Ferroelectric Ceramics - A Unique Class of Smart Materials

advertisement

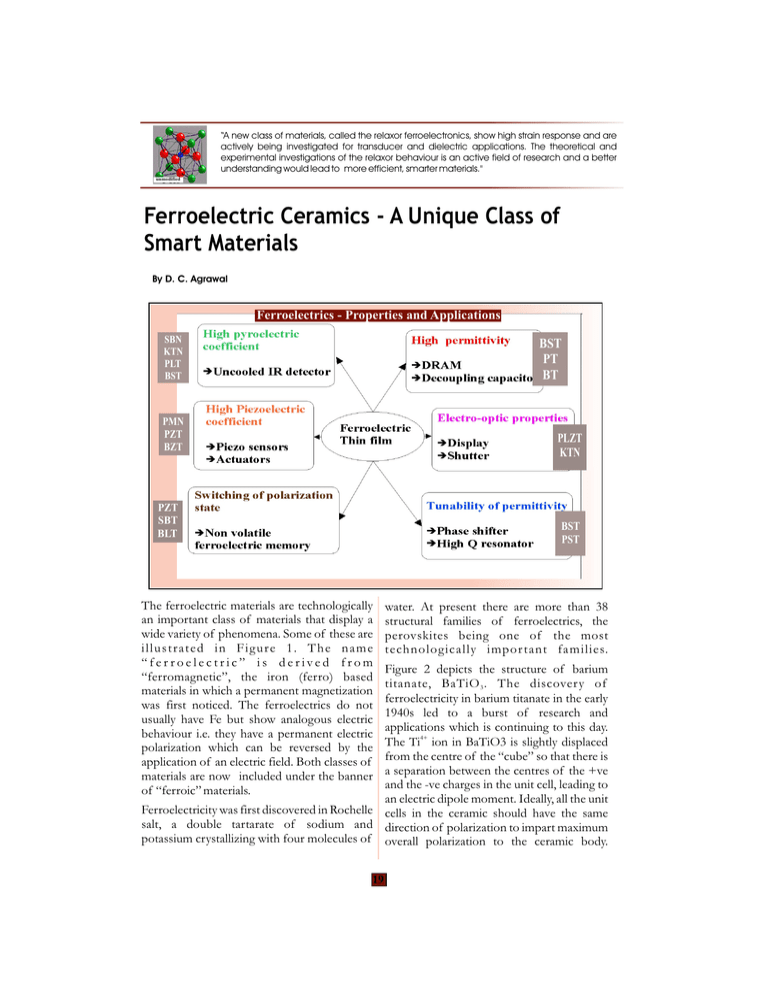

Brics “A new class of materials, called the relaxor ferroelectronics, show high strain response and are actively being investigated for transducer and dielectric applications. The theoretical and experimental investigations of the relaxor behaviour is an active field of research and a better understanding would lead to more efficient, smarter materials." unmodified Ferroelectric Ceramics - A Unique Class of Smart Materials By D. C. Agrawal Ferroelectrics - Properties and Applications SBN KTN PLT BST BST PT BT PMN PZT BZT PLZT KTN PZT SBT BLT BST PST The ferroelectric materials are technologically an important class of materials that display a wide variety of phenomena. Some of these are illustrated in Figure 1. T he name “ferroelectric” is derived from “ferromagnetic”, the iron (ferro) based materials in which a permanent magnetization was first noticed. The ferroelectrics do not usually have Fe but show analogous electric behaviour i.e. they have a permanent electric polarization which can be reversed by the application of an electric field. Both classes of materials are now included under the banner of “ferroic” materials. water. At present there are more than 38 structural families of ferroelectrics, the perovskites being one of the most technologically impor tant families. Figure 2 depicts the structure of barium titanate, BaTiO 3 . The discovery of ferroelectricity in barium titanate in the early 1940s led to a burst of research and applications which is continuing to this day. 4+ The Ti ion in BaTiO3 is slightly displaced from the centre of the “cube” so that there is a separation between the centres of the +ve and the -ve charges in the unit cell, leading to an electric dipole moment. Ideally, all the unit Ferroelectricity was first discovered in Rochelle cells in the ceramic should have the same salt, a double tartarate of sodium and direction of polarization to impart maximum potassium crystallizing with four molecules of overall polarization to the ceramic body. 19 However, to minimize the total energy, the direction of polarization is same in only small regions in a grain of the ceramic. These regions are called domains. The domains form spontaneously when the ceramic is cooled from its processing temperature below a characteristic temperature, called the Curie temperature, Tc (~ 120o C for barium titanate). unmodified Figure 2: Unit cell of BaTiO 3 ; the green spheres are Ba2+, the red are O 2- and the blue are Ti 4+ The polarization direction in the various domains is randomly oriented so that the net polarization in the as prepared ceramic is nearly zero. The ceramic is subjected to an operation called “poling” in which a high electric field (~ 3 kV mm-1) is applied to it. The polarization in the domains tends to orient in the direction of the external field. The favourably oriented domains grow. A high temperature, below Tc is used to facilitate this process. The ceramic is then cooled with the field on and remains in the poled condition upon removal of the field due to the randomization process having a negligible rate at room temperature. Piezoelectricity - the basis of smart electromechanical behaviour These field related electromechanical coupling constants are very large in ferroelectrics and are the basis for their application for efficient transduction between the electrical and mechanical signals leading to uses in acceleration and pressure sensing, smart mirrors, automobile suspension control, AFM cantilevers, non destructive evaluation (NDE), sonics and ultrasonics and a host of other transducing and sensing applications. The electromechanical coupling coefficients are found to be particularly high for the ferroelectric ceramic lead zirconate titanate, (Pb,Zr)TiO3 or PZT which can be looked at as a solid solution of PbTiO3 and PbZrO3 . When these two constituents are in the ratio 0.535:0.465, the piezoelectric constants of PZT are found to be the largest. This is the so called morphotropic phase boundary (MPB) composition of PZT. The PZT compositions near the MPB are therefore almost exclusively used for the various