Taber Abraser - Proinex Instruments, sro

advertisement

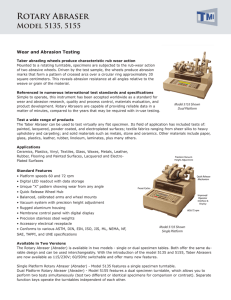

DATA SHEET Page 1/26 Taber Abraser The TABER® Rotary Platform Abraser (Abrader) was developed to perform accelerated wear testing. First introduced in the 1930's, this precision built instrument rapidly became the world standard for evaluating abrasion resistance. Since its inception, the Taber Abraser has been used for quality & process control, research & development and material evaluation. Used to test a wide spectrum of materials, the abraser (abrader) has been referenced in numerous standards and specifications and is frequently called a Rotary Platform Dual (Double) Head Tester. Description Up to ½" thick specimens, are mounted to a rotating turntable and subjected to the wearing action of two abrasive wheels, w hich are applied at a specific pressure. Characteristic rub-wear action is produced by contact of the test sample, turning on a vertical axis, against the sliding rotation of two abrading wheels. The wheels are driven by the sample in opposite directions about a horizontal axis displaced tangentially from the axis of the sample. One abrading wheel rubs the specimen outward toward the periphery and the other, inward toward the center. The resulting abrasion marks form a pattern of crossed arcs over an area approximately 30 square centimeters. An important feature of the TABER® Abraser (Abrader) is the wheels traverse a complete circle on the specimen surface. This reveals abrasion resistance at all angles relative to the weave or grain of the material. Test parameters can be altered, which enables the user to determine the optimal setting for each product or material. The TABER Abraser (Abrader) allows you to select: Load standard range includes 250g, 500g and 1000g optional counter weights increase range to 75g, 125g, 325g, 375g, 825g and 875g Abradants • wide selection of Taber wheels available (resilient or vitrified) • specialty wheels • custom formulations Vacuum level • programmable from keypad • adjustable vacuum nozzle clearance • range from 50% to 100% Test Duration • programmable up to 50,000 cycles Conditions • wet or dry • • ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 1/26 DATA SHEET Page 2/26 Each turntable has dual abrading arms that are precision balanced. Independently operated, the abrading arms can be raised (or lowered) to mount or inspect specimens. Each arm is loaded for 250 gram pressure against the specimen with the wheel mounting assembly in place (exclusive of the weight of the wheel). To increase the load to 500 or 1000 grams, a mount for auxiliary weights is located on the outside of the abrading wheel bearing assembly. The location ensures that weights are concentric with the abrading wheel. A stud on the rear end of the abrading arm is used to carry an optional counterweight (used to reduce the wheel load 125 or 175 grams). The stud is also used to hold an abrading wheel as a counterweight to compensate for the weight of the working wheel. Taber Rotary Platform Abrasers (Abraders) are capable of providing reliable data in a matter of minutes, compared to the years that may be required by in-use testing Click here to view a Taber abrasion test on Exatec(r) automotive glazing products according to test method ASTM D1044 (video is courtesy of Exatec LLC). Models The TABER® Abraser (Abrader) is available in two models - single or dual specimen tables. Both offer the same durable design and can be used interchangeably. With the introduction of the model 5135 and 5155, Taber Abrasers are now available as 115/230V; 60/50Hz switchable and offer many new features. TABER® Abraser (Abrader) - Model 5135 Model 5135 (shown in above picture) features a single specimen turntable. • • Model 5135 [part# 985135] CE approved TABER® Abraser (Abrader) - Model 5155 Model 5155 features a dual specimen turntable, which allows you to perform two tests simultaneously (test two different or identical specimens for comparison or contrast). Separate function keys operate the turntables independent of each other. • • Model 5155 [part# 985155] CE approved All TABER Abrasers are assembled in a sturdy, sealed aluminum housing and operated by a Control Panel Membrane. A vacuum system is included with each abraser, and is critical for the proper operation of the instrument. The vacuum nozzle(s) is hinged to an adjustable mounting at the rear of the housing. This allows the height to be modified for accommodating varying specimen thickness. Precision stainless steel weights of 250 grams and 750 grams are furnished to provide standard wheel loads of 500 and 1000 grams. NOTE: Weights are marked to show total load on each wheel. This marking includes the weight of the abrading arm. ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 2/26 DATA SHEET Page 3/26 Incorporated into the rear of the abraser are two additional electrical receptacles. Conveniently marked, each receptacle has been designated for the vacuum system or an optional accessory instrument. NEW FEATURES!!! A Quick Release Mounting Hub is now standard on all abrasers. An expanding collet hub with push-button operation permits quick wheel mounting without the need of a locking nut. A beveled retaining nut provides a positive locking force on the wheel hub retaining lip making certain that the wheels remain securely fastened until disengaged. This feature results in increased clearance for the vacuum pick-up nozzle and offers a larger viewing area for the test specimen. The model 5135 and 5155 offer both 60 rpm and 72 rpm turntable speed. [The turntable speed on previous versions of the Taber Abraser was dependent on the electrical line current. At 115V/60Hz the turntable speed was 72 rpm and at 230V/50Hz the turntable speed was 60 rpm.] The operator interface is an easy to use membrane panel with tactile feel buttons and a four line digital display. Simple on-screen instructions allow the operator to change the test parameters via the MENU button. An internal memory stores the data. Four preset cycle buttons conveniently allow the operator to set commonly used test cycles. A precision vacuum nozzle adjustment is easily accessible and controls the raising or lowering of the vacuum pick-up nozzle. ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 3/26 DATA SHEET Page 4/26 Wheel Sets TABER® abrading wheels are available in a range of abrasiveness to suit a wide variety of testing applications. Deciding which abrading wheel is best suited for your application is best determined with preliminary testing on the actual material. The ideal selection criteria is to reproduce, as nearly possible, the wear which the material will be subjected to in actual use. The composition of TABER® abrading wheels has been carefully chosen and a rigorous quality program maintains the uniformity of the wheels. Wheels are sold in pairs, and shipped in tight-lidded containers to prevent damage. Each wheel is labeled "LEFT HAND (or RIGHT HAND) - THIS SIDE OUT" to assure that the mounting position will be duplicated after the wheels have been removed and later re-installed. Model Abrasive Description Type CS-10F Very Mild - Mild Calibrase (resilient) ST-11 Stone 2 years CS-10 Mild - Medium Calibrase (resilient) S-11 Refacing Disc 4 years CS-17 Medium - Coarse Calibrase (resilient) S-11 Refacing Disc 4 years H-38 Very Fine Calibrade (vitrified) Wheel Refacer with multipoint tool None H-10 Fine - Medium Calibrade (vitrified) Wheel Refacer None H-18 Medium - Coarse Calibrade (vitrified) Wheel Refacer None H-22 Very Coarse Calibrade (vitrified) Wheel Refacer None CS-0 None - Very Mild Non-Abrasive Rubber (resilient) N/A 2 years S-32 None - Very Mild Non-Abrasive Rubber (resilient) N/A 2 years CS-5 None Wool Felt (resilient) N/A 3 years S-35 Severe Cutting / Tearing Action Tungsten Carbide (non-resilient) N/A None S-39 None - Very Mild Leather (resilient) N/A 3 years Refacing Medium Shelf Life NOTES: • Shelf life is dependent on proper storage conditions: relative humidity = 50% +/- 5%, temperature = 23° C +/- 2° C. • The abrasive coefficient can be altered by oil or contaminants. When handling wheels, only touch the sides. ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 4/26 DATA SHEET Page 5/26 Selecting Wheels: Throughout the years, test procedures have been developed for many different types of products. If you are following a particular standard, please refer to it for the appropriate wheel. The information provided is intended to serve as a guideline only. TABER® wheels are designed so that the binder material breaks down during use, exposing and creating a new abrading surface. Depending on the abradant type and test specimen, the wheel surface may change (i.e. become clogged) due to the transfer of material from the test specimen to the abrading wheel, and must be cleaned at frequent intervals. Calibrase® - Resilient wheel comprised of resilient binder and aluminum oxide abrasive or silicon carbide particles. Often used to test rigid specimens. CS-10F [part# 125321] A mild abrasive wheel designed to operate under loads not exceeding 500 grams. CS-10 [part# 125320] A medium abrasive wheel, designed to simulate the abrading action like that of normal handling, cleaning, and polishing. Used to evaluate resistance of wear on materials such as coatings, plastics, textiles, leather and paper products. CS-10W [part# 130950] Same as CS-10, but white in color. Especially useful for evaluating transparent materials where color transfer may be a problem. CS-17 [part# 125322] These coarse abrasive wheels produce harsher results, like that associated with traffic or "underfoot" wear. Used to test anodized aluminum, ceramics, plastics and enamels. Calibrade® - Non-resilient wheel composed of vitrified (clay) and silicon carbide or aluminum oxide abrasive particles. Often used to test flexible specimens. H-38 [part# 125326] Designed to operate under loads not exceeding 500 grams. This finegrained wheel is principally used for testing woven fabrics. H-10 [part# 125323] The abrading action of this wheel makes it ideal for testing steel and ferrous alloys for resistance to abrasion. It is also used to test the effect of hardening and tempering treatments on steel and other ferrous materials. H-18 [part# 125324] With medium abrasive properties, this wheel is recommended for abrading rubber (non-tacky), woven textile fabrics, coated fabrics, flexible plastic sheet, and other soft, resilient materials. H-22 [part# 125325] With the coarse abrasion produced by this wheel, it has been used to test rubber, linoleum, leather, and certain deep pile fabrics (i.e. automobile floor covering). Specialty Wheels - Used for special applications. CS-0 [part# 125344] Rubber - This wheel contains no abrasive grain and is used when a very mild abrasive action is required, and for wet tests. Uses include determining the relative abrasion of dental powder and cream, cleaning powders, and similar compounds. Is also used to apply S-33 or S-42 sandpaper strips. S-32 [part# 125344] NEMA wheel - same as CS-0. CS-5 [part# 125319] Felt - A densely, compacted wool felt wheel. Its principal use is in testing textile fabrics when the service wear requires one fibrous ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 5/26 DATA SHEET Page 6/26 material to rub against another. S-35 [part# 1253345] Tungsten Carbide -This wheel is manufactured with sharp, helical teeth cut in its periphery (25 per inch set at 45°spiral pitch). Combining both a cutting and tearing action, it provides very severe abrasion for use on resilient materials only (rubber, linoleum, and leather). S-39 [part# 125529] Leather - Mounted on a brass hub, leather wheels are used in conjunction with the Taber GRIT FEEDER. Custom abradants can be developed upon request. APPLICATION Adhesives & Sealants Anodized Aluminum Ceramic Finishes Coatings (Paint, Enamel) Concrete Floors Dental Powder Electroplate Films Glass Hard Surface Coverings Home Furnishings Insulated Wire Laminates Leather (Shoe Soles) Leather Products Linoleum Masonite Optical Products Packaging Paper Paper & Cardboard Plastics Plastics Plating Porcelain Enamel Printing Rubber Sanitary Products Steel CS-10F CS-10 CS-17 X X X X X H-38 H-10 H-18 H-22 S-35 CS-0 X X X X X X X X X X X X X X X X X X X X X X ProInex Instruments, s. r. o. X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 6/26 DATA SHEET Page 7/26 Textile (floor coverings) Textile (coated fabrics) Textiles (pile fabric) Textiles (natural & synthetic) Tile (rubber and asphalt) Upholstery Wax Wood Wool X X X X X X X X X X X X X X X X X X X X X X X Test Accessories TABER® Industries offers a full line of test accessories to be used with the TABER® Rotary Platform Abraser (Abrader). S-16; Steel Specimen Plates [part# 125563] 4" square, 20 gauge steel with ¼" hole (sold in packages of 10) S-17; Wood Specimen Plaques [part# 132088-1] 4" square, ¼" birch plywood with ¼" hole (sold in packages of 10) S-18; Aluminum Specimen Plates [part# 132086] 4" square, Aluminum with ¼" hole (sold in packages of 10) S-31; NEMA Glass Standardization Plates [part# 125561] 4" square, 1/8" plate glass with ¼" hole (sold in packages of 10) S-34; NEMA Zinc Standardization Plates [part# 125562] 4" square, 0.032" zinc with ¼" hole (sold in packages of 5) S-38; Standardization Plates [part# 121257] 4" square, 1/16" plexiglass with ¼" hole (sold in packages of 10) S-32; NEMA Wheels [part# 125344] Manufactured out of rubber, this wheel contains no abrasive grain and is used to apply S-33 or S-42 sandpaper strips (same as CS-0) S-33; Sandpaper Strips [part# 121124] Backed with a pressure sensitive adhesive, these coated abrasive strips are attached to the periphery of S-32 (CS-0) resilient rubber wheels; 12.7mm x 160mm, 360 FEPA, closed coat (sold in packages of 100 or 500) S-42; Sandpaper Strips [part# 125564] Backed with a pressure sensitive adhesive, these coated abrasive strips are attached to the periphery of S-32 (CS-0) resilient rubber wheels; 12.7mm x 160mm, 180 ANSI-CAMI, open coat (sold in packages of 100 or 500) ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 7/26 DATA SHEET Page 8/26 S-11; Refacing Discs [part# 121102] 4" diameter, 150 grit abrasive paper for refacing resilient