uniframe 100, 70

advertisement

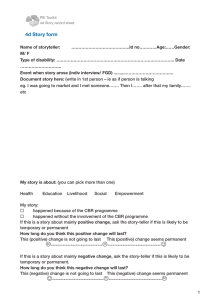

Automatic flexural and compression tester 100 kN cap. 70 UNIFRAME 100, 70-T0109/E Multipurpose compression machine 100 kN cap. for load and displacement control testing CBR test Marshall test Soil: unconfined compression UNIFRAME 100 Soil mechanics: quick triaxial Few examples of applications. MAIN FEATURES - Suitable for testing of Soil, Asphalt, Rock, Building stone, Cement, Mortars, Resin etc., using the suitable accessories Load and displacement control with PID closed loop feedback Two channels for load cells (not for simultaneous use) Two channels for displacement transducers (not for simultaneous use) Large graphic display 240x128 pixel RS 232 port for real time and delayed data download Real time display of load versus displacement diagram Dedicated software package Extensive range of accessories Built-in firmware for CBR, Marshall, and general purpose load/displacement control test For more information please visit our web site controlsgroup.net 53 70 Automatic flexural and compression tester 100 kN cap. General description The UNIFRAME 100 is a accurate 100 kN cap. universal electromechanical machine suitable for various tests under load and displacement control. The two column frame is fitted with an upper cross beam which can be positioned at various heights depending on the mounted accessory. The jack is driven by a DC motor controlled by microprocessor. The load measuring device (load cell) shall be ordered separately (see accessories).The machine is supplied complete with displacement transducer. Specifications Max. load capacity: 100 kN Displacement rate: 0.10 to 51,00 mm/min, infinitely variable Load rate: 1 to 10000 N/sec selectable Rapid approach speed: 50 mm/min Power: 1200 W Max. ram travel: 100 mm Horizontal span: 456 mm Max vertical span: 1040 mm Overall dimensions (lxdxh): 600x515x1820 mm Weight approx.: 165 kg Hardware PID digital controller 10 keys membrane keyboard with 4 main function keys Large 240x128 pixel graphic display Real time clock/date 4 input channels with 130000 divisions effective resolution, 2 for linear transducers (not for contemporaneous use) and 2 for load cells (not for contemporaneous use) Sampling rate: 15 samples/s RS 232 port for real time and delayed data downloading Baud rate for data transmission to serial printer: 9,600 bps Baud rate for data transmission to PC: 38,400 bps Firmware Multi-language Unit selection: kN, kgf Input of operator name Automatic CBR, Marshall or general purpose tests under load and displacement control Permanent memory up to 100 tests including load/displacement vs. time diagram Real time display of data, load-displacement/time diagram, load rate Files management function to display, download to serial printer and PC, erase single/multiple tests Machine calibration protected by password Advanced calibration function with auto-linearization mode allowing the segmentation of load/ displacement sensor curve and automatic interpolation of coefficients Advanced PID algorithm optimized for the typical applications Code 70-T0109/E 70-T0109/EZ Description UNIFRAME 100, Universal electromechanical automatic tester, 100 kN capacity, 230 V, 50-60 Hz, 1 ph UNIFRAME 100, Universal electromechanical automatic tester, 100 kN capacity, 110 V, 60 Hz, 1 ph Automatic flexural and compression tester 100 kN cap. 70 UNIFRAME 70-T0109/E equipped for Marshall test TEST MENU: Test selection. TEST PARAMETERS: It is possible to introduce peak sensitivity and preload, to enable peak and graph during the test, to choose data transmission format. Selection of screenshots: FILE MANAGER: It is possible to save the test or to recall a test previously saved. The tests can be printed or downloaded to a PC. CALIBRATION MENU: The software allows to check and calibrate the 4 available channels. PERFORM TEST MENU: Marshall test final screen with graph enabled. The display shows load/displacement in real time. MAIN MENU: Perform test. PERFORM TEST MENU: Marshall test final screen with graph disabled. 53 70 Automatic flexural and compression tester 100 kN cap. ACCESSORIES (Selection) Very often this machine is used for both CBR, Marshall and Asphalt indirect tensile test , but can also be used for many other applications for Soil, Rock, Building stones, Cement and Concrete testing (compression and flexural tests). We list hereunder the most popular accessories, for more details visit our web site www.controlsgroup.net. Accessories required for: 82-S1001 Test selection menu 82-S1001 CBR test data (graphic and numeric format) 76-B0033/D Stability mould for specimen 71.4 mm dia. Example of CBR test certificate. wfi.co.uk CONTROLS S.R.L. is certified to ISO 9001:2008 controlsgroup.net Italy controlsitalia.it France controls.fr Mexico controls.com.mx Poland controls.pl Spain controls.es United Kingdom controlstesing.co.uk In line with its continual program of product research and development, Control s reserves the right to alter specifications to equipment at any time.- R0- 5/12/E/0102. CBR: EN 13286-47, ASTM D1883, AASHTO T193 - 34-V0107/CBR Test set to perform CBR test, including Load cell 50 kN cap. displacement transducer, transducer holder, CBR penetration piston, adapters. Marshall: EN 12697-34, ASTM D1559, ASTM D6927 - 34-V0107/MAR Test set to perform Marshall test including load cell 50 kN cap. displacement transducer, transducer holder, compression device, stability mould, adapters. CBR and Marshall (to avoid duplications when both tests are requested) - 34-V0107/CM Test set to perform CBR and Marshall tests including load cell 50 kN cap., transducer, transducer holder, CBR penetration piston, compression device, stability mould, extensions and adapters. Duriez: NF P98-251-1/4 (for 80 mm dia. mould only, mould set not included) - 82-P0376 Load cell 100 kN cap. - 82-P0376/C Load cell adapter - 34-T0104/3 Lower and upper platen spherically seated Marshall (Russian specs.): Gost 12801 - 82-P0375 Load cell 50 kN cap. - 82-P0375/C Load cell adapter - 76-B0033/D Stability mould for specimen 71.4 mm dia. Data acquisition and processing - 82-S1001 PC software for CBR, Marshall and Indirect tensile test with up to 4 displacement transducers. Graphical and numerical display of data in real or delayed time. Input of descriptive data used to create a test report. Saving and manage ment of tests through single files. Data export to MS Excel®. For more and detailed information visit our web site www.controlsgroup.net .