Six Sigma Green Belt Part 5

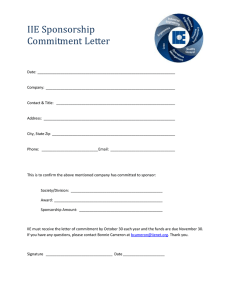

advertisement

Six Sigma Green Belt Part 5 Process Capability © 2011 IIE and Aft Systems, Inc. 5-1 Process Capability • • Is the measured, inherent reproducibility of the product turned out by the process. It can be quantified from data which, in turn, are the result of measurements of work performed by the process. It defines limits we would normally expect virtually all individuals to fall within. By definition a process is “capable” when it is operating at the three sigma level. © 2011 IIE and Aft Systems, Inc. 5-2 Process Capability • • Is the range over which the natural variation of a process occurs as determined by the system of common causes. It is the ability of the combination of people, machines, methods, materials, and measurements to produce a product or service that will consistently meet design specifications. © 2011 IIE and Aft Systems, Inc. 5-3 Measuring Process Capability • • Process capability is measured by the proportion of output that can be produced within design specifications-It is a long term prediction. It is a measure of the uniformity of the process. It can be measured only if all special causes have been eliminated and the process is in a state of statistical control. © 2011 IIE and Aft Systems, Inc. 5-4 Components of Process Capability • • • Design specifications Centering of natural variation Range or spread of variation © 2011 IIE and Aft Systems, Inc. 5-5 Capability Measures • • Short term measures show the capability at a specific instance in time, e.g., 5 out of 90 samples did not meet customer requirements Long term measures show the expected capability of the process based on statistical projections using inherent process variability © 2011 IIE and Aft Systems, Inc. 5-6 Establishing Process Capability • • Histogram Control Chart These must be performed prior to calculating any process capability measures © 2011 IIE and Aft Systems, Inc. 5-7 Statistics Green Belts are expected to be able to calculate the following: • • • Percent or proportion Non-Conforming Cp Index Cpk Index © 2011 IIE and Aft Systems, Inc. 5-8 Percent Non-Conforming • • Reflects the proportion of the population that we normally expect not to meet the process specifications. Corresponds to the ‘tail’ areas on the normal curve sketch USL LSL LSL Acceptable © 2011 IIE and Aft Systems, Inc. 5-9 Calculating Use z transform. Values in Normal Curve Table zu zl Uspec - x x is also called the mean Lspec - x R MR ' or d2 d2 Process must be centered somewhere between the customer requirements. © 2011 IIE and Aft Systems, Inc. 5-10 Z Value 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.13 0.14 0.15 0.16 0.17 0.18 0.19 0.20 0.21 0.22 0.23 0.24 0.25 0.26 0.27 0.28 0.29 0.30 Tail Prop. 0.4960 0.4920 0.4880 