wheels (sold in packages of 100) ST-11; Duplex Refacing Stone [part# 125777] 4" diameter x ¼" thick; Used to test natural or synthetic rubber "wheels" molded or cut from sheet, in place of a flat specimen. Also used to reface CS-10F wheels. One side of stone contains a coarse grit for refacing wheels at the start of a test (new wheels reface 100 cycles, previously used wheels reface 25 - 50 cycles); the other side has a fine grit which is used at intervals throughout a test (25 cycles each 1000 cycles for the duration of the test). S-36; Specimen Mounting Cards [part# 125560] 4 ¼" square; Mounting card that has one side coated with pressure sensitive adhesive to hold textiles and other flexible test specimens tightly to the mounting surface, preventing wrinkles under the abrading wheels. On the plain side of the card, a test record form is printed. (sold in packages of 50) S-36-1; Specimen Mounting Cards [part# 129270] Same description as S-36, but round (sold in packages of 50) S-37; Specimen Mounting Sheets [part# 12558] 4 ¼" square; Both sides of smooth card stock are coated with pressure sensitive adhesive, overlaid with a protective paper that is peeled off prior to use. Mounting sheets are interleaved between the specimen and the abraser turntable to provide a non-slip attachment for material specimens such as ceramics, plastics and glass - when no center hole is present. (sold in packages of 100) S-37; Specimen Mounting Sheets [part# 129271] Same description as S-37, but round (sold in packages of 100) 125g Counterweights [part# 126108] Counterweight used with the Taber Abraser to reduce the wheel load by 125 grams (2 pieces) 175g Counterweights [part# 133004] Counterweight used with the Taber Abraser to reduce the wheel load by 175 grams (2 pieces) 503-0022; Auxiliary Weight (500 gram load) [part# 125769] Auxiliary weight used with the Taber Abraser to increase the wheel load to 500 grams (requires 2 pieces). Note; actual weight is 250 grams. 503-0023; Auxiliary Weight (1000 gram load) [part# 125770] Auxiliary weight used with the Taber Abraser to increase the wheel load to 1000 grams (requires 2 pieces). Note; actual weight is 750 grams. Replacement Auxiliary Weight Set [part# 125734] Includes 500 gram load (503-0022) and 1000 gram load (503-0023) 5130-70; Replacement Vacuum Set (120V, 60Hz) [part# 121127] The Abraser Vacuum Unit is manufactured specifically for use with the TABER Abraser, and incorporates a heavy-duty motor with life-lubricated sealed bearings. Mounted above a sturdy tank, the motor is kept clear of dust and debris resulting from your testing. ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 8/26 DATA SHEET Page 9/26 A flexible suction hose is provided to connect the vacuum unit with the abraser or other accessory instrument. And a round clean-up brush aids in cleaning loose debris from the instrument or surrounding work area, includes flexible suction hose and round brush 5131-70; Replacement Vacuum Set (230V, 50Hz) [part# 127788] Same description as 5130-70 Replacement Paper Filter Bag [part# 114309] For use with Taber Vacuum equipped with plastic tanks Replacement Paper Filter Bag [part# 129259] For use with Taber Vacuum equipped with metal tanks Cloth Filter Bag [part# 128086] For use with Taber Vacuum Filter, Cartridge Type [part# 131680] For use with Taber Vacuum Replacement Foam Filter [part# 114310] For use with Taber Vacuum Replacement Round Brush [part# 114312] For use with Taber Vacuum Replacement Flexible Suction Hose [part# 114311] For use with Taber Vacuum Taber Abraser Clean-up Hose [part# 129280] Using the vacuum only feature on your abraser, this simple accessory makes clean-up easy. The hose mounts to the rear vacuum nozzle opening. The small brush is ideal for cleaning test specimens, the abraser or your work area without the need to disconnect the vacuum hose from your abraser. S-21; Extension Nut [part# 121224] Provides the ability to test materials ¼" - ½" thick (samples require 3/8" diameter center hole) S-19; Rubber Pad [part# 121016] 4 ¼" O.D. pad for Specimen Holder (sold in packages of 5) S-12; Brush [part# 121103] Brush for cleaning Specimen Plates 100-237; Wrench [part# 121095] For use with hold down ring clamp screw ETF-11; Step-down Transformer [part# 121110] 230/115V, 50/60Hz, 1000 watt ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 9/26 DATA SHEET Page 10/26 Accessories Quick Release Wheel Hub Retrofit your Taber Abraser with the Quick Release Wheel Hub. An expandable collet hub design permits quick wheel mounting. Activated by a push button, a spring-loaded, beveled retaining nut provides a positive locking force on the hub retaining lip making certain that wheels remain securely fastened until disengaged. By eliminating the left and right hand locking nuts, the viewing area of the test specimen is increased and interference with the vacuum pick-up nozzle is eliminated. Sample Cutter [part# 985000] Prepare your specimens for the TABER® Abraser (Abrader) using this bench top cutter. The Model 5000 Sample Cutter will cut precise, 4.2" circular samples with a ¼" center hole. An easy clockwise cutting motion allows you to cut a variety of materials. Optional pads allow you to cut materials in thickness of 0.001" to 0.25". With a recessed cutting blade, shielded punch drive shaft, and ergonomic handle, this rugged instrument was designed for safety and can be used in any production or laboratory environment. Optional accessories include: • 0.187" Upper Pad Assembly *[part# 131569] 0.250" Upper Pad Assembly [part# 131570]*Note: Standard pad included with Sample Cutter Diamond Wheel Refacer [part# 980250] To ensure accurate test results, Calibrade abrading wheels should be precision dressed when abrading surfaces are out of round, crowned or clogged with abraded material. The Diamond Wheel Refacer allows you to true and completely renew the working surfaces of your TABER abrading wheels. Wheels are located on a flanged extension of the motor shaft, and enclosed by a hinged cover for safety. A diamond tool, mounted on a shielded traverse slide, permits light cuts across a pair of wheels providing identical wheel diameters. Attaching the abraser vacuum to the receptacle hole of the refacer will enable you to draw off the abrasive cuttings and maintain a clean work area. Optional Accessories include: • Single Point Diamond Tool (for Model 250) [part# 131543] • Multiple Point Diamond Tool (for Model 250) [part# 131661] (used to reface H-38 Calibrade© Wheels) ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 10/26 DATA SHEET Page 11/26 Quiet Cabinet The typical sound level of operating a TABER Abraser (Abrader) and its vacuum system can reach 78dB. With the Quiet Cabinet, you can reduce this level by approximately 20%. Comprised of an upper and lower unit, this solid wood cabinet blends with any laboratory environment. The upper cabinet provides a convenient, dust-free work space for your Abraser and features a Plexiglas viewing window to monitor testing, and detachable front for easy transfer of Abraser into or out of the cabinet. The lower cabinet holds the Abraser