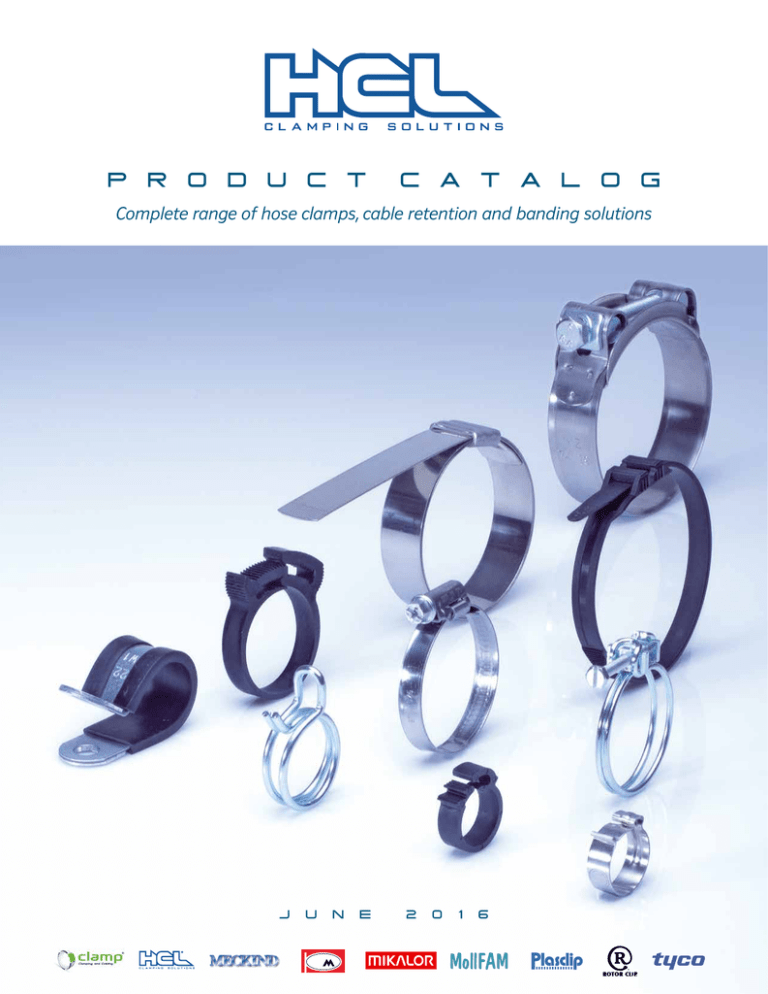

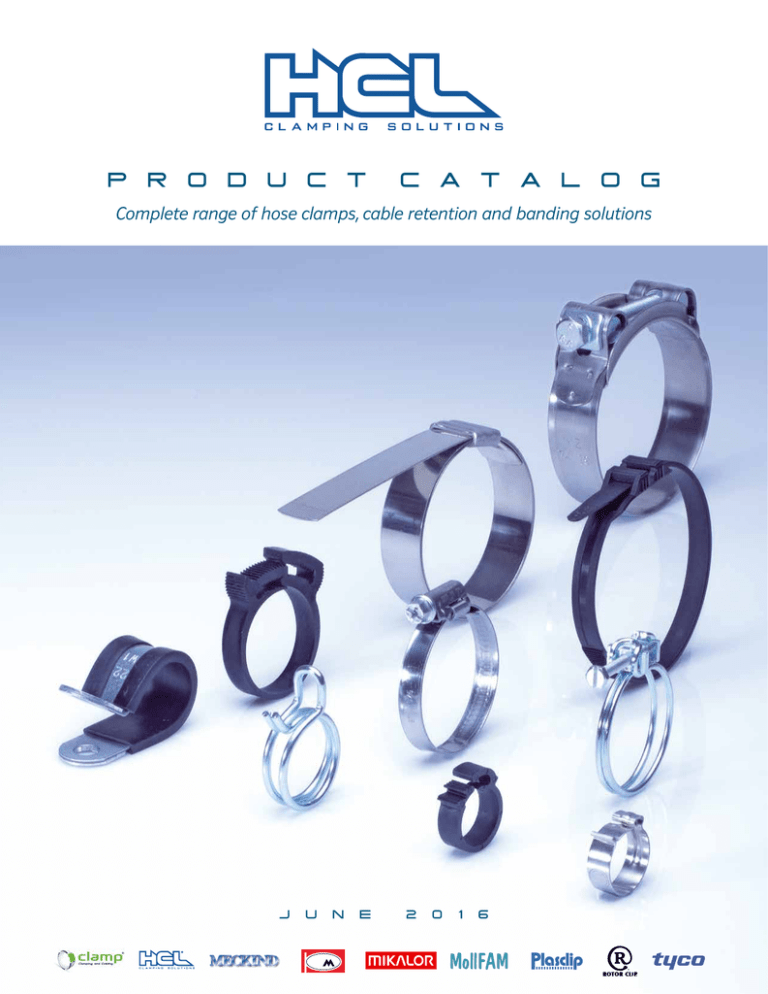

P R O D U C T

C A T A L O G

Complete range of hose clamps, cable retention and banding solutions

J

U

N

E

2

0

1

6

INDEX

The complete range of HCL products

Below is the index for the complete HCL Product Catalog.

HCL’s comprehensive range of hose clamps, cable retention

and banding solutions is complimented by introductory and

ancilliary pages, providing advice on hose clamp selection,

a variety of installation tools and technical information. The

catalog pages are designed to guide the customer through the

HCL range and to offer peace of mind when making a product

selection.

Cable Retention

Introductory Pages

6.1

Heavy Duty Nylon Cable Tie – Smart Tie™

1.1

Company Profile

6.2

Metal Cable Tie – Tyco Ball Locking Type – 316SS

1.2

Online Shop

6.3

Metal Cable Tie – Tyco Re-Usable – 316SS Coated

6.4

Nylon (Plastic) P Clips Black or Natural – Micro Plastics

Snap Fit & Ear Clamps

Banding & Strapping

2.1

Herbie Clip® Plastic (Nylon) Hose Clamp – Double Grip

2.2

Ezyclik™-P Low Profile Plastic Hose Clamp

7.1

Heavy Duty Nylon Banding – Smart Band® Standard

2.3

Ezyclik™-M Low Profile Automotive Hose Clip

7.2

High Strength Nylon Banding – Smart Band® Hybrid

2.4

Zero Leak – Low Profile Ear Clamp

2.5

Single Ear Hose Clamp – Mikalor

2.6

Double Ear Hose Clamp – Mikalor

Special Hose Clamps

8.1

Special Clamp Designs

Installation Tooling

Compensating Clamps

9.1

Manual Tools – Plastic Snap Fit Hose Clamps

3.1

Ezyclik™-M+ – Spring Automotive Hose Clip

9.2

Manual Tools – Metal Snap Fit, Ear & Spring Hose Clamps

3.2

Zinc Plated Steel – Double Wire Spring Hose Clip

9.3

Manual Tools – Worm Drive & Screw Hose Clamps

3.3

Rotor Spring Band Hose Clamp – Constant Tension

9.4

Manual Tools – Plastic and Steel (metal) Cable Ties

3.4

Rotor Spring Band Light Hose Clamp – Constant Tension

9.5

Manual Tools – Banding & Strapping – Smart Band® &

Worm Drive & Screw Clamps

Metal Banding

9.6

Installation Tools – Pneumatic Air Tools for Hose Clamps

4.1

Worm Gear Hose Clamp – Perforated US Style

4.2

Quick Release Worm Drive Hose Clamp

Ancillary Pages

4.3

Mini Screw or Petrol Pipe Clip – Mollfam

10.1

Choosing the Right Clamp

4.4

Double Wire Screw Hose Clamp – Mollfam

10.2

Technical Information

4.5

Plastic Worm Drive Hose Clamp

10.3

Material Information

4.6

Continuous Worm Drive Clamping Kit

10.4

Conditions of Sale

Heavy Duty Clamps

5.1

T-Bolt Heavy Duty Hose Clamp

5.2

Worm Drive Super (High) Torque Hose Clamp

5.3

Preformed Band Clamps

w w w . h c l - c l a m p i n g . c o m

COMPANY

PROFILE

HCL’s Quality Policy

Within HCL Fasteners Ltd (the parent company of HCL Fasteners

Corp) we are committed to provide products and services

which meet the customers’ specified contractual and project

requirements and those of all applicable regulating authorities.

We are totally committed to setting and achieving quality

standards that are capable of meeting, in all respects, the

specified requirements and reasonable expectations of our

customers, whilst working within the framework of statutory,

regulatory and legal requirements.

In order to achieve this objective, it is the policy of HCL

Fasteners Ltd to maintain an effective quality system based on

the requirements of: BS EN ISO 9001-2008.

Specialists in banding and clamping products

HCL is uniquely placed to provide a first class clamping

service thanks to its long term exclusive arrangements with

high quality clamping suppliers around the world, and its

ability to manufacture a variety of clamping products and

fitting tools.

Founded in 1994, HCL was originally known for the

manufacture and supply of the original double grip

plastic hose clamp, the Herbie Clip®. Since then, HCL

has established a focused range of products which

specialise in plastic clamping and banding; including

Smart Band®, Smart Tie™ and the Ezyclik™. Our

hi-tech manufacturing facility consisting of

numerous injection moulding machines and

bespoke extrusion lines.

2010 saw an exciting change for HCL, as for

the first time we combined our manufactured and

supplied clamping products to create a complete portfolio of

clamping solutions.

With an established office in North America and a worldwide

distribution network, our continuous objective is to innovate

and service the market with quality-engineered products that

will stand the test of time.