0.4840 0.4801 0.4761 0.4721 0.4681 0.4641 0.4602 0.4562 0.4522 0.4483 0.4443 0.4404 0.4364 0.4325 0.4286 0.4247 0.4207 0.4168 0.4129 0.4090 0.4052 0.4013 0.3974 0.3936 0.3897 0.3859 0.3821 Z Value 0.31 0.32 0.33 0.34 0.35 0.36 0.37 0.38 0.39 0.40 0.41 0.42 0.43 0.44 0.45 0.46 0.47 0.48 0.49 0.50 0.51 0.52 0.53 0.54 0.55 0.56 0.57 0.58 0.59 0.60 Tail Z Value Prop. 0.3783 0.61 0.3745 0.62 0.3707 0.63 0.3669 0.64 0.3632 0.65 0.3594 0.66 0.3557 0.67 0.3520 0.68 0.3483 0.69 0.3446 0.70 0.3409 0.71 0.3372 0.72 0.3336 0.73 0.3300 0.74 0.3264 0.75 0.3228 0.76 0.3192 0.77 0.3156 0.78 0.3121 0.79 0.3085 0.80 0.3050 0.81 0.3015 0.82 0.2981 0.83 0.2946 0.84 0.2912 0.85 0.2877 0.86 0.2843 0.87 0.2810 0.88 0.2776 0.89 0.2743 0.90 Tail Z Value Prop. 0.2709 0.91 0.2676 0.92 0.2643 0.93 0.2611 0.94 0.2578 0.95 0.2546 0.96 0.2514 0.97 0.2483 0.98 0.2451 0.99 0.2420 1.00 0.2389 1.01 0.2358 1.02 0.2327 1.03 0.2296 1.04 0.2266 1.05 0.2236 1.06 0.2206 1.07 0.2177 1.08 0.2148 1.09 0.2119 1.10 0.2090 1.11 0.2061 1.12 0.2033 1.13 0.2005 1.14 0.1977 1.15 0.1949 1.16 0.1922 1.17 0.1894 1.18 0.1867 1.19 0.1841 1.20 © 2011 IIE and Aft Systems, Inc. Tail Prop. 0.1814 0.1788 0.1762 0.1736 0.1711 0.1685 0.1660 0.1635 0.1611 0.1587 0.1562 0.1539 0.1515 0.1492 0.1469 0.1446 0.1423 0.1401 0.1379 0.1357 0.1335 0.1314 0.1292 0.1271 0.1251 0.1230 0.1210 0.1190 0.1170 0.1151 5-11 Z Value 1.21 1.22 1.23 1.24 1.25 1.26 1.27 1.28 1.29 1.30 1.31 1.32 1.33 1.34 1.35 1.36 1.37 1.38 1.39 1.40 1.41 1.42 1.43 1.44 1.45 1.46 1.47 1.48 1.49 1.50 Tail Z Value Prop. 0.1131 1.51 0.1112 1.52 0.1093 1.53 0.1075 1.54 0.1056 1.55 0.1038 1.56 0.1020 1.57 0.1003 1.58 0.0985 1.59 0.0968 1.60 0.0951 1.61 0.0934 1.62 0.0918 1.63 0.0901 1.64 0.0885 1.65 0.0869 1.66 0.0853 1.67 0.0838 1.68 0.0823 1.69 0.0808 1.70 0.0793 1.71 0.0778 1.72 0.0764 1.73 0.0749 1.74 0.0735 1.75 0.0721 1.76 0.0708 1.77 0.0694 1.78 0.0681 1.79 0.0668 1.80 Tail Z Value Prop. 0.0655 1.81 0.0643 1.82 0.0630 1.83 0.0618 1.84 0.0606 1.85 0.0594 1.86 0.0582 1.87 0.0571 1.88 0.0559 1.89 0.0548 1.90 0.0537 1.91 0.0526 1.92 0.0516 1.93 0.0505 1.94 0.0495 1.95 0.0485 1.96 0.0475 1.97 0.0465 1.98 0.0455 1.99 0.0446 2.00 0.0436 2.01 0.0427 2.02 0.0418 2.03 0.0409 2.04 0.0401 2.05 0.0392 2.06 0.0384 2.07 0.0375 2.08 0.0367 2.09 0.0359 2.10 Tail Z Value Prop. 0.0351 2.11 0.0344 2.12 0.0336 2.13 0.0329 2.14 0.0322 2.15 0.0314 2.16 0.0307 2.17 0.0301 2.18 0.0294 2.19 0.0287 2.20 0.0281 2.21 0.0274 2.22 0.0268 2.23 0.0262 2.24 0.0256 2.25 0.0250 2.26 0.0244 2.27 0.0239 2.28 0.0233 2.29 0.0228 2.30 0.0222 2.31 0.0217 2.32 0.0212 2.33 0.0207 2.34 0.0202 2.35 0.0197 2.36 0.0192 2.37 0.0188 2.38 0.0183 2.39 0.0179 2.40 © 2011 IIE and Aft Systems, Inc. Tail Prop. 0.0174 0.0170 0.0166 0.0162 0.0158 0.0154 0.0150 0.0146 0.0143 0.0139 0.0136 0.0132 0.0129 0.0125 0.0122 0.0119 0.0116 