electromechanical and transducer applications. The property of the PZT ceramics can be further tailored for a given application by incorporating additional cations, called dopants, in the PZT lattice. Special care has to be taken to minimize the loss of Pb due to volatilization during the processing of the ceramic. Ferroelectric Thin Films Coatings and thin films of PZT are of interest in transducer, dielectric and nonvolatile memory applications. Figure 3 shows the “hysteresis loop” of a PZT film which is a plot of the externally applied electric field vs. polarization in the film. The nonzero remnant polarization at zero field and the ability to reverse the direction of polarization by going along the loop by half a cycle, is the basis for the application of these films in information storage (e.g. nonvolatile random access memory), parametric bistable devices, microwave frequency tripler, etc. All insulators experience a strain upon application of an electric field due to the so called electrostriction effect. However, in the ferroelectrics large piezoelectric strains are produced due to the reorientation of the electric domain states upon application of an The thin film of PZT can be deposited by electric field; conversely, the application of a various methods. In the sol-gel method, a liquid stress leads to a change in the polarization. precursor solution is prepared from the 20 (b) (a) Figure 4 : (Ankur 280nm )RBS spectra from PZT film deposited on (a) sapphire and (b) quartz ; substantial diffusion of Pb into the quartz substrate has taken place in the latter case. The spectra on platinum, a much used coating on the substrate to provide the electrical contact to the bottom of the film, is similar to that for sapphire. In case of quartz (also silicon), there is a large depletion of Pb from the film due to the diffusion into the substrate and only a slight loss from the top surface due to volatilization. In case of the sapphire or platinum substrates, the loss by diffusion is negligible. The Pb deficiency in the film in the former case causes the film to assume a pyrochlore phase which is not ferroelectric. Figure 3:( Ankur2Hystloopundoped) Hysteresis loop of PZT thin film alkoxides (e.g. titanium butoxide, zirconium isopropoxide) and salts (lead acetate) containing the required metal ions. The “sol” is then deposited on the substrate by spin coating or dip coating. A heat treatment at about 700oC results in the removal of the organic matter and the formation of a crystalline ceramic film. The problem of loss of Pb during the heat treatment is also significant in the film preparation. However, unlike the bulk ceramics, the loss can be more due to diffusion into the substrate, rather than by volatilization. This is illustrated in Figures 4 and 5 which show the RBS (Rutherford Back Scattering) spectra of films deposited on sapphire and quartz and their analysis. X-ray phase Perovskite Pyrochlore In most applications involving polarization reversal, an important problem is the degradation of the remnant polarization by the cycling of the polarization state, as during the read and write cycles of a ferroelectric memory cell. RBS simulation structure Layer thickness Layer # (A) Pb1.0Zr0.53Ti 0.47O3 3000 3000 Al2O3 20000 3000 Pb0.85Zr0.53Ti0.47O3 3000 1 Pb0.82Zr0.53Ti0.47O3 200 2 Pb0.71Zr0.53Ti0.47O2.5Si0.5 400 3 Pb1.4Si2O6 1000 4 Pb1.2Si2O6 Pb1.0Si2O6 2000 1200 5 6 SiO2 10000 7 Figure 5: Results of the analysis of the spectra of Figure 4; initial PZT film thicknesses are290 nm and 390 nm respectively on sapphire and quartz. 21 (b) (a) Figure 6: Hysteresis loops of (a) undoped and (b) 3 at % Ce doped PZT thin films before and after cycling for a million cycles; doped sample shows significantly higher resistance to degradation Figure 6 shows the hysteresis loops of (a) undoped and (b) 3 at(atomic) % Ce doped) 6 PZT film at the beginning and after 10 cycles of switching at a frequency of 1 kHZ. In both cases, the remnant polarization has degraded; however, the Ce doped sample has withstood the “fatigue” process much better in fact, the undoped sample can hardly be called ferroelectric after fatigue. The results imply that the Ce doping decreases the drift