Bending the rules - Installer Online

advertisement

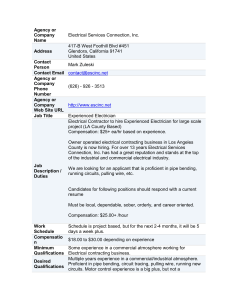

PLUMBING TECHNICAL Bending the rules Despite the increasing presence of plastic piping, copper remains the first choice for many plumbers and heating engineers. Kim Morris looks at how using the right methods for bending copper pipe can save time, money and effort during an installation. The author Kim Morris has over 30 years’ experience in the plumbing and gas industry. Kim had a key role at EAL (Excellence, Achievement & Learning Ltd) as an External Verifier for Gas and Plumbing qualifications. He was also a lecturer at Chichester College delivering plumbing and gas courses and was the Training Support Inspector at CAPITA for the Gas Safe Register and CORGI for over 18 years. He has also served on the committee for a branch of the CIPHE. Kim now works for CORGI Technical Services as Head of Training & Membership. C opper pipe has been used in the UK for such a long time that it has become one of the most important and reliable metals used in plumbing services – despite the development and popularity of plastic piping and fittings. It is suggested that copper tubes were first used by Ancient Egyptians to transport water around 2750BC. One of the many advantages of copper pipe is that it’s easy to cut and bend. Few tools are required – especially if the pipe that is to be bent does not exceed 22mm in diameter. For this application, a ‘scissor’ or ‘hand’ bending machine would be suitable. For bending applications above 22mm, a static tripod bending machine would be more suitable. This generally would be used for pipework up to 42mm in diameter. There are also internal bending springs that are available to bend pipe up to 35mm, but these have not widely been used since the development of the hand bender, and to bend copper that size would require some form of heat treatment (annealing) to the copper to make it more workable. Making accurate bends may need some training and practice, but it’s cheaper than buying specially-shaped fittings like an elbow or long radius bend. Crossover fittings can also be eliminated as these can be formed by the use of a bending machine. Copper piping can be used for many applications such as carrying water and gas. Whatever the pipe is carrying, though, it must be able to run smoothly with nothing causing resistance to the flow. The best design practice is to ensure pipe runs are as straight and direct as possible. Sometimes bends are unavoidable, for example when pipe is required to go around a room or change direction, and if available fittings are neither right for the angle nor attractive to look at, then the only solution would be to bend the pipe. Copper piping is both light and resistant to corrosion, and can be joined with either capillary or compression fittings, but when bends are required, angles can be created in several ways. The standard for copper tube used for gas, water and sanitation installations is BS EN 1057 Copper and copper alloys. Seamless, round copper tubes for water and gas in sanitary and heating applications, and the copper is generally available in three grades: • R220 – Fully annealed soft copper tube generally supplied in coils. • R250 – Half hard copper tube that is generally supplied in 3m or 6m lengths and is also suitable for bending. 59 PLUMBING TECHNICAL • R290 – Hard tempered, thin-walled and unsuitable for bending. Bending copper pipe If lots of changes of direction are necessary in a pipe run, it is cheaper and quicker to bend the pipe than use fittings. This also makes the neatest finish – particularly if the pipework is going to be exposed. Using fittings would be more costly as well as possibly being unsightly, while the cheaper alternative of making bends means the pipework is less conspicuous. The pipe can also be bent to the exact angle required so this method of changing direction is not limited by the angles of the fittings. Also, with fewer fittings Figure 1: Marking out for a 90º spring bend. a b c 2 1 3 bending length a. measured length (end to centre) – make first mark at ‘1’ b. measure back 4 pipe diameters – make a mark at ‘2’ c. measure forward 2 pipe diameters from ‘1’ – make a mark at ‘3’ completed bend Figure 2. Components of a bending machine. tube stop formers guide pressure roller half pipe diameter in a pipe system there are fewer places where leaks might occur. The smaller sizes of copper pipe – those most commonly used in domestic plumbing (15mm, 22mm and 28mm) – can be bent quite easily by hand. The technique of annealing, which requires heating the pipe to make bending easier, is unnecessary when working with these pipe sizes. You will, however, need to support the pipe wall either internally or externally when producing the bend, otherwise the profile of the pipe will be flattened. Bending techniques Bending springs are used to support the tube walls while the bend is made to prevent the walls from collapsing. It is very important to use the correct size spring to prevent wrinkling or snapping of the tube during the bending process. When tube is bent to pass around a corner or an obstruction, the tube takes a ‘short cut’ and so tube gain is achieved. The actual amount of tube gained depends on the angle through which the bend is pulled and the bend radius to be used. This radius in turn depends on the diameter of the tube. As a general rule, the radius of a spring-loaded bend should be equal to four times the outside diameter (OD) of the tube. This radius is slightly greater than the radius of a typical bending machine. For simplicity, the method shown would be to form a 90° bend (although offsets are possible). As an example, a spring loaded 90° bend on 15 mm diameter tube is required 300 mm from the end of the tube to the centre of the bend (see Figure 1). Mark