1.1

w w w . h c l - c l a m p i n g . c o m

ONLINE

SHOP

Our complete range available to buy online

Whether you need a single clamp or 100

clamps to finish that important job, visit

our online web site where you can choose

and purchase from the complete range of

products contained in this catalogue.

As well as our own manufactured clamping

products, HCL has also partnered with

a number of hose clamp manufacturers

to provide a complete clamping solution

portfolio.

We are also continually researching and

reviewing new products that may add

value to our already extensive

range.

www.hcl-clamping.com

1.2

w w w . h c l - c l a m p i n g . c o m

SNAP FIT &

EAR CLAMPS

Herbie Clip® Plastic (Nylon) Hose Clamp – Double Grip

PERFORMANCE

Manufactured by HCL, the Herbie Clip®

Strength

Temperature

is the original Double Grip plastic hose

Speed

clip. It is a quick and easy to install nylon

Weathering

hose clamp with exceptional strength

Chemical

arising from its unique double row of

Dynamic Range

interlocking toothed jaws. The double row

of teeth offers over twice the clamping

force achieved by similar products with only a single row of teeth. No

other nylon hose clamps can rival the Herbie Clip in terms of overall

strength and performance. Temperature range: Nylon 6.6 -40°F to 338°F,

PP -40°F to 194°F.

Applications

JAgricultural

JAutomotive

JHydro Massage

JIrrigation

em

Materials – see section 10.3

Standard

JHeat/UV Stabilised ROHS compliant Nylon 6.6.

On Request

JPolypropylene

Strength

All teeth engaged

Temperature

Weathering

Chemical

B

3 teeth engaged

D

A1

A2

C

Installation Tools – see section 9.1

MT-HC-VT-01

PT-HC-C

Other Herbie Clip® tools also available.

PT-HC-P

JPharmaceutical

JVending

JWhite Goods

JGeneral Industry

HCL

Part No

Diameter Range

(A1-A2) inch

Band Width

(B) inch

Band Thickness

(C) inch

Head Height

(D) inch

Box

Quantity

HC-A

HC-AA

HC-B

HC-BB

HC-C

HC-CC

HC-D

HC-E

HC-F

HC-G

HC-H

HC-J

HC-K

HC-L

HC-M

HC-N

HC-P

HC-Q

HC-R

HC-S

HC-T

HC-U

HC-V

HC-W

HC-X

HC-59

HC-64

HC-66

HC-70

HC-75

HC-80

HC-85

HC-91

HC-96

HC-105

HC-109

HC-115

HC-163

0.22 – 0.25

0.26 – 0.31

0.31 – 0.36

0.36 – 0.40

0.40 – 0.46

0.43 – 0.50

0.47 – 0.54

0.51 – 0.59

0.59 – 0.67

0.66 – 0.75

0.71 – 0.80

0.79 – 0.90

0.87 – 0.97

0.96 – 1.08

1.03 – 1.15

1.12 – 1.26

1.25 – 1.36

1.34 – 1.48

1.48 – 1.60

1.56 – 1.72

1.69 – 1.80

1.79 – 1.97

1.89 – 2.10

2.07 – 2.20

2.15 – 2.36

2.30 – 2.52

2.42 – 2.63

2.57 – 2.78

2.73 – 2.94

2.91 – 3.14

3.11 – 3.32

3.32 – 3.74

3.55 – 3.74

3.81 – 3.98

4.11 – 4.36

4.21 – 4.46

4.49 – 4.72

6.36 – 6.59

0.17

0.18

0.18

0.18

0.23

0.24

0.24

0.28

0.28

0.27

0.28

0.25

0.28

0.28

0.29

0.35

0.36

0.35

0.36

0.35

0.35

0.35

0.35

0.35

0.37

0.37

0.37

0.36

0.36

0.36

0.35

0.35

0.37

0.34

0.35

0.35

0.37

0.37

0.06

0.33

0.39

0.37

0.43

0.48

0.48

0.51

0.54

0.51

0.49

0.50

0.56

0.51

0.49

0.53

0.53

0.54

0.53

0.56

0.53

0.50

0.57

0.57

0.59

0.61

0.67

0.61

0.62

0.61

0.65

0.70

0.68

0.66

0.69

0.64

0.69

0.69

0.63

3000

2500

0.06

0.07

0.08

0.08

0.08

0.08

0.09

0.08

0.09

0.08

0.09

0.08

0.09

0.11

0.10

0.08

0.10

0.11

0.10

0.10

All weights, dimensions & quantities are subject to a 2.5% tolerance. To add material selection to the HCL Part No: for Nylon 6.6. Black, add “-PA66-BK”.

Other colours available on request.

2.1

w w w . h c l - c l a m p i n g . c o m

2000

1000

1500

1000

750

500

1000

750

500

100

SNAP FIT &

EAR CLAMPS

PERFORMANCE

Ezyclik™-P Low Profile Plastic Hose Clamp

Manufactured by HCL in the UK,

Strength

Temperature

the Ezyclik™-P (Plastic) hose clip is

Speed

specifically designed for hose clamping

Weathering

applications where space is restricted.

Chemical

The unique design of the patent

Dynamic Range

pending Ezyclik™-P ensures strong, fast

and reliable clamping with a low profile design and fully corrosion

resistant materials. Temperature range: Nylon 6.6 -40°F to 338°F, PP

-40°F to 194°F.

Applications

J Automotive

J Hydro Massage

J Irrigation

J Pharmaceutical

em

HCL

Part No

Materials – see section 10.3

Standard

J Heat/UV Stabilised ROHS compliant Nylon 6.6.

On Request

J Polypropylene

Strength

Temperature

Weathering

Chemical

J Glass-filled Nylon 6.6.

Strength

Temperature

B

D

A

C

Installation Tools – see section 9.1

MT-EZP-LVT-01

MT-EZP-HT-01

Other Ezyclik™-P tools also available.

PT-EZY-C

EZY-P-8.5

EZY-P-8.7

EZY-P-8.9

EZY-P-9.2

EZY-P-9.5

EZY-P-10.0

EZY-P-11.4

EZY-P-12.0

EZY-P-12.5

EZY-P-12.7

EZY-P-13.2

EZY-P-13.7

EZY-P-14.5

EZY-P-14.6

EZY-P-15.0

EZY-P-15.7

EZY-P-15.9

EZY-P-16.5

EZY-P-16.8

EZY-P-17.1

EZY-P-17.5

EZY-P-17.6

EZY-P-18.0

EZY-P-18.5

EZY-P-19.1

EZY-P-19.6

EZY-P-20.1

EZY-P-20.8

EZY-P-21.1

EZY-P-22.0

EZY-P-22.1

EZY-P-22.6

EZY-P-23.1

EZY-P-23.6

EZY-P-24.7

EZY-P-25.8

EZY-P-26.8

EZY-P-28.0

EZY-P-30.6

EZY-P-31.4

EZY-P-36.5

EZY-P-42.4

EZY-P-43.3

EZY-P-45.5

Closed

Diameter

(A) inch

0.33

0.34

0.35

0.36

0.37

0.39

0.44

0.47

0.49

0.50

0.51

0.53

0.57

0.57

0.59

0.61

0.62

0.64

0.66

0.67

0.68

0.69

0.70

0.72

0.74

0.76

0.78

0.81

0.82

0.85

0.86

0.88

0.90

0.92

0.96

1.01

1.05

1.09

1.19

1.22

1.42

1.65

1.69

1.77

J Vending

J White Goods

J General Industry

Band

Width

(B) inch

Band

Thickness

(C) inch

0.07

Head

Height

(D) inch

Box

Quantity

0.21

2000

0.22

0.22

0.22

1500

0.23

1000

0.31

0.08

0.27

1500

1000

500

0.35

0.10

0.29

400

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for Nylon 6.6. Black, add “-PA66-BK”. Other colours available on request.

2.2

w w w . h c l - c l a m p i n g . c o m

SNAP FIT &

EAR CLAMPS

PERFORMANCE

Ezyclik™-M Low Profile Automotive Hose Clip

Strength

The Ezyclik™-M (Metal) type hose

Temperature

clamp offers exceptional strength

Speed

and is used extensively in the

Weathering

automotive and general industry. It

Chemical

Dynamic Range

is quick and easy, to assemble and

disassemble; has a low profile design

and is manufactured from corrosion resistant Stainless Steel.

The Ezyclik™-M offers an alternative to the Clic hose clamp often

used in these applications. The Ezyclik™-M hose clip is often

used in automotive applications.

Applications

J Automotive

J Hydro Massage

Materials – see section 10.3

J

4 304 SS

B

A

C

Installation Tools – see section 9.1

MT-EZM-VT-01

MT-EZM-SJ-01

PT-EZY-C

HCL

Part No

Diameter

Range

(A) inch

EZY-M-8.0

EZY-M-8.5

EZY-M-9.0

EZY-M-9.5

EZY-M-10.0

EZY-M-10.5

EZY-M-11.0

EZY-M-11.5

EZY-M-12.0

EZY-M-12.5

EZY-M-13.0

EZY-M-13.5

EZY-M-14.0

EZY-M-14.5

EZY-M-15.0

EZY-M-15.5

EZY-M-16.0

EZY-M-16.5

EZY-M-17.0

EZY-M-17.5

EZY-M-18.0

EZY-M-18.5

EZY-M-19.0

EZY-M-19.5

EZY-M-20.0

EZY-M-20.5

EZY-M-21.0

EZY-M-21.5

EZY-M-22.0

EZY-M-23.0

EZY-M-23.5

0.33 – 0.37

0.35 – 0.41

0.37 – 0.43

0.39 – 0.45

0.41 – 0.47

0.43 – 0.49

0.45 – 0.51

0.47 – 0.53

0.49 – 0.55

0.51 – 0.55

0.53 – 0.59

0.55 – 0.60

0.57 – 0.62

0.59 – 0.64

0.60 – 0.66

0.62 – 0.68

0.64 – 0.70

0.66 – 0.72

0.68 – 0.74

0.70 – 0.76

0.72 – 0.76

0.74 –0.80

0.76 – 0.82

0.78 – 0.84

0.80 – 0.86

0.82 – 0.90

0.84 – 0.92

0.86 – 0.94

0.88 – 0.96

0.92 – 0.99

0.94 – 1.01

J White Goods

J General Industry

Band

Width

(B) inch

Band

Thickness

(C) inch

0.02

0.23

0.02

0.31

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W4, add “-W4”.

