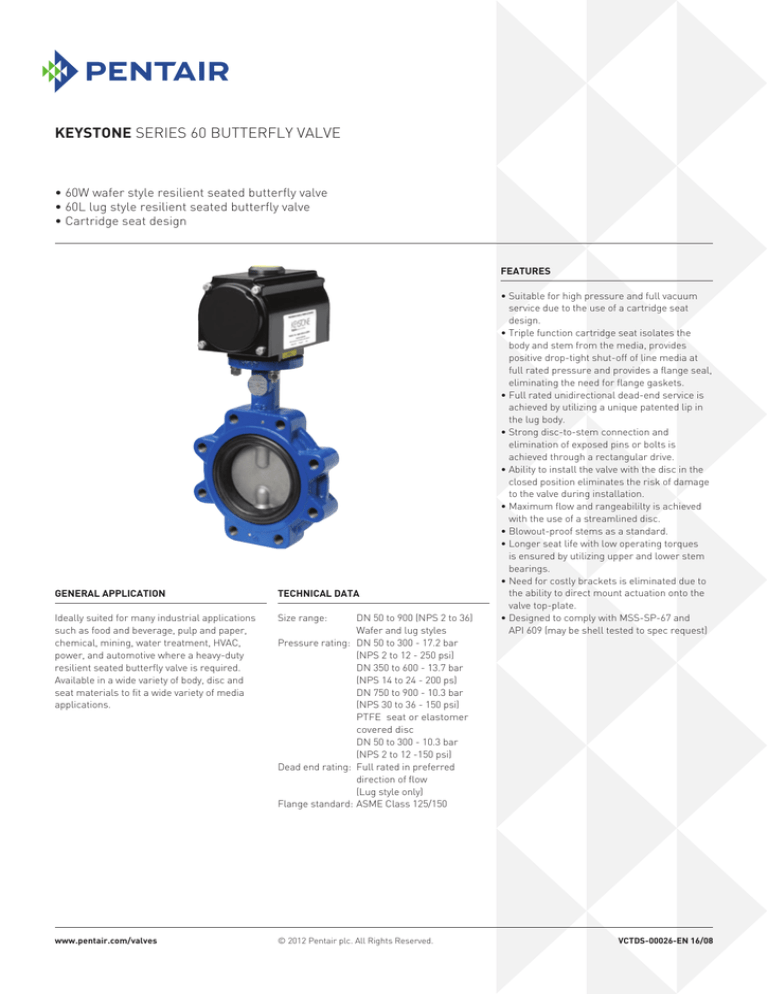

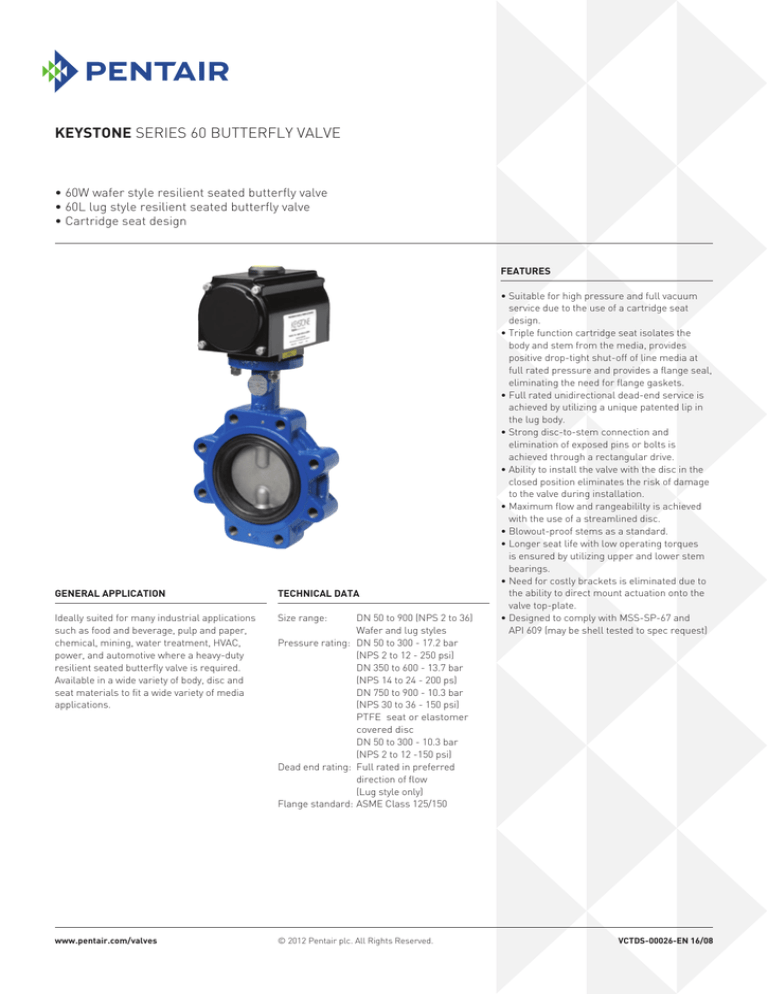

KEYSTONE SERIES 60 BUTTERFLY VALVE

• 60W wafer style resilient seated butterfly valve

• 60L lug style resilient seated butterfly valve

• Cartridge seat design

FEATURES

GENERAL APPLICATION

TECHNICAL DATA

Ideally suited for many industrial applications

such as food and beverage, pulp and paper,

chemical, mining, water treatment, HVAC,

power, and automotive where a heavy-duty

resilient seated butterfly valve is required.

Available in a wide variety of body, disc and

seat materials to fit a wide variety of media

applications.

Size range:

DN 50 to 900 (NPS 2 to 36)

Wafer and lug styles

Pressure rating: DN 50 to 300 - 17.2 bar

(NPS 2 to 12 - 250 psi)

DN 350 to 600 - 13.7 bar

(NPS 14 to 24 - 200 ps)

DN 750 to 900 - 10.3 bar

(NPS 30 to 36 - 150 psi)

PTFE seat or elastomer

covered disc

DN 50 to 300 - 10.3 bar

(NPS 2 to 12 -150 psi)

Dead end rating: Full rated in preferred

direction of flow

(Lug style only)

Flange standard:ASME Class 125/150

www.pentair.com/valves

© 2012 Pentair plc. All Rights Reserved.

• Suitable for high pressure and full vacuum

service due to the use of a cartridge seat

design.

• Triple function cartridge seat isolates the

body and stem from the media, provides

positive drop-tight shut-off of line media at

full rated pressure and provides a flange seal,

eliminating the need for flange gaskets.

• Full rated unidirectional dead-end service is

achieved by utilizing a unique patented lip in

the lug body.

• Strong disc-to-stem connection and

elimination of exposed pins or bolts is

achieved through a rectangular drive.

• Ability to install the valve with the disc in the

closed position eliminates the risk of damage

