturers below. Please contact the couplers suppliers for details and pricing. APPLICATIONS Couplers Grade 60 - 80 Designs Manufacturers Grade 100 Designs Type 1 Type 2 Type 1 Type 2(4) 125 percent of specified yield strength 150 percent of specified yield strength 125 percent of specified yield strength Actual Tensile strength (1) (2) (3) Barsplice5 www.barsplice.com Grip-Twist® ‘XT’ Zap Screwlok® ‘FXT’ BPI® 100KSI Barsplicer Zap Screwlok® ‘XT’ Grip-Twist® Bargrip® XL BPI® 100KSI Barsplicer #4 through #18 #4 through #18 #4 through #18 #4 through #18 #4 through #18 #4 through #18 #4 through #18 #4 through #18 #4 through #18 #4 through #18 #4 through #18 #4 through #18 #4 through #11 #4 through #11 #4 through #11 #4 through #11 5 Dextra www.dextragroup.com Standard Coupler #4 through #18 #4 through #18 #4 through #18 Small Anchor Plate #4 through #18 #4 through #18 #4 through #18 Large Anchor Plate #4 through #18 #4 through #18 #4 through #18 Erico5 www.erico.com Lenton® Standard #3 through #18 #3 through #18 #3 through #18 Lenton® Lock #3 through #18 #3 through #18 #3 through #18 Williams Form5 www.williamsform.com Stop-Type Couplers #6 through #14 #6 through #14 #6 through #14 HRC5 www.hrc-usa.com 100 Series T-Headed 400 Series Couplers #5 through #18 #4 through #18 #5 through #18 #4 through #18 #5 through #18 #4 through #18 #4 through #18 #4 through #18 #4 through #18 #3 through #18 #3 through #18 #6 through #14 #5 through #18 #4 through #18 (1) Type 1 mechanical couplers for Grade 60-80 designs are full mechanical splice connections that shall develop in tension or compression, as required, at least 125 percent of specified yield strength of the spliced bar as per ACI 318. (2) Type 2 mechanical couplers for Grade 60-80 designs are full mechanical splice connections that shall meet Type 1 requirements and develop in tension or compression, as required, at least 150 percent of specified yield strength, which equates to the specified tensile strength of the spliced bar as per ACI 318. (3) Type 1 mechanical couplers for Grade 100 designs are full mechanical splice connections that shall develop in tension or compression, as required, at least 125 percent of specified yield strength of the spliced bar as per ACI 318 and ACI ITG-6. (4) Type 2 mechanical couplers for Grade 100 designs are full mechanical connections that shall meet Type 1 requirements and develop in tension or compression, as required, the actual tensile strength of the spliced bar as per ACI ITG-6 and ICC-ES AC429. (5) Couplers made from MMFX materials are available through these coupler suppliers in select sizes and styles. MMFX STEEL CORPORATION 2415 Campus Drive, Suite 100, Irvine, CA 92612 • Phone (949) 476-7600 Toll Free: (866) 466-7878 • www.mmfx.com