Healesville Sewage Treatment Plant Fact Sheet

advertisement

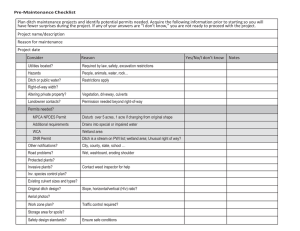

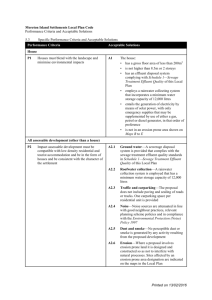

Healesville Sewage Treatment Plant Introduction Around 93% of the sewage that Yarra Valley Water collects is transferred to Melbourne Water for treatment at either the Western or Eastern Treatment Plants. However, the remaining 7% of wastewater is treated in small treatment plants, which we own and operate, located in suburban and semi-rural areas, such as the Healesville STP. The water from these treatment plants is released into rivers and streams, or reused and must therefore undergo a high standard of treatment. The Healesville STP was initially commissioned as a small neighbourhood plant in 1987 however; it was replaced in 1990 by the larger current plant. Over the following years, a chemical dosing facility was installed and once the plant came close to reaching capacity, the decommissioned aeration tanks from the Whittlesea STP were relocated to the Healesville STP. The plant is located on the outskirts of Healesville on Argoon Road; it is EPA licensed and treats sewage from the Healesville Township and surrounding areas; with the treated effluent being discharged into the Yarra River in accordance with EPA standards. The Treatment Process The treatment process includes an influent pump station, an inlet screen, biological treatment utilising an oxidation ditch and two treatment reactors, secondary clarification, upward flow clarification and UV disinfection. The oxidation ditch is a horseshoe-shaped basin where incoming effluent is mixed with return sludge from a secondary clarifier. The ditch provides a mechanism for circulation and oxygen transfer promoting the growth of micro-organisms that consume organic matter to breakdown and release nitrogen. Alum is dosed to the sewage at the inlet to the oxidation ditch to aid phosphorus removal. Capacity The current design and licensed capacity of the Healesville treatment plant are shown below: Parameter Organic Capacity Equivalent Population Average Dry Weather Flow Licensed Mean Daily Flow Rate Value 720 kg/d BOD 10,000 1.5 ML/d 1.4 ML/d Healesville Sewage Treatment Plant Healesville STP Treatment Process Sewage is pumped into the treatment plant Fig 1 (right): Briefly describes the main treatment processes that occur at the plant Fig 2 (below): A schematic diagram of the plant’s treatment process Preliminary Treatment Influent from Healesville Branch Sewer Screenings to Landfill The flow of sewage passes through screens so that rubbish and other large objects can be removed Alum is dosed to the sewage at the inlet to the oxidation ditch to aid phosphorus removal Caustic soda is dosed into the oxidation ditch to maintain a neutral pH Influent Pump Station Inlet Screens Secondary Treatment Alum Caustic Soda Oxidation Ditch Sludge Thickening Tank RAS Aeration Tanks WAS Secondary Clarifier Educt off-site to Brushy Creek STP Secondary treatment involves the use of an oxidation ditch and two sidestream reactors. The mixed liquor is then piped back to the oxidation ditch from the reactors. Removal of soluble organic matter; nitrogen and some phosphorus occurs. The effluent then flows into the secondary clarifier, where settling occurs to remove suspended solids Waste sludge is thickened and then transported to Brushy Creek for disposal into Melbourne Water’s sewage system Tertiary Treatment The effluent then flows through the upward flow clarifiers, for further removal of suspended solids Following clarification, the effluent undergoes UV disinfection to inactivate and destroy any disease causing pathogens that are still present Upward Flow Clarifier Now the effluent is of an acceptable standard to be discharged into the Yarra River, without causing harm to the environment UV Disinfection System Yarra River