Other sizes available on request.

2.3

w w w . h c l - c l a m p i n g . c o m

Colour

Mark

Blue

Green

Purple

Black

Green

Blue

Green

Purple

Black

Red

Green

Purple

Red

Purple

Black

Blue

Green

Black

Red

Blue

Green

Purple

Blue

Black

Red

Blue

Green

Purple

Black

Blue

Green

Box

Quantity

3000

2500

3500

3000

2500

2000

SNAP FIT &

EAR CLAMPS

PERFORMANCE

Zero Leak – Low Profile Ear Clamp

Strength

HCL’s Zero Leak Ear clamp (O-Clip) is

Temperature

ideal for rubber and PVC hoses. The

Speed

steel hose clamp forms a complete

Weathering

circle, removing the possibility of

Chemical

Dynamic Range

leakage. It is quick and easy to

assemble, has a low profile design

and is manufactured from corrosion resistant Stainless

Steel 304 or W4. The Zero leak metal hose clip is also known

sometimes as a low profile hose clamp.

Applications

J Automotive

J Vending

Materials – see section 10.3

J

4 304 SS

B

A

C

Installation Tools – see section 9.1

MT-EC-VHT-01

MT-EC-VT-01

J White Goods

J General Industry

HCL

Part No

Diameter

Range

(A) inch

ZLEC-7.0

ZLEC-8.0

ZLEC-8.7

ZLEC-9.0

ZLEC-9.5

ZLEC-10.0

ZLEC-10.5

ZLEC-10.9

ZLEC-11.3

ZLEC-11.8

ZLEC-11.9

ZLEC-12.3

ZLEC-12.8

ZLEC-13.3

ZLEC-13.8

ZLEC-14.0

ZLEC-14.2

ZLEC-14.5

ZLEC-14.8

ZLEC-15.3

ZLEC-15.7

ZLEC-16.0

ZLEC-16.8

ZLEC-17.0

ZLEC-17.5

ZLEC-17.8

ZLEC-18.0

ZLEC-18.5

ZLEC-19.2

0.22 – 0.27

0.27 – 0.31

0.27 – 0.34

0.28 – 0.35

0.30 – 0.37

0.32 – 0.39

0.34 – 0.41

0.36 – 0.43

0.37 – 0.44

0.39 – 0.46

0.37 – 0.46

0.38 – 0.48

0.40 – 0.50

0.42 –0.52

0.44 – 0.54

0.45 – 0.55

0.46 – 0.55

0.47 – 0.57

0.48 – 0.58

0.50 – 0.60

0.51 – 0.61

0.53 – 0.62

0.56 – 0.66

0.57 – 0.66

0.59 – 0.68

0.57 – 0.69

0.58 –0.70

0.60 –0.72

0.60 –0.75

Band

Width

(B) inch

Band

Thickness

(C) inch

0.20

0.02

Box

Quantity

100

0.27

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W4, add “-W4”.

Other sizes available on request.

2.4

w w w . h c l - c l a m p i n g . c o m

0.02

SNAP FIT &

EAR CLAMPS

PERFORMANCE

Single Ear Hose Clamp – Mikalor

Strength

The Mikalor Single Ear Hose Clip

Temperature

(O-Clip) is manufactured from

Speed

a choice of materials and is an

Weathering

economical solution for many

Chemical

Dynamic Range

simple hose assemblies. The single

ear hose clamps can be used with

air or other fluids. These O clips are ideal for demanding

applications involving soft or hard rubbers and plastics. The

design also ensures a uniform compression around the whole

circumference of the hose clamp.

Applications

J Automotive

J Vending

Materials – see section 10.3

J

1

Zinc Plated Steel

On Request

J 4 304 SS

Weathering

Chemical

B

J White Goods

J General Industry

HCL

Part No

Diameter

Range

(A) inch

SEC-7

SEC-8

SEC-9

SEC-10

SEC-11

SEC-12

SEC-13*

SEC-14

SEC-15*

SEC-16

SEC-17*

SEC-18*

0.27 – 0.35

0.31 – 0.39

0.35 – 0.43

0.39 – 0.47

0.43 – 0.51

0.47 – 0.55

0.51 – 0.59

0.55 – 0.62

0.59 – 0.66

0.62 – 0.70

0.66 – 0.74

0.70 – 0.78

Band

Width

(B) inch

Box

Quantity

0.23

0.03

0.25

100

0.27

0.04

0.29

Part numbers marked with * are only available in W4 Material

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W4, add “-W4”.

A

C

Installation Tools – see section 9.1

MT-EC-VHT-01

Band

Thickness

(C) inch

MT-EC-VT-01

2.5

w w w . h c l - c l a m p i n g . c o m

SNAP FIT &

EAR CLAMPS

PERFORMANCE

Double Ear Hose Clamp – Mikalor

The Mikalor Double Ear Hose Clip

Strength

Temperature

(O-Clip) is manufactured from a choice of

Speed

materials and is an economical solution

Weathering

for many simple hose assemblies. The

Chemical

double ear hose clamps can be used with

Dynamic Range

air or other fluids. These O clips are ideal

for demanding applications involving soft or hard rubbers and plastics.

The ears of the hose clamp should be closed with the recommended

uniform force resulting in a constant stress within the clamp material,

without overloading either the clamp or the parts being assembled.

The nominal diameter of the two ear clamp should always be chosen

so that, when installed with the correct clamping force, the ears are

almost closed.

Applications

J Automotive

J Vending

Materials – see section 10.3

J

1

Zinc Plated Steel

On Request

J 4 304 SS

Weathering

Chemical

B

A

C

J White Goods

J General Industry

HCL

Part No

Diameter

Range

(A) inch

DEC-5

DEC-7

DEC-9

DEC-11

DEC-13

DEC-14*

DEC-15

DEC-17

DEC-18

DEC-20

DEC-22

DEC-23*

DEC-25*

DEC-28*

DEC-31*

DEC-34*

DEC-37*

DEC-40*

DEC-43*

0.20 – 0.27

0.27 – 0.35

0.35 – 0.43

0.43 – 0.51

0.51 – 0.59

0.55 – 0.66

0.59 – 0.70

0.66 – 0.78

0.70 – 0.82

0.78 – 0.90

0.86 – 0.98

0.90 – 1.05

0.98 – 1.09

1.09 – 1.21

1.21 – 1.33

1.33 – 1.44

1.44 – 1.56

1.56 – 1.68

1.68 – 1.77

Band

Width

(B) inch

0.23

Box

Quantity

0.02

0.03

0.25

0.27

0.29

0.31

0.04

0.04

0.05

0.05

0.33

0.35

0.05

0.37

0.39

0.41

Part numbers marked with * are only available in W1 Material

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W4, add “-W4”.

Installation Tools – see section 9.1

MT-EC-VHT-01

Band

Thickness

(C) inch

MT-EC-VT-01

2.6

w w w . h c l - c l a m p i n g . c o m

0.06

100

COMPENSATING

CLAMPS

Ezyclik™-M+ – Spring Automotive Hose Clip

PERFORMANCE

Strength

The Ezyclik™-M+ hose clamp

Temperature

offers exceptional strength and

Speed

a diameter that self-adjusts

Weathering

Chemical

to compensate for diametrical

Dynamic Range

variations. This spring loaded

hose clip is quick and easy, to

assemble and disassemble; has a low profile design and

is manufactured from corrosion resistant Stainless Steel.

Applications

J Automotive

J Hydro Massage

Materials – see section 10.3

J

4 304 SS

B

A

C

MT-EZM-SJ-01

Diameter

Range

(A) inch

EZY-M+-8

EZY-M+-9

EZY-M+-10

EZY-M+-11

EZY-M+-12

EZY-M+-13

EZY-M+-14

EZY-M+-15

EZY-M+-16

EZY-M+-17

EZY-M+-18

EZY-M+-19

EZY-M+-20

EZY-M+-21

EZY-M+-22

EZY-M+-23

EZY-M+-24

0.33 – 0.37

0.37 – 0.41

0.41 – 0.45

0.45 – 0.49

0.49 – 0.55

0.55 – 0.59

0.57 – 0.63

0.61 – 0.67

0.65 – 0.71

0.69 – 0.75

0.73 – 0.79

0.77 – 0.83

0.81 – 0.87

0.89 – 0.91

0.89 – 0.94

0.93 – 0.98

0.96 – 1.02

Band

Width

(B) inch

Band

Thickness

(C) inch

Box

Quantity

0.28

1000

0.02

0.31

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W4, add “-W4”.

Other sizes available on request.

Installation Tools – see section 9.1

MT-EZM-VT-01

HCL

Part No

J White Goods

J General Industry

PT-EZY-C

3.1

w w w . h c l - c l a m p i n g . c o m

500

COMPENSATING

CLAMPS

PERFORMANCE

Zinc Plated Steel – Double Wire Spring Hose Clip

Strength

Mollfam’s Double Wire Spring hose

Temperature

clips are ideal on rubber and PVC

Speed

hoses. Made from Zinc Plated steel

Weathering

the spring effect compensates

Chemical

Dynamic Range

for diametrical variation and the

complete circle guarantees a uniform

radial pressure. These Double Wire Spring Hose Clips are ideal

for low pressure applications.