the measured length position. In this example, the mark will be 300 mm from the end of the tube (shown as ‘a’). Decide on the bending radius. Usually this will be four times the tube diameter, e.g 4 3 15 = 60mm. i NOTE: Some manufacturers might require three or five times the tube diameter. For simplicity, this example requires four times. Mark the start of the bending length. The position of this mark is four tube diameters (60 mm or one bend radius) back from the first mark (shown as ‘b’). The last mark required is the end of the bending length. The position of this mark is two tube diameters (30 mm or half a bend radius) forward from the first mark (shown as ‘c’). Then insert the correct size spring and bend to the required angle. The pipe can be bent over the knee, over-bending slightly then bringing back to the required angle. The spring will now be fixed tightly in the pipe and is sometimes difficult to remove. However, its removal is quite simple – insert a bar through the ring at the end of the spring and twist it. This reduces the spring’s diameter and will enable the spring to be withdrawn. It is a good idea to apply lubricant to Figure 5. Correct positioning of pipework in the bending machine. end to centre pressure roller bending mark measured end Figure 3. Measuring for a single 90º bend., Figure 4. Forming a 90º offset. bending mark pipe pipe stop measure centre to centre measured inside to back gives bending mark position directly 60 › INSTALLER › May 2014 bending mark guide pipe bender Set position of pipe so the square touches both the mark and the edge of the former, then bend to 90º. the spring before it is inserted into the pipe as this will make pulling it out that much easier. 8mm and 10mm copper pipes can be bent using either an external spring or by using a mini bender. Using a hand bender Before any bending can be undertaken, it is good practice to understand the components of the bending machine (see Figure 2). Figure 5 shows how to accurately position the bending mark in the machine for 90° bends. When more than one bend is required on a length of tube, it is essential to check whether the bends are in the same plane prior to pulling the second bend. Check and adjust if necessary. In this example, we need to establish the bending mark position (see Figure 3). If the length to where the back of the bend is going to be is 350mm and the pipe size is 22mm OD, measure the end-to-centre length required and then add 0.5 3 OD. This will give you a measurement of 350 1 11=361mm. Mark this position clearly on the tube. Insert the copper tube into the bending machine and line the mark at the back of the formers using a square. Ensure the pipe is located properly and is located firmly within the tube stop. Pull the bend until 90° has been formed. Check with a set square and rule. Forming an offset bend When bending a single or double offset, it is possible to use a 600mm folding rule method to determine a suitable angle for the bends. Figure 6 shows how to move the ends of the rule to obtain the desired angle. In this instance, an offset of 55mm is required. This figure is subtracted from 600, giving 600 –55=545mm. Close the folding rule until this figure is reached, giving the angle to which the pipe must be bent. Bend the pipe until this is achieved. The next stage is to establish the mark for the second offset. This is achieved by laying the pipe on a flat surface and – with the use of a straight edge – aligning the first bend so that they are parallel to each other. Making sure that the separation distance between the two is the offset measurement required. Ensure that the position of the bending mark is in line with the straight edge and make a mark. Place the pipe back into the bender so that the bending mark forms a tangent to the former (see Figure 7). Check to ensure the bends are in the same plane prior to starting the second bend and proceed until the required offset is formed. Check with a straight edge to ensure the offset measurement is uniform throughout the pipe. In this example, it would be 55mm. With the aid of the bending machine it is possible to achieve both pass-over and partial passover bends. Forming a 90° offset: In this example, the centreto-centre length must be determined and then accurately measured. Add 0.5 3 OD, mark off and then insert the pipe into the bending machine. Ensure the two bends are in the same plane with each other and not offset. Adjust if necessary and pull the bend until 90° has been obtained. Check with a square and rule (See Figure 4). Rippling This generally occurs with prolonged use because the formers become worn and, as the pressure rollers are nonadjustable, they cannot be repositioned or tightened. If ripples appear when bending copper pipe, the solution is either to insert a thin piece of metal between the guide and the pressure roller when bending the pipe or to replace the formers. n Forming a 90° bend It is important to remember not to waste copper tube – because it is expensive – so accuracy when measuring is very important. Equally, there are many variations on techniques that are used when bending copper pipe. ››You will need to support the pipe wall when producing the bend, otherwise the profile of the pipe will be flattened.‹‹ Figure 6. Creating offsets using a folding rule method. required offset 55mm 55mm 600mm Bend first set to angle formed by rule Figure 7. Forming the offset. straight edge required offset Reposition pipe in bender so that bending mark forms a tangent to former edge and bend till parallel bending mark bending mark TO SUM UP › Bending copper pipe is more economically friendly than using fittings. › Resistance within the pipe is reduced. › Bending pipe is a good option when there are limitations to apply heat. › Multiply bends can be formed very quickly. 61