0.0113 0.0110 0.0107 0.0104 0.0102 0.0099 0.0096 0.0094 0.0091 0.0089 0.0087 0.0084 0.0082 5-12 Z Value 2.41 2.42 2.43 2.44 2.45 2.46 2.47 2.48 2.49 2.50 2.51 2.52 2.53 2.54 2.55 2.56 2.57 2.58 2.59 2.60 2.61 2.62 2.63 2.64 2.65 2.66 2.67 2.68 2.69 2.70 Tail Z Value Prop. 0.0080 2.71 0.0078 2.72 0.0075 2.73 0.0073 2.74 0.0071 2.75 0.0069 2.76 0.0068 2.77 0.0066 2.78 0.0064 2.79 0.0062 2.80 0.0060 2.81 0.0059 2.82 0.0057 2.83 0.0055 2.84 0.0054 2.85 0.0052 2.86 0.0051 2.87 0.0049 2.88 0.0048 2.89 0.0047 2.90 0.0045 2.91 0.0044 2.92 0.0043 2.93 0.0041 2.94 0.0040 2.95 0.0039 2.96 0.0038 2.97 0.0037 2.98 0.0036 2.99 0.0035 3.00 Tail Z Value Prop. 0.0034 3.10 0.0033 3.20 0.0032 3.30 0.0031 3.40 0.0030 3.50 0.0029 3.60 0.0028 3.70 0.0027 3.80 0.0026 3.90 0.0026 4.00 0.0025 4.10 0.0024 4.20 0.0023 4.30 0.0023 4.40 0.0022 4.50 0.0021 4.60 0.0021 4.70 0.0020 4.80 0.0019 4.90 0.0019 5.00 0.0018 5.10 0.0018 5.20 0.0017 5.30 0.0016 5.40 0.0016 5.50 0.0015 6.00 0.0015 6.50 0.0014 7.00 0.0014 7.50 0.0013 8.00 Tail Prop. 0.00096760 0.00068714 0.00048342 0.00033693 0.00023263 0.00015911 0.00010780 0.00007235 0.00004810 0.00003167 0.00002066 0.00001335 0.00000854 0.00000541 0.00000340 0.00000211 0.00000130 0.00000079 0.00000048 0.00000029 0.00000017 0.00000010 0.00000006 0.00000003 0.00000002 0.000000001 0.00000000 0.00000000 0.00000000 0.00000000 © 2011 IIE and Aft Systems, Inc. 5-13 Example 1. 2. 3. A process has a mean of 600 and a standard deviation of 6. Spec limits are 585 and 615. What is the percent nonconforming? (The total proportion in both tails.) What is the DPMO? What is the sigma level? (The sigma level is the smaller of the two z values.) Unacceptable LSL LSL © 2011 IIE and Aft Systems, Inc. USL Unacceptable 5-14 Example Unacceptable LSL LSL USL 1. Unacceptable 2. 3. A process has a mean of 100 and a standard deviation of 4. Spec limits are 95 and 106. What is the percent nonconforming? What is the sigma level? What is the DPM? © 2011 IIE and Aft Systems, Inc. 5-15 Example Continued In the preceding example if each incorrect transaction costs $4 and annual volume is 400,000, what is the cost of the incorrect transactions? © 2011 IIE and Aft Systems, Inc. 5-16 Example Continued If in the preceding example the standard deviation were reduced to 2 via a DMAIIC Green Belt project. If this were done at a cost of $100,000 would it be worth it? (One year payback.) © 2011 IIE and Aft Systems, Inc. 5-17 Example Continued What would it take (or be worth) to now reduce the standard deviation to 1? © 2011 IIE and Aft Systems, Inc. 5-18 More Practice • • • A process has a mean of 200 and and a standard deviation of 2. Upper specification limit is 212. Lower specification limit is 188. • Determine – – – Proportion non conforming DPMO Sigma Level Motorola Shift © 2011 IIE and Aft