Applications

J Agricultural

J Irrigation

HCL

Part No

Diameter

Range

(A) inch

DW-6.8

DW-7.3

DW-7.6

DW-8.1

DW-8.6

DW-9.1

DW-9.6

DW-10.1

DW-10.7

DW-11.3

DW-11.9

DW-12.6

DW-13.3

DW-13.7

DW-14.0

DW-14.8

DW-15.6

DW-15.8

DW-16.4

DW-17.3

DW-18.2

DW-19.2

DW-20.2

DW-21.2

DW-22.1

DW-22.6

DW-23.1

DW-24.2

DW-25.2

0.26 – 0.27

0.27 – 0.29

0.28 – 0.30

0.30 – 0.32

0.32 – 0.34

0.34 – 0.36

0.36 – 0.38

0.38 – 0.41

0.41 – 0.43

0.43 – 0.45

0.45 – 0.48

0.48 – 0.50

0.50 – 0.53

0.52 – 0.55

0.53 – 0.56

0.56 – 0.59

0.59 – 0.62

0.60 – 0.64

0.62 – 0.66

0.66 – 0.69

0.69 – 0.73

0.73 – 0.76

0.76 – 0.80

0.80 – 0.84

0.84 – 0.88

0.86 – 0.90

0.87 – 0.92

0.92 – 0.96

0.96 – 1.01

Materials – see section 10.3

J

1 Zinc Plated Steel

B

A

C

Installation Tools – see section 9.1

MT-SC-TP-01

MT-SC-FR-01

J White Goods

J General Industry

Clamp

Width

(B) inch

Wire

Diameter

(C) inch

Box

Quantity

0.20

0.04

0.21

0.23

0.05

0.27

0.06

1000

0.31

0.07

0.35

0.07

0.37

0.08

0.40

0.09

0.43

0.10

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W1, add “-W1”.

Other sizes available on request.

3.2

w w w . h c l - c l a m p i n g . c o m

COMPENSATING

CLAMPS

HCL supplies Rotor Constant

Tension Band Clamps. The

spring loaded Zinc Plated Steel

hose clamps are ideal for many

automotive, truck and spa

applications.

PERFORMANCE

Rotor Spring Band Hose Clamp – Constant Tension

Strength

Temperature

Speed

Weathering

Chemical

Dynamic Range

Applications

J Agricultural

J Automotive

J Vending

Materials – see section 10.3

J

1

Zinc Plated Steel

On Request

Clamps can also be supplied in finished colours Black, Brown,

Tan, Green or Red.

B

HCL

Part No

Diameter

Range

(A) inch

CTB-14.4

CTB-15.2

CTB-17.8

CTB-18.4

CTB-20.5

CTB-22.0

CTB-24.3

CTB-25.2

CTB-27.0

CTB-29.3

CTB-31.5

CTB-37.2

CTB-40.5

CTB-41.4

CTB-43.5

0.56 – 0.67

0.59 – 0.72

0.69 – 0.78

0.72 – 0.84

0.80 – 0.96

0.86 – 1.01

0.95 – 1.09

0.98 – 1.13

1.05 – 1.23

1.14 – 1.35

1.23 – 1.48

1.45 – 1.74

1.58 – 1.89

1.61 – 1.95

1.70 – 2.07

J White Goods

J General Industry

Clamp

Width

(B) inch

0.05

0.59

C

Installation Tools – see section 9.1

MT-SC-TP-01

Box

Quantity

0.04

0.03

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W1, add “-W1”.

A

Band

Thickness

(C) inch

MT-SC-FR-01

3.3

w w w . h c l - c l a m p i n g . c o m

0.06

0.07

0.07

0.08

100

COMPENSATING

CLAMPS

PERFORMANCE

Rotor Spring Band Light Hose Clamp – Constant Tension

Strength

HCL supplies Rotor Constant Tension

Temperature

Light Band Clamps. The spring loaded

Speed

Zinc Plated Steel hose clamps are

Weathering

cost effective alternatives to other

Chemical

Dynamic Range

types of hose clamps but do not

compromise quality or reliability. The

Light Constant Tension Clamps are used on such applications

as small engines, agricultural and utility vehicles, automotive

systems and appliances.

Applications

J Agricultural

J Automotive

J Vending

Materials – see section 10.3

J

1 Zinc Plated Steel

On Request

Clamps can also be supplied in finished colours Black, Green,

Red or Yellow.

B

A

J White Goods

J General Industry

HCL

Part No

Diameter

Range

(A) inch

Clamp

Width

(B) inch

Band

Thickness

(C) inch

CTL-6.1

CTL-7.7*

CTL-8.5

CTL-9.5

CTL-10.3

CTL-11.7

CTL-12.5

CTL-13.2

CTL-13.7

CTL-14.8*

CTL-15.8

CTL-16.4

CTL-19.1

CTL-21.8

0.24 – 0.30

0.30 – 0.34

0.33 – 0.41

0.37 – 0.44

0.40 – 0.48

0.46 – 0.54

0.49 – 0.57

0.51 – 0.60

0.53 – 0.64

0.58 – 0.66

0.62 – 0.72

0.64 – 0.82

0.74 – 0.89

0.85 – 1.02

0.25

0.02

0.03

0.02

0.02

0.31

100

0.03

0.37

Part numbers with * standard colour is Black

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W1, add “-W1”.

C

Installation Tools – see section 9.1

MT-SC-TP-01

Box

Quantity

MT-SC-FR-01

3.4

w w w . h c l - c l a m p i n g . c o m

0.04

0.06

WORM DRIVE &

SCREW CLAMPS

HCL’s robust perforated Worm Gear

clamps are manufactured from 430

Stainless Steel. These Screw Drive

Hose Clamps are designed for higher

sealing pressure with minimal torque.

PERFORMANCE

Worm Gear Hose Clamp – Perforated US Style

Strength

Temperature

Speed

Weathering

Chemical

Dynamic Range

Applications

J Chemical Industry

J Food Processing

J Marine Engines

HCL

Part No

SAE

No

Diameter

Range

(A) inch

WD-SAE-8-2

WD-SAE-8-6

WD-SAE-8-9

WD-SAE-8-12

WD-SAE-8-16

WD-SAE-13-4

WD-SAE-13-7

WD-SAE-13-9

WD-SAE-13-12

WD-SAE-13-16

WD-SAE-13-20

WD-SAE-13-24

WD-SAE-13-28

WD-SAE-13-32

WD-SAE-13-36

WD-SAE-13-40

WD-SAE-13-44

WD-SAE-13-48

WD-SAE-13-52

WD-SAE-13-56

WD-SAE-13-60

WD-SAE-13-64

WD-SAE-13-72

WD-SAE-13-80

WD-SAE-13-88

WD-SAE-13-96

WD-SAE-13-104

2

6

9

12

16

4

7

9

12

16

20

24

28

32

36

40

44

48

52

56

60

64

72

80

88

96

104

0.24 – 0.63

0.47 – 0.87

0.63 – 1.06

0.79 – 1.26

0.98 – 1.57

0.43 – 0.79

0.47 – 0.94

0.55 – 1.06

0.67 – 1.26

0.79 – 1.54

0.79 – 1.77

1.02 – 2.01

1.30 – 2.28

1.53 – 2.52

1.77 – 2.76

2.05 – 3.03

2.28 – 3.27

2.56 – 3.50

2.80 – 3.78

3.03 – 4.02

3.31 – 4.25

3.54 – 4.53

4.06 – 5.00

4.61 – 5.51

5.12 – 6.02

5.56 – 6.54

6.14 – 7.61

Materials – see section 10.3

J

2 Screw – Zinc Plated Steel

Band & Housing – 430 SS

On Request

J 4 304 SS

Weathering

Chemical

D

A

C

B

Installation Tools – see section 9.1

J Petrochemical Industry

J Shipyards

Band

Width

(B) inch

Band Hex Screw

Thickness

A/F

(C) inch

(D) inch

0.31

MT-AD-01

Box

Quantity

3.5

2000

0.24

3.0

1000

0.02

0.50

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W2, add “-W2”.

MT-D-01

Max

Torque

Nm

MT-TD-01

4.1

w w w . h c l - c l a m p i n g . c o m

500

0.31

8.0

250

200

WORM DRIVE &

SCREW CLAMPS

PERFORMANCE

Quick Release Worm Drive Hose Clamp

Strength

HCL’s Quick Release Worm Drive

Temperature

hose clamps offer a tilting Worm

Speed

Weathering

Drive housing. These quick

Chemical

release hose clamps are ideal for

Dynamic Range

rapid application and removal,

especially for large diameter pipes and hoses.

Applications

J Exhaust Fans

J Flexible Ducting

Materials – see section 10.3

J

2 Screw & Cover – Zinc Plated Steel

Band & Housing – 430 SS

On Request

J 4 304 SS

Weathering

Chemical

HCL

Part No

Diameter

Range

(A) inch

QR-100

0.98 – 3.90

QR-200

0.98 – 7.80

QR-300

0.98 – 11.70

QR-400

0.98 – 15.60

QR-500

0.98 – 19.50

QR-750

0.98 – 29.25

J HVAC

J General Industry

Band

Width

(B) inch

Band

Thickness

(C) inch

Hex Screw

A/F

(D) inch

Max

Torque

Nm

Box

Quantity

0.35

0.02

0.28

4.0

100

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W2, add “-W2”.

Other sizes available on request.

D

A

C

B

Installation Tools – see section 9.1

MT-D-01

MT-AD-01

MT-TD-01

4.2

w w w . h c l - c l a m p i n g . c o m

WORM DRIVE &

SCREW CLAMPS

Mollfam’s Mini Screw Hose

clamps, Petrol Pipe or Fuel Line

Clips are particularly suitable for

soft hoses and small diameters.