Vacuum Unit and includes a built-in exhaust system to provide the proper air circulation. Both cabinets offer ample room to store test specimens, supplies, and accessories. The Quiet Cabinet can be purchased as a complete unit or the top half or bottom half only. The lower cabinet exhaust system is available for 115V, 60Hz or 230V, 50Hz (CE marked). • • • • • Quiet Cabinet - complete set (115V/60Hz) [part# 128372] Quiet Cabinet - complete set (230V/50Hz) [part# 129497] Quiet Cabinet - top [part# 128370] Quiet Cabinet - bottom (115V/60Hz) [part# 128371] Quiet Cabinet - bottom (230V/50Hz) [part# 129498] ** Abraser and vacuum system sold separately Abraser (Abrader) Vacuum Unit The Abraser (Abrader) Vacuum Unit is manufactured specifically for use with the TABER Abraser (Abrader), and incorporates a heavy-duty motor with life-lubricated sealed bearings. Mounted above a sturdy tank, the motor is kept clear of dust and debris resulting from your testing. A flexible suction hose is provided to connect the vacuum unit with the abraser or other accessory instrument. And a round clean-up brush aids in cleaning loose debris from the instrument or surrounding work area. • • Model 5130-70 Vacuum Set (120V/60Hz) [part# 121127] Model 5131-70 Vacuum Set (230V/50Hz) [part# 127788] Optional accessories include: Paper Filter Bag [part# 114309] Paper Filter Bag [part# 129259] Cloth Filter Bag [part# 128086] Clean-Up Hose [part# 129280] Using the vacuum only feature on your abraser, this simple accessory makes clean-up easy. The hose mounts to the rear vacuum nozzle opening. The small brush is ideal for cleaning test specimens, the abraser or your work area without the need to disconnect the vacuum hose from your abraser. ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 11/26 DATA SHEET Page 12/26 Grit Feeder When used with the TABER Abraser (Abrader), the Grit Feeder provides a unique method to evaluate 3-body abrasion resistance on a variety of materials. This instrument was originally designed to simulate abrasion caused from grit embedded in leather soled shoes and is typically used to test flooring. Aluminum Oxide grit particles are evenly distributed onto the specimen wear path, and pass under a pair of leather wheels. This loose grit acts as an abradant and aids in the rolling action that contributes to the physical breakdown of materials. The Abraser Vacuum is attached to the grit feeder, and continuously removes both abraded material and used grit. Two Grit Feeder models are available. Model 255 offers left hand or right hand positioning, plus a hand crank makes adjusting nozzle height more precise allowing for improved repositioning of samples. Optional Accessories include: • • • • • • Standardization Plates (S-38) [part# 121257] #240 Aluminum Oxide Abradant, 50 lb. container (S-41) [part# 121086] U.S. Standard #80 Sieve (S-40) [part# 125629] Replacement Leather Wheels (S-39) [part# 125529] Static Eliminator [part# 125610] Rimmed Specimen Holders (E140-14 [part# 121155] or E140-75 [part# 125604]) Scuffing Attachment Mounted to the left hand abraser arm mount, a scuffing head and weight are used in place of the abrading wheels. As the table rotates, the scuffing head is dragged across the specimen surface. There are three standard scuffing heads: Type "A" Type "B" [part# 120918] Type "C" [part# 120920] [part# 127524] Scuffing Attachment Model 503-13 [part# 980503-13] • meets Ford Test Method BN 108-04, and includes "A" and "B" heads, and a 2 lb. weight Scuffing Attachment Model 503-GM [part# 980503-13-1] • meets General Motors Test Method GM9911P, and includes C" head and a 1 lb. weight ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 12/26 DATA SHEET Page 13/26 Haze Kit [part# 132615] This kit is recommended for those customers who evaluate haze measurements on transparent materials using a haze meter. Included in the kit is a modified vacuum pick-up nozzle; 2” soft bristle, anti-static brush, and 1/32” vacuum gap gage pin. The modified vacuum pick-up nozzle includes two precision machined 7/16” orifices, and is electro-etched “Haze Test Nozzle – Modified Openings” to distinguish this nozzle from the standard version (which includes two 5/16” orifices). Arm Height Extension Kit [part# 132690 and 132705] This kit permits the testing of samples up to 40mm. Using precision-machined adaptor, abraser (abrader) arms are raised to accommodate specimens that exceed the recommended maximum thickness. Located off a reference point, tolerances are maintained to ensure correct wheel alignment and positioning. A set of shims is also included to maintain proper position of the arms relative to the test specimen. [Requires instrument to be returned to factory for modification and calibration.] Calibration Verification Kit [part# 132030] The Calibration Verification Kit enables operators to check critical parameters to verify the performance of a TABER Rotary Platform Abraser (Abrader). This fast, reliable system check identifies potential concerns signifying when the instrument should be returned for adjustment or repair. [Not intended as a substitute for regular calibration.] Specimen Holders Different configurations of specimen holders add to the versatility of the TABER Abraser (Abrader), and permits testing most any material. All holders are interchangeable, and have been designed to lock in place yet still be easily removed from the abraser (abrader). A common feature to most specimen tables is the clamp plate and nut. Mounted on top of your specimen, these help keep flexible materials flat and rigid materials secure. The rubber pad (S-19) ensures specimen materials do not slip during testing. E100-125; Specimen Holder [part# 120990] Test all rigid, flat specimens of any material (standard specimen holder included with all abrasers). E100-101; Hold Down Ring (4 17/64" ID) [part# 125795] Used for flexible materials up to 1/16" thick [use with E100-125]. E100-102; Hold Down Ring (4 21/64" ID) [part# 125796] Used for flexible materials up to 1/16" thick [use with E100-125]. E100-10; Transparent Plastic [part# 121205] Used for viewing textile specimens against a light source to determine wear characteristics without having to remove the specimen from the holder. (Can be used with E100-101 or E100-102). ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 13/26 DATA SHEET Page 14/26 E140-14; Ring Clamp Holder [part# 121155] Eight (8) screws spaced evenly on the clamp plate allow you to test slightly warped specimens (dry or wet). Furnished with (S) or without (NS) center screw. E140-15; Textile (Tensioning Type) [part# 121148] Used for flexible materials. Incorporates a raised wear track to provide extra tensioning to the material when the hold down ring is drawn down over the edge of the holder and clamp plate is mounted. Requires 5 ¼" circle of test material. E140-18; Textile (Rimmed) [part# 121208] Used for flexible materials. This holder provides an initial stretch to woven fabrics, thereby minimizing their tendency to wrinkle if they are tested moist. E140-19; Drive Pin Type [part# 121207] Used for rigid, square specimens without the need for a center hole. Specimens are attached to this holder with S-37 or S-37-1 mounting sheets. E140-21; Threaded Ring (NEMA) [part# 121206] Used for slightly warped specimens, this holder incorporates a clamp plate and flanged clamp ring. The clamp ring is threaded to the body of the holder, which securely holds the outer edges of a specimen up to 5 3/8" diameter. E140-75; Rimmed Specimen Holder [part# 125604] Used for wet testing materials. A 3/8" raised rim retains liquids, allowing you to determine the effect of absorbed and or surface moisture on abrasion resistance. E-3945; Multiple Specimen [part# 121241] Divided into eight (8) sections, this holder permits simultaneous testing of lightweight, flexible specimens. Used primarily for nylon hosiery and light fabrics. ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 14/26 DATA SHEET Page 15/26 Specimen Holder - Silicon Rubber Wet Test [part# 121241-1] Specially designed for testing silicon rubber products (including breast implants). Abraser modification required. S-19 Replacement Pads [part# 121016] Rubber pads for specimen holders (4 ¼" OD) S-21 Extension Nut [part# 121224] Use this center nut to test materials ¼" - ½" thick (requires a 3/8" center hole). Arm Height Extension Kit [part# 132160] This kit changes the position of the abraser arms to permit the evaluation of samples up to 40mm. A set of shims permits the user to maintain proper position of the arms relative to the test specimen. [Requires instrument to be returned] Interpreting Results There are different ways to interpret TABER Rotary Platform Abraser (Abrader) test results. They can range from a visual inspection to a detailed computer analysis using TaberWear™ 1.0. The method of evaluation that you select should reflect the type of material that is being tested. In many cases, if you are following a specification - the method for interpreting test results will be listed. Test results are typically expressed as a wear factor or numerical abrasion index of the test specimen. The most common methods of evaluating results from the Taber Abraser (Abrader) include: Visual End Point - Test ends when there is a clearly marked change in specimen appearance or other characteristic. When the abrasion test end-point is described in a material specification, the end-point may consist of pass/fail criteria such as yarn breakage, loss in coating, loss of luster, napping, pilling, color loss, or other changes in appearance. Specimens are typically compared with a known standard of the material tested. Weight Loss - Usually shown in milligrams, indicates how much material has been removed by abrasion. L=A-B where L = weight loss A = weight of test specimen before abrasion B = weight of test specimen after abrasion Taber Wear Index - Indicates rate of wear, and is calculated by measuring the loss in weight (in milligrams) per thousand cycles. The lower the wear index, the better the abrasion resistance. I = (A - B) * 1000 / C where I = wear index A = weight of test specimen before abrasion B = weight of test specimen after abrasion C = number of cycles ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 15/26 DATA SHEET Page 16/26 Volume Loss - For specimens of different specific gravities. Using a correction factor, you can obtain a true indication of wear resistance. Depth of Wear - Measure the depth of the wear with an instrument such as an OPTICAL MICROMETER. Wear Cycles Per Mil - Represents the wear cycles required to break through a coating of a certain thickness. where W = wear cycles per mil D = cycles required to wear coating through to substrate T = thickness of coating, mils (0.001 in)to one decimal place W=D/T Residual Breaking Force (textile fabrics) - The effective strength of the fabric, or force required to break a specific width of fabric. To determine the individual breaking force of the abraded specimen use the procedure described in the ASTM D5034 and D5035 Standard Test Method for Breaking Strength and Elongation of Textile Fabrics. To work, you must change the distance between clamps to 25mm and horizontally place the path of abrasion on the abraded specimen midway between the clamps. Report the breaking load to the nearest 0.5kg. Average Breaking Strength (textile fabrics) - Calculated by averaging the breaking strength of the abraded specimens and the unabraded specimens, as determined by the Residual Breaking Force. Percentage Loss in Breaking Strength (textile fabrics) - To determine the breaking load of the original fabric and the abraded specimen, use the procedure noted above (ASTM D5034 and D5035). Calculate the percentage loss in breaking strength to the nearest 1% for each lengthwise and widthwise directions. AR% = 100 * (X-Y) / X where AR% = abrasion resistance, % X = breaking force before abrasion, g(lb) Y = breaking force after abrasion, g(lb) Test Specifications Test procedures for the TABER® Rotary Platform Abraser (Abrader) have been established by a number of organizations. The following is a partial listing. Decorative High Pressure Laminates (HPL); Sheets Based AENOR UNE 53-173-92 Part 2 on Thermosetting Resins; Part 2: Determination of Properties UNE EN 13672 Surfaces for Sports Areas - Determination of Resistance to Abrasion of Non-Filled Synthetic Turf AENOR UNE EN 14431 Vitreous and Porcelain Enamels - Characteristics of the Enamel Coatings Applied to Steel Panels Intended for Architecture AENOR UNE EN 14864 Vitreous and Porcelain Enamels - Enamel Coatings Applied to Steel for Writing Surfaces - Specification AENOR ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 16/26 DATA SHEET Page 17/26 UNE 57095 Paper and cardboard - Determination of Resistance to Abrasion - Taber Method AENOR UN EN 438-2 Decorative High Pressure Laminates (HPL); Sheets Based on Thermosetting Resins; Part 2: Determination of Properties AENOR UN EN 13329:E Laminate floor Coverings - Specifications, Requirements and Test Methods AENOR UN EN 13696 Wood and Parquet Flooring - Determination of Elasticity and Resistance to Wear AFNOR FD ENV 13696 Wood and Parquet Flooring - Determination of Elasticity and Resistance to Wear AFNOR NF B 51-282 Melamine Faced Particleboards - Determination of Resistance to Abrasion AFNOR NF EN 13672 Surfaces for Sports Areas - Determination of Resistance to Abrasion of Non-Filled Synthetic Turf AFNOR NF EN 14431 Vitreous and Porcelain Enamels - Characteristics of the Enamel Coatings Applied to Steel Panels Intended for Architecture AFNOR NF EN 14864 Vitreous and Porcelain Enamels - Enamel Coatings Applied to Steel for Writing Surfaces - Specification AFNOR NF G 37-121 Rubber or Plastic Coated Fabric-Determination of the Wear Resistance by Rubbing with two Abrasive Wheels AFNOR NF Q 03-055 Paper and Board Tests - Determination of Abrasion Resistance of Paper and Board (by Taber Method) AFNOR NF T 30-015 Paints and Varnishes - Abrasion Resistance Test AFNOR NF EN 438-2 Decorative High Pressure Laminates (HPL); Sheets Based on Thermosetting Resins; Part 2: Determination of Properties AFNOR NF EN 660-2 Resilient floor coverings - Determination of wear resistance - Part 2: Frick-Taber Test AFNOR