to the valve during installation.

• Maximum flow and rangeabililty is achieved

with the use of a streamlined disc.

• Blowout-proof stems as a standard.

• Longer seat life with low operating torques

is ensured by utilizing upper and lower stem

bearings.

• Need for costly brackets is eliminated due to

the ability to direct mount actuation onto the

valve top-plate.

• Designed to comply with MSS-SP-67 and

API 609 (may be shell tested to spec request)

VCTDS-00026-EN 16/08

KEYSTONE SERIES 60 BUTTERFLY VALVE

3

5

1

6

5

2

4

6

MATERIALS

Part

1 Body

2 Disc

3 Stem

4 Seat

5 Bearing[5]

6 Pin

Standard material

Cast iron[1]

Ductile iron (DN 50 - 300/ NPS 2 - 12)

Ductile iron[2] (DN 350 - 600/ NPS 14 - 24 Lug style)

316 Stainless steel[3]

Ductile iron/Nickel plated

Aluminum bronze

316 Stainless steel

EPDM Coated (DN 80 - 300/ NPS 3 - 12)

NBR Coated (DN 80 - 300/ NPS 3 - 12)

416 Stainless steel (standard)

316 Stainless steel (optional)[4]

EPDM (-28°C - 120°C/ -20°F - 250°F)

NBR (-17°C - 82°C/ 0°F - 180°F)

Fluoroelastomer (-17°C - 149°C/ 0°F - 300°F)

PTFE (-28°C - 120°C/ -20°F - 250°F) (DN 50 - 300/ NPS 2 - 24)

PTFE Gar-Fil® (DN 50 - 600/ NPS 2 - 24)

Carbon steel

Material specifications

ASTM A126 Class B

ASTM A395 Grade 60/40/18

ASTM A536 Grade 65/45/12

ASTM A351 CF8M

ASTM A536 Grade 65/45/12

ASTM B148 C95400

ASTM A351 CF8M

ASTM A582 UNS S41600 cond. A

ASTM A276 UNS S31600 cond. A

NOTES

1. DN 350 (NPS 14) and larger wafer style available in cast iron body only.

2. DN 350 (NPS 14) and larger lug style available in ductile iron body only.

3. Offered in DN 50 - 150 (NPS 2 - 6) only. These bodies come s­ tandard with a vented shaft and food grade seats.

4. 316 Stainless steel stem available in DN 50 - 300 (NPS 2 - 12) only.