The clamp forms a complete circle

and has smooth edges.

PERFORMANCE

Mini Screw or Petrol Pipe Clip – Mollfam

Strength

Temperature

Speed

Weathering

Chemical

Dynamic Range

Applications

J Automotive

J Gas Equipment

Materials – see section 10.3

1 Zinc Plated Steel

On Request

J 4 304 SS

J

Weathering

Chemical

E

D

HCL

Part No

Diameter

Range

(A) inch

MC-8

MC-9

MC-10

MC-11

MC-12

MC-13

MC-14

MC-15

MC-16

MC-17

MC-18

MC-19

MC-20

MC-25-IMQ*

0.27 – 0.35

0.31 – 0.39

0.35 – 0.43

0.39 – 0.47

0.43 – 0.51

0.47 – 0.55

0.51 – 0.59

0.55 – 0.62

0.59 – 0.66

0.62 – 0.70

0.66 – 0.74

0.70 – 0.78

0.74 – 0.82

0.94 – 0.98

J White Goods

J General Industry

Band

Width

(B) inch

Band

Hex Screw Hex Screw

Thickness Length

A/F

(C) inch

(D) inch

(E) inch

0.35

0.02

C

B

Installation Tools – see section 9.1

MT-D-01

MT-AD-01

Box

Quantity

2000

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W1, add “-W1”.

Other sizes up to 3.31” diameter available on request.

*IMQ code = Crosshead screw.

A

Max

Torque

Nm

MT-TD-01

4.3

w w w . h c l - c l a m p i n g . c o m

0.87

0.28

1.2

3000

2500

WORM DRIVE &

SCREW CLAMPS

Mollfam’s Double Wire Screw

Clamps are highly suited to soft

and semi-rigid hoses, with spiral

or braided reinforcement; as well

as aluminium foil ducting.

PERFORMANCE

Double Wire Screw Hose Clamp – Mollfam

Strength

Temperature

Speed

Weathering

Chemical

Dynamic Range

Applications

J Agricultural

J Automotive

J HVAC

Materials – see section 10.3

J

1

Zinc Plated Steel

D

E

A

C

B

MT-AD-01

Diameter

Range

(A) inch

DWS-012

DWS-014

DWS-016

DWS-018

DWS-020

DWS-023

DWS-025

DWS-027

DWS-029

DWS-031

DWS-033

DWS-035

DWS-037

DWS-040

DWS-043

DWS-046

DWS-049

DWS-053

DWS-056

DWS-060

0.37 – 0.47

0.45 – 0.55

0.51 – 0.62

0.59 – 0.70

0.66 – 0.78

0.74 – 0.90

0.84 – 0.98

0.91 – 1.05

0.98 – 1.13

1.05 – 1.21

1.13 – 1.29

1.19 – 1.37

1.29 –1.44

1.38 – 1.56

1.50 – 1.68

1.60 – 1.79

1.70 – 1.91

1.81 – 2.07

1.97 – 2.18

2.09 – 2.34

Clamp

Width

(B) inch

Wire

Diameter

(C) inch

Hex Screw

Length

(D) inch

0.06

0.79

0.07

0.98

0.43

Hex Screw

A/F

(E) inch

Box

Quantity

0.22

0.08

0.55

500

1.18

0.28

1.57

0.31

0.09

100

0.59

0.10

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W1, add “-W1”.

Other sizes up to 7.49” diameter available on request.

Installation Tools – see section 9.1

MT-D-01

HCL

Part No

J Irrigation

J General Industry

MT-TD-01

4.4

w w w . h c l - c l a m p i n g . c o m

WORM DRIVE &

SCREW CLAMPS

PERFORMANCE

Plastic Worm Drive Hose Clamp

Strength

HCL’s Plastic Worm Drive Hose clip

Temperature

is ideal in applications requiring a

Speed

Weathering

non-conductive and non-corrosive

Chemical

clamp. Manufactured in the UK

Dynamic Range

it is a unique clamping product

which offers the non-corrosive features of a plastic

clamping product combined with the strength of a metal

worm drive hose clamp product.

Applications

J Electrical

J HVAC

J Irrigation

J Marine

Materials – see section 10.3

J Screw – PC/ABS

J Band & Housing – PA66

J Medical

J Pharmaceutical

J General Industry

HCL

Part No

Diameter

Range

inch

Length

(A) inch

Band

Width

(B) inch

Hex Screw

A/F

(C) inch

Max

Torque

Nm

Box

Quantity

PWD-15-65

0.59 – 2.54

9.25

0.39

0.28

2.5*

100

All weights, dimensions & quantities are subject to a 2.5% tolerance.

*It should be noted that torque data does not relate directly to the hoop strength of the clamp like a metal hose clip,

as a significant amount of torque used in a metal clamp is needed to overcome the friction of the metal worm with the

metal band of the clamp. This is not the case with the Plastic worm drive clamp as less torque is required to achieve the

same hoop strength.

C

B

A

Installation Tools – see section 9.1

MT-D-01

MT-AD-01

MT-TD-01

4.5

w w w . h c l - c l a m p i n g . c o m

WORM DRIVE &

SCREW CLAMPS

PERFORMANCE

Continuous Worm Drive Clamping Kit

Strength

HCL offers a high strength

Temperature

continuous worm drive kit,

Speed

Weathering

comprising of a 0.58” wide

Chemical

perforated band with a separate

Dynamic Range

screw and housing. The band

can be cut to a desired length and fitted using standard

tools to make a complete worm drive hose clamp of any

diameter, thereby offering a versatile clamping solution.

Applications

J Electrical Exhaust Fans

J Flexible Ducting

J HVAC

HCL Part No

Materials – see section 10.3

J

4 304 SS

Band

Screw/Housing

Band

Width

inch

FC-BA-25M

FC-BU

0.58

J Sign Fixing

J General Industry

Band

Thickness

inch

0.03

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W4, add “W4”.

Installation Tools – see section 9.1

MT-D-01

MT-AD-01

MT-TD-01

4.6

w w w . h c l - c l a m p i n g . c o m

Hex Screw

Band

A/F

Reel Lengths

inch

ft

0.31

80

Screw/

Housing

Box

Quantity

25

HEAVY DUTY

CLAMPS

PERFORMANCE

T-Bolt Heavy Duty Hose Clamp

Strength

HCL’s T-Bolt Hose clamps provide a

Temperature

leak-proof, heavy duty, durable and

Speed

corrosion resistant clamping solution.

Weathering

Chemical

Commonly found in the US market,

Dynamic Range

they are regarded as the ideal choice

for medium and heavy duty applications and are often used as

a hydraulic hose clamping solution.

Applications

J Automotive

J Ducting

J Industrial Cleaners

Materials – see section 10.3

J

2 Screw – Zinc Plated Steel

Band & Housing – 301 SS

On Request

J 4 304 SS

Weathering

Chemical

D

A

C

B

HCL

Part No

Diameter

Range

(A) inch

TB-34

TB-40

TB-43

TB-46

TB-51

TB-58

TB-64

TB-70

TB-76

TB-83

TB-89

TB-95

TB-102

TB-108

TB-114

TB-121

TB-127

TB-133

TB-140

TB-146

TB-152

TB-159

TB-165

TB-171

TB-178

TB-184

TB-191

TB-197

TB-203

1.34 – 1.57

1.57 – 1.73

1.69 – 1.93

1.81 – 2.05

2.01 – 2.24

2.28 – 2.56

2.52 – 2.83

2.76 – 3.07

2.99 – 3.31

3.27 – 3.58

3.50 – 3.82

3.74 – 4.52

4.02 – 4.33

4.25 – 4.57

4.49 – 4.80

4.76 – 5.08

5.00 – 5.31

5.24 – 5.55

5.51 – 5.83

5.75 – 6.06

5.98 – 6.30

6.26 – 6.57

6.50 – 6.81

6.73 – 7.05

7.01 – 7.32

7.24 – 7.56

7.52 – 7.83

7.76 – 8.07

7.99 – 8.31

Band

Width

(B) inch

J Irrigation

J Medical Industry

J Pharmaceutical

Band

Thickness

(C) inch

Nut

A/F

(D) inch

Max

Torque

Nm

Box

Quantity

100

0.75

0.02

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W2, add “-W2”.

5.1

w w w . h c l - c l a m p i n g . c o m

0.43

8.5

50

HEAVY DUTY

CLAMPS

PERFORMANCE

Worm Drive Super (High) Torque Hose Clamp

Strength

HCL’s perforated Worm Drive

Temperature

Super (High) Torque Worm

Speed

Weathering

Drive Hose Clamps are ideal for

Chemical

heavy duty sealing applications,

Dynamic Range

particularly where high vibration

resistance is required. It is stronger than conventional

Worm Drive clamps due to the wider band and the ‘inline’ housing, which enables every thread on the worm to

engage with the band.

Applications

J Agricultural

J Chemical Industry

J Food Processing

J Fluid Transfer

HCL

Part No

SAE

No

Diameter

Range

(A) inch

ST-16-126

ST-16-176

ST-16-238

ST-16-312

ST-16-362

ST-16-412

ST-16-462

ST-16-512

ST-16-562

ST-16-612

ST-16-738

ST-16-812

ST-16-912

ST-16-950

126

176

238

312

362

412

462

512

562

612

738

812

912

950

0.78 – 1.25

1.25 – 1.72

1.56 – 2.34

2.22 – 3.08

2.73 – 3.59

3.24 – 4.13

3.71 – 4.60

4.21 – 5.07

4.72 – 5.58

5.19 – 6.08

5.69 –7.33

7.28 – 8.11

8.19 – 9.05

8.58 – 9.36

Materials – see section 10.3

J

4 304 SS

D

A

J Marine Industry

J Petrochemical Industry

J Shipyards

Band

Band Hex Screw

Width Thickness

A/F

(B) inch (C) inch

(D) inch

0.62

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W4, add “-W4”.

