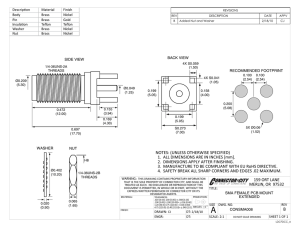

Compression Fittings

advertisement