5. Valves with 316 S/S bodies are provided with two additional bearings in the lower stem journal.

2

KEYSTONE SERIES 60 BUTTERFLY VALVE

METRIC DATA

ØM

TOP PLATE DIMENSIONS

ØM

4xJ

equally

spaced

4xJ

equally

spaced

ØM

8xJ

equally

spaced

E

E

E

45˚

22.5˚

45˚

DN 250 - 600

DN 50 - 200

DN 750 - 900

VALVE DIMENSIONS

H

ØG

H

F

C1, C2

ØB

Q

D

WAFER

DIMENSIONS (mm)

Size DN

50

65

80

100

125

150

200

250

300

350

400

450

500

600

750

900

N thread on ØP

bolt circle

LUG

B

C1

C2

D

E

F

G

H

J

M

N

P

Q*

129

148

159

198

222

248

305

368

445

495

560

595

652

764

984

1162

146

159

165

184

197

213

244

279

318

337

375

400

413

486

629

721

119

124

152

165

-

41

44

44

51

54

54

60

67

76

78

102

114

127

152

165

200

102

102

102

102

102

102

152

152

152

152

152

171

171

203

235

298

31.75

31.75

31.75

31.75

31.75

31.75

31.75

50.80

50.80

76.20

76.20

76.20

107.95

107.95

136.65

136.65

14.22

14.22

14.22

16.00

19.05

19.05

22.10

28.45

34.80

34.80

41.40

41.40

47.75

47.75

76.20

91.95

9.4

9.4

9.4

10.9

12.7

12.7

16.0

-

10.3

10.3

10.3

10.3

10.3

10.3

14.3

14.3

14.3

13.5

13.5

13.5

20.6

20.6

17.4

17.4

82.6

82.6

82.6

82.6

82.6

82.6

127.0

127.0

127.0

127.0

127.0

127.0

165.1

165.1

190.5

260.4

⅝" -11

⅝" -11

⅝" -11

⅝" -11

¾" -10

¾" -10

¾" -10

⅞" -9

⅞" -9

1" -8

1" -8

1⅛" -7

1⅛" -7

1¼" -7

1¼" -7

1½" -6

121

140

152

191

216

241

298

362

432

476

540

578

635

749

914

1086

36

46

67

92

119

144

192

245

292

329

377

426

475

574

726

876

Adapt key

6.4 x 6.4

8x8

8x8

9.5 x 9.5

9.5 x 9.5

12.7 x 9.5

12.7 x 9.5

19 x 12.7

22.2 x 15.9

Code

BAB

BAB

BAB

BAC

BAD

BAD

CAE

CAF

CAG

CAG

CAH

CAH

DAJ

DAJ

-

NOTE

C1 Dimensions apply to cast iron and ductile iron bodies ONLY.

C2 Dimensions apply to stainless steel bodies ONLY.

Q* Dimension is the minimum allowable pipe or flange inside diameter at the centered body face to protect the disc sealing edge against damage when opening the valve.

3

KEYSTONE SERIES 60 BUTTERFLY VALVE

IMPERIAL DATA

ØM

TOP PLATE DIMENSIONS

ØM

4xJ

equally

spaced

4xJ

equally

spaced

ØM

4xJ

equally

spaced

E

E

E

45˚

22.5˚

45˚

NPS 10 - 24

NPS 2 - 8

NPS 30 - 36

VALVE DIMENSIONS

H

ØG

H

F

C1, C2

ØB

Q

N thread on ØP

bolt circle

D

WAFER

DIMENSIONS (inches)