C

B

Installation Tools – see section 9.1

MT-D-01

MT-AD-01

MT-TD-01

5.2

w w w . h c l - c l a m p i n g . c o m

0.03

0.31

Max

Torque

Nm

Box

Quantity

15.0

100

HEAVY DUTY

CLAMPS

PERFORMANCE

Preformed Band Clamps

Preformed Band Clamps offer a

Strength

Temperature

smooth inner diameter and provide

Speed

the highest strength capability. They

Weathering

are manufactured in a wide range of

Chemical

fixed diameters and come in 2 types

Dynamic Range

of materials. Vibration resistant and

automatically locked with one simple lever movement, these clamps

are ideal where superior strength is required. These are often the ideal

hose clamping solutions for Hydraulic applications.

Applications

J Agricultural Machinery

J Offshore

J Railway Industry

HCL

Part No

PC-6-19

PC-6-21

PC-6-25

PC-6-35

PC-6-38

PC-6-51

PC-6-63

PC-6-70

PC-6-76

PC-6-90

PC-6-102

PC-6-114

PC-10-21

PC-10-25

PC-10-35

PC-10-51

PC-10-64

PC-10-76

PC-10-90

PC-10-102

PC-13-26

PC-13-32

PC-13-38

PC-13-45

PC-13-51

PC-13-64

PC-13-70

PC-13-76

PC-13-90

PC-13-102

PC-16-38

PC-16-45

PC-16-51

PC-16-57

PC-16-64

PC-19-51

PC-19-64

PC-19-70

PC-19-76

PC-19-89

PC-19-102

PC-19-114

PC-19-127

PC-19-133

PC-19-152

PC-19-165

PC-19-178

PC-19-203

Materials – see section 10.3

3 301 SS

On Request

J 5 316 SS

J

Weathering

Chemical

Installation Tools – see section 9.1

MT-MB-01

MT-MB-02

Both tools are required to install Preformed clamps.

Max Diameter

inch

0.74

0.80

0.99

1.36

1.46

1.98

2.48

2.73

2.97

3.47

3.96

4.46

0.80

0.99

1.36

1.98

2.48

2.97

3.47

3.96

0.99

1.24

1.49

1.74

1.98

2.48

2.73

2.97

3.47

3.96

1.49

1.74

1.98

2.23

2.48

1.98

2.48

2.73

2.97

3.47

3.96

4.46

4.95

5.20

5.94

6.44

6.93

7.92

J Sewer Cleaning Equipment

J Welding Equipment

Band Width

inch

Band Thickness

inch

0.25

0.02

0.37

0.03

Box

Quantity

100

0.50

0.62

0.03

50

0.75

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W3, add “-W3”

5.3

w w w . h c l - c l a m p i n g . c o m

25

CABLE

RETENTION

PERFORMANCE

Heavy Duty Nylon Cable Tie – Smart Tie™

Strength

Smart Tie™ is a patented heavy duty

Temperature

nylon cable tie, able to withstand

Speed

system loads well in excess of 600kg.

Weathering

Manufactured by HCL, in a selection

Chemical

Dynamic Range

of materials; it is able to perform in

the most aggressive environments

around the world, both on and offshore. Lightweight, easy to

use and non-corrosive; the Smart Tie™ is the ideal cable tie

solution for smaller diameters. The Smart Tie cable tie can also

be made from Nylon 11 which is a long life polymer used in the

offshore & subsea industry. In addition the Smart Tie is widely

used in the downhole application as an alternative to metallic

solutions.

Applications

em

Materials – see section 10.3

Onshore:

Heat/UV Stabilised ROHS Nylon 6.6.

Offshore:

J Cable Protection

J Oil Rigs

J Subsea Marking

Onshore:

J Processing Plants

J HVAC

J General Industry

HCL

Part No

Diameter

Range

inch

Length

(A) inch

Band

Width

(B) inch

Band

Thickness

(C) inch

System

Strength

lb

Box

Quantity

ST-750

2.95 – 8.0

29.53

0.79

0.14

1500

50

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for Nylon 6.6, add “-PA66”, or for Nylon 11, add “-PA11”.

Offshore:

Nylon 11

Weathering

Chemical

Online Videos

Demonstration videos are available to view on our website.

Smart Tie™ and SM-FT-2000-19

Hand Tool

A

C

Installation Tools – see section 9.1

B

SM-FT-2000-19

6.1

w w w . h c l - c l a m p i n g . c o m

CABLE

RETENTION

PERFORMANCE

Metal Cable Tie – Tyco Ball Locking Type 316SS

Strength

Tyco’s 316 Stainless Steel Ball Locking

Temperature

Cable ties are very quick and easy

Speed

to use. They are extremely nonWeathering

corrosive, making them highly suited

Chemical

Dynamic Range

to aggressive environments, such as

marine cable bundling. These marine

grade ball lock cable ties are supplied either coated or uncoated

to suit the customers requirements.

Applications

J Aerospace

J Automotive Aftermarket

J Chemical Industry

J Electrical and Electronic

J Fixing Identification

J Offshore

J Railway Industry

J Shipyards

Industries

Certifications

E227552

E-6729

HCL

Part No

Max

Diameter

inch

Length

inch

BLT-4.6-100

BLT-4.6-150

BLT-4.6-200

BLT-4.6-260

BLT-4.6-360

BLT-4.6-520

BLT-4.6-620

BLT-4.6-840

BLT-4.6-1000

BLT-7.9-100

BLT-7.9-150

BLT-7.9-200

BLT-7.9-260

BLT-7.9-360

BLT-7.9-520

BLT-7.9-620

BLT-7.9-840

BLT-7.9-1000

0.98

1.57

1.97

2.72

4.02

5.98

7.48

10.00

11.81

6.98

1.57

1.97

2.72

4.02

5.98

7.48

10.00

11.81

3.90

5.85

7.80

10.14

14.04

20.28

23.40

32.76

39.00

3.90

5.85

7.80

10.14

14.04

20.28

24.18

32.76

39.00

Materials – see section 10.3

J

5 316 SS

On Request

5 316 SS coated

J

Temperature

Installation Tools – see section 9.1

MT-MCT-01

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W5, add “-W5”.

6.2

w w w . h c l - c l a m p i n g . c o m

Band

Width

inch

Band

Thickness

inch

Bag

Quantity

0.02

100

0.18

0.31

CABLE

RETENTION

PERFORMANCE

Metal Cable Tie – Tyco Re-Usable – 316SS Coated

Strength

Tyco’s 316 Stainless Steel Coated

Temperature

Cable ties are very quick and easy

Speed

to use and can be used more than

Weathering

Chemical

once. Because they are Coated

Dynamic Range

these cable ties are extremely

non-corrosive, making them highly suited to aggressive

corrosive environments, such as marine cable bundling.

Applications

J Chemical Industry

J Fixing Identification

J Offshore

J Shipyards

Certifications

E227552

E-6729

HCL

Part No

Max

Diameter

inch

Length

inch

RCT-6.4-152

RCT-6.4-229

RCT-6.4-305

RCT-6.4-457

RCT-6.4-610

RCT-6.4-762

RCT-6.4-914

RCT-9.5-152

RCT-9.5-229

RCT-9.5-305

RCT-9.5-457

RCT-9.5-610

RCT-9.5-762

RCT-9.5-914

1.50

2.48

3.39

5.39

7.28

9.09

11.02

1.50

2.48

3.39

5.39

7.28

9.09

11.02

5.93

8.93

11.90

17.82

23.79

29.72

35.65

5.93

8.93

11.90

17.82

23.79

29.72

35.65

Materials – see section 10.3

J

5 316 SS with PPA coating

Installation Tools – see section 9.1

MT-MCT-01

Band

Width

inch

w w w . h c l - c l a m p i n g . c o m

Bag

Quantity

pcs

0.05

100

0.25

0.37

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for W5 with PPA coating, add “-W5-PPA”.

6.3

Band

Thickness

inch

CABLE

RETENTION

PERFORMANCE

Nylon (Plastic) P Clips Black or Natural – Micro Plastics

Strength

Micro Plastics Nylon P Clips (Plastic

Temperature

Cable Clamps) secure, insulate and

Speed

route cable, wiring, tubing, piping and

Weathering

fibre optics.

Chemical

Dynamic Range

These Nylon P clamps are available

in Black or natural colour and are

designed for medium to lightweight applications. All contact

edges have a full radius for product protection.

Sizes are clearly marked on each clamp.

Applications

J Marine

J Railway

J General Industry

J Aerospace

J Automotive

J Electrical

J Engines

Certifications

Materials – see section 10.3

J Natural Nylon 6.6

J Black Nylon 6.6

Weathering

On Request

J Polypropylene

Chemical

J 2% Carbon Black

Weathering

(UV Resistant) Nylon 6.6

J Flame Retardant Nylon 6.6

Temperature

Weathering

E

C

HCL

Part No

Max

Diameter

(A) inch

Offset

Distance

(B) inch

NPC-10-3

NPC-10-5

NPC-10-6

NPC-10-8

NPC-10-10

NPC-10-11

NPC-10-13

NPC-10-14

NPC-10-16

NPC-13-3

NPC-13-5

NPC-13-6

NPC-13-8

NPC-13-10

NPC-13-11

NPC-13-13

NPC-13-14

NPC-13-16

NPC-13-18

NPC-13-19

NPC-13-21

NPC-13-22

NPC-13-26

NPC-13-29

NPC-13-30

NPC-13-32

NPC-13-35

NPC-13-38

0.12

0.19

0.25

0.31

0.37

0.43

0.50

0.56

0.62

0.12

0.19

0.25

0.31

0.37

0.43

0.50

0.56

0.62

0.68

0.74

0.80

1.24

1.00

1.13

1.19

1.25

1.37

1.50

0.33

0.42

0.41

0.50

0.59

0.57

0.61

0.61

0.68

0.31

0.43

0.41

0.50

0.53

0.56

0.59

0.61

0.66

0.76

0.78

0.81

0.89

0.91

0.97

1.00

1.06

1.13

1.19

Hole

Diameter

(C) inch

Band

Thickness

(E) inch

Box

Quantity

0.05

1000

0.37

0.2

All weights, dimensions & quantities are subject to a 2.5% tolerance.