Systems, Inc. 5-19 Another Problem What is the capability of the process, in terms of proportion defective or sigma level or dpmo, we collected data on earlier in the course? (page 4-12) © 2011 IIE and Aft Systems, Inc. 5-20 Capability Indices Show the relationship between the process capability and the process specifications Cp measures potential capability assuming that the process average is equal to the midpoint of the specification limits and the process is operating in statistical control. Cpk reflects the current process mean’s proximity to either specification limit. (When the process is centered Cp = Cpk.) Although the indices are calculated differently, the interpretation is the same © 2011 IIE and Aft Systems, Inc. 5-21 Cp or Cpk Less than 1.0 Cp or Cpk Value Sigma Level 0.33 0.67 1 2 © 2011 IIE and Aft Systems, Inc. 5-22 4.39 4.15 3.91 3.67 3.43 3.19 2.95 2.71 2.47 2.23 1.99 1.75 1.51 1.27 1.03 0.79 0.55 0.31 0.07 -0.2 -0.4 -0.7 -0.9 -1.1 -1.4 -1.6 -1.9 -2.1 -2.3 -2.6 -2.8 -3.1 -3.3 -3.5 -3.8 -4 -4.3 -4.5 Cp or Cpk Equal to 1.0 Cp or Cpk Value Sigma Level 0.33 0.67 1.00 1 2 3 © 2011 IIE and Aft Systems, Inc. 5-23 4.39 4.15 3.91 3.67 3.43 3.19 2.95 2.71 2.47 2.23 1.99 1.75 1.51 1.27 1.03 0.79 0.55 0.31 0.07 -0.2 -0.4 -0.7 -0.9 -1.1 -1.4 -1.6 -1.9 -2.1 -2.3 -2.6 -2.8 -3.1 -3.3 -3.5 -3.8 -4 -4.3 -4.5 Cp or Cpk Greater than 1.0 Cp or Cpk Value Sigma Level 0.33 0.67 1.00 1.33 1.67 2.00 2.33 2.67 3.00 1 2 3 4 5 6 7 8 9 No Motorola Shift © 2011 IIE and Aft Systems, Inc. 5-24 Calculating Cp Cp = (Uspec – Lspec)/6 Process must be centered at the midpoint of the specification limits. © 2011 IIE and Aft Systems, Inc. 5-25 Cpk Calculation Smaller of the following: Cpku = (Uspec – Mean) / 3 Cpkl = (Mean – Lspec) / 3 Cpk also is equal to the sigma level divided by 3 Note: Can also use these for one sided requirements © 2011 IIE and Aft Systems, Inc. 5-26 Capability What is the capability index for the process we analyzed earlier? (page 4-12) © 2011 IIE and Aft Systems, Inc. 5-27 Interpretation Capability Measure Not Capable Proportion Non More than Conforming .0027 More than DPMO 2700 Less than Sigma Level 3.0 Less than Cpk 1.0 Capable More than Capable 0.0027 Less than .0027 2700 3.0 1 © 2011 IIE and Aft Systems, Inc. Less than 2700 More than 3.0 More than 1.0 5-28 Another Cost Study • • • • A process has customer requirements of 50 and 75. It is in control with an adjustable mean and a known standard deviation (based on the Shewhart approximation) of 8. Accounting tells us that a “defect” on the low side will cost of $10 and on the high side $5. (Scrap vs. rework.) Engineering has not been able to figure out a way to reduce variation. What is the optimum location for the process centering in order to minimize cost? © 2011 IIE and Aft Systems, Inc. 5-29 Homework Exercise U-Bolts • • On the following page is data on U-bolts for the dimension shown at the right. Determine the capability of the process regarding the indicated dimension. (Specs are 10.70 + .15) © 2011 IIE and Aft Systems, Inc. 5-30 Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 10.65 10.75 10.75 10.60 10.70 10.60 10.75 10.65 10.60 10.80 10.85 10.70 10.65 10.70 10.65 10.75 10.90 10.75 10.75 10.65 10.60 10.50 10.80 10.65 10.70 10.85 10.80 10.70 10.75 10.75 10.80 10.80 10.70 10.75 10.70 10.75 10.70 10.80 10.80 10.70 10.70 10.65 10.60 10.55 10.65 10.60 10.70 10.65 Observations 10.65 10.75 10.80 10.65 10.70 10.75 10.65 10.50 10.70 10.60 10.65 10.75 10.75 10.90 10.65 10.65 10.80 10.70 10.75 10.70 10.65 10.70 10.65 10.90 10.80 10.70 10.70 10.65 10.65 10.75 10.75 10.70 10.65 10.75 10.70 10.70 10.65 10.80 10.60 10.75 10.70 10.65 10.60 10.70 10.70 10.65 10.50 10.80 © 2011 IIE and Aft Systems, Inc. 10.55 10.65 10.75 10.90 10.65 10.70 10.45 10.80 10.60 10.65 10.65 10.65 10.50 10.70 10.65 10.65 10.75 10.55 10.90 10.65 10.65 10.75 10.65 10.65 Average 10.670 10.740 10.760 10.700 10.690 10.710 10.680 10.690 10.650 10.710 10.710 10.710 10.650 10.780 10.670 10.700 10.770 10.660 10.720 10.650 10.650 10.640 10.660 10.730 Range 0.25 0.20 0.10 0.30 0.10 0.15 0.35 0.30 0.10 0.20 0.20 0.10 0.25 0.20 0.20 0.10 0.20 0.20 0.30 0.15 0.10 0.25 0.30 0.25 104 5-31 Statistics Mean 10.6958 Average Range .2021 Shewhart Standard Deviation .0869 Calculated Standard Deviation .0871 © 2011 IIE and Aft Systems, Inc. 5-32 28 27 26 25 24 23 22 21 20 19 18 17 16 Frequency 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 © 2011 IIE and Aft Systems, Inc. 5-33 Sample ID Averages Ranges © 2011 IIE and Aft Systems, Inc. 5-34 Histogram 40 35 # Observations 30 25 20 15 10 5 0 10.45 10.495 10.54 10.585 10.63 10.675 10.72 10.765 10.81 10.855 to <= to <= to <= to <= to <= to <= to <= to <= to <= to <= 10.495 10.54 10.585 10.63 10.675 10.72 10.765 10.81 10.855 10.9 Class © 2011 IIE and Aft Systems, Inc. 5-35 Xbar Chart 10.85 10.8 10.75 10.7 10.65 10.6 10.55 10.5 10.45 UCL=10.81244 CEN=10.69583 LCL=10.57923 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 19 20 21 22 23 24 R Chart 0.5 UCL=0.4272 0.4 0.3 CEN=0.20208 0.2 0.1 0 1 LCL=0.0 2 3 4 5 6 7 8 9 10 11 12 13 © 2011 IIE and Aft Systems, Inc. 14 15 16 17 18 5-36 © 2011 IIE and Aft Systems, Inc. 11.07 11.05 11.02 11.00 10.97 10.95 10.93 10.90 10.88 10.85 10.83 10.80 10.78 10.75 10.73 10.70 10.68 Mean = 10.696 StdDev = 0.0869 USL = 10.85 LSL = 10.55 Sigma Level = 1.6801 10.65 10.63 10.60 10.58 10.55 10.53 10.50 10.48 10.45 10.43 10.40 10.38 10.35 10.33 10.30 Process Capability Cpk Analysis Cpk = .5600 DPM = 84,654 5-37

![IIE Continuing Education Benefits You and Your Company[1]](http://s3.studylib.net/store/data/007679605_2-bb634887790654c6045e40acc116701d-300x300.png)