SOW QUMBU SUBSTATION 132kV FEEDER BAY

advertisement

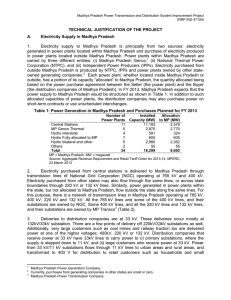

August 2015 QUMBU SUBSTATION SCOPE FOR 132kV FEEDER BAYS Scope of Works 1.1 LOCATION OF SITE Qumbu substation is an existing 132/22kV substation located approximately 60km from Umthatha, G.P.S Long 28° 53' 9.3" Lat-31° 10' 46.4" 1.2 PHASING OF THE PROJECT The aim of the project is to reposition the existing Ugie 132kV feeder, construct a double busbar and add a new Amacwera 132kV feeder. A more integrated outage plan must be developed taking into account if the use of live team where possible in consultation with all construction parties as well as taking the network constraints into account. 1.3 YARD WORKS 1.3.1 BENCH MARK Create a benchmark on site in the position suited to the construction of the 132kV feeder bay. ELECTRICAL PHASING Electrical phasing of Feeders, Busbar 2 &3 is to be done as per D-EC-855-11-01A 132KV BUSBAR 1 The existing 132kV tubular busbar is to be modified as shown in D-EC-855-11-07 rev 6 132KV BUSBAR 2 & 3 Establish a double busbar using a tubular support busbar construction as shown on D-EC-855-1107&08 rev 6. 132KV BUSBAR 2 & 3 VOLTAGE TRANSFORMER Install a voltage transformer on red phase per busbar on the 132kV busbar as detailed on D-EC-855-1107 rev 6. UGIE 1 132KV FEEDER The existing Ugie 132kV feeder bay is to be repositioned as shown in D-EC-855-11-07 rev 6. All equipment in this bay is new. The current transformers will be re-used in a new position with new supports as indicated, the jumpers and clamps are to be installed and connected as shown on D-EC-85511-08 rev 6. AMACWERA 1 132KV FEEDER Establish a 132kV feeder bay as detailed on D-EC-885-11-07 rev 6. After the line termination has been completed to the beam, the jumpers can be installed and connected as shown D-EC-855-11-08 rev 6. KERBING Install stone kerbing as indicated on D-EC-855-11-11 rev 6. Allow 10mm gaps (ungrouted) every 3m between kerbing for water seepage. LIGHTNING PROTECTION Install 1 x 21m lighting masts and for the direction of floodlights is indicated on D-EC-855-11- 07 rev 6. Each mast must be fitted with a surge arrestor which is not indicated on the wiring diagram. Install earth wire between the earth wire peaks on the columns as well as lightning spikes as indicated on DEC-855-11-06 & 07 rev 6. 1.3.2 1.3.3 1.3.4 1.3.5 1.3.6 1.3.7 1.3.8 1.3.9 1.3.10 EARTHING All steelwork is to be earthed to the foundation HD bolts inclusive of the columns. The 132kV Voltage Transformers, 132kV Current Transformers to earthed in accordance with the Project Specification and Earthing Standard. Install portable earthing balls on the equipment steelwork supports as detailed on DEC-855-11-04 rev 6 and positions are to be confirmed by the Technical Services Officer for Qumbu Technical Services Centre. The new section of the main earthmat is to be installed at a depth and position indicated on D-EC-855-11-04 rev 6. 2 1.3.11 YARD STONING Stock pile yard stone on the area where work is to be carried out and re-spread when all work has been done as indicated on D-EC-855-11-11 rev 6 (Project Specifications). Supply and install yard stone in the new section when all work has been done as indicated on D-EC-855-11-11 rev 6 (Project Specification). 1.3.12 TRENCHING Extend the existing trenches by installing new 750mm wide trenches with covers as shown on D-EC855-11-11 rev 6. 1.3.13 FENCING The existing palisade fence is to be modified with the installation of new palisade security fencing as shown in D-EC-885-11-11 rev 6. 1.3.14 WEED KILLER Spray weed killer in the substation on all the stoned and paved areas once all the stoning and paving has been completed (Project Specification). 1.3.15 LABELS Install equipment labels, busbar labels and phasing discs as detailed on D-EC-855-11-01A. The positions of the phasing discs and label brackets are indicated on D-EC-855-11-06 rev 6. Install fence and gate labels (Project Specification). 1.3.16 JB BRACKETS The Isolator JB bracket is to be mounted on the busbar isolator (IS4) 1.3.17 LV CONTROL CABLES Install the secondary cables where required. Note; The cable block diagram will be issued once the contract is awarded. 1.3.18 BREAKER STAINLESS STEEL BOLTS The stainless steel bolts and washer for the 132kV breakers are required only if ABB does not supply 1.3.19 DECOMMISSION Disconnect and remove existing 132kV Ugie feeder bay with its foundations. Disconnect and remove all jumpers in the existing 132kV Ugie feeder bay. Dismantle and remove all equipment for re-use in the new position of the 132kV Ugie. Rehabilitate the soil in the area where the existing feeder was. Dismantle and remove the existing internal fence as shown in D-EC-855-11-11 rev 6. 1.3.20 CONSTRUCTION RISK Risk Mitigation Access: Substation is restricted area and public and visitors should not be allowed to enter without approval. Insects: Existing cabinets are often inhabited by bees, wasps and hornets. Gates: The substation is a restricted area and gates must be closed at all times. Oil Spill: Some equipment is oil filled and extreme care must be taken when handling the same since the risk of an oil spill is high Snake: Since the construction will take place during the summer the risk of encountering snakes is high. 3 Induction training of both staff and visitors required. Induction training of both staff and visitors required. Observe status of gates at all times. Induction training of staff to include oil spill risk and action if a spill should occur. Staff should be educated regarding the types of local snakes that may be encountered. Porcelain: The equipment has in most instances porcelain insulators and extreme care must be taken when handling the equipment not to chip and/or break the insulators. Chipped insulators could render equipment unfit for use or injury. Close proximity: Should works be undertaken in an operational yard care must be taken when handling/erecting conductive components such as steelwork. Staff must be made aware of the risk and the correct lifting equipment must be used when lifting the equipment. Induction training of staff to include risk associated with working in close proximity. 1.3.21 GENERAL The contractor to whom the tender is awarded must make his own copies of the drawings to use during construction. For ease of reading, references has been made throughout this document to relevant project drawings , BOQ & specifications, it however remains the contractors responsibility to ensure the he/she complies to all specifications and standards relating to the Project. 4