Size NPS

2

2½

3

4

5

6

8

10

12

14

16

18

20

24

30

36

B

5.09

5.81

6.25

7.81

8.75

9.75

12.00

14.50

17.50

19.50

22.06

23.44

25.68

30.06

38.75

45.75

C1

5.75

6.25

6.50

7.25

7.75

8.38

9.62

11.00

12.50

13.25

14.75

15.75

16.25

19.12

24.75

28.38

C2

4.69

4.87

6.00

6.50

-

D

1.63

1.75

1.75

2.00

2.13

2.14

2.35

2.63

3.00

3.06

4.01

4.48

4.99

6.00

6.51

7.88

E

4.00

4.00

4.00

4.00

4.00

4.00

6.00

6.00

6.00

6.00

6.00

6.75

6.75

8.00

9.25

11.75

F

1.25

1.25

1.25

1.25

1.25

1.25

1.25

2.00

2.00

3.00

3.00

3.00

4.25

4.25

5.38

5.38

G

0.56

0.56

0.56

0.63

0.75

0.75

0.87

1.12

1.37

1.37

1.63

1.63

1.88

1.88

3.00

3.62

LUG

H

0.37

0.37

0.37

0.43

0.50

0.50

0.63

-

J

0.406

0.406

0.406

0.406

0.406

0.406

0.562

0.562

0.562

0.531

0.531

0.531

0.812

0.812

0.687

0.687

M

3.25

3.25

3.25

3.25

3.25

3.25

5.00

5.00

5.00

5.00

5.00

5.00

6.50

6.50

7.50

10.25

N

⅝ -11

⅝ -11

⅝ -11

⅝ -11

¾ -10

¾ -10

¾ -10

⅞ -9

⅞ -9

1-8

1-8

1⅛ -7

1⅛ -7

1¼ -7

1¼ -7

1½ -6

P

4.75

5.50

6.00

7.50

8.50

9.50

11.75

14.25

17.00

18.75

21.25

22.75

25.00

29.50

36.00

42.75

Q*

1.41

1.82

2.62

3.62

4.67

5.68

7.54

9.65

11.49

12.97

14.85

16.76

18.72

22.59

28.6

34.48

Adapt key

¼x¼

5/16 x 5/16

5/16 x 5/16

⅜x⅜

⅜x⅜

½x⅜

½x⅜

¾x½

⅞x⅝

Code

BAB

BAB

BAB

BAC

BAD

BAD

CAE

CAF

CAG

CAG

CAH

CAH

DAJ

DAJ

-

NOTE

C1 Dimensions apply to cast iron and ductile iron bodies ONLY.

C2 Dimensions apply to stainless steel bodies ONLY.

Q* Dimension is the minimum allowable pipe or flange inside diameter at the centered body face to protect the disc sealing edge against damage when opening the valve.

4

KEYSTONE SERIES 60 BUTTERFLY VALVE

METRIC DATA

VALVE SIZING

Rate of flow through a valve depends upon the pressure drop. The most common method of

presenting this information is by Kv. The Kv is the valve coefficient of flow and represents the

volume of water in cubic meters per hour (m³/h) that will pass through a valve with a pressure

drop of 1 bar at 21°C. The higher the Kv, the greater the flow and the better the control

characteristics. Throttling characteristics are shown in the same manner with Kv’s at the various

disc openings. Tabulated below are the Kv’s for the Series 60 Butterfly Valve.

Kv CHART

Valve size DN

50

65

80

100

125

150

200

250

300

350

400

450

500

600

750

900

Disc position (Degrees open)

50°

60°

70°

25°

30°

40°

3

3

12

26

74

143

182

350

476

562

692

952

1211

1730

2509

3720

6

9

18

45

112

195

260

497

649

714

865

1211

1427

2076

3028

4498

16

21

39

87

182

311

415

735

1038

1298

1600

2119

2638

3633

5363

7958

31

41

73

143

298

493

675

1038

1622

1990

2509

3287

4152

5709

8391

12110

54

67

115

234

454

709

1142

1644

2465

3028

3979

4325

6401

9083

12975

19030

73

98

176

363

714

1090

1972

2855

4347

5363

6488

8391

10813

14705

21625

32005

80°

90°

99

157

330

608

1168

1622

3270

5277

8045

8391

9169

11980

15354

1990

30275

44115

104

168

372

718

1298

1713

3348

5579

8477

9083

11678

15570

19895

26815

39790

58820

TORQUE DATA

Torque is the rotary effort required to operate a valve. This turning force in a butterfly valve is

determined by three factors - the friction of the disc and seat due to interference for sealing,

bearing friction, and fluid dynamic torque.