NF EN ISO 5470-1 Rubber or Plastics Coated Fabric-Determination of Abrasion Resistance ANSI INCITS 322-2002 Card Durability Test Methods ANSI/NSF 35 High Pressure Decorative Laminates for Surfacing Food Service Equipment ANSI/NSF 49 Class II (Laminar Flow) Biohazard Cabinetry ANSI/NSF 51 Food Equipment Materials AENOR ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 17/26 DATA SHEET Page 18/26 ANSI/SAE Z26.1-1996 Safety Glazing Materials for Glazing Motor Vehicles and Motor Vehicle Equipment AS AS 2001.2.28 Methods of Test for Textiles AS AS/NZS 1580.403.2 Paints and Related Materials - Methods of Test AS AS/NZS 4266.2 Reconstituted wood-based panels - Methods of Test Determination of resistance to surface abrasion (Taber abrasion test) ASTM C501 Standard Test Method for Relative Resistance to Wear of Unglazed Ceramic Tile by the Taber Abraser ASTM C1353 Standard Test Method Using the Taber Abraser for Abrasion Resistance of Dimension Stone Subjected to Foot Traffic ASTM D1044 Standard Test Method for Resistance of Transparent Plastics to Surface Abrasion ASTM D3389 Standard Test Method for Coated Fabrics Abrasion Resistance (Rotary Platform Double-Head Abrader) ASTM D3451 Standard Practices for Testing Polymeric Powders and Powder Coatings ASTM D3730 Standard Guide for Testing High-Performance Interior Architectural Wall Coatings ASTM D3884 Standard Guide for Abrasion Resistance of Textile Fabrics (Rotary Platform, Double-Head Method) ASTM D4060 Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser ASTM D4685 Standard Test Method for Pile Fabric Abrasion ASTM D4712 Standard Guide for Testing Industrial Water-Reducible Coatings ASTM D5144 Standard Guide for Use of Protective Coating Standards in Nuclear Power Plants ASTM D5146 Standard Guide to Testing Solvent-Borne Architectural Coatings ASTM D5324 Standard Guide for Testing Water-Borne Architectural Coatings ASTM D6037 Standard Test Methods for Dry Abrasion Mar Resistance of High Gloss Coatings ASTM D7255 Standard Test Method for Abrasion Resistance of Leather (Rotary Platform, Double-Head Method) ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 18/26 DATA SHEET Page 19/26 F362 Standard Test Method for Determining the Erasability of Inked Ribbons F510 Standard Test Method for Resistance to Abrasion of Resilient Floor Coverings Using an Abrader with a Grit Feed Method F1478 Standard Test Method for Determination of Abrasion Resistance of Images Produced from Copiers and Printers (Taber Method) ASTM F1978 Standard Test Method for Measuring Abrasion Resistance of Metallic Thermal Spray Coatings by Using the Taber Abraser BSI BS 3900 Paints and Varnishes; Determination of Resistance to Abrasion BSI BS DD ENV 13696 Wood and Parquet Flooring - Determination of Elasticity and Resistance to Wear BSI BS EN 13672 Surfaces for Sports Areas - Determination of Resistance to Abrasion of Non-Filled Synthetic Turf BSI BS EN 14431 Vitreous and Porcelain Enamels - Characteristics of the Enamel Coatings Applied to Steel Panels Intended for Architecture BSI BS EN 14864 Vitreous and Porcelain Enamels - Enamel Coatings Applied to Steel for Writing Surfaces - Specification BSI BS EN 438-2 Decorative High Pressure Laminates (HPL); Sheets Based on Thermosetting Resins; Part 2: Determination of Properties BSI BS EN 660-2 Resilient floor coverings - Determination of wear resistance - Part 2: Frick-Taber Test BSI BS EN ISO 5470-1 Rubber or Plastics Coated Fabric-Determination of Abrasion Resistance CEN EN 13672 Surfaces for Sports Areas - Determination of Resistance to Abrasion of Non-Filled Synthetic Turf CEN EN 14431 Vitreous and Porcelain Enamels - Characteristics of the Enamel Coatings Applied to Steel Panels Intended for Architecture CEN EN 14864 Vitreous and Porcelain Enamels - Enamel Coatings Applied to Steel for Writing Surfaces - Specification CEN prEN 14688 Sanitary appliances - Wash basins - Functional requirements and test methods (part 5.7) ASTM ASTM ASTM ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 19/26 DATA SHEET Page 20/26 CFFA P-101C Min Performance Standards for Vinyl Swimming Pool Liners - In-Ground CFFA Test 1 Standard Test Methods - Chemical Coated Fabrics and Film CFFA Test 200 Standard Test Methods - Chemical Coated Fabrics and Film CNS K6591 Method of Test for Polyurethane Athletic Installation Material DaimlerChrysler LP-463KB-21-01 Wear Resistance of Trim Materials - Taber Method DaimlerChrysler MS-PP11-1 Vacuum Metallizing for Plastic Parts - First Surface Interior DaimlerChrysler MS-PP11-2 Vacuum Metallizing - High Wear Resistance- For Plastic Parts - First Surface Interior Dept of Defense MIL-A-8625F(1) Military Specification - Anodic Coatings for Aluminum and Aluminum Alloys Dept of Defense MIL-C-22992E General Specification for Connectors, Plugs and Receptacles, Electrical Waterproof, Quick Disconnect, Heavy Duty Type Dept of Defense MIL-P 18493 (NAVY) Military Specification - Packing, Performed, Carbon; and Carbon Stock, Packing Dept of Defense MIL-PRF-61002A Military Specification - Pressure-Sensitive Adhesive Labels for Bar Coding Dept of Defense MIL-STD-13231 Department of Defense Standard Practice - Marking of Electronic Items Dept of Defense MIL-T-28800E Military Specification - General Specification for Test Equipment for use with Electrical and Electronic Equipment DIN DIN 52 347 Testing of Glass and Plastics; Abrasion Test; Method Using Abrasion Wheels and Measurements of Scattered Light DIN DIN 53 109 Testing of Paper and Board; Determination of Abrasion by the Abrasion Wheel Method DIN DIN 53 754 Testing of Plastics; Determination of Resistance of Wear by Abrasive Wheels DIN DIN 53 799 Decorative Laminated Sheets on Basis of Aminoplastic Resins; Test Method DIN DIN 68 861 T2 Furniture Surfaces: Behavior at Abrasion ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 20/26 DATA SHEET Page 21/26 DIN DIN EN 660-2/A1 Resilient Floor Coverings - Determination of Wear Resistance - Part 2: Frick-Taber Test; Amendment A1 DIN DIN EN 13672 Surfaces for Sports Areas - Determination of Resistance to Abrasion of Non-Filled Synthetic Turf DIN DIN EN 14431 Vitreous and Porcelain Enamels - Characteristics of the Enamel Coatings Applied to Steel Panels Intended for Architecture DIN DIN EN 14864 Vitreous and Porcelain Enamels - Enamel Coatings Applied to Steel for Writing Surfaces - Specification DIN DIN EN ISO 5470-1 Rubber or Plastics Coated Fabric-Determination of Abrasion Resistance CEN EN 438-2 Decorative High Pressure Laminates (HPL); Sheets Based on Thermosetting Resins; Part 2: Determination of Properties CEN EN 660-2 Resilient floor coverings - Determination of wear resistance - Part 2: Frick-Taber Test CEN EN 13329:E Laminate floor Coverings - Specifications, Requirements and Test Methods CEN ENV 13696 Wood and Parquet Flooring - Determination of Elasticity and Resistance to Wear Federal Test Method Std. No. 191A Method 5306.1 Abrasion Resistance of Cloth: Rotary Platform, DoubleHead (Taber) Method Federal Test Method Std. No. GG-P455b Plates and Foils, Photographic (Photosensitive Anodized Aluminum) Federal TT-P-0091D Interim Federal Specification - Paint, Rubber Base, Styrene-Butadiene Type, Interior, for concrete floors. Ford BN 108-02 Resistance to Abrasion - Taber Abraser Ford BN 108-04 Resistance to Scuffing Ford ESB-M99P14-A1 Engineering Material Specification - Pad Printing, First Surface Plastic or Painted Plastic, Interior Ford WSS-M15P34-B1 Engineering Material Specification - Performance, Interior Trim Appliques, High Wear Ford WSS-M15P34-B2 Engineering Material Specification - Performance, Interior Trim Appliques, Low Wear Ford WSS-M15P4-E Engineering Material Specification - Interior Trim, Assembly Performance Specification General GM2751M Automotive Upholstery Fabric ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 21/26 DATA SHEET Page 22/26 Motors General Motors GM9515P Abrasion Resistance of Organic Coatings (Taber Abraser Method) General Motors GM9911P Scuff Resistance to Surface Wear General Motors HN0245 Determination of Resistance to Abrasion Hyundai/Kia MS300-32 Abrasion Resistance of Woven Knits for Automotive Interiors & Trim ISO 3537 Road Vehicles - Safety Glazing Materials - Mechanical Tests ISO 4586-2/Amd.4 High-pressure decorative laminates - Sheets made from thermosetting resins ISO 5470-1 Rubber or Plastics Coated Fabrics - Determination of Abrasion Resistance ISO 7784-2 Paints and Varnishes; Determination of Resistance to Abrasion ISO 9352 Plastics; Determination of Resistance to Wear by Abrasive Wheels ISO 10074 Specifications for Hard Anodic Oxidation Coatings on Aluminum and its Alloys JIS A 1453 Method of Abrasion Test for Building Materials and Part of Building Construction (Abrasive-Paper Method) JIS H 8503 Methods of Wear Resistance for Metallic Coatings JIS K 6902 Testing Method for Laminated Thermosetting Decorative Sheets JIS K 7204 Testing Method for Abrasion Resistance of Plastics by Abrasive Wheels JIS L 1096 Testing for Woven Fabrics NALFA LF-01-2001 Laminate Flooring NASTA Manufacturing Standards and Specifications for Non-Consumable Soft-Cover Texts Specifications for Textbooks Cover Coating NEMA LD3 - 3.13 High Pressure Decorative Laminates SAE J 365 Method of Testing Resistance to Scuffing of Trim Materials SAE J 948 Test Method for Determining Resistance to Abrasion of Automotive Bodycloth, Vinyl, and Leather, and the ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 22/26 DATA SHEET Page 23/26 Snagging of Automotive Bodycloth SAE J 1530 Test Method for Determining Resistance to Fiber Loss, Resistance to Abrasion and Bearding of Automotive Carpet Materials SAE J 1847 Abrasion Resistance Testing - Vehicle Exterior Graphics and Pin Striping SAE J 2394 Seven-Conductor Cable for Abs Power SAE J80 Abrasion Resistance of Automotive Rubber Mats SIS SIS 92 35 09 Floor Materials - Determination of Abrasion Resistance SIS SS EN 438-2 Decorative High Pressure Laminates (HPL); Sheets Based on Thermosetting Resins; Part 2: Determination of Properties SIS SN EN 660-2 Resilient Floor Coverings - Determination of Wear Resistance - Part 2: Frick-Taber Test SIS SS EN 13672 Surfaces for Sports Areas - Determination of Resistance to Abrasion of Non-Filled Synthetic Turf SIS SS EN 14431 Vitreous and Porcelain Enamels - Characteristics of the Enamel Coatings Applied to Steel Panels Intended for Architecture SIS SS EN 14864 Vitreous and Porcelain Enamels - Enamel Coatings Applied to Steel for Writing Surfaces - Specification SIS SN EN ISO 5470-1 Rubber or Plastics Coated Fabric-Determination of Abrasion Resistance Tappi T 476 Abrasion Loss of Paper and Paperboard (Taber-type method) UNI UNI EN 660-2 Resilient Floor Coverings - Determination of Wear Resistance - Part 2: Frick-Taber Test UNI UNI EN ISO 5470 Rubber or Plastics Coated Fabric-Determination of Abrasion Resistance UNI UNI 9115 Furniture: Test for surface finishes. Behavior of surfaces to wear abrasion. UNI UNI 10559 Paints and Varnishes; Determination of abrasion resistance by the Taber apparatus. UNI UNI EN 13672 Surfaces for Sports Areas - Determination of Resistance to Abrasion of Non-Filled Synthetic Turf UNI UNI EN 14431 Vitreous and Porcelain Enamels - Characteristics of the Enamel Coatings Applied to Steel Panels Intended for ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 23/26 DATA SHEET Page 24/26 Architecture UNI UNI EN 14864 Vitreous and Porcelain Enamels - Enamel Coatings Applied to Steel for Writing Surfaces - Specification United Nations ECE Regulation 43 Uniform Provisions Concerning the Approval of Safety Glazing and Glazing Material Calibration The Taber® Rotary Platform Abraser (Abrader) is a precision instrument that must be calibrated by an authorized Taber Calibration Center on a regular basis. The frequency of this calibration should be based on instrument usage and become part of your company’s quality procedures. Taber Industries calibration service for the Rotary Platform Abraser (Abrader) incorporates a proprietary gauging system used to measure critical parameters. Our skilled technicians evaluate the instrument against established tolerances and make the necessary adjustments to ensure that each unit is set to the required specifications. If any problems are identified during this evaluation, the customer is notified prior to the repair. A Calibration Verification Kit is also available for the Taber Rotary Platform Abraser. Not intended as a substitute for regular instrument calibration, the kit allows the operator to monitor the following critical parameters: • • • • Proper wheel alignment Proper wheel tracking Irregular bearing wear Vacuum suction force It also describes other miscellaneous inspections that are critical to the performance of the instrument. This fast, reliable system check is useful to identify potential concerns during the year. And will signify if an instrument should be returned for recalibration or repair prior to it’s scheduled calibration. FAQ's How often, and is it necessary to have my abraser calibrated? The Taber® Rotary Platform Abraser is a precision test instrument. To ensure your test results are accurate, Taber recommends that you have your Abraser calibrated on an annual basis. Instruments must be returned to the factory for calibration. To verify calibration during the year, a Calibration Verification Kit is available. What is the speed of the turntable? The Model 5135 and 5155 offer both 60 and 72 rpm turntable speeds. The turntable speed on previous versions of the Taber Abraser was dependent on the electrical line frequency. At 60Hz, the turntable speed was 72 rpm and at 50 Hz the turntable speed was 60 rpm. The test results are different than I expected, why? There are many factors that can influence test results. For consistent test results, it is imperative that you test the same each and every time. Some potential causes of test variation include: operator error; ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 24/26 DATA SHEET Page 25/26 changes in environmental conditions; static build-up; improper test set-up; failure to resurface wheels; variation in specimens; different vacuum pick-up nozzle height; full vacuum collection bag; etc. How do I determine what height to set the vacuum pick-up nozzle? The