Other sizes available on request.

B

Band

Width

(D) inch

A

D

6.4

w w w . h c l - c l a m p i n g . c o m

0.50

BANDING &

STRAPPING

Heavy Duty Nylon Banding – Smart Band® Standard

PERFORMANCE

Strength

Manufactured by HCL, Smart Band®

Temperature

Standard is a non-metallic band and

Speed

buckle system. Quick, easy to use

Weathering

and versatile; it is the ideal strapping

Chemical

Dynamic Range

solution for smaller diameters, both

on and offshore.

Smart Band® Standard plastic banding system is available in a

variety of materials, offering long-life, non-corrosive and high

strength/relaxation properties; making it the ideal alternative

to metallic strapping solutions, such as Stainless Steel,

Titanium, Monel & Alloy 625.

Applications

em

HCL Part No

Materials – see section 10.3

Onshore:

Nylon 6.6. – 0.28-¾ inch

Offshore:

JMarine Pile Protection

JOil Rigs

JSubsea Marking

Onshore:

JCooling Towers

JHVAC

JProcessing Plants

JSign Fixing

JGeneral Industry

Band Width

Band

Buckle

mm

in

SM-7R

SM-10R

SM-19R

SM-7HST

SM-10HST

SM-19HST

7

10

19

¼

3⁄8

¾

Band

Thickness

inch

0.09

0.14

2.09

4.41

11.02

65 / 820

100 / 410

100 / 200

Buckle

Box

Quantity

100

50

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for Nylon 6.6, add “-PA66”; for Acetal, add “-POM”.

Offshore:

Acetal – ¾-1 inch

On Request

Nylon 11 – 0.39-¾ inch

Strength

Chemical

Strength

Temperature

Weathering

Chemical

Online Videos

Demonstration videos are available to view on our website.

Sign Attachment using 0.75 inch

Smart Band® and SM-FT-2000-19

Hand Tool

Installation Tools – see section 9.1

SM-TA-528A

Max System

Band

Strength Reel Lengths

lb

ft

SM-FT-2000-19

SM-FT-1000-19

7.1

w w w . h c l - c l a m p i n g . c o m

BANDING &

STRAPPING

PERFORMANCE

High Strength Nylon Banding – Smart Band® Hybrid

Strength

Manufactured by HCL, Smart Band®

Temperature

Hybrid is a patented nylon banding

Speed

system. Incorporating an innovative

Weathering

Chemical

snapfit latch, which allows the perfect

Dynamic Range

blend of strength and flexibility; it is

the strongest plastic band and buckle

system in the world.

Smart Band® Hybrid is available in a variety of materials,

offering long-life, non-corrosive and high strength/relaxation

properties; making it the ideal alternative to metallic strapping

solutions, such as Kevlar, Stainless Steel, Titanium, Monel &

Alloy 625.

Applications

Offshore:

JCable Protection

JMarine Pile Protection

JOil Rigs

JPiggyback Pipe Lay

JSubsea Marking

JVIV Strakes

Onshore:

JHVAC

JProcessing Plants

JGeneral Industry

em

Onshore:

Nylon 6.6. – ¾ inch only

Glass-filled Nylon 11

Buckle

mm

in

Band

Thickness

inch

SM-19R

SM-32R

SM-19HHY

SM-32HHY

19

32

¾

1¼

0.14

0.18

HCL Part No

Materials – see section 10.3

Offshore:

Acetal

Band

Band Width

Max System

Band

Strength Reel Lengths

lb

ft

2680

5640

Buckle

Box

Quantity

100 / 200

100

All weights, dimensions & quantities are subject to a 2.5% tolerance.

To add material selection to the HCL Part No: for Nylon 6.6, add “-PA66”; for Acetal, add “-POM”; or for Glass-filled Nylon

11, add “-PA11GF”.

Strength

Chemical

Strength

Temperature

Weathering

Chemical

Installation Tools – see section 9.1

Technical

The Smart Band® Hybrid system has been fully tested

to offshore standards for Piggyback loading, Impact

strength & long life performance – All of which can be

found in our technical booklet available online.

Online Videos

Demonstration videos are available to view on our website.

0.75 inch Smart Band® and

SM-FT-1000 Hand Tool

SM-FT-1000-19 or

SM-FT-1000-32

50

25

SM-FT-1000-PR-19 or

SM-FT-1000-PR-32

SM-FT-1000-PS-19 or

SM-FT-1000-PS-32

7.2

w w w . h c l - c l a m p i n g . c o m

SPECIAL

HOSE CLAMPS

Special Clamp Designs

From time to time, customers approach HCL with applications

requiring a bespoke clamp design. On such occasions, HCL’s

in-house product development team will work closely with

the customer to produce a unique clamp, based on either the

Herbie Clip® or the Ezyclik™-P, but designed specifically for the

particular application.

Below are a few examples of special clamp designs:

Herbie Clip® Capacitor Cradle

This special clamp is based on the Herbie

Clip®, but has been adapted to function as

a capacitor cradle. The clamp incorporates

a rectangular recess for fixing it to a

sheet metal frame and a living hinge for

isolating the capacitor from the frame.

Ezyclik™ Fuel Pump Spigot Retaining

Clamp

This bespoke clamp is based on the

Ezyclik™-P, but has been modified to retain

a moulded spigot in a cast automotive

fuel pump housing. The clamp profile was

designed to fit snugly around the housing

boss, with various retaining features to

prevent removal of the spigot or the

clamp.

Herbie Clip® Dishwasher Clamp

This special Herbie Clip® is narrower than

a standard clip, in order for it to fit in the

restricted space on a certain dishwasher

application. The head of the clip is full

width where possible, so that the clip

can be satisfactorily tightened using the

Herbie Clip® Hand Tool.

Herbie Clip® Washing Machine Door Seal Clamp

This special clamp is based on the Herbie Clip®, but has been

adapted to retain the rubber door seal on a washing machine. The

clamp incorporates various bespoke features, including sealing,

retaining and strengthening ribs.

81

8.1

w w w . h c l - c l a m p i n g . c o m

INSTALLATION

TOOLING

Manual Tools – Plastic Snap Fit Hose Clamps

em

Herbie Clip® – Vertical Tool

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

em

Adjustable Waterpump Pliers

MT-HC-VFT-01

8.86 x 4.92 x 0.98”

1.01lb

1

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

APPLICABLE CLAMPS

MT-PL-01

9.25 x 8.07 x 0.79”

0.75lb

1

2.1

Ezyclik™-P – Lightweight Vertical

Tool

WEIGHT

BOX QUANTITY

WEIGHT

BOX QUANTITY

2.1

6.1

Herbie Clip®

em

Ezyclik™-P – Horizontal Tool

MT-EZP-LVT-01

7.01 x 4.92 x 1.18”

0.22lb

1

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

APPLICABLE CLAMPS

Ezyclik™-P

DIMENSIONS

MT-EZP-HT-01

9.06 x 5.31 x 0.98”

0.82lb

1

APPLICABLE CLAMPS

2.2

MT-HC-RT-01

6.23 x 1.97 x 0.12”

0.20lb

1

APPLICABLE CLAMPS

Herbie Clip®

Ezybond®

em

DIMENSIONS

PART NUMBER

APPLICABLE CLAMPS

Herbie Clip® Sizes A-85

PART NUMBER

Herbie Clip® – Removal Tool

Ezyclik™-P

2.2

9.1

w w w . h c l - c l a m p i n g . c o m

2.1

INSTALLATION

TOOLING

Manual Tools – Metal Snap Fit, Ear & Spring Hose Clamps

Ezyclik™-M/M+ – Vertical Tool

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

Ezyclik™-M/M+ – Swivel Jaw Tool

MT-EZM-VT-01

5.91 x 7.09 x 0.59”

0.49lb

1

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

APPLICABLE CLAMPS

2.3

3.1

Ear Clamp – Vertical Tool

DIMENSIONS

WEIGHT

BOX QUANTITY

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

MT-EC-VT-01

8.86 x 7.48 x 1.38”

1.19lb

1

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

2.3

3.1

Zero Leak Ear

2.4

Spring Clamp – Flexible Ratchet Tool

MT-SC-TP-01

7.87 x 6.30 x 0.98”

0.46lb

1+1

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

APPLICABLE CLAMPS

2.4

MT-EC-VHT-01

9.06 x 8.67 x 0.98”

0.95lb

1

APPLICABLE CLAMPS

Ezyclik™-M

Ezyclik™-M+

Spring Clamp – Tool Pack

APPLICABLE CLAMPS

Zero Leak Ear

MT-EZM-SJ-01

7.09 x 5.71 x 1.57”

0.55lb

1

APPLICABLE CLAMPS

Ezyclik™-M

Ezyclik™-M+

PART NUMBER

Ear Clamp – Vertical/Horizontal Tool

MT-SC-FR-01

34.45 x 7.48 x 0.98”