Breakaway torque at 21°C

Breakaway torque is the total of the torques resulting from bearing friction and disc/seat

interference friction at a given pressure differential. Listed below are torques to open and close

the valve at pressures shown in wet services (normal conditions).

NOTE

These values are valid for water and lubricating fluids only at 21°C. Since torques are greatly increased for dry

and nonlubricating fluids and temperature variations, contact your Keystone representative for accurate values

in these applications.

BREAKAWAY TORQUE (Nm)*

Line pressure (bar)

3.5

7

10

14

17

Size

50

65

80

100

125

150

200

250

300

350

400

450

500

600

750

900

10

12

14

16

18

14

17

20

22

25

20

23

29

34

38

40

47

53

60

67

63

74

81

89

98

104

117

130

143

157

163

191

217

249

280

279

340

401

463

527

397

468

635

868

1193

588

678

847

966

-

780

904

1073

1215

-

1017

1186

1356

1525

-

1243

1582

1717

1989

-

1808

2373

3164

3808

-

2113

2486

3130

-

3107

3672

4180

-

* For wet service applications/standard disc

5

KEYSTONE SERIES 60 BUTTERFLY VALVE

IMPERIAL DATA

VALVE SIZING

Rate of flow through a valve depends upon the pressure drop. The most common method of

presenting this information is by Cv. The Cv is the valve coefficient of flow and represents the

volume of water in gallons per minute (GPM) that will pass through a valve with a pressure drop

of 1 psi at 70°F. The higher the Cv, the greater the flow and the better the control characteristics.

Throttling characteristics are shown in the same manner with Cv’s at the various disc openings.

Tabulated below are the Cv’s for the Series 60 Butterfly Valve.

Cv CHART

Valve size NPS

2

2½

3

4

5

6

8

10

12

14

16

18

20

24

30

36

Disc position (Degrees open)

50°

60°

70°

25°

30°

40°

3

4

14

30

85

165

210

405

550

650

800

1100

1400

2000

2900

4300

7

10

21

52

130

225

300

575

750

825

1000

1400

1650

2400

3500

5200

19

24

45

100

210

360

480

850

1200

1500

1850

2450

3050

4200

6200

9200

36

47

84

165

345

570

780

1200

1875

2300

2900

3800

4800

6600

9700

14000

63

78

133

270

525

820

1320

1900

2850

3500

4600

5000

7400

10500

15000

22000

84

113

203

420

825

1260

2280

3300

5025

6200

7500

9700

12500

17000

25000

37000

80°

90°

115

182

382

703

1350

1875

3780

6100

9300

9700

10600

13850

17750

2300

35000

51000

120

194

430

830

1500

1980

3870

6450

9800

10500

13500

18000

23000

31000

46000

68000

TORQUE DATA

Torque is the rotary effort required to operate a valve. This turning force in a butterfly valve is

determined by three factors - the friction of the disc and seat due to interference for sealing,

bearing friction, and fluid dynamic torque.

Breakaway torque at 70°F

Breakaway torque is the total of the torques resulting from bearing friction and disc/seat

interference friction at a given pressure differential. Listed below are torques to open and close

the valve at pressures shown in wet services (normal conditions).

NOTE

These values are valid for water and lubricating fluids only at 70°F. Since torques are greatly increased for dry

and nonlubricating fluids and temperature variations, contact your Keystone representative for accurate values

in these applications.

BREAKAWAY TORQUE (inch/pounds)*

Line pressure (psi)

50

100

150

200

250

Size

2

2½

3

4

5

6

8

10

12

14

16

18

20

24

30

36

85

108

126

144

162

126

153

175

198

221

180

207

256

297

339

355

414

472

531

590

562

652

715

787

869

918

1035

1152

1269

1386

1440

1692

1922

2205

2476

2466

3010

3550

4095

4660

3510

4140

5616

7686

10556

5200

6000

7500

8550

-

6900

8000

9500

10750

-

9000

10500

12000

13500

-

11000

14000

15200

17600

-

16000

21000

28000

33700

-

18700

22000

27700

-

27500

32500

37000

-

* For wet service applications/standard disc

6

KEYSTONE SERIES 60 BUTTERFLY VALVE

Valve weights

WAFER BODY (kg)