height of the vacuum pick-up nozzle is normally set between 1/8" and 1/4". The intent is to remove the abraded material. If the nozzle is set too close, you run the risk of lifting flexible test specimen and preventing sufficient cooling of the vacuum motor. If the nozzle is set too high, the suction may not be great enough to remove the abradant material. My specimens are greater than ¼" thick, can I still use the abraser? Specimens up to ½" thick can be tested on the Taber Abraser with the S-21 Extension Nut. An arm height extension kit [part# 132160] is available and permits the testing of specimens up to 40mm (requires return of abraser for modification). What is the proper method for changing specimen tables? Turntables can be removed by placing your fingers under the table (180° apart), and gently lifting straight up. A spring-loaded retention mechanism locks the turntable onto the motor drive shaft. The upward pressure will release the retention mechanism. NOTE: The drive shaft and holder bores are machined to precise tolerances; never force the removal of a holder as it may result in damage. Can I use my abraser to run wet tests? Yes - using the Rimmed Specimen Holder (model E-140-75), you can determine the effect of absorbed and or surface moisture on abrasion resistance. What criteria should I use to select which wheels to use? Under normal conditions, the general rule of thumb is, a load and wheel combination should run a minimum of 300 cycles on a material before the end point occurs. Otherwise, the test may be too harsh. If you are following a specific test standard, the wheel may be called out. What are the differences between Calibrase® and Calibrade® wheels? Calibrase wheels are composed of resilient binder and aluminum oxide or silicon carbide abrasive particles. Typical uses include testing rigid specimens. Calibrade are non-resilient wheels composed of vitrified (clay) and silicon carbide or aluminum oxide abrasive particles. They are often used to test flexible specimens. How many tests can be performed with a pair of wheels? The wear life of a wheel varies with the surface texture and frictional characteristics of the material tested. Under ordinary conditions, they can provide 10,000 to 50,000 wear cycles. Abnormally short wheel life may indicate incorrect wheel or load selection, too frequent refacing or improper procedure. The wheels have been designed to operate until worn down to a minimum of 1 ¾" (outside edge of label). Is there a shelf life on the wheels? There is no shelf life on Calabrade® wheels. However, due to their composition, Calabrase® wheels should be used before the expiration date printed on them. For CS-10F, the shelf life is 2 years. For CS-10 and CS-17, the shelf life is 4 years. NOTE: Shelf life is dependent on proper storage conditions. How often do I reface my Calibrase® wheels? Before using a new set of Calibrase® wheels, two refacings of 50 cycles each are recommended to ensure perfect contact of abrading faces with specimen surface. Before each test, reface previously used wheels 25 (for short tests on similar material) or 50 cycles (for tests of 1000 cycles or more, or for unlike material). ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 25/26 DATA SHEET Page 26/26 How do I reface my Calibrase® wheels? Calibrase wheels typically are refaced with the S-11 refacing disc or the ST-11 refacing stone. For refacing, use the same weight on the abrading arms as in testing, and adjust the vacuum pick-up nozzle height to ¼". As the wheels are used, they slowly disintegrate and continually expose fresh abrasive grains. In testing certain materials however, the wheel faces may become clogged as a result of the adhesive character of particles worn off the specimen thereby changing the abrasive characteristics of the wheel. To correct this, reface the wheels. Color changes may occur when the wheel faces become coated with fine abradings. This is a normal condition, and should not be confused with clogging. The resilient composition of these wheels makes them subject to slight changes of form. When operating the abraser, out of round wheels may be detected by the slight up and down movement of the abrading arm. This condition can be corrected with the Diamond Wheel Refacer. NOTE: Truing Calibrase® wheels on the Diamond Wheel Refacer will remove some of the abrasive grain from the wheel faces. To reestablish the normal abrasion coefficient, each wheel set should be given two refacings of 50 cycles each using the S-11 refacing discs. How often do I reface my Calibrade® wheels? Calibrade® wheels are diamond trued before leaving the factory. Unless the wheels show indications of being out of round, crowned or clogged with abraded material, they can be used continuously without further refacing. Taber recommends refacing previously used Calibrade® wheels whenever starting a new test, changing to different test material, and whenever there is a tendency for the working surface of the wheels to pick up excess materials. How do I reface my Calibrade® wheels? The Diamond Wheel Refacer is used to precisely dress Calibrade® wheels. Wheels may be refaced as often as required, down to the minimum usable diameter of 1 ¾" as indicated on the wheel label. Why did the color of the CS-10F wheels change? In late 2002, Taber introduced an improved version of the CS-10F wheel. Those customers performing haze measurements discovered that the wheel left a residue on the specimen surface. Taber eliminated this residue by making a slight adjustment to the formulation, however it also caused the haze values to increase on certain materials. During 2004, Taber conducted an extensive study to reformulate the improved CS-10F wheels so the results would match the old style wheels. To avoid further confusion in the marketplace, the wheel color was changed to easily distinguish this reformulated wheel. What is the useful life of a S-11 Refacing Disc? The useful life of a S-11 Refacing Disc is only 1 refacing. Regardless whether the disc has been used for 25 or 50 cycles, the refacing disc should be discarded. Refacing with a used disc may change the wear coefficient of the wheel faces, and invalidate your test results. I am using the CS-0 wheels with S-33 or S-42 sandpaper, and find that glue sticks to the wheels. NEMA test method LD3 recommends using a light dusting of zinc stearate to rectify this situation. Another alternative is to use a light dusting of talc powder. Is there an easy way to prepare specimens for the Taber Abraser? Taber offers the Model 5000 Sample cutter that will cut a 5 ¼" circle in many materials and punch a ¼" center hole. What material can I use on the Model 5000 Sample Cutter? Applications include paper, cardboard, fabric, leather, linoleum, flexible plastics, carpet, films, and thin metals. ProInex Instruments, s. r. o. CZECH REPUBLIC Head office: U Cukrovaru 509/4, Usti nad Labem, 400 07 VAT No:CZ27297845 Office Ostrava: Keltickova 58, Slezska 0strava, 710 00 Tel.: +420 599 509 995, Fax.: +420 599 509 994 Homepage: www.proinexinstruments.com E-mail: nyklova@proinex.cz, pacakova@proinex.cz 26/26