1.04lb

1

APPLICABLE CLAMPS

Double Wire Spring

3.2

Double Wire Spring

9.2

w w w . h c l - c l a m p i n g . c o m

3.2

INSTALLATION

TOOLING

Manual Tools – Worm Drive & Screw Hose Clamps

Worm Drive & Screw Clamp Driver –

0.24/0.28” Reversible Hex Socket

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

MT-D-01

11.02 x 1.38 x 1.38”

0.42lb

1

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

APPLICABLE CLAMPS

Worm Drive SAE J1670

(only up to size WD-SAE-8-12)

Quick Release Worm Drive

Mini Screw

Double Wire Screw

Plastic Worm Drive

Super Torque Worm Drive

Angled Worm Drive & Screw Clamp

Driver – 0.24, 0.28 & 0.31” Hex Sockets

MT-AD-01

9.06 x 3.94 x 1.38”

0.62lb

1

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

APPLICABLE CLAMPS

4.2

4.2

4.4

4.5

4.6

5.3

Worm Drive & Screw Clamp Torque

Driver – 0.24, 0.28 & 0.31” Hex Sockets

MT-TD-01

10.04 x 1.77 x 1.77”

0.99lb

1

APPLICABLE CLAMPS

Worm Drive SAE J1670

Quick Release Worm Drive

Mini Screw

Double Wire Screw

Plastic Worm Drive

Super Torque Worm Drive

4.2

4.2

4.4

4.5

4.6

5.3

Worm Drive SAE J1670

Quick Release Worm Drive

Mini Screw

Double Wire Screw

Plastic Worm Drive

Super Torque Worm Drive

9.3

w w w . h c l - c l a m p i n g . c o m

4.2

4.2

4.4

4.5

4.6

5.3

INSTALLATION

TOOLING

Manual Tools – Plastic and Steel (Metal) Cable Ties

Plastic Cable Tie, 0.09 - 0.19” width –

Tensioning & Cutting Tool

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

MT-PCT-01

6.30 x 5.12 x 0.79”

0.66lb

1

Plastic Cable Tie, 0.19 - 0.31” width –

Tensioning & Cutting Tool

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

APPLICABLE CLAMPS

MT-PCT-02

6.50 x 5.31 x 0.98”

0.44lb

1

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

APPLICABLE CLAMPS

Nylon Cable Tie Standard

6.5

Plastic Cable Tie, 0.14 - 0.51” width –

Tensioning & Cutting Tool

APPLICABLE CLAMPS

Nylon Cable Tie Standard

6.5

Nylon Cable Tie Standard

Nylon Cable Tie Flat Head

Metal Cable Tie, Max 0.47” width –

Tensioning & Cutting Tool

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

MT-MCT-01

8.47 x 6.10 x 1.57”

1.23lb

1

APPLICABLE CLAMPS

Metal Ball Locking Tie

Metal Re-usable Coated Tie

MT-PCT-03

7.48 x 4.72 x 0.98”

0.57lb

1

6.2

6.3

9.4

w w w . h c l - c l a m p i n g . c o m

6.5

6.6

INSTALLATION

TOOLING

Manual Tools – Banding & Strapping – Smart Band® & Metal Banding

em

Smart Band® Standard, 0.28 - 0.39”

width – Tensioning & Cutting Tool

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

PART NUMBER

SM-TA-528A

0.46 x 5.12 x 1.18”

0.95lb

1

DIMENSIONS

WEIGHT

BOX QUANTITY

7.1

Metal Banding – Tensioning &

Cutting Tool

DIMENSIONS

WEIGHT

BOX QUANTITY

PART NUMBER

SM-FT-2000-19

14.57 x 11.22 x 2.17”

1.65lb

1

DIMENSIONS

WEIGHT

BOX QUANTITY

Smart Tie™

Smart Band® Standard

Smart Band® Hybrid

6.1

7.1

7.2

Metal Banding – Tool Adaptor

(only works with MT-MB-01)

PART NUMBER

MT-MB-01

11.81 x 8.07 x 2.76”

3.95lb

1

DIMENSIONS

WEIGHT

BOX QUANTITY

APPLICABLE CLAMPS

Preformed

Metal Banding

Smart Band® 0.75 or 1.25” –

Tensioning & Cutting Tool

APPLICABLE CLAMPS

Smart Band® Standard

em

Smart Tie™ & Smart Band® 0.75” –

Tensioning & Cutting Tool

APPLICABLE CLAMPS

PART NUMBER

em

APPLICABLE CLAMPS

Smart Band® Standard

Smart Band® Hybrid

7.1

7.2

Band Cutters

PART NUMBER

MT-MB-02

10.83 x 1.97 x 1.77”

1.10lb

1

DIMENSIONS

WEIGHT

BOX QUANTITY

APPLICABLE CLAMPS

5.4

7.3

SM-FT-1000-19 or

SM-FT-1000-32

16.14 x 10.04 x 5.31”

6.15lb

1

MT-C-01

9.84 x 2.95 x 1.18”

0.86lb

1

APPLICABLE CLAMPS

Preformed

5.4

Smart Band® Standard

Smart Band® Hybrid

Metal Banding

9.5

w w w . h c l - c l a m p i n g . c o m

7.1

7.2

7.3

INSTALLATION

TOOLING

Installation Tools – Pneumatic Air Tools for Hose Clamps

em

em

em

Herbie Clip® – Calliper Tool

(Various Jaw options available)

Handle Options:

Gun grip (shown)

Straight grip

Vertical grip

PART NUMBER

PT-HC-C

DIMENSIONS

9.45 x 3.15 x 6.69”

WEIGHT

1.96lb

BOX QUANTITY

1

Herbie Clip® – Piston Tool

(Various Piston options available)

Handle Options:

Gun grip

Straight grip (shown)

Vertical grip

PART NUMBER

PT-HC-P

DIMENSIONS

13.19 x 2.17 x 2.56”

WEIGHT

1.46lb

BOX QUANTITY

1

Ezyclik™ – Calliper Tool

(Various Jaw options available)

Handle Options:

Gun grip

Straight grip

Vertical grip (shown)

PART NUMBER

PT-EZY-C

DIMENSIONS

2.36 x 2.36 x 10.63”

WEIGHT

2.01lb

BOX QUANTITY

1

APPLICABLE CLAMPS

APPLICABLE CLAMPS

APPLICABLE CLAMPS

Herbie Clip® Sizes F-85

2.1

Herbie Clip® Sizes A-105

em

Control Box (works with Piston and

Calliper tools)

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

PT-CB-01

11.81 x 12.60 x 5.71”

8.60lb

1

2.1

Ezyclik™-P

Ezyclik™-M

Ezyclik™-M+

2.2

2.3

3.1

em

Smart Band® 0.75 or 1.25”, Air

Ratchet – Tensioning & Cutting Tool

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

SM-FT-1000-PR-19 or

SM-FT-1000-PR-32

17.72 x 11.81 x 5.31”

8.82lb

1

APPLICABLE CLAMPS

em

Smart Band® 0.75 or 1.25”, Air Shutoff Driver – Tensioning & Cutting Tool

PART NUMBER

DIMENSIONS

WEIGHT

BOX QUANTITY

SM-FT-1000-PS-19 or

SM-FT-1000-PS-32

18.70 x 17.72 x 5.31”

14.99lb

1

APPLICABLE CLAMPS

Smart Band® Hybrid

7.2

Smart Band® Hybrid

9.6

w w w . h c l - c l a m p i n g . c o m

7.2

CHOOSING THE

RIGHT CLAMP

Bar chart guide

The catalog uses a bar chart guide, which rates each clamp in

relation to its properties. The higher the number of bars, the

better the performance. In this way, the bar chart guide can be

used to compare the relative performance of the products in

the catalog.

When selecting a clamp, it is important to prioritise its desired

properties. Once prioritised, the bar chart guide can be used to

select the right clamp.

For clamps that are offered in a selection of materials, the

figure shown represents the standard material and may be

improved by selecting an alternative grade.

Weathering

‘The resistance of the clamp to weathering, such as Ultra

Violet (UV) and moisture attack.’

Strength

‘The maximum pressure exerted by the clamp’

The resistance of a clamp to weathering can be attributed entirely

to the material from which it has been manufactured. Nylon offers

superior resistance to weathering than Polypropylene. Metal

products are more resistant to UV than plastic; however, the

majority of HCL’s plastic products are manufactured using a UV

resistant carbon black additive. The materials used for metal clamps

are given a ‘W’ rating from 1 to 5: the higher the rating, the more

resistant the metal is to corrosion. For clamps that are offered in

a selection of materials, the figure shown represents the standard

material and may be improved by selecting an alternative grade.

For any hose clamp application, it is important to match the

clamping strength of the hose clamp with the sealing capabilities

of the hose and pipe fitting. A hose clamp with inadequate strength

may allow leakages, whilst a hose clamp with excessive strength

may distort and damage the hose or fitting.

Temperature

‘The maximum operating temperature of the clamp’

The maximum operating temperature of a clamp can be

attributed almost entirely to the material from which it has been

manufactured. Metal products are more temperature resistant

than plastic; however, the majority of HCL’s plastic products are

manufactured from heat resistant polymers, such as Nylon 6.6.

Fluctuating temperatures may cause diametrical variations to the

hose or fitting; in which case, clamps in the ‘Constant Tension’

section of the catalogue may be required.

Chemical

‘The resistance of the clamp to chemicals, such as acids

and alkalis.”

The resistance of a clamp to chemicals can be attributed entirely to

the material from which it has been manufactured. Polypropylene

offers superior resistance to chemicals than Nylon. The materials

used for metal clamps are given a ‘W’ rating from 1 to 5: the higher

the rating, the more resistant the metal is to chemicals. For clamps

that are offered in a selection of materials, the figure shown