Valve size

DN

50

65

80

100

125

150

200

250

300

350

400

450

500

600

750

900

LUG BODY (kg)

Bare stem

Lever OP

Gear OP

2.3

2.7

3.2

7.7

8.6

13

16

26

39

64

80

101

157

211

372

699

4.5

5.0

5.4

10

11

15

19

29

42

-

6.4

6.8

8.6

11

14

15

28

38

59

74

91

112

168

243

404

730

WAFER BODY (lbs)

Valve size

NPS

2

2½

3

4

5

6

8

10

12

14

16

18

20

24

30

36

Bare stem

5

6

7

17

19

29

36

58

87

140

177

222

347

465

820

1540

Valve size

DN

50

65

80

100

125

150

200

250

300

350

400

450

500

600

750

900

Bare stem

3.6

4.5

5.0

6.8

12

14

20

29

54

71

101

121

187

225

426

830

Lever OP

5.9

6.8

7.3

9.1

15

16

22

31

57

-

Gear OP

7.7

8.6

9.1

12

18

20

36

52

74

82

113

132

198

256

458

862

Lever OP

13

15

16

20

32

36

49

69

125

-

Gear OP

17

19

20

27

40

44

79

115

163

180

250

290

436

565

1010

1900

LUG BODY (lbs)

Lever OP

10

11

12

22

24

34

41

63

92

-

Gear OP

14

15

19

24

30

32

62

84

130

164

201

246

371

535

890

1610

Valve size

NPS

2

2.5

3

4

5

6

8

10

12

14

16

18

20

24

30

36

Bare stem

8

10

11

15

27

31

44

64

120

156

223

266

412

495

940

1830

7

KEYSTONE SERIES 60 BUTTERFLY VALVE

SELECTION GUIDE

Example:

040

60

L

C

A

S

2

UC

1

DN 100 (NPS 4) lug style with cast iron body, aluminium bronze U/C disc, 416 S/S

shaft and NBR seat with handle – 04060LCAS2UC1

Size DN (NPS)

020 50 (2)

080 200 (8)

200 500 (20)

025 65 (2½)

100 250 (10)

240 600 (24)

030 80 (3)

120 300 (12)

300 750 (30)

040 100 (4)

140 350 (14)

360 900 (36)

050 125 (5)

160 400 (16)

060 150 (6)

180 450 (18)

Series

60

Body style

WWafer

LLug

Body material

C

Cast iron (DN 350/NPS 14 and larger wafer style available only in cast iron)

D

Ductile iron (DN 350/NPS 14 and larger lug style available only in ductile iron)

S

Stainless steel (available only for DN 50 - 150/NPS 2 - 6)

E

Di Ni plated (DN 200 - 300/NPS 8 - 12)

Disc material

S

316 Stainless steel (DN 50 - 300/NPS 2 - 12 valves with 316 S/S disc are available only with 316 S/S stem)

A

Aluminum bronze

D

Ductile iron - ENP

E

EPDM coated (DN 80 - 300/NPS 3 - 12 only)

N

NBR coated (DN 80 - 300/NPS 3 - 12 only)

P

Ductile iron/PVDF coated

Stem material

S

416 Stainless steel (standard)

P

316 Stainless steel (optional; available only in DN 50 - 300/NPS 2 - 12 sizes)

Seat material

1

EPDM (Food grade)

6

Black neoprene

2

NBR

7

PTFE

3

FKM

8

EPDM- XP

5

White neoprene

Specials (Leave blank if no special)

UC

Undercut disc

SAN Sanitary

DA

Dry assembly

B

Brewery

Actuation

0

None

4

Pneumatic direct acting[2]

1

10 Position handles

5

Pneumatic spring return[2]

2

Gear

6

Electric[2]

3

Chain wheel[2,3]

NOTE

1. PTFE liner will be supplied over EPDM and only with 316SS or PVDF covered disc available.

2. Operator designation 3,4,5 and 6 must have actuator name, model and details provided.

3. Chain to be provided by customer.

PENTAIR VALVES & CONTROLS

www.pentair.com/valves

All Pentair trademarks and logos are owned by Pentair plc. All other brand or product names are trademarks or registered marks of their respective owners.

Because we are continuously improving our products and services, Pentair reserves the right to change product designs and specifications without notice.

Pentair is an equal opportunity employer. © 2016 Pentair plc. All rights reserved.

8