mobility of the oxygen vacancies. The Ce as a dopant is somewhat unique in that it can exist as Ce3+ as well as Ce4+. Binding with Ce is believed to lead to deeper potential wells for the oxygen vacancies resulting in decreased degradation kinetics. Relaxors - A New Class of Smart Ferroelectrics In the PZT films, the charged oxygen vacancies are known to be highly mobile. The movement of these charged species in the presence of As mentioned above, the PZT ceramics show field is primarily responsible for their the largest coupling between the electric field redistribution leading to the formation of a and strain amongst all the ferroelectric nonswitching layer at the electrode. The net ceramics. The PZT is therefore the material of drift of these charged species can be shown to choice for such transduction applications. be proportional to N/f2 where N is the total However, a new class of materials, called the number of cycles imposed at a frequency f. The relaxor ferroelectrics, show an even higher experiments show that the model is able to strain response and are actively being reproduce the observed scaling behaviour as investigated for transducer and dielectric 2 N/f (Figure 7). applications. A distinguishing feature of the relaxor ferroelectrics is that the peak in the dielectric constant vs temperature plot shifts to higher temperatures with an increase in the frequency of measurement.; also, the peak is much broader than the peak in the regular ferroelectric. Some examples of relaxors are : Lead magnesium niobate Pb(Mg1/3Nb2/3)O3 (PMN), lead zinc niobate Pb(Zn1/3Nb2/3)O3 PZN, etc. The relaxor ferroelectrics are characterized by very high dielectric constants (e.g. Figure 8). This leads to very high strains. Figure 7: Normalized polarization as a function As mentioned earlier, the total strain produced of N/f2 where N is the number of cycles and f the on application of a field E = Ek in (say) Z frequency for doped and Ce doped samples for frequencies differing in three orders of magnitude; direction is stated in the first expression on the solid line is fitted to the model. page 21. 22 2 The Q constants are not very large for the relaxor ferroelectrics - in fact they are smaller Here dijk are the piezoelectric constants and Mykk than the normal ferroelectrics. However, are the electrostriction coefficients. To because the dielectric constants are very high, understand the origin of high strains in the the strains produced are 10-4 to 10-3, the highest relaxor, we can write the strain in terms of that are obtained in these materials (Table 1). polarization: xij = dijkEk + MykkEk xij = gijkEijPk + QijklPkPl Table 1: Comparison of electrostrains achievable in different materials The most accepted mechanism for the relaxor behaviour is that there are microcompositional fluctuations which produce a distribution of Curie temperatures. Thus at any temperature, the material is a mixture of the polar and the nonpolar regions, becoming steadily more polar as the temperature is decreased. It is the interfaces between the polar and the nonpolar regions that may hold the key to the extremely high dielectric constants in these materials. The theoretical and experimental investigations of the relaxor behaviour is an active field of research and a better understanding would lead to more efficient, smarter materials. Figure 8: Dielectric constant vs temperature for Relaxor ferroelectrics as exemplified by the series lead zinc niobate (PZN)-lead iron niobate (PFN); dielectric constant values higher than those shown here are achieved in many other relaxors Table 1 Material Non ferroelectrics Normal ferroelectics Relaxor ferroelectrics Q 10 10-1 10-2 Dielectric constant 10 103 104 Strain 10-7 10-5 10-4 References: · Sambit K. Saha and D. C. Agrawal, American Ceramic Society Bulletin, 71 (1992) 1424 · S.B. Majumder, V.N. Kulkarni, Y.N. Mohapatra and D.C. Agrawal, Bul. Mat. Sc., 17 (1994). · S. B. Majumder, Y. N. Mohapatra and D. C. Agrawal, App. Phy. Let. 70 (1997)138 About the author: Dr. D. C. Agrawal is a professor in the Materials Science Programme. His research interests include nanoparticle preparation and their assembly, ceramic thin films and sol-gel processing. 23