EJOT® Micro Screws – Secure and cost effective fastening solutions

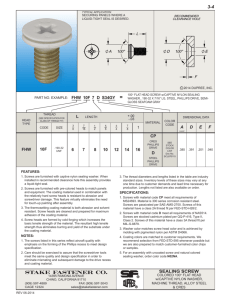

advertisement

EJOT GmbH & Co. KG Industrial Fasteners Division P.O. Box 11 63 D-57323 Bad Laasphe phone +49 2752 109-0 telefax +49 2752 109-141 Internet: www.ejot.com e-mail: industrie@ejot.de EJOT® Micro Screws – Secure and cost effective fastening solutions for even the smallest components EJOT is well known for the development of innovative fastening elements. In cooperation with the customer we develop individual fastening solutions that fulfil the highest demands of reliability and durability. EJOT is the specialist in thread-forming screws for the direct assembly in plastic material. Since there is no need for preparatory steps such as thread cutting, the use of EJOT products guarantees maximum cost-efficiency. Reliability and cost-efficiency are a matter of course for all EJOT products even though one completely different challenge has recently become apparent in many areas of industrial production: the trend towards miniaturisation and weight reduction of the components. Representative of this is the cellular phone industry, where every gram and millimetre which can be saved counts for competitive advantage. For this reason EJOT fulfils those especially high demands on the use of fastening elements with the development of small dimensioned screws, the EJOT micro screws. It is now possible to produce a DELTA PT screw for direct assembly in thermoplastics with a nominal diameter of just 1 mm. These micro screws offer all known advantages of the larger dimensions. They range from manual assembly to automated serial assembly, as already applied in the telecommunications and electrical industries. Examples of these are mobile phones, notebooks and cameras. By also using self-tapping screws in the micro screw area, a high degree of mechanical strength of the assembly can be reached. The maximum strength is realised with a zero tolerance thread. In comparison to metric screw joints, where a certain "play" in the thread always exists due to their design. This advantage of zero tolerance thread is amplified the smaller the screw joint gets. Therefore a long-lasting and very reliable joint is guaranteed for EJOT micro screw as well. Furthermore the thread-forming design of the EJOT micro screw saves the additional step of thread cutting the material, which is naturally much harder with smaller screw dimensions than with the larger ones. The self-tapping micro screws also prevent the oftentimes very high tool wear and tear, which occurs with metric screws due to the necessary step of thread cutting. Therefore significant cost saving potentials can usually be realised with EJOT micro screws. EJOT GmbH & Co. KG Industrial Fasteners Division P.O. Box 11 63 D-57323 Bad Laasphe phone +49 2752 109-0 telefax +49 2752 109-141 Internet: www.ejot.com e-mail: industrie@ejot.de The advantages of the EJOT micro screws at a glance: • Thread-forming direct assembly of even the smallest components • No need for additional inserts or add-ons • Reduction of cycle times or omission of complete work-steps • Assembly possible even in the smallest installation space • Use in the automated assembly possible EJOT micro screws are available for use in plastic material, light metal and steel. Legend I: EJOT® micro screws – individual fastening solutions for even the smallest components EJOT GmbH & Co. KG Industrial Fasteners Division P.O. Box 11 63 D-57323 Bad Laasphe Legend II: EJOT® micro screws – reliable fastening solutions even in the smallest installation space Legend III: EJOT® The Quality Connection Contact person in the Marketing Department: Dipl.-Kfm. Andreas Blecher Telephone +49 2752 109-118 Fax +49 2752 109-141 e-mail ablecher@ejot.de phone +49 2752 109-0 telefax +49 2752 109-141 Internet: www.ejot.com e